EP2106294B1 - Appareil de sélection granulométrique et/ou de séchage de matière - Google Patents

Appareil de sélection granulométrique et/ou de séchage de matière Download PDFInfo

- Publication number

- EP2106294B1 EP2106294B1 EP07870307A EP07870307A EP2106294B1 EP 2106294 B1 EP2106294 B1 EP 2106294B1 EP 07870307 A EP07870307 A EP 07870307A EP 07870307 A EP07870307 A EP 07870307A EP 2106294 B1 EP2106294 B1 EP 2106294B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- gas

- matter

- pipe

- selector

- inlet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000001035 drying Methods 0.000 title claims abstract description 38

- 239000002245 particle Substances 0.000 claims abstract description 26

- 229910052500 inorganic mineral Inorganic materials 0.000 claims abstract description 9

- 239000011707 mineral Substances 0.000 claims abstract description 9

- 239000007789 gas Substances 0.000 claims description 92

- 239000000725 suspension Substances 0.000 claims description 13

- 230000001174 ascending effect Effects 0.000 claims description 10

- 238000000926 separation method Methods 0.000 claims description 10

- 239000004568 cement Substances 0.000 claims description 5

- 230000002093 peripheral effect Effects 0.000 claims description 5

- 238000009825 accumulation Methods 0.000 claims description 2

- 230000003628 erosive effect Effects 0.000 claims description 2

- 230000000149 penetrating effect Effects 0.000 claims description 2

- 230000037431 insertion Effects 0.000 claims 2

- 238000003780 insertion Methods 0.000 claims 2

- 238000003801 milling Methods 0.000 claims 1

- 238000000227 grinding Methods 0.000 abstract description 7

- 238000004064 recycling Methods 0.000 abstract 1

- 239000000463 material Substances 0.000 description 74

- 235000021183 entrée Nutrition 0.000 description 12

- 238000009434 installation Methods 0.000 description 5

- 229940082150 encore Drugs 0.000 description 3

- 230000002349 favourable effect Effects 0.000 description 3

- 238000001914 filtration Methods 0.000 description 2

- 230000004907 flux Effects 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 241001415961 Gaviidae Species 0.000 description 1

- 238000005299 abrasion Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000036461 convulsion Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 238000001228 spectrum Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000009423 ventilation Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B4/00—Separating solids from solids by subjecting their mixture to gas currents

- B07B4/02—Separating solids from solids by subjecting their mixture to gas currents while the mixtures fall

Definitions

- the present invention relates to an apparatus for granulometric selection and / or material drying, for the suspension treatment of granular mineral materials of which at least 90% by weight have a size less than 60 mm.

- these devices are not considered granulometric selectors. Indeed, when these devices are loaded with a coarse fraction composed of particles of various diameters, generally, most of the fraction falls, without separation and suspension of the finest particles that compose it.

- the document device GB-2,193,448 which corresponds to the preamble of claim 1 comprises a substantially vertical pipe, upflow, provided with a gas inlet at its base, equipped with an upper opening through which the fines escape and a lower opening by which drop the coarse materials.

- the feed of the materials is at a point of introduction between the upper opening and the lower opening.

- the pipe of the apparatus is equipped with funnels distributed over the height of the pipe, and in particular below the point of introduction, intended to divert the materials of the internal walls of the pipe.

- This apparatus is also equipped with means for creating a vortex, constituted by fixed propellers, distributed over the height of the pipe.

- Vertical plates arranged between the funnels and the propellers, are intended to create turbulence allowing the disintegration of agglomerated materials.

- the object of the present invention is to provide an apparatus for granulometric selection and / or drying of pulverulent materials, for the suspension treatment of granular mineral materials of which at least 90% by weight are less than 60 mm in size, which operates in line and stably for application to materials with a wide particle size spectrum.

- Another object of the invention is to provide a particle size selection apparatus and / or drying allowing a good separation of fractions, which can be resuspended.

- Another object of the invention is to provide an apparatus for granulometric selection and / or drying of pulverulent materials, consisting mainly of a vertical gas pipe of small size, especially of height substantially less than the height of the gas pipe. flash type drying apparatus known to those skilled in the art.

- Another object of the invention is to provide an apparatus for granulometric selection and / or drying of pulverulent materials, operating with the aid of an ascending flow of gas whose speed is much lower than the speed of the upward flow of gas. flash drying apparatus known to those skilled in the art, thus reducing the pressure drop.

- the apparatus relates to an apparatus for granulometric selection and / or drying of pulverulent materials, for the suspension treatment of granular mineral matter of which at least 90% by weight is less than 60 mm in size, the apparatus consisting mainly of a substantially vertical upflow gas line provided with a gas inlet at its base, equipped with a lower opening and an upper opening between which a supply opening is also provided for the introduction of materials, in which apparatus a part of the material, in particular said fine, can escape with the gas through the upper opening through the lift of said upward flow, while another part of matter, more coarse, is not driven by said gas and falls through the lower opening, the apparatus has, in addition, means for creating turbulence, favorable to the separation of different size fractions and the suspension of the materials, provided at the inner wall of the gas pipe, and located between the lower opening and the supply opening of said pipe.

- the means for creating turbulence are formed at least in part, by obstacles for the upward gas flow, in the form of generally horizontal blades, fixed against the inner wall of said gas pipe, of length oriented towards the center of the gas pipe, and arranged at least on two successive levels of height, distributed angularly staggered between said at least two successive levels of height, with the possible lateral overlapping areas.

- the apparatus for selecting granulometric and / or drying pulverulent materials differs from the known "flash" type drying systems, which comprise as a main element for suspending materials, a venturi in the where the speed of the gases is raised between 30 and 40 m / s.

- the construction of the venturi forces a total height of the device which is 5 to 6 times the value of the diameter of the vertical pipe.

- the apparatus for granulometric selection and / or drying of pulverulent materials, according to the invention, is intended for the suspension treatment of granular mineral materials of which at least 90% by weight have a size of less than 60 mm.

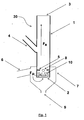

- the apparatus consists mainly of a gas pipe 1, substantially vertical, upflow Fa, provided with a gas inlet at its base.

- This pipe may be of substantially circular elliptical or rectangular section.

- the form factor that is to say the length / width ratio of the dimensions of the section does not exceed three.

- This pipe is equipped with a lower opening 2, and an upper opening 3, between which a feed opening 4 is also provided for the introduction of materials.

- the lower opening 2 can be fed with gas including a plenum 7 also called wind box.

- Part of the granular mineral matter, in particular so-called “fines”, can escape with the gas through the upper opening 3 thanks to the lift of the upward flow Fa, while another part of the materials, more coarse, is not driven by the gas and falls through the lower opening 2.

- the apparatus 30 has, in addition, means 5 for creating turbulence, favorable to the separation of the different particle size fractions, as well as to the suspension of the materials, provided at the level of the internal wall of the gas pipe 1 and located between the lower opening 2 and the feed opening 4 of the gas pipe 1.

- the turbulences allow in particular the separation of the particles of various diameters, a coarse fraction of material, thus allowing the suspension and the evacuation by the upper opening 3 of the so-called “fine” particles of this fraction, and the larger particles fall through the opening 2.

- the means 5 for creating the turbulences may consist, at least in part, of obstacles for the upward gas flow Fa, located against the inner wall of the gas pipe 1.

- the obstacles may take the form of generally horizontal blades, whose length is oriented towards the center of the gas pipe 1.

- the blades can be arranged at least in two successive levels of height, as illustrated in particular in the figure 1 .

- the blades may be arranged angularly staggered between two successive levels of height, with, where appropriate, lateral overlapping zones, forcing in particular the flow of ascending gas to zigzag between the blades of different levels.

- the length of each blade can represent between 2 and 30% of the free width of the conduct 1 along the axis of the blade.

- the sum of the widths of each blade in particular disposed at least at two successive levels of height may represent at least 60% of the peripheral length of the pipe.

- the sum of the widths of the blades may advantageously be between 120% and 200% of the peripheral length of the pipe.

- the shape and position of the blades 10 in the gas pipe 1 may be favorable to an accumulation of materials, including stagnant, on top of said blades 10 during operation, to protect said blades against erosion.

- the blade may be of concave shape on the blade top or may have one or more upper flanges, in particular at the end of blades 13.

- the end 13 may be protected by a harder material, the pipe 1 may be covered with a material 12 of protection against abrasion.

- the means 5 for creating turbulence may be constituted, at least in part, by at least one wall gas flow Fp, oriented generally perpendicular to the direction of the ascending flow Fa penetrating notably radially or tangentially in the internal volume of the gas pipe 1 through the wall orifices 8 of said gas pipe 1.

- the surface sum of the orifices 8 may represent between 15% and 150% of the free section of the pipe 1.

- the apparatus may have at least one plenum 7 surrounding the lower part of the pipe, for supplying gas to the lower opening 2 of the gas inlet and / or where appropriate the orifices 8 of the walls of the pipe.

- the gas inlet may consist solely of the lower opening 2.

- the gas inlet of the pipe is constituted by the lower opening 2 and the wall openings 8.

- the gas supply is constituted solely by the wall orifices 8.

- the plenum 7 can be in the form of a box having an evacuation outlet 9 for falling materials, as illustrated in particular in FIG. figure 1 or 2 .

- the plenum 7 can be supplied with gas via at least one radial gas inlet 6, 6-1 and / or at least one tangential gas inlet 6-2, 6-3.

- the plenum chamber 7 is fed by one or two radial inlets 6; 6, 6-1.

- the plenum chamber 7 is fed by one or two tangential inlets 6-2; 6-2, 6-3.

- the exemplary embodiment illustrated in figure 1 comprises mainly a gas pipe 1 having an upper opening 3, a lower opening 2 also constituting a main gas inlet.

- the means 5 for creating turbulence are constituted, on the one hand, by obstacles constituted by blades 10, distributed in several successive height levels and angularly arranged in staggered rows in two successive levels of height, and on the other hand, by wall openings 8 passing through the wall gas flows Fp.

- a single plenum will surround the lower part of the pipe and can supply gas, on the one hand, the orifices 8, and on the other hand the lower opening 2.

- This apparatus can be implemented with a gas pipe whose length does not exceed 4 to 5 times the value of the diameter.

- the speed of the upward flow of gas can be 15 m / s.

- the topics have a maximum grain size of 100 mm at a specific concentration of between 5 and 6 kg / kg of gas.

- the installation can operate without instability and selects materials such that only particles smaller than about 0.8 mm are flown and particles larger than about 2 mm fall.

- the resulting pressure drop is of the order of 60% compared to the "flash" type drying system known from the state of the art for the same flow of material.

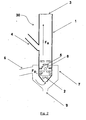

- the example of figure 2 differs from the example of the figure 1 in that the lower opening 2 is of smaller diameter than the largest section of the gas pipe 1, formed at the end of a truncated cone.

- figure 3 describes an apparatus in which all the gases are introduced through the wall openings 8 and not through the lower opening 2.

- the sum of the wall flows Fp then allows the creation of the upflow Fa.

- the wall orifices 8 are located , in large part, below the level of blades 10 constituting obstacles for the upward flow Fa.

- the raw material fed into the apparatus forming the subject of the invention has a particle size such that 50% of the grains are smaller (or greater) than 3.2 mm with 10% greater than a mesh of 15 mm and a maximum size of 35 mm. mm.

- the specific feed rate is 5 to 6 kg / kg of gas.

- the material flown to the exit 3 has a particle size such that almost all the grains have a size less than 7 mm with 50% lower (or higher) than 0.48 mm.

- the material falling through the lower opening 2 is such that almost all the grains have a size greater than 0.15 mm with 50% lower (or higher) than 5 mm.

- the separation curve that expresses the split ratio between the two streams for each grain size has a steep slope between grain sizes of 0.7 mm where only 20% of the material falls back and 3 mm where 90% of the materials fall back. This steep slope expresses a high power of selection.

- the invention will also relate to a drying installation comprising an apparatus according to the invention, the gas inlet of which is fed by a source of gas in temperature.

- the figure 6 Non-exhaustively illustrates a grinding plant incorporating a device 30 for selecting granulometric and drying. This facility processes materials 17, 18 at least one of which is wet.

- the plant which processes the materials comprises a grinder 15, a dynamic selector 16, a filter 21 which collects the ground finished product, and material handling means such as a bucket chain or other conveyors, as well as ventilation means for the gases.

- This plant receives hot gases from an undescribed source.

- the material feed 17 feeds the mill 15, and the product 19 leaving the mill is fed to the selector 16.

- the fine fraction is the finished product collected at 21 and the coarse fraction is returned to the mill.

- the hot gases 20 feed the mill 15, the dryer selector 22 and the dynamic selector 16.

- the particle size selection and drying apparatus 30 is located on the path of the gas supplying the dynamic selector 16 to which it is connected via its gas line 1.

- the apparatus receives the hot gases through the inlet 6 and is fed by a supply of material 18 to perform the drying more effectively than if this material was fed directly to the mill 15.

- the thinnest fraction continues to the dynamic selector 16 in the gas path while the coarse fraction returns through the outlet 9 to the mill 15 at the same time as the rejection 23 of the selector.

- the refusal can be carried out by a refusal line 23 'of the dynamic selector 16 disposed internally to the gas line 1 of the apparatus 30 of the dryer selector 22, said refusal line 23' opening below or at near the exit 9 of said selector dryer 22.

- the selector dryer 22 can make it possible to select the material whose grain size is less than about one millimeter, the dynamic selector 16 allowing the selection of material whose grain size is less than one hundred or even ten micrometers.

- the particle size selection operated by the apparatus 22 avoids both the dynamic selector 16 to be overloaded in coarse fractions from the suspension drying step of a conventional "flash" type system, and the grinder 15. be overloaded in fine fractions if the new material supplied by the feed 18 contains a significant amount. If the drying capacity of the mill 15 is low, the material 19 leaving the mill can be divided into two streams 19-1 and 19-2, the second being again subjected to the fast drying step.

Landscapes

- Drying Of Solid Materials (AREA)

- Combined Means For Separation Of Solids (AREA)

- Crushing And Grinding (AREA)

- Preparation Of Clay, And Manufacture Of Mixtures Containing Clay Or Cement (AREA)

- Glanulating (AREA)

- Compositions Of Oxide Ceramics (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL07870307T PL2106294T3 (pl) | 2006-11-20 | 2007-11-20 | Urządzenie do separacji granulometrycznej i/lub do suszenia materiału |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0610144A FR2908673B1 (fr) | 2006-11-20 | 2006-11-20 | Appareil de selection granulometrique et/ou de sechage de matiere. |

| PCT/FR2007/001901 WO2008068432A2 (fr) | 2006-11-20 | 2007-11-20 | Appareil de sélection granulométrique et/ou de séchage de matière |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2106294A2 EP2106294A2 (fr) | 2009-10-07 |

| EP2106294B1 true EP2106294B1 (fr) | 2012-03-14 |

Family

ID=38120376

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07870307A Active EP2106294B1 (fr) | 2006-11-20 | 2007-11-20 | Appareil de sélection granulométrique et/ou de séchage de matière |

Country Status (14)

| Country | Link |

|---|---|

| US (1) | US8245963B2 (sv) |

| EP (1) | EP2106294B1 (sv) |

| JP (1) | JP5497443B2 (sv) |

| CN (1) | CN101583429B (sv) |

| AT (1) | ATE549088T1 (sv) |

| CA (1) | CA2670906C (sv) |

| DK (1) | DK2106294T3 (sv) |

| ES (1) | ES2384402T3 (sv) |

| FR (1) | FR2908673B1 (sv) |

| MX (1) | MX2009005334A (sv) |

| PL (1) | PL2106294T3 (sv) |

| RU (1) | RU2445174C2 (sv) |

| UA (1) | UA95818C2 (sv) |

| WO (1) | WO2008068432A2 (sv) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2959679B1 (fr) | 2010-05-05 | 2015-02-20 | Fives Fcb | Procede de broyage d'une matiere minerale contenant au moins du calcium et des impuretes metalliques, et installation convenant pour le broyage d'une matiere minerale contenant du calcium et des impuretes metalliques en tant que tels. |

| JP5179540B2 (ja) * | 2010-05-20 | 2013-04-10 | 株式会社キンキ | 粉砕乾燥機とそれを備えた粉砕・乾燥設備 |

| DE102010054849A1 (de) * | 2010-12-17 | 2012-06-21 | Zeppelin Systems Gmbh | Verfahren und Vorrichtung zur Abscheidung von feinen Partikeln aus granulatförmigen Schüttgütern in einer Rohrleitung |

| CN104990390A (zh) * | 2015-07-30 | 2015-10-21 | 天能水泥有限责任公司 | 干排电石渣干燥和硅铁收集方法及系统 |

| CN109012888A (zh) * | 2018-10-26 | 2018-12-18 | 南京中材粉体工程科技有限公司 | 一种辊式立磨 |

| CN112742049B (zh) * | 2019-10-30 | 2022-04-08 | 中国石油化工股份有限公司 | 旋转闪蒸干燥机 |

| CN114226248B (zh) * | 2021-11-16 | 2022-11-18 | 太原理工大学 | 循环流化床燃煤灰渣分质分级的处理方法 |

Family Cites Families (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US271604A (en) * | 1883-02-06 | Grain cooler and drier | ||

| US1861248A (en) * | 1930-01-03 | 1932-05-31 | Albert H Stebbins | Air classifier |

| US2808213A (en) * | 1954-01-13 | 1957-10-01 | West Canadian Collieries Ltd | Gas entrained lump-breaking and drying equipment |

| US2813318A (en) * | 1954-06-29 | 1957-11-19 | Simpson Herbert Corp | Method and apparatus for treating granular material |

| GB767646A (en) * | 1955-03-17 | 1957-02-06 | Smidth & Co As F L | Improvements relating to the removal of fine or light particles from mixtures of particles |

| US2949245A (en) * | 1957-03-19 | 1960-08-16 | Cities Service Refining Corp | Elutriation of solids |

| SU692637A1 (ru) * | 1974-05-12 | 1979-10-25 | Всесоюзный Научно-Исследовательский Институт Металлургической Теплотехники "Вниимт" | Воздушный классификатор дл разделени твердых материалов по крупности |

| US3975263A (en) * | 1975-02-25 | 1976-08-17 | Elo Heikki K | Material separation apparatus and method |

| JPS5237258A (en) * | 1975-09-19 | 1977-03-23 | Kawasaki Heavy Ind Ltd | Preventing device for fall of raw materials in air-current type heat-e xcanger |

| SU900876A1 (ru) * | 1980-06-03 | 1982-01-30 | Уральский ордена Трудового Красного Знамени политехнический институт им.С.М.Кирова | Гравитационный пневматический классификатор |

| US4299694A (en) * | 1980-08-25 | 1981-11-10 | The Direct Reduction Corporation | Method and apparatus for char separation from the discharge materials of an iron oxide reducing kiln |

| DE3626044A1 (de) * | 1986-08-08 | 1988-02-04 | Uralsky Politekhn Inst | Windsichter zum trennen von schuettstoffen |

| DE3840510A1 (de) * | 1988-12-01 | 1990-06-07 | Metallgesellschaft Ag | Schuettschichtfilter mit zentrifugalabscheider |

| JPH0491748U (sv) * | 1990-12-26 | 1992-08-10 | ||

| JPH05147734A (ja) * | 1991-11-26 | 1993-06-15 | Nippon Ester Co Ltd | ダスト除去装置 |

| DE4218318C2 (de) * | 1992-06-03 | 2002-10-24 | Lehmann Maschf F B | Reinigungseinrichtung für Luftdruckfühler an Windsichtern |

| US5695130A (en) * | 1992-07-01 | 1997-12-09 | Csendes; Ernest | Method and apparatus for the dry grinding of solids |

| DE4306930B4 (de) * | 1992-07-25 | 2005-11-10 | Khd Humboldt Wedag Ag | Anlage zur Zerkleinerung von Mahlgut |

| DE4309920A1 (en) * | 1993-03-26 | 1993-08-26 | Voith Gmbh J M | Hydro-cyclone separator with central outlet tube for lighter fraction - which has internal guide vanes at a distance from end equal to half diameter of tube. |

| RU2100102C1 (ru) * | 1996-01-31 | 1997-12-27 | Алтайский государственный технический университет им.И.И.Ползунова | Воздушный сепаратор |

| US6283300B1 (en) * | 1998-08-21 | 2001-09-04 | Joseph B. Bielagus | Feed distribution for low velocity air density separation |

| JP2001009434A (ja) * | 1999-06-28 | 2001-01-16 | Ishikawajima Harima Heavy Ind Co Ltd | 廃棄石膏ボードの処理方法及び装置 |

| RU2206844C1 (ru) * | 2001-12-24 | 2003-06-20 | Государственное образовательное учреждение Воронежской государственной технологической академии | Устройство для сушки комкующихся дисперсных материалов |

| CN1485139A (zh) * | 2003-08-19 | 2004-03-31 | 李家春 | “磁浮式”钢球磨煤机 |

| JP2005066423A (ja) * | 2003-08-21 | 2005-03-17 | Takuma Co Ltd | 熱分解残渣分離装置 |

| JP4122438B2 (ja) * | 2004-01-21 | 2008-07-23 | 独立行政法人産業技術総合研究所 | 多段風力選別装置 |

| RU2277980C2 (ru) * | 2004-06-10 | 2006-06-20 | Тольяттинский государственный университет | Способ получения порошкообразных материалов |

| KR100592096B1 (ko) * | 2004-10-08 | 2006-06-22 | 삼성광주전자 주식회사 | 사이클론 집진장치 |

| JP4599540B2 (ja) * | 2005-06-23 | 2010-12-15 | 太平工業株式会社 | 石炭灰処理設備 |

-

2006

- 2006-11-20 FR FR0610144A patent/FR2908673B1/fr not_active Expired - Fee Related

-

2007

- 2007-11-20 DK DK07870307.1T patent/DK2106294T3/da active

- 2007-11-20 MX MX2009005334A patent/MX2009005334A/es active IP Right Grant

- 2007-11-20 PL PL07870307T patent/PL2106294T3/pl unknown

- 2007-11-20 ES ES07870307T patent/ES2384402T3/es active Active

- 2007-11-20 AT AT07870307T patent/ATE549088T1/de active

- 2007-11-20 UA UAA200904956A patent/UA95818C2/ru unknown

- 2007-11-20 CN CN2007800430756A patent/CN101583429B/zh active Active

- 2007-11-20 WO PCT/FR2007/001901 patent/WO2008068432A2/fr active Application Filing

- 2007-11-20 CA CA2670906A patent/CA2670906C/fr active Active

- 2007-11-20 EP EP07870307A patent/EP2106294B1/fr active Active

- 2007-11-20 JP JP2009536765A patent/JP5497443B2/ja active Active

- 2007-11-20 US US12/447,973 patent/US8245963B2/en active Active

- 2007-11-20 RU RU2009123505/03A patent/RU2445174C2/ru active

Also Published As

| Publication number | Publication date |

|---|---|

| WO2008068432A2 (fr) | 2008-06-12 |

| US20100133369A1 (en) | 2010-06-03 |

| RU2445174C2 (ru) | 2012-03-20 |

| RU2009123505A (ru) | 2010-12-27 |

| US8245963B2 (en) | 2012-08-21 |

| JP5497443B2 (ja) | 2014-05-21 |

| PL2106294T3 (pl) | 2012-08-31 |

| EP2106294A2 (fr) | 2009-10-07 |

| CN101583429A (zh) | 2009-11-18 |

| DK2106294T3 (da) | 2012-06-18 |

| ES2384402T3 (es) | 2012-07-04 |

| WO2008068432A3 (fr) | 2008-08-07 |

| ATE549088T1 (de) | 2012-03-15 |

| CN101583429B (zh) | 2011-11-16 |

| JP2010510468A (ja) | 2010-04-02 |

| MX2009005334A (es) | 2009-09-02 |

| FR2908673B1 (fr) | 2009-11-06 |

| UA95818C2 (ru) | 2011-09-12 |

| CA2670906C (fr) | 2012-01-10 |

| FR2908673A1 (fr) | 2008-05-23 |

| CA2670906A1 (fr) | 2008-06-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2106294B1 (fr) | Appareil de sélection granulométrique et/ou de séchage de matière | |

| EP2382056B1 (fr) | Dispositif de séparation granulométrique sélective de matières pulvérulentes solides, à action centrifuge, et procédé d'utilisation d'un tel dispositif | |

| KR100566525B1 (ko) | 플래시 건조 장치 | |

| FR2986445A1 (fr) | Presse integrale ventilee | |

| FR2524819A1 (fr) | Procede et broyeur a meules verticales, pour le classement pneumatique des matieres broyees | |

| JP2010510468A5 (sv) | ||

| EP0039270B1 (fr) | Installation pour le traitement par séchage et/ou chauffage et broyage d'un matériau granuleux | |

| EP2718028B1 (fr) | Séparateur dynamique pour matériaux pulvérulents et méthode de séparation correspondante | |

| FR2746329A1 (fr) | Procede et installation pour la production simultanee et en continu de plusieurs fractions granulometriques d'une matiere minerale | |

| EP2563515B1 (fr) | Installation de broyage de matières minérales avec presse à rouleaux | |

| EP1401583B1 (fr) | Procede et dispositif de broyage fin de particules minerales | |

| CA2797004C (fr) | Procede et installation de broyage d'une matiere minerale contenant au moins du calcium et des impuretes metalliques | |

| RU2436634C1 (ru) | Трубная мельница с классифицирующей перегородкой | |

| EP0094307B1 (fr) | Perfectionnements aux broyeurs à jets | |

| JP2724652B2 (ja) | 砕砂ダスト除去装置 | |

| EP3360407B1 (fr) | Grille pour nettoyeur de grains | |

| EP1908523A1 (fr) | Dispositif de broyage de matériaux minéraux | |

| JP3211420B2 (ja) | 分級装置 | |

| JP2684579B2 (ja) | 砕砂ダスト除去装置 | |

| BE488971A (sv) | ||

| FR2462196A1 (fr) | Broyeur a dispersion rapide pour fluides | |

| JPH05301079A (ja) | 砕砂ダスト除去装置 | |

| BE540275A (sv) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20090507 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: CORDONNIER, ALAIN Inventor name: MARECHAL, PASCAL Inventor name: DEVROE, SEBASTIEN |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20110201 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 549088 Country of ref document: AT Kind code of ref document: T Effective date: 20120315 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602007021383 Country of ref document: DE Effective date: 20120510 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ISLER & PEDRAZZINI AG |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2384402 Country of ref document: ES Kind code of ref document: T3 Effective date: 20120704 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20120314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120314 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20120314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120314 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120314 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20120401300 Country of ref document: GR Effective date: 20120713 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 549088 Country of ref document: AT Kind code of ref document: T Effective date: 20120314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120714 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120314 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120314 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120314 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120314 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120716 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120314 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120314 |

|

| 26N | No opposition filed |

Effective date: 20121217 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602007021383 Country of ref document: DE Effective date: 20121217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120614 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120314 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071120 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20191024 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20191022 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210608 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20231019 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20231201 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20231023 Year of fee payment: 17 Ref country code: IT Payment date: 20231019 Year of fee payment: 17 Ref country code: FR Payment date: 20231019 Year of fee payment: 17 Ref country code: DK Payment date: 20231019 Year of fee payment: 17 Ref country code: DE Payment date: 20231019 Year of fee payment: 17 Ref country code: CZ Payment date: 20231025 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20231025 Year of fee payment: 17 Ref country code: BE Payment date: 20231019 Year of fee payment: 17 |