EP2467666B1 - Culasse à coin d'une arme - Google Patents

Culasse à coin d'une arme Download PDFInfo

- Publication number

- EP2467666B1 EP2467666B1 EP10742434.3A EP10742434A EP2467666B1 EP 2467666 B1 EP2467666 B1 EP 2467666B1 EP 10742434 A EP10742434 A EP 10742434A EP 2467666 B1 EP2467666 B1 EP 2467666B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- wedge

- breechblock

- sliding

- blocking

- blocking element

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 230000000903 blocking effect Effects 0.000 claims description 49

- 238000000034 method Methods 0.000 description 2

- 238000010276 construction Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 230000001960 triggered effect Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F41—WEAPONS

- F41A—FUNCTIONAL FEATURES OR DETAILS COMMON TO BOTH SMALLARMS AND ORDNANCE, e.g. CANNONS; MOUNTINGS FOR SMALLARMS OR ORDNANCE

- F41A3/00—Breech mechanisms, e.g. locks

- F41A3/02—Block action, i.e. the main breech opening movement being transverse to the barrel axis

- F41A3/10—Block action, i.e. the main breech opening movement being transverse to the barrel axis with sliding breech-block, e.g. vertically

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F41—WEAPONS

- F41A—FUNCTIONAL FEATURES OR DETAILS COMMON TO BOTH SMALLARMS AND ORDNANCE, e.g. CANNONS; MOUNTINGS FOR SMALLARMS OR ORDNANCE

- F41A17/00—Safety arrangements, e.g. safeties

- F41A17/42—Safeties for locking the breech-block or bolt in a safety position

Definitions

- the invention relates to a wedge lock for a gun with a rear side connected to a gun barrel bottom piece and a displaceable in the bottom piece perpendicular to the axis of the weapon barrel in a leadership of the bottom piece, a loading tray having closure wedge, wherein the partial closing of the closure wedge by means of at least one holding device behind the loading trough of the closure cella is arranged on the bottom piece is made.

- a blocking element of the holding device is extended when the piecing for loading a cartridge moves into the loading trough, which then blocked in the closing movement of the closure wedge this in the partially closed position. In the partially closed position the closing wedge is blocked by the locking device.

- Such a wedge lock is for example from the DE 38 39 496 C2 known.

- a loading device of the shutter wedge initially moved from an open position to a partially closed position and the shutter wedge blocked in this by blocking the opener shaft of the shutter blocking device.

- This is intended, on the one hand, to prevent the respective cartridge from slipping out of the cargo space through the closing wedge when the piecing-back device is moved back.

- the US 5,481,958 A discloses a movable shutter wedge weapon moveable between a closed position and an open position.

- a latch in turn serves to hold the shutter wedge in its open position.

- an ammunition is introduced by means of a loader into a cartridge chamber of the weapon barrel.

- Means are mounted on the loading tube which bring the latch to an unlocked position while shifting the loading tube to the opposite armory.

- the shutter wedge of the charging tube is always unlocked only when it is removed from the ammunition chamber and after the ammunition has been inserted. A slipping back of each cartridge from the armory can not be excluded with this construction

- the invention has for its object to provide a wedge lock of the type mentioned, in which after the complete loading of a cartridge, the closure wedge is automatically closed after the piecing has passed the loading trough of the closure wedge.

- the invention is based essentially on the idea of partial closure of the closure wedge by means of at least one holding device which is arranged behind the loading trough of the closure wedge on the bottom piece.

- a blocking element of the holding device is extended when the piecing runs for loading a cartridge in the loading trough, which then blocked in the closing movement of the closure wedge this in the partially closed position.

- the blocking element is in operative connection with an actuating device of the holding device, which comprises a movable actuating part, which is held by at least one return element in a starting position, wherein the blocking element is in its rest position, and which in the preparation of the ammunition by the piecing of Loading machine is pressed against the pressure of the return element in an operating position and thereby shifts the locking element from its rest position to its locked position.

- an actuating device of the holding device which comprises a movable actuating part, which is held by at least one return element in a starting position, wherein the blocking element is in its rest position, and which in the preparation of the ammunition by the piecing of Loading machine is pressed against the pressure of the return element in an operating position and thereby shifts the locking element from its rest position to its locked position.

- the guide of the closure wedge contained in the bottom piece is delimited on the rear side by two guide strips of the bottom piece encompassing the closure wedge, the holding device being fastened in one of the mutually facing end faces.

- the blocking element is slidably disposed in the holding device from a rest position to a blocking position.

- the blocking element is preferably formed bolt-shaped and may be formed flattened on its side facing the corresponding abutment surface of the closure wedge.

- the abutment surface of the closure wedge can be tapered beveled on the rear side, wherein the slope of the beveled abutment surface so dimensioned is that no self-locking of the abutment surface pressed flattened, bolt-shaped locking element takes place, so that the locking element can move independently against the closing force of the closure wedge, if it would not be prevented by a blocking of the operating part by the piecing of the loading machine.

- the actuating part of the holding device is a first pivoting lever whose first end is pivotable about a holder-fixed first axis of rotation and the second end of which projects laterally into the space of the bottom piece to be passed by the piecemeal during loading of the ammunition, wherein in the region of the second end of the first pivot lever, a second pivot lever is pivotally mounted about a passing through the first pivot lever second axis of rotation, the end remote from the second axis of rotation about a third axis of rotation is pivotally connected to the displaceable in an axial guide of the holding device arranged blocking element.

- the layers of the three axes of rotation should be selected such that they lie in a substantially line in the blocking position of the blocking element. This ensures that the closing force of the closure wedge, which acts on the bolt-shaped blocking element, causes no opening moment on the actuating part of the holding device and the closure wedge is reliably held in the partially closed position.

- the first pivot lever are flap-shaped and the second pivot lever formed as a rocker.

- the locking device comprises two holding devices, which are arranged on the rear side behind the closure wedge on both sides of the loading trough of the closure wedge on the bottom piece.

- Another advantage of this design is that no additional sensors or actuators are required.

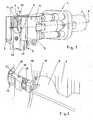

- Fig.1 1 denotes a barrel weapon, which comprises a weapon barrel 2 with a wedge closure 3 arranged at the rear (here a drop wedge closure).

- the wedge lock 3 consists essentially of a connected to the gun barrel 2 bottom piece 4 and in the bottom piece 4 perpendicular to the axis of the shaft 5 of the gun barrel 2 in a guide 6 of the bottom piece 4 displaceable, a loading tray 7 having shutter wedge 8. It is in the bottom piece 4 contained guide 6 of the closure wedge 8 rear side limited by two the locking wedge 8 embracing guide rails 9 of the bottom piece 4.

- the closure wedge 8 is movable from an open position, in which ammunition 10 can be loaded axially into the cargo space 11 of the weapon barrel 2 by means of a piecing device of a loading device (not shown), into a partially closed position (shown in FIG Fig.1 ), in which a slipping back of the ammunition 10 from the cargo space 11 is prevented by the shutter wedge 8, displaceable in a closed position.

- the locking device 12 comprises two holding devices 13, which rear side behind the closure wedge 8 at the mutually facing end faces 14, 15 of the guide rails 9 of the bottom piece 4 are attached.

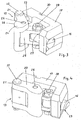

- Each holding device 13 has a bolt-shaped blocking element 16 which is mounted axially displaceably in a corresponding holding device 17 from a rest position into a blocking position.

- the blocking element 16 is in its locking position on a stop surface 18 of the closure wedge 8 ( Fig.2 ).

- the respective blocking element 16 is in operative connection with an actuating device 19 of the corresponding holding device 13.

- actuating device 19 of the corresponding holding device 13.

- These have a flap-shaped first pivot lever (actuating part) 20, whose first end 21 is pivotable about a holder-fixed first axis of rotation 22 and is held by two return elements (springs) 23 in an initial position ( Figure 3 ).

- a groove 30 and a counterbore in the holder 17 serve to fix the position and attachment to the bottom piece. 4

- the second end 24 of the first pivot lever 20 projects laterally into the space defined by the two guide rails 9 of the bottom piece 4 ( Fig.1 ).

- a second rocker arm formed as a rocker arm 25 is pivotally mounted about a passing through the first pivot lever 20 second pivot axis 26, the second axis of rotation 26 remote from the second end 27 about a third axis of rotation 28 hinged to the in the axial guide of the holding device 17 slidably disposed locking element 16 is connected.

- the positions of the three axes of rotation 22, 26 and 28 are selected such that they lie in the blocking position of the blocking element 16 substantially in line and the closing force of the closure wedge 8, which acts on the bolt-shaped blocking element 16, no opening moment on the actuating part 20 of the holding device 13 causes, so that the shutter wedge 8 is reliably held in the partially closed position.

- the bolt-shaped blocking element 16 is on its stop surface 18 of the closure wedge Flattened 8 and the stop surface 18 of the closure wedge 8 tapered beveled tapered rear side, wherein the slope of the beveled abutment surface 18 is dimensioned such that no self-locking of the pressed against the abutment surface 18, flattened, bolt-shaped blocking element 16 takes place.

- the shutter wedge 8 remains in the in Fig.1 illustrated, partially closed position, as the piecing when retracting laterally against the cap-shaped first pivot lever 20 keeps this in the operating position.

- the return elements 23 push the second end 24 of the first pivoting lever 20 into the space located between the guide rails 9 and the rocker 25 retracts the blocking element 16 so that the closure wedge 8 does not move to its closed position pressed closing spring is pressed.

- the return movement of the blocking element 16 is supported by the closure wedge 8, since the slope of the chamfered stop surface 18 of the closure wedge 8 does not cause self-locking.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Quick-Acting Or Multi-Walled Pipe Joints (AREA)

- Operating, Guiding And Securing Of Roll- Type Closing Members (AREA)

- Lock And Its Accessories (AREA)

Claims (12)

- Culasse à coin pour une arme (1) avec un bloc-culasse (4) assemblé à l'arrière à un canon (2) et avec un coin de culasse (8) pouvant coulisser dans le bloc-culasse (4) perpendiculairement à l'âme (5) du canon (2) dans un guidage (6) du bloc-culasse (4) et présentant un plateau de chargement (7), avec un dispositif d'arrêt (12) pour le blocage du coin de culasse (8) dans une position partiellement fermée, caractérisée en ce que le dispositif d'arrêt (12) comprend au moins un dispositif de maintien (13), qui est disposé sur le bloc-culasse (4) à l'arrière derrière le plateau de chargement (7) du coin de culasse (8), le dispositif de maintien (13) présente au moins un élément d'arrêt (16), qui est en liaison active avec un dispositif d'actionnement (19) du dispositif de maintien (13) qui comprend une pièce d'actionnement mobile (20), laquelle est maintenue par au moins un élément de rappel (23) dans une position initiale, dans laquelle l'élément d'arrêt (16) se trouve dans sa position de repos, et qui est poussée dans une position d'actionnement contre la pression de l'élément de rappel (23) et déplace ainsi l'élément d'arrêt (16) de sa position de repos à sa position d'arrêt.

- Culasse à coin selon la revendication 1, caractérisée en ce que, en position d'arrêt, l'élément d'arrêt (16) est disposé à l'arrière devant la face frontale du coin de culasse (8) contenant le plateau de chargement (7) et s'applique sur une face de butée (18) du coin de culasse (8).

- Culasse à coin selon la revendication 1 ou 2, caractérisée en ce que le guidage (6) du coin de culasse (8) contenu dans le bloc-culasse (4) est limité à l'arrière par deux lattes de guidage (9) du bloc-culasse (4) entourant le coin de culasse (8), dans laquelle le dispositif de maintien (13) est fixé dans une des deux faces frontales se faisant face (14, 15) des lattes de guidage (9).

- Culasse à coin selon l'une quelconque des revendications 1 à 3, caractérisée en ce que l'élément d'arrêt (16) est disposé dans le dispositif de maintien (17) de façon coulissante d'une position de repos à une position d'arrêt.

- Culasse à coin selon l'une quelconque des revendications 1 à 4, caractérisée en ce que l'élément d'arrêt (16) est réalisé en forme de boulon.

- Culasse à coin selon la revendication 5, caractérisée en ce que l'élément d'arrêt en forme de boulon (16) est réalisé sous forme aplatie sur son côté (29) tourné vers la face de butée (18) du coin de culasse (8).

- Culasse à coin selon l'une quelconque des revendications 2 à 6, caractérisée en ce que la face de butée (18) du coin de culasse (8) est réalisée à l'arrière sous forme d'amincissement oblique, dans laquelle la pente de la face de butée oblique (18) est définie de telle manière qu'il ne se produise pas d'auto-blocage de l'élément d'arrêt en forme de boulon aplati (16) poussé contre la face de butée (18).

- Culasse à coin selon l'une quelconque des revendications 1 à 7, caractérisée en ce que la pièce d'actionnement (20) du dispositif de maintien (13) est un premier levier pivotant, dont la première extrémité (21) peut pivoter autour d'un premier axe de rotation (22) solidaire du dispositif de maintien et dont la deuxième extrémité (24) pénètre latéralement dans l'espace du bloc-culasse (4) à traverser par le refouloir lors du chargement de la munition (10), en ce qu'un deuxième levier pivotant (25) est monté dans la région de la deuxième extrémité (24) du premier levier pivotant (20) d'une façon pivotante autour d'un deuxième axe de rotation (26) passant à travers le premier levier pivotant (20), et dont l'extrémité éloignée du deuxième axe de rotation (26) est reliée de façon articulée autour d'un troisième axe de rotation (28) à l'élément d'arrêt (16) disposé de façon coulissante dans un guidage axial du dispositif de maintien (17).

- Culasse à coin selon la revendication 8, caractérisée en ce que les positions des trois axes de rotation (22, 26, 28) sont choisies de telle manière qu'ils se situent essentiellement sur une ligne dans la position d'arrêt de l'élément d'arrêt (16).

- Culasse à coin selon la revendication 8, caractérisée en ce que la deuxième extrémité (24) du premier levier pivotant (20) pénètre latéralement dans l'espace délimité par les deux lattes de guidage (9) du bloc-culasse (4).

- Culasse à coin selon l'une quelconque des revendications 8 à 10, caractérisée en ce que le premier levier pivotant (20) est réalisé en forme de clapet et le deuxième levier pivotant (25) est réalisé sous forme de bielle.

- Culasse à coin selon l'une quelconque des revendications 1 à 11, caractérisée en ce que le dispositif d'arrêt (12) comprend deux dispositifs de maintien (13), qui sont disposés à l'arrière sur le bloc-culasse (4) derrière le coin de culasse (8), de part et d'autre du plateau de chargement (7) du coin de culasse (8).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE200910037899 DE102009037899A1 (de) | 2009-08-19 | 2009-08-19 | Keilverschluss einer Rohrwaffe |

| PCT/EP2010/004726 WO2011020555A1 (fr) | 2009-08-19 | 2010-08-02 | Culasse à coin d'une arme à canon |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2467666A1 EP2467666A1 (fr) | 2012-06-27 |

| EP2467666B1 true EP2467666B1 (fr) | 2015-07-29 |

Family

ID=42797313

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP10742434.3A Active EP2467666B1 (fr) | 2009-08-19 | 2010-08-02 | Culasse à coin d'une arme |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP2467666B1 (fr) |

| DE (1) | DE102009037899A1 (fr) |

| ES (1) | ES2548151T3 (fr) |

| WO (1) | WO2011020555A1 (fr) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9429387B1 (en) | 2015-03-20 | 2016-08-30 | Magpul Industries Corp. | Modular stock for a firearm |

| US10101102B2 (en) | 2015-07-31 | 2018-10-16 | Magpul Industries Corp. | Magazine well for a firearm |

| USD844735S1 (en) | 2017-03-07 | 2019-04-02 | Magpul Industries Corp. | Firearm stock |

| US10345076B2 (en) | 2017-03-07 | 2019-07-09 | Magpul Industries Corp. | Firearm barrel tray, stock, and related methods |

| DE102019122290B3 (de) | 2019-08-20 | 2021-02-25 | Rheinmetall Waffe Munition Gmbh | Verschlusssystem und Rohrwaffe |

| DE102020108551A1 (de) | 2020-03-27 | 2021-09-30 | Rheinmetall Waffe Munition Gmbh | Waffenrohrverschluss und Rohrwaffe |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1651128A (en) * | 1923-10-15 | 1927-11-29 | Thomas M Jervey | Automatic gun |

| FR944047A (fr) * | 1945-09-13 | 1949-03-24 | Canon semi-automatique à tir rapide à chargement asservi | |

| DE3839496A1 (de) | 1988-11-23 | 1990-05-31 | Rheinmetall Gmbh | Sperrvorrichtung zur unterbrechung der verschlusskeilschliessbewegung |

| FR2713755B1 (fr) * | 1993-12-07 | 1996-02-09 | Giat Ind Sa | Arme à coin de culasse mobile. |

-

2009

- 2009-08-19 DE DE200910037899 patent/DE102009037899A1/de not_active Withdrawn

-

2010

- 2010-08-02 EP EP10742434.3A patent/EP2467666B1/fr active Active

- 2010-08-02 ES ES10742434.3T patent/ES2548151T3/es active Active

- 2010-08-02 WO PCT/EP2010/004726 patent/WO2011020555A1/fr active Application Filing

Also Published As

| Publication number | Publication date |

|---|---|

| DE102009037899A1 (de) | 2011-02-24 |

| ES2548151T3 (es) | 2015-10-14 |

| WO2011020555A1 (fr) | 2011-02-24 |

| EP2467666A1 (fr) | 2012-06-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102006009895B3 (de) | Steckmagazin einer Handfeuerwaffe | |

| EP2467666B1 (fr) | Culasse à coin d'une arme | |

| DE2812759B2 (de) | Abzugsvorrichtung für einen Revolver | |

| DE19713988C1 (de) | Verriegelbare Handfeuerwaffe | |

| EP0803698B3 (fr) | Arme à feu individuelle automatique | |

| DE2752721A1 (de) | Verschlussblockanordnung fuer ein automatisches geschuetz sowie betaetigungsvorrichtung fuer eine derartige anordnung | |

| EP1296110B1 (fr) | Canon | |

| DE102019120184A1 (de) | Verschluss und Waffensystem mit dem Verschluss | |

| DE3835556A1 (de) | Geradzug-verschlusssystem | |

| DE102009058551B4 (de) | Weiterentwickeltes, rückstoßbetriebenes, selbsttätig in Schußrichtung öffnendes Verschlußsystem für Feuerwaffen | |

| EP3623740B1 (fr) | Culasse munie d'un verrou à manoeuvre rectiligne pour une arme à répétition | |

| EP0766056A2 (fr) | Dispositif de sécurité pour le percuteur d'une arme à feu | |

| EP1469273A1 (fr) | Culasse à coin | |

| DE10051708B4 (de) | Selbstladepistole | |

| DE102016117184B4 (de) | Handfeuerwaffe | |

| DE19928277C2 (de) | Keilverschluß für eine großkalibrige Waffe | |

| EP4230950B1 (fr) | Culasse pour fusil à répétition | |

| DE2240878A1 (de) | Revolver mit wechselseitig zusammenwirkenden sicherungen | |

| EP3885692B1 (fr) | Arme avec culasse | |

| DE102019122290B3 (de) | Verschlusssystem und Rohrwaffe | |

| AT388613B (de) | Einrichtung zur kompensation der hochschlagund rueckstossenergie von faustfeuerwaffen | |

| DE19633904C2 (de) | Vorderladerwaffe | |

| DE19729292C2 (de) | Horizontalblockverschluß für eine großkalibrige Waffe | |

| EP2363679B1 (fr) | Arme de tir, notamment arme de chasse | |

| DE2418915C3 (de) | ZylinderverschluB für Jagd- und Sport gewehre |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20120126 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20141120 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: SCHMEES, HEINER |

|

| INTG | Intention to grant announced |

Effective date: 20150316 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 739656 Country of ref document: AT Kind code of ref document: T Effective date: 20150815 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: WEINMANN ZIMMERLI, CH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502010009961 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2548151 Country of ref document: ES Kind code of ref document: T3 Effective date: 20151014 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20150729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151030 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151029 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151129 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20151130 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502010009961 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20160502 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20160907 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 739656 Country of ref document: AT Kind code of ref document: T Effective date: 20150802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150802 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150929 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20100802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150729 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502010009961 Country of ref document: DE Representative=s name: DREISS PATENTANWAELTE PARTG MBB, DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502010009961 Country of ref document: DE Representative=s name: DREISS PATENTANWAELTE PARTG MBB, DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20230902 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20231027 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240821 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20240826 Year of fee payment: 15 |