EP1993399B1 - Mehrfilamentige borsten für zahnbürsten - Google Patents

Mehrfilamentige borsten für zahnbürsten Download PDFInfo

- Publication number

- EP1993399B1 EP1993399B1 EP07703053.4A EP07703053A EP1993399B1 EP 1993399 B1 EP1993399 B1 EP 1993399B1 EP 07703053 A EP07703053 A EP 07703053A EP 1993399 B1 EP1993399 B1 EP 1993399B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- bristle

- filament

- filaments

- etching process

- bristles

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 claims description 45

- 230000008569 process Effects 0.000 claims description 38

- 238000005530 etching Methods 0.000 claims description 31

- 239000000463 material Substances 0.000 claims description 29

- 238000004519 manufacturing process Methods 0.000 claims description 11

- 238000003486 chemical etching Methods 0.000 claims description 9

- 229920000728 polyester Polymers 0.000 claims description 9

- 230000007423 decrease Effects 0.000 claims description 6

- 239000004677 Nylon Substances 0.000 claims description 5

- -1 PA6.6 Polymers 0.000 claims description 5

- 239000004952 Polyamide Substances 0.000 claims description 5

- 229920001778 nylon Polymers 0.000 claims description 5

- 229920002647 polyamide Polymers 0.000 claims description 5

- 229920001707 polybutylene terephthalate Polymers 0.000 claims description 5

- 229920000139 polyethylene terephthalate Polymers 0.000 claims description 5

- 239000005020 polyethylene terephthalate Substances 0.000 claims description 5

- 238000000227 grinding Methods 0.000 claims description 3

- 239000000126 substance Substances 0.000 description 16

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 9

- QAOWNCQODCNURD-UHFFFAOYSA-N Sulfuric acid Chemical compound OS(O)(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-N 0.000 description 6

- 229920000642 polymer Polymers 0.000 description 6

- 230000006378 damage Effects 0.000 description 5

- 238000005452 bending Methods 0.000 description 4

- BDAGIHXWWSANSR-UHFFFAOYSA-N methanoic acid Natural products OC=O BDAGIHXWWSANSR-UHFFFAOYSA-N 0.000 description 4

- 208000027418 Wounds and injury Diseases 0.000 description 3

- 230000008901 benefit Effects 0.000 description 3

- 208000014674 injury Diseases 0.000 description 3

- OSWFIVFLDKOXQC-UHFFFAOYSA-N 4-(3-methoxyphenyl)aniline Chemical compound COC1=CC=CC(C=2C=CC(N)=CC=2)=C1 OSWFIVFLDKOXQC-UHFFFAOYSA-N 0.000 description 2

- 230000009471 action Effects 0.000 description 2

- 230000000844 anti-bacterial effect Effects 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 230000003247 decreasing effect Effects 0.000 description 2

- 239000000551 dentifrice Substances 0.000 description 2

- 235000019253 formic acid Nutrition 0.000 description 2

- 238000007654 immersion Methods 0.000 description 2

- 210000000214 mouth Anatomy 0.000 description 2

- 238000002360 preparation method Methods 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 241000549893 Carphochaete Species 0.000 description 1

- 230000002745 absorbent Effects 0.000 description 1

- 239000002250 absorbent Substances 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000012824 chemical production Methods 0.000 description 1

- 238000007598 dipping method Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 210000003128 head Anatomy 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 229920006149 polyester-amide block copolymer Polymers 0.000 description 1

- 238000003672 processing method Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 230000000087 stabilizing effect Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D1/00—Bristles; Selection of materials for bristles

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D1/00—Bristles; Selection of materials for bristles

- A46D1/02—Bristles details

- A46D1/023—Bristles with at least a core and at least a partial sheath

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D1/00—Bristles; Selection of materials for bristles

- A46D1/02—Bristles details

- A46D1/0276—Bristles having pointed ends

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D1/00—Bristles; Selection of materials for bristles

- A46D1/02—Bristles details

- A46D1/0292—Bristles having split ends

-

- A—HUMAN NECESSITIES

- A46—BRUSHWARE

- A46D—MANUFACTURE OF BRUSHES

- A46D1/00—Bristles; Selection of materials for bristles

- A46D1/04—Preparing bristles

- A46D1/05—Splitting; Pointing

Definitions

- the invention relates to a bristle according to the preamble of claim 5, a method for producing or processing bristles according to the preamble of claim 1 and a bristle, in particular toothbrush.

- Bristles for toothbrushes are typically made of polyester or nylon monofilaments, that is, of plastic filaments which are extruded, stretched and fixed.

- Nylon bristles are flexible, easily deformable and especially water absorbent. They must therefore be designed relatively thick, so that given flexibility requirements can be achieved. This requires rounding the bristle ends to prevent injury to the gums.

- polyester bristles made of, for example, polybutylene terephthalate (PBT) and / or polyethylene terephthalate (PET) have a low water absorption rate and good durability properties.

- PBT polybutylene terephthalate

- PET polyethylene terephthalate

- these bristles usually do not meet the requirements of elasticity or bending stiffness. They are typically too stiff and inflexible and can thus lead to damage to the gums.

- polyester bristles are immersed in corrosive chemicals until the immersed portion of the monofilaments is completely eroded. This eventually leads to a tapered bristle end.

- the chemically sharpened ends of the bristle are attacked and subject to massive damage due to the etching process.

- the etching process thus produces a high reject rate which adversely affects the production costs.

- the tapered bristles made of a monofilament have a low durability and an already too low flexural rigidity due to the eroded lateral surface.

- the shape of the tapered bristles essentially determined solely by the etching process and can not be designed according to predetermined requirements.

- the monofilament is split along the boundary layers between the at least two Polymers always provided the action of mechanical forces.

- the mechanical introduction of slots, columns and flags is complex on the one hand and relatively imprecise on the other hand, because the formation of such gaps depends essentially on the amplitude and the direction of the applied force and the binding forces between the polymers.

- the slots thus produced often have different and difficult to control lengths, irregular shapes and frayed lateral surfaces.

- Bristles which can be produced by multi-component extrusion and which are tapered at the end region by material removal, rounded or configured in several individual filaments.

- From the JP2003 339440 is a method for producing or processing bristles according to the preamble of claim 1 and a bristle according to the preamble of claim 5.

- the present invention is therefore based on the object of providing tapered bristles, in particular for toothbrushes, with freely selectable geometry and improved elasticity properties. Furthermore, the invention has for its object to optimize a manufacturing or processing method for such bristles under production rational aspects.

- the bristle according to the invention has in the longitudinal direction at least two jointly extruded filaments of different materials and is characterized in that the cross-sectional area of at least one of the two filaments decreases towards the free end of the bristle.

- at least one of the at least two coextruded filaments changes its geometry in the region of the bristle end.

- the two extruded filaments consist of different materials, such as polyester and polyamide, which can be subjected to a material-selective machining process to form the bristle according to the invention.

- both the flexurally elastic properties of the bristle and its geometric configuration, in particular in the region of the bristle ends, can be designed almost as desired.

- the cross-sectional area of the at least one filament steadily decreases toward the free end of the bristle.

- a steady decrease in the cross-sectional area is accompanied by a continuously decreasing lateral surface and a continuously decreasing diameter of this bristle filament. Sharp corners or edges, the characteristics of discontinuously extending lateral surfaces or surfaces are thus avoided in an advantageous manner. The risk of injury to sensitive areas within the oral cavity, such as the gums, can thus be lowered advantageously.

- the cross-sectional area of the free end of the bristle is substantially determined by the at least one other filament.

- its cross-sectional area is substantially constant in the longitudinal direction of the bristles.

- the at least one filament at the free end of the bristle has a cross-sectional area of zero, so that the total cross section of the bristle at the free end of the bristle is determined essentially by the remaining at least other filament.

- the entire bristle can better meet the given elasticity or bending stiffness requirements correspond.

- the bristle according to the invention is not chemically sharpened at its end of the filament and therefore also not attacked or otherwise damaged.

- the at least one other filament is at least partially radially enclosed by the at least one filament.

- this core sheathing finally tapers, until at the free end of the bristle only the other filament forming the bristle core remains and forms a tapered bristle cross section.

- the at least other filament e.g. the core filament is wider in the axial direction than the one filament, e.g. the sheath filament extends.

- the free end of the bristle is therefore formed only by that filament whose cross-sectional area does not change substantially.

- a plurality of filaments not changing in cross-section are regularly distributed over the cross-section of the bristle and are surrounded by the at least one filament, the cross-sectional area of which has a change towards the bristle end, at least in regions in the radial direction.

- a configuration can ultimately be formed at the bristle end that forms a plurality of individual filaments separated by gaps.

- Such filament arrangements are advantageous, for example, for receiving dentifrices or dental or antibacterial preparations.

- the at least other filament is rounded or rounded at its free end.

- the filaments forming the free end of the bristle thus have essentially no edges which could lead to injuries in the oral cavity.

- the at least two filaments have a different elasticity and / or a different bending stiffness.

- the elasticity and / or bending stiffness properties of the bristle can be adjusted specifically to a predetermined level.

- the at least one filament can be removed by means of an etchant, in particular a chemical etchant, such as sodium hydroxide, sulfuric acid or formic acid, wherein the at least other filament is substantially resistant to the respective chemical etchant.

- an etchant in particular a chemical etchant, such as sodium hydroxide, sulfuric acid or formic acid

- the free end of the bristle can be processed material selectively using a chemical etching process.

- almost any elasticity properties of the bristle ends and correspondingly versatile bristle end geometries can be realized by any arrangement and geometry of individual filaments.

- polyamide and / or polyester is provided as material for the filaments.

- These materials have different elasticity and stiffness properties. Furthermore, only one of these materials is attacked by the chemicals intended for a chemical etching process, such as, for example, sodium hydroxide solution, sulfuric acid or formic acid, while the respective other material is substantially resistant to the chemical.

- Nylon, PA 6.6, PA 6.10 and PA 6.12 are particularly suitable as the polyamide, while the polyester is essentially PET and / or PBT.

- the invention relates to a method for producing or processing bristles, in particular toothbrush bristles, which have in the longitudinal direction at least two jointly extruded filaments of different materials.

- the method is characterized in that at least one of the filaments in the region of the free end of the bristles is at least partially removed by means of a chemical etching process.

- the at least one other filament is essentially resistant to the chemical used in the chemical etching process and corrodes at most to a negligible extent in the chemical etching process.

- At least one filament which is substantially resistant to the etchant is exposed at least in areas, preferably in the region of the free end, by means of the etching process.

- the parameters of the etching process such as immersion depth of the bristle ends in the chemical and their residence time in the chemical are preferably determined by the shape and the geometry, in particular to the radial dimensions of the filaments adapted. In this way, the etching process can be optimized so that the at least one filament in the region of the free end of the bristle are completely removed, so that there at least the other filaments can be substantially exposed.

- the bristle core is formed by a resistant to the chemical used filament, which is radially enclosed by the corroded filaments in the etching process as a sheath.

- the sheath of the multi-filament bristle surrounding the inner bristle core is removed in the chemical etching process in such a way that it tapers conically toward the bristle end. Consequently, only the bristle sheath tapers, while a bristle core that is chemically undamaged extends beyond the end of the bristle sheath.

- the etching process is universally applicable to a variety of different arrangements of different filaments.

- the free ends of a plurality of filaments preferably arranged regularly and spaced from one another, can also be exposed. This ultimately allows even the cost-effective and chemical production of slots that can be used to hold media.

- the production of bristles with split, consisting of several individual filaments, use-side end on a chemical and therefore cost-effective way is possible.

- the bristle ends are rounded or rounded after the etching process by means of grinding.

- the bristles are fixed before the etching process on a bristle carrier provided for the bristles, in particular on a toothbrush head.

- the bristles are already in front of the processing of the bristle end etching and grinding process at its predetermined position on the brush head and no longer need to be attached to the etching of this, which would be associated with a much higher cost, since the tapered at their ends formed bristles should be treated with greater care.

- fixation of the bristles on the bristle head prior to processing of the bristle ends in particular enables a simplified production of complicated Taftgeometrien of bristles on the bristle carrier.

- the invention therefore relates to bristles of any kind, but in particular to toothbrushes with a bristle carrier, on which the multi-filament and tapered bristles according to the invention are arranged.

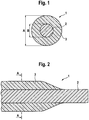

- the bristle 1 is a bristle 1, which is not part of the invention, in particular the bristle of a toothbrush shown schematically in cross section.

- the bristle 1 here consists of two filaments 2, 3 different material, which are extruded, stretched and fixed together.

- the one filament 2 forms an inner core of the bristle 1, while the other filament 3 surrounds the inner filament 2 as a sheath.

- the inner filament is made of polyamide, such as nylon, while the outer filament 3 is polyester.

- the originally cylindrical shell 3 is removed material selectively, while the resistant to the chemical bristle core 2 compared to its (not shown) basic state unchanged Geometry preserves.

- the polyester filament 3 forming the bristle jacket is etched away by immersion in the chemical such that the jacket 3 of the bristle, before reaching the free end of the bristle, tapers conically with a cross-sectional area which steadily decreases toward the bristle end.

- this material-selective etching process has the advantage that the inner core 2 of the bristle is in no way damaged by the etching process. This still has a required flexural rigidity and can be easily sharpened or rounded mechanically in subsequent process steps. Furthermore, it is ensured on account of the material-selective etching of the bristle end that a predetermined minimum thickness of the bristle end can not be undershot, so that the risk of breaking or uncontrolled breaking off is reliably counteracted.

- FIG. 3 shows a further example of a multi-filament bristle 4.

- filaments 6 which consist of the same material, regularly and spaced apart, arranged distributed over the cross section of the bristle 4.

- the spaces between the filaments 6 are filled with the filament 5, which is removed by the chemical used in the etching process.

- the filament 5 can also be completely removed at the free end of the bristle, so that the individual filaments 6 remain with a smaller diameter, which are suitable for receiving material in the filament interspaces as well as for penetration into the smallest interdental spaces.

- FIG. 4 shows an embodiment of a bristle 7, which has radially symmetrically arranged segments of different filaments 8, 9 in cross section.

- all filaments 8, 9 extend from the bristle center to the bristle edge.

- FIG. 5 shows a further embodiment of a bristle end, in which individual filaments 12 are arranged of a material adjacent to the bristle periphery and spaced from each other, while the other filament 11 fills the core region of the bristle.

- the filament 11 is partially removed by the etching process, so that the individual bristle filaments 12 are at least partially exposed and thus form a spread-open end of the bristle 10.

- FIG. 1 shows a schematic side view of a further bristle end 13, which has different filaments 14, 15, which are preferably detached from one another by means of a chemical etching process and thus form a fanned-out bristle end.

- the filaments 14, 15 consisting of different materials are replaced by means of a further, not explicitly shown filament, such as for example in the manner of in FIG. 5 shown filaments 11, are first held together, which is finally removed in the etching process, so that ultimately in the FIG. 6 shown fan-like structure at the end of the bristle arises.

Landscapes

- Brushes (AREA)

- Chemical Or Physical Treatment Of Fibers (AREA)

- Treatments For Attaching Organic Compounds To Fibrous Goods (AREA)

- Yarns And Mechanical Finishing Of Yarns Or Ropes (AREA)

- Multicomponent Fibers (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102006012004A DE102006012004A1 (de) | 2006-03-16 | 2006-03-16 | Mehrfilamentige Borsten für Zahnbürsten |

| PCT/EP2007/000664 WO2007104381A1 (de) | 2006-03-16 | 2007-01-26 | Mehrfilamentige borsten für zahnbürsten |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1993399A1 EP1993399A1 (de) | 2008-11-26 |

| EP1993399B1 true EP1993399B1 (de) | 2018-09-26 |

Family

ID=38134639

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07703053.4A Active EP1993399B1 (de) | 2006-03-16 | 2007-01-26 | Mehrfilamentige borsten für zahnbürsten |

Country Status (13)

| Country | Link |

|---|---|

| US (1) | US20090094770A1 (enExample) |

| EP (1) | EP1993399B1 (enExample) |

| JP (1) | JP2009529612A (enExample) |

| KR (1) | KR20090006067A (enExample) |

| CN (1) | CN101404912A (enExample) |

| AU (1) | AU2007224819A1 (enExample) |

| BR (1) | BRPI0709398A2 (enExample) |

| CA (1) | CA2645152A1 (enExample) |

| DE (1) | DE102006012004A1 (enExample) |

| MX (1) | MX2008011496A (enExample) |

| RU (1) | RU2008140938A (enExample) |

| WO (1) | WO2007104381A1 (enExample) |

| ZA (1) | ZA200807199B (enExample) |

Families Citing this family (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012000148A (ja) * | 2010-06-14 | 2012-01-05 | Panasonic Electric Works Co Ltd | ブラシ体およびこれを備えた歯ブラシ |

| US20150150366A1 (en) * | 2012-06-05 | 2015-06-04 | Lg Household & Healthcare Ltd. | Toothbrush bristles having tip with double structure and toothbrush comprising same |

| KR101385623B1 (ko) * | 2012-08-17 | 2014-04-16 | 케이필라 주식회사 | 코어-시스 필라멘트의 제조방법, 제조된 칫솔모 제조용 모노필라멘트 및 그를 포함하는 칫솔 |

| CN104902785B (zh) * | 2012-10-04 | 2017-03-22 | Bbc有限公司 | 牙刷毛的制造方法及利用该牙刷毛的牙刷 |

| BR112016012422B1 (pt) | 2013-12-12 | 2021-11-03 | Colgate-Palmolive Company | Cerda de múltiplos componentes que tem componentes com diferentes aditivos para cuidado oral e implemento para cuidado oral que compreende os mesmos |

| US10477958B2 (en) | 2013-12-12 | 2019-11-19 | Colgate-Palmolive Company | Multi-component bristle having components with different oral care additives, and oral care implement comprising the same |

| CN105792701B (zh) | 2013-12-12 | 2018-03-02 | 高露洁-棕榄公司 | 具有带有不同的口腔护理添加剂的股线部件的螺旋刷毛以及包括该螺旋刷毛的口腔护理器具 |

| USD764177S1 (en) | 2014-07-31 | 2016-08-23 | Colgate-Palmolive Company | Oral care implement |

| USD764176S1 (en) | 2014-07-31 | 2016-08-23 | Colgate-Palmolive Company | Oral care implement |

| US10702057B2 (en) | 2015-07-07 | 2020-07-07 | Colgate-Palmolive Company | Oral care implement and monofilament bristle for use with the same |

| BR112018011445A2 (pt) | 2015-12-14 | 2018-11-27 | Colgate Palmolive Co | instrumento para higiene bucal e cerdas em espiral para uso com o mesmo |

| GB201600846D0 (en) * | 2016-01-18 | 2016-03-02 | Glaxosmithkline Consumer Healt | Novel device |

| JPWO2017130901A1 (ja) * | 2016-01-25 | 2018-11-15 | 東レ・モノフィラメント株式会社 | ブラシ用毛材及びそれを用いたブラシ |

| KR101874948B1 (ko) * | 2016-03-09 | 2018-07-10 | 비비씨 주식회사 | 이중 구조의 필라멘트 |

| US20180199701A1 (en) * | 2017-01-16 | 2018-07-19 | L'oreal Usa Creative, Inc. | Cosmetic brush head including anti-aging ingredients |

| ES3027651T3 (en) * | 2017-03-31 | 2025-06-16 | Gillette Co Llc | Head for an oral care implement, oral care implement and method for manufacturing such head |

| ES3029487T3 (en) * | 2017-03-31 | 2025-06-24 | Gillette Co Llc | Head for an oral care implement, oral care implement and method for manufacturing such head |

| ES3028878T3 (en) * | 2017-03-31 | 2025-06-20 | Gillette Co Llc | Head for an oral care implement, oral care implement and method for manufacturing such head |

| EP3381320B1 (en) * | 2017-03-31 | 2025-03-19 | The Gillette Company LLC | Head for an oral care implement, oral implement and method for manufacturing such head |

| USD883677S1 (en) | 2018-12-13 | 2020-05-12 | Colgate-Palmolive Company | Toothbrush |

| CA3119552A1 (en) | 2018-12-13 | 2020-06-18 | Colgate-Palmolive Company | Oral care implement |

| CN113194785A (zh) | 2018-12-13 | 2021-07-30 | 高露洁-棕榄公司 | 口腔护理器具 |

| USD961269S1 (en) | 2020-07-31 | 2022-08-23 | Colgate-Palmolive Company | Oral care implement |

| USD1024571S1 (en) | 2022-06-17 | 2024-04-30 | Colgate-Palmolive Company | Oral care implement |

| USD1024572S1 (en) | 2022-06-24 | 2024-04-30 | Colgate-Palmolive Company | Oral care implement |

| EP4575052A1 (en) * | 2023-12-21 | 2025-06-25 | GEKA GmbH | Multi-strand filament |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003339440A (ja) * | 2002-05-30 | 2003-12-02 | Lion Corp | ブラシおよびその製造方法 |

| JP2005253712A (ja) * | 2004-03-12 | 2005-09-22 | Toray Monofilament Co Ltd | 電動歯ブラシ用ブリッスルおよび電動歯ブラシ |

| WO2006082799A1 (ja) * | 2005-02-02 | 2006-08-10 | Sunstar Inc. | 歯ブラシ |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS584113B2 (ja) * | 1979-03-01 | 1983-01-25 | 株式会社新和製作所 | 合成繊維の先端を細くする方法 |

| DE3400941A1 (de) * | 1983-01-14 | 1984-10-11 | Coronet - Werke Heinrich Schlerf Gmbh, 6948 Wald-Michelbach | Kunststoffborste |

| DE19932376A1 (de) * | 1999-07-13 | 2001-01-18 | Coronet Werke Gmbh | Borste für Zahnbürsten und Zahnbürste mit solchen Borsten |

| DE19942147A1 (de) * | 1999-09-03 | 2001-03-08 | Trisa Holding Ag Triengen | Einzelborste aus Kunststoff für eine Bürste, insbesondere eine Zahnbürste sowie ein Verfahren zur Herstellung einer Einzelborste |

-

2006

- 2006-03-16 DE DE102006012004A patent/DE102006012004A1/de not_active Withdrawn

-

2007

- 2007-01-26 JP JP2008558659A patent/JP2009529612A/ja active Pending

- 2007-01-26 BR BRPI0709398-5A patent/BRPI0709398A2/pt not_active IP Right Cessation

- 2007-01-26 MX MX2008011496A patent/MX2008011496A/es not_active Application Discontinuation

- 2007-01-26 EP EP07703053.4A patent/EP1993399B1/de active Active

- 2007-01-26 CA CA002645152A patent/CA2645152A1/en not_active Abandoned

- 2007-01-26 CN CNA2007800093042A patent/CN101404912A/zh active Pending

- 2007-01-26 AU AU2007224819A patent/AU2007224819A1/en not_active Abandoned

- 2007-01-26 WO PCT/EP2007/000664 patent/WO2007104381A1/de not_active Ceased

- 2007-01-26 RU RU2008140938/12A patent/RU2008140938A/ru not_active Application Discontinuation

- 2007-01-26 US US12/293,011 patent/US20090094770A1/en not_active Abandoned

- 2007-01-26 KR KR1020087022155A patent/KR20090006067A/ko not_active Ceased

-

2008

- 2008-08-20 ZA ZA200807199A patent/ZA200807199B/xx unknown

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003339440A (ja) * | 2002-05-30 | 2003-12-02 | Lion Corp | ブラシおよびその製造方法 |

| JP2005253712A (ja) * | 2004-03-12 | 2005-09-22 | Toray Monofilament Co Ltd | 電動歯ブラシ用ブリッスルおよび電動歯ブラシ |

| WO2006082799A1 (ja) * | 2005-02-02 | 2006-08-10 | Sunstar Inc. | 歯ブラシ |

| EP1844677A1 (en) * | 2005-02-02 | 2007-10-17 | Sunstar Inc. | Toothbrush |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2009529612A (ja) | 2009-08-20 |

| BRPI0709398A2 (pt) | 2011-07-05 |

| WO2007104381A1 (de) | 2007-09-20 |

| MX2008011496A (es) | 2008-09-22 |

| ZA200807199B (en) | 2009-05-27 |

| EP1993399A1 (de) | 2008-11-26 |

| RU2008140938A (ru) | 2010-04-27 |

| CN101404912A (zh) | 2009-04-08 |

| US20090094770A1 (en) | 2009-04-16 |

| CA2645152A1 (en) | 2007-09-20 |

| DE102006012004A1 (de) | 2007-09-20 |

| KR20090006067A (ko) | 2009-01-14 |

| AU2007224819A1 (en) | 2007-09-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1993399B1 (de) | Mehrfilamentige borsten für zahnbürsten | |

| EP1113737B1 (de) | Borste für eine zahnbürste, insbesondere für eine elektrische zahnbürste, sowie verfahren zu deren herstellung | |

| EP2028969B1 (de) | Zahnbürste sowie zahnbürstenkopf und zahnputzborste hierfür | |

| EP4025412B1 (de) | Vorrichtung und verfahren zur herstellung eines gerafften oder raffbaren materials | |

| EP0467126B1 (de) | Bürste, insbesondere Maskarabürste | |

| DE2112441C2 (de) | Verfahren zur Herstellung eines Kunststoffilaments | |

| DE3413945C2 (de) | Mit schraubenlinienförmigen Nuten versehene Zahnhaltevorrichtung | |

| EP0850004A1 (de) | Zahnbürste und verfahren zu ihrer herstellung | |

| EP1301103B1 (de) | Behandlungsteil für einen apparat zur reinigung von zahnzwischenräumen, verfahren und vorrichtung zu dessen herstellung | |

| DE60308206T2 (de) | Wimperntuschebürstchen mit drahtkern | |

| EP1030937A1 (de) | Monofil für und zur herstellung von borsten oder interdentalreiniger, sowie borstenware mit solchen borsten und interdentalreiniger | |

| DE19723695C2 (de) | Wurzelkanalinstrument | |

| WO2025103793A1 (de) | Bürste | |

| EP3517014B1 (de) | Rotierbare reinigungswalze und kehrvorrichtung mit einer solchen walze | |

| EP3672446B1 (de) | Interdentalbürste | |

| EP2866677B1 (de) | Chirurgisches instrument zur behandlung von fisteln | |

| DE19852931C1 (de) | Wurzelkanalinstrument mit mehreren unterschiedlichen Querschnitten | |

| EP1386562A1 (de) | Mascara-Bürstchen, Herstellungsverfahren sowie Mascara-Vorratsbehälter hierfür | |

| DE3410970A1 (de) | Seil und verfahren seiner herstellung | |

| EP2277702B1 (de) | Rotationsbürstenanordnung | |

| DE2407490B2 (de) | Drahtbuerste, insbesondere drehbare stahldrahtbuerste und verfahren zu ihrer herstellung | |

| DE102023102091A1 (de) | Zahnbürste mit flexiblem Zahnbürstenkopf | |

| DE2828246A1 (de) | Nadel fuer tuftingmaschinen | |

| EP2135543A1 (de) | Vorrichtung zum minimalinvasiven Einführen in ein physiologisches Lumen | |

| EP0959714A1 (de) | Kosmetikbürste |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20080820 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: STIEF, CHRISTIAN Inventor name: DORNHEIM, JUERGEN Inventor name: ZOSCHKE, CHRISTINE Inventor name: EMGE, THORSTEN |

|

| 17Q | First examination report despatched |

Effective date: 20100610 |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20180418 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAJ | Information related to disapproval of communication of intention to grant by the applicant or resumption of examination proceedings by the epo deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR1 |

|

| GRAL | Information related to payment of fee for publishing/printing deleted |

Free format text: ORIGINAL CODE: EPIDOSDIGR3 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTC | Intention to grant announced (deleted) | ||

| INTG | Intention to grant announced |

Effective date: 20180716 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1044989 Country of ref document: AT Kind code of ref document: T Effective date: 20181015 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502007016406 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: FP |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180926 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181227 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180926 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180926 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181226 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180926 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180926 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180926 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180926 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180926 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180926 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190126 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180926 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180926 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20190126 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502007016406 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180926 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180926 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| 26N | No opposition filed |

Effective date: 20190627 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190126 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190131 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190131 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180926 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190131 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190126 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 1044989 Country of ref document: AT Kind code of ref document: T Effective date: 20190126 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180926 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190126 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180926 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20070126 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230430 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20241214 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20241205 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20241203 Year of fee payment: 19 |