EP2037175B2 - Vormischbrenner - Google Patents

Vormischbrenner Download PDFInfo

- Publication number

- EP2037175B2 EP2037175B2 EP08015450.3A EP08015450A EP2037175B2 EP 2037175 B2 EP2037175 B2 EP 2037175B2 EP 08015450 A EP08015450 A EP 08015450A EP 2037175 B2 EP2037175 B2 EP 2037175B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- holes

- tubular body

- disk

- premixed burner

- openings

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D14/00—Burners for combustion of a gas, e.g. of a gas stored under pressure as a liquid

- F23D14/46—Details

- F23D14/48—Nozzles

- F23D14/58—Nozzles characterised by the shape or arrangement of the outlet or outlets from the nozzle, e.g. of annular configuration

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D14/00—Burners for combustion of a gas, e.g. of a gas stored under pressure as a liquid

- F23D14/02—Premix gas burners, i.e. in which gaseous fuel is mixed with combustion air upstream of the combustion zone

- F23D14/04—Premix gas burners, i.e. in which gaseous fuel is mixed with combustion air upstream of the combustion zone induction type, e.g. Bunsen burner

- F23D14/10—Premix gas burners, i.e. in which gaseous fuel is mixed with combustion air upstream of the combustion zone induction type, e.g. Bunsen burner with elongated tubular burner head

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D14/00—Burners for combustion of a gas, e.g. of a gas stored under pressure as a liquid

- F23D14/46—Details

- F23D14/70—Baffles or like flow-disturbing devices

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D2203/00—Gaseous fuel burners

- F23D2203/10—Flame diffusing means

- F23D2203/101—Flame diffusing means characterised by surface shape

- F23D2203/1012—Flame diffusing means characterised by surface shape tubular

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D2203/00—Gaseous fuel burners

- F23D2203/10—Flame diffusing means

- F23D2203/102—Flame diffusing means using perforated plates

- F23D2203/1023—Flame diffusing means using perforated plates with specific free passage areas

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D2213/00—Burner manufacture specifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D2900/00—Special features of, or arrangements for burners using fluid fuels or solid fuels suspended in a carrier gas

- F23D2900/00003—Fuel or fuel-air mixtures flow distribution devices upstream of the outlet

Definitions

- the present invention relates to a premixed burner.

- the present invention relates to a premixed burner, typically of cylindrical shape and especially suitable for combustion boilers.

- premixed burners comprise a header along which a fan conveys the air-gas mixture.

- Said burners are traditionally provided with an inner liner or distributor, provided with suitable through openings and that lead the mixture to the burner surface; the latter is also provided with multiple holes or slits having much smaller size than that of the header to prevent backfires. While this known solution is functional, it shows some considerable drawbacks.

- the inner liner or distributor causes considerable unevenness of temperature on the burner surface; this is due to the fact that the mixture that flows from the inner distributor holes directly impinges the outer body, cooling it in correspondingly localised zones and thereby creating thermal gradients with consequent cyclical endurance stress, caused by the same boiler cycle. Due to the high temperatures reached, even higher than 700°C, microfissures may occur on the burner surface that over time, cause real and extended breakage; in these cases, the burner must be replaced in full, as it cannot be repaired anymore, but there is also a concrete risk of explosion due to backfire.

- the object of this invention is to provide a premixed burner which should not require setting up and coupling an inner distributor of the air-gas mixture to the burner itself.

- a further object of the invention is to provide a premixed burner the surface whereof should show a substantial temperature evenness in operation, preventing or at least reducing in a substantial manner the risk of formation of microfissures and backfires.

- a further object of the invention is to provide the users with a premixed burner suitable for ensuring high level of resistance and reliability over time, also such as to be easily and inexpensively constructed.

- ⁇ EP 1 813 864 discloses a burner with a double-wall diffuser.

- the diffuser comprises a plate-like body with two opposite diffusion surfaces facing the outside of the so formed plate-like body, such as to allow a combustion to take place on two

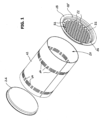

- the premixed burner of the present invention globally indicated with 10 at figure 2 and by way of an example with cylindrical or optionally truncated-cone shape, comprises a tubular body 12, generally of steel, closed on a head by a welded or crimped plate 24.

- the side surface of the tubular body 12 is provided with a plurality of small through openings or slits and holes of any shape, indicated with 14; by way of an example, said holes and slits are only represented on limited parts of body 12, it being understood that they may be made along the entire side surface of said body according to any configuration and/or size.

- the head of the tubular body 12 opposite plate 24 is closed by at least one disk 16 provided with flange 18 with circumferential lowering 18' for coupling with the inlet indicated with 20; disk 16 is made in a single body with flange 18 and is provided with a plurality of holes 22, having by way of an example a circular shape and even diameter.

- Said holes 22, which extend almost by the entire surface of disk 16, in any case may have any diameter or shape and optionally be made in groups with different diameters and/or shapes, also distributed randomly on said surface of disk 16.

- Diameter, shape and distribution of holes 22 along disk 16 are, in the practice, defined upon the system calibration and vary according to the different types of burners, since such calibration is specifically intended for optimising the efficiency thereof.

- disk 16 with holes 22 replaces the traditional inner distributor; flange 18 is coupled in a known manner to the conventional header that feeds the air-gas mixture and the latter, as a consequence, enters frontally rather than circumferentially, into body 12 constituting the burner.

- disk 16 defines the distribution head of burner 10, thus making the inner distributor unnecessary.

- Experimental tests carried out by the applicant have enabled checking that the burner according to this invention ensures the same levels of efficiency of the known solutions that envisage the use of the inner distributor, with the further advantage of preventing lack of homogeneity in the heat distribution on the tubular body 12.

- a solution of this type is also suitable for burners of the combustion type on fabric, wherein the side surface is covered by a metal or ceramic fabric layer.

- Disk 16 with flange 18 is constrained by welding or crimping to the tubular body 12 and preferably has a planar development; it is also to be provided for said disk to have non-planar configuration, for example concave or convex according to specific requirements.

- the distribution head of burner 10 it is possible to provide for the distribution head of burner 10 to be composed of two disks 16, suitably spaced from one another, respectively provided with holes, slots or through openings of different shape and/or extension, or for disk 16 to be spaced from flange 18 for creating one or more circumferentially open zones for the passage of mixture.

- disk 16 with holes 22 that closes one of the heads of the tubular body 12 integrally and effectively replaces the inner distributor used on the conventional burners, with clear advantages in terms of production and assembly cost saving.

- the absence of the inner distributor moreover, prevents the localised overheating of zones of the tubular body 12 along which the flame develops, preventing the onset of breakage phenomena and above all, excluding the risk of dangerous backfires.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Gas Burners (AREA)

- Manufacture, Treatment Of Glass Fibers (AREA)

Claims (8)

- Vormischbrenner (10), insbesondere für Brennwertkessel, umfassend:einen rohrförmigen Körper (12), dessen Seitenfläche mit mehreren Löchern und Schlitzen (14) versehen ist, wobei der rohrförmige Körper (12) einen Kopf aufweist, der einen Einlass (20) bildet,und zumindest eine Scheibe (16), die an dem Kopf des rohrförmigen Körpers (12) befestigt ist und den Verteilerkopf zum Verteilen des Luft-Gasgemisches in den Körper (12) hinein bildet,wobei die mindestens eine Scheibe (16) mit Durchgangsöffnungen oder Löchern (22) versehen ist und der rohrförmige Körper (12) auf dem anderen Kopf durch eine Platte (24) geschlossen ist, wobei die Platte (24) entlang der Seitenfläche des rohrförmigen Körpers (12) geschweißt oder gefalzt ist,wobei die Scheibe (16) (16) mit Löchern (22), welche eines der Enden des rohrförmigen Körpers (12) schließt, mit einem Flansch (18) mit umlaufender Absenkung (18') zur Kopplung mit dem gegenüber dem durch die Platte (24) verschlossenen Kopf angeordneten Einlass (20) des rohrförmigen Körpers (12) versehen ist,dadurch gekennzeichnet, dassder Vormischbrenner (10) keinen inneren Verteiler zur Verteilung des Luft-Gas-Gemisches in den Brenner (10) hinein umfasst, wobei die Scheibe (16) mit Löchern (22) die Funktion des internen Luft-Gasgemisch-Verteilers zur Verteilung des Luft-Gas-Gemisches ausführt,

unddie mindestens eine Scheibe (16) einstückig mit dem Flansch (18) ausgebildet ist. - Vormischbrenner nach Anspruch 1, dadurch gekennzeichnet, dass die Löcher (22) sich fast über die gesamte Oberfläche der Scheibe (16) erstrecken.

- Vormischbrenner nach Anspruch 1, dadurch gekennzeichnet, dass die Durchgangsöffnungen oder Löcher (22) durch einen geprägten Kragen (26) gebunden sind, der sich zum inneren Teil des rohrförmigen Körpers (12) hin erstreckt.

- Vormischbrenner nach Anspruch 1, dadurch gekennzeichnet, dass die Durchgangsöffnungen oder Löcher (22) durch teilweises Schneiden und Falten eines Abschnitts der Scheibe (16) erhalten sind, um geprägte Zungen auszubilden, die sich zum inneren Teil des rohrförmigen Körpers (12) hin entwickeln und sich mit den Öffnungen (22) abwechseln.

- Vormischbrenner nach Anspruch 4, dadurch gekennzeichnet, dass die Scheibe (16) mit dem Flansch (18) durch Schweißen und/oder Falzen an dem Kopf des rohrförmigen Körpers (12) gehalten ist.

- Vormischbrenner nach Anspruch 5, dadurch gekennzeichnet, dass die Scheibe (16) eine nicht-planare Entwicklung aufweist.

- Vormischbrenner nach einem oder mehreren der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass die Durchgangsöffnungen oder Löcher (22) heterogene Durchmesser oder Oberflächen aufweisen.

- Vormischbrenner nach Anspruch 7, dadurch gekennzeichnet, dass die Durchgangsöffnungen oder Löcher (22) auf zwei Scheiben (16) hergestellt sind, die voneinander beabstandet sind.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL08015450.3T PL2037175T5 (pl) | 2007-09-12 | 2008-09-02 | Palnik z mieszaniem wstępnym |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT001751A ITMI20071751A1 (it) | 2007-09-12 | 2007-09-12 | Bruciatore premiscelato |

Publications (4)

| Publication Number | Publication Date |

|---|---|

| EP2037175A2 EP2037175A2 (de) | 2009-03-18 |

| EP2037175A3 EP2037175A3 (de) | 2012-11-21 |

| EP2037175B1 EP2037175B1 (de) | 2016-11-23 |

| EP2037175B2 true EP2037175B2 (de) | 2024-11-27 |

Family

ID=40111124

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP08015450.3A Active EP2037175B2 (de) | 2007-09-12 | 2008-09-02 | Vormischbrenner |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP2037175B2 (de) |

| ES (1) | ES2616500T5 (de) |

| IT (1) | ITMI20071751A1 (de) |

| PL (1) | PL2037175T5 (de) |

| PT (1) | PT2037175T (de) |

Families Citing this family (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITPD20070388A1 (it) * | 2007-11-19 | 2009-05-20 | Sit La Precisa S P A Con Socio | Bruciatore, in particolare bruciatore a gas con pre-miscelazione |

| ITMO20080069A1 (it) * | 2008-03-10 | 2009-09-11 | Worgas Bruciatori Srl | Bruciatore dotato di mezzi di riduzione del rumore |

| EP2510281B1 (de) | 2009-12-11 | 2017-10-25 | Bekaert Combustion Technology B.V. | Brenner mit brennerdeck mit geringer porosität |

| DE202011005262U1 (de) | 2010-05-28 | 2011-12-22 | Jaroslav Klouda | Brenner mit Zündhilfe |

| WO2012069534A1 (en) * | 2010-11-26 | 2012-05-31 | Bekaert Combustion Technology B.V. | Burner with secondary axial flow elements |

| DE102011017023A1 (de) | 2011-04-14 | 2011-12-01 | Jaroslav Klouda | Brenner mit Zündhilfe |

| DE202011107309U1 (de) | 2011-11-02 | 2012-07-24 | Jaroslav Klouda | Brenner mit Zündhilfeeinrichtung |

| EP2805111B1 (de) | 2012-01-19 | 2018-07-04 | Bekaert Combustion Technology B.V. | Zylinderförmiger gasvormischungsbrenner |

| EP2815179A1 (de) | 2012-02-16 | 2014-12-24 | Bekaert Combustion Technology B.V. | Vorgemischgasbrenner |

| EP2815181A1 (de) | 2012-02-16 | 2014-12-24 | Bekaert Combustion Technology B.V. | Vorgemischgasbrenner |

| FR2993040B1 (fr) * | 2012-07-05 | 2016-07-15 | Giannoni France | Bruleur a gaz a combustion de surface |

| CN103742911B (zh) * | 2014-01-07 | 2015-12-23 | 天津城建大学 | 完全预混燃气燃烧器 |

| GB2529233B (en) * | 2014-08-14 | 2017-09-27 | Munster Simms Eng Ltd | Burner device for heating apparatus |

| EP3006826B1 (de) * | 2014-10-10 | 2017-05-03 | WORGAS BRUCIATORI S.r.l. | Brenner |

| EP3018408B1 (de) | 2014-11-05 | 2017-06-07 | WORGAS BRUCIATORI S.r.l. | Brenner |

| US10767900B2 (en) * | 2015-05-14 | 2020-09-08 | Lochinvar, Llc | Burner with flow distribution member |

| US10533740B2 (en) | 2015-07-09 | 2020-01-14 | Carrier Corporation | Inward fired ultra low NOX insulating burner flange |

| TR201517546A2 (tr) * | 2015-12-30 | 2017-07-21 | Bosch Termoteknik Isitma ve Klima Sanayi Ticaret Anonim Sirketi | Hava ve/veya yakıt için bir açıklığa sahip olan brülör ve bu tip bir brülöre sahip olan bir ısıtma cihazı. |

| WO2017194394A1 (en) | 2016-05-13 | 2017-11-16 | Bekaert Combustion Technology B.V. | Gas premix burner with a cylindrical burner deck |

| EP3455555A1 (de) | 2016-05-13 | 2019-03-20 | Bekaert Combustion Technology B.V. | Zylinderförmiger gasvormischungsbrenner |

| JP6988209B2 (ja) * | 2017-07-11 | 2022-01-05 | 株式会社Ihi | 流体分散器及び流体分散装置 |

| EP3752770A1 (de) | 2018-02-14 | 2020-12-23 | Bekaert Combustion Technology B.V. | Zylindrischer vormischungsgasbrenner |

| EP3628924B1 (de) | 2018-09-25 | 2021-06-02 | Polidoro S.p.A. | Variabler querschnitt verteilereinrichtung für einen vormischbrenner und brenner mit einer solchen verteilereinrichtung |

| EP3628923B1 (de) | 2018-09-25 | 2021-06-16 | Polidoro S.p.A. | Verteilvorrichtung für einen vormischbrenner und brenner mit dieser verteilvorrichtung |

| DE102019129639A1 (de) * | 2019-11-04 | 2021-05-06 | Rational Aktiengesellschaft | Gasbrennerbaugruppe für ein Gargerät sowie Gargerät |

| NL2024623B1 (en) | 2020-01-08 | 2021-09-07 | Bekaert Combustion Tech Bv | Gas burner and heating appliance |

| CN114945777A (zh) * | 2020-01-08 | 2022-08-26 | 贝卡尔特燃烧技术股份有限公司 | 气体燃烧器和加热器具 |

| NL2028637B1 (en) | 2021-07-06 | 2023-01-12 | Bekaert Combustion Tech Bv | Premix gas burner system and method |

| WO2026009171A1 (en) | 2024-07-04 | 2026-01-08 | Polidoro S.P.A. | Metal plate for premix burner |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4766883A (en) † | 1986-02-26 | 1988-08-30 | Mor-Flo Industries, Inc. | Forced draft controlled mixture heating system using a closed combustion chamber |

| EP1087180A1 (de) † | 1999-09-24 | 2001-03-28 | Joh. Vaillant GmbH u. Co. | Geschlossenes Verbrennungssystem mit Schwankungenminderungsvorrichtung |

| US6540505B1 (en) † | 1998-09-01 | 2003-04-01 | Toby Ag | Burner for liquid fuel |

| EP1538395A1 (de) † | 2003-12-05 | 2005-06-08 | Riello S.p.a. | Brennerkopf für einen Vormischbrenner |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2190249A5 (de) | 1972-06-22 | 1974-01-25 | Utilisation Ration Gaz | |

| DE3868815D1 (de) | 1987-09-26 | 1992-04-09 | Ruhrgas Ag | Gasbrenner. |

| DE8714532U1 (de) | 1987-10-31 | 1987-12-10 | Ruhrgas Ag, 4300 Essen | Überstöchiometrisch vormischender Gasbrenner für Gasheizgeräte |

| US5022352A (en) | 1990-05-31 | 1991-06-11 | Mor-Flo Industries, Inc. | Burner for forced draft controlled mixture heating system using a closed combustion chamber |

| DE4029313A1 (de) | 1990-09-15 | 1992-03-19 | Buderus Heiztechnik Gmbh | Vormischender gasbrenner |

| US5085579A (en) | 1991-03-25 | 1992-02-04 | Mor-Flo Industries, Inc. | Powered chamber combustion system and burner therefor |

| BR9306001A (pt) | 1992-03-03 | 1997-10-21 | Bekaert Sa Nv | Placa de fibra metálica porosa |

| FR2706986B1 (de) | 1993-06-21 | 1995-09-01 | Mts Sa | |

| US6916174B2 (en) | 1999-02-09 | 2005-07-12 | Beckett Gas, Inc. | Gas burner |

| DE60107597T2 (de) * | 2000-12-01 | 2005-12-08 | Bekaert Combustion Technology Nv | Vormischbrenner mit gekrümmter, undurchlässiger endkappe |

| ITMO20030154A1 (it) | 2003-05-23 | 2004-11-24 | Worgas Bruciatori Srl | Bruciatore modulabile |

| EP2484974A3 (de) | 2003-06-19 | 2014-08-27 | Worgas Bruciatori S.R.L. | Brenner mit einem gegen hohe Betriebstemperaturen resistenten Diffusor |

| ITMI20060147A1 (it) * | 2006-01-27 | 2007-07-28 | Worgas Bruciatori Srl | Dispositivo bruciatore a potenza elevata |

| US7607226B2 (en) * | 2006-03-03 | 2009-10-27 | Pratt & Whitney Canada Corp. | Internal fuel manifold with turned channel having a variable cross-sectional area |

| EP1840460A1 (de) * | 2006-03-29 | 2007-10-03 | Aeromatix Limited | Gasbrenner |

| ITMI20061961A1 (it) | 2006-10-13 | 2008-04-14 | Polidoro S P A | Distributore differenziato specie per bruciatori premiscelati |

| ITMO20070167A1 (it) | 2007-05-21 | 2008-11-22 | Worgas Bruciatori Srl | Bruciatore modulante |

-

2007

- 2007-09-12 IT IT001751A patent/ITMI20071751A1/it unknown

-

2008

- 2008-09-02 PL PL08015450.3T patent/PL2037175T5/pl unknown

- 2008-09-02 PT PT80154503T patent/PT2037175T/pt unknown

- 2008-09-02 ES ES08015450T patent/ES2616500T5/es active Active

- 2008-09-02 EP EP08015450.3A patent/EP2037175B2/de active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4766883A (en) † | 1986-02-26 | 1988-08-30 | Mor-Flo Industries, Inc. | Forced draft controlled mixture heating system using a closed combustion chamber |

| US6540505B1 (en) † | 1998-09-01 | 2003-04-01 | Toby Ag | Burner for liquid fuel |

| EP1087180A1 (de) † | 1999-09-24 | 2001-03-28 | Joh. Vaillant GmbH u. Co. | Geschlossenes Verbrennungssystem mit Schwankungenminderungsvorrichtung |

| EP1538395A1 (de) † | 2003-12-05 | 2005-06-08 | Riello S.p.a. | Brennerkopf für einen Vormischbrenner |

Also Published As

| Publication number | Publication date |

|---|---|

| PT2037175T (pt) | 2017-02-27 |

| EP2037175B1 (de) | 2016-11-23 |

| PL2037175T5 (pl) | 2025-11-12 |

| ITMI20071751A1 (it) | 2009-03-13 |

| ES2616500T3 (es) | 2017-06-13 |

| ES2616500T5 (en) | 2025-04-07 |

| EP2037175A2 (de) | 2009-03-18 |

| EP2037175A3 (de) | 2012-11-21 |

| PL2037175T3 (pl) | 2017-05-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2037175B2 (de) | Vormischbrenner | |

| USRE36743E (en) | Pre-mix flame type burner | |

| CN101861496A (zh) | 燃烧器、尤其是预混合燃烧器 | |

| US6939126B2 (en) | Gas burner | |

| US20190368726A1 (en) | Heat exchanger | |

| CN101849139A (zh) | 燃烧器、尤其是预混合气的燃烧器 | |

| JP4669997B2 (ja) | 五徳および該五徳を備えたガスコンロ | |

| JP2010256005A (ja) | 燃焼システムのシンブルファン | |

| JP2008209058A (ja) | 熱交換バーナ | |

| US9057524B2 (en) | Shielding wall for a fuel supply duct in a turbine engine | |

| JP5268971B2 (ja) | こんろバーナ及びこんろ | |

| CN220038452U (zh) | 一种燃气灶用燃烧器 | |

| KR20220022505A (ko) | 가스 버너 | |

| EP2242952A2 (de) | Vormischgasbrenner | |

| US20060154193A1 (en) | Advanced commercial range burner | |

| KR100399677B1 (ko) | 가스렌지용 버너 | |

| JP3863821B2 (ja) | 燃焼装置 | |

| JP4452879B2 (ja) | コンロ | |

| EP2759768A1 (de) | Gasbrenner | |

| JP4136843B2 (ja) | 蓄熱式熱交換型バーナユニット及び調理用バーナユニット | |

| JP3829437B2 (ja) | 温水暖房装置 | |

| JP5022766B2 (ja) | 貯湯式給湯器 | |

| JPH05149518A (ja) | ガス燃焼器のバーナ装置 | |

| JP2005274024A (ja) | ガスこんろ | |

| JP2024180035A (ja) | ガスこんろ |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: F23D 14/70 20060101ALI20121019BHEP Ipc: F23D 14/58 20060101AFI20121019BHEP Ipc: F23D 14/10 20060101ALI20121019BHEP |

|

| 17P | Request for examination filed |

Effective date: 20130515 |

|

| AKY | No designation fees paid | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R108 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R108 Ref document number: 602008047487 Country of ref document: DE Effective date: 20130724 Ref country code: DE Ref legal event code: R108 Effective date: 20130724 |

|

| 17Q | First examination report despatched |

Effective date: 20151221 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20160809 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 848259 Country of ref document: AT Kind code of ref document: T Effective date: 20161215 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602008047487 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Ref document number: 2037175 Country of ref document: PT Date of ref document: 20170227 Kind code of ref document: T Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20170221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161123 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161123 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170224 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161123 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170223 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161123 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161123 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2616500 Country of ref document: ES Kind code of ref document: T3 Effective date: 20170613 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161123 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161123 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161123 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 602008047487 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: WORGAS BRUCIATORI S.R.L. Effective date: 20170802 |

|

| 26 | Opposition filed |

Opponent name: VIESSMANN WERKE GMBH & CO. KG Effective date: 20170822 Opponent name: BEKAERT COMBUSTION TECHNOLOGY B.V. Effective date: 20170822 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161123 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161123 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170902 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170902 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20080902 |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20161123 |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161123 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: UEP Ref document number: 848259 Country of ref document: AT Kind code of ref document: T Effective date: 20161123 |

|

| R26 | Opposition filed (corrected) |

Opponent name: BEKAERT COMBUSTION TECHNOLOGY B.V. Effective date: 20170822 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20170323 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: BEKAERT COMBUSTION TECHNOLOGY B.V. Effective date: 20170822 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: VIESSMANN GROUP GMBH & CO. KG Effective date: 20170822 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230522 |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| P04 | Withdrawal of opt-out of the competence of the unified patent court (upc) registered |

Free format text: CASE NUMBER: APP_33910/2024 Effective date: 20240606 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20240829 Year of fee payment: 17 |

|

| 27A | Patent maintained in amended form |

Effective date: 20241127 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 602008047487 Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20241021 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: T5 Ref document number: E 23547 Country of ref document: SK |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: DC2A Ref document number: 2616500 Country of ref document: ES Kind code of ref document: T5 Effective date: 20250407 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20250901 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250926 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20250901 Year of fee payment: 18 Ref country code: NL Payment date: 20250925 Year of fee payment: 18 Ref country code: IT Payment date: 20250923 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20250925 Year of fee payment: 18 Ref country code: GB Payment date: 20250923 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250925 Year of fee payment: 18 Ref country code: AT Payment date: 20250917 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CZ Payment date: 20250901 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SK Payment date: 20250901 Year of fee payment: 18 |