EP1982932A1 - Spray nozzle - Google Patents

Spray nozzle Download PDFInfo

- Publication number

- EP1982932A1 EP1982932A1 EP08012577A EP08012577A EP1982932A1 EP 1982932 A1 EP1982932 A1 EP 1982932A1 EP 08012577 A EP08012577 A EP 08012577A EP 08012577 A EP08012577 A EP 08012577A EP 1982932 A1 EP1982932 A1 EP 1982932A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- spray

- passage

- color

- fold

- lid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000007921 spray Substances 0.000 title claims abstract description 60

- 238000007789 sealing Methods 0.000 claims description 37

- 238000001514 detection method Methods 0.000 claims description 23

- 238000005507 spraying Methods 0.000 claims description 11

- 239000000443 aerosol Substances 0.000 claims description 4

- 230000037431 insertion Effects 0.000 claims 1

- 238000003780 insertion Methods 0.000 claims 1

- 230000002441 reversible effect Effects 0.000 abstract 1

- 239000000463 material Substances 0.000 description 10

- 239000003973 paint Substances 0.000 description 9

- 238000011161 development Methods 0.000 description 2

- 230000018109 developmental process Effects 0.000 description 2

- 238000004064 recycling Methods 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000002966 varnish Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers for dispensing liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant

- B65D83/40—Closure caps

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers for dispensing liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant

- B65D83/75—Aerosol containers not provided for in groups B65D83/16 - B65D83/74

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2203/00—Decoration means, markings, information elements, contents indicators

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2565/00—Wrappers or flexible covers; Packaging materials of special type or form

- B65D2565/38—Packaging materials of special type or form

- B65D2565/381—Details of packaging materials of special type or form

- B65D2565/385—Details of packaging materials of special type or form especially suited for or with means facilitating recycling

Definitions

- the invention relates to a spray can with a can body for receiving the Sprühguts, wherein the can body is assigned a spraying device for the Sprühgut, and a lid for protecting the spraying device, wherein the can body is associated with a color detection element for displaying the color of the Sprühguts and wherein the color detection element as ring-like outer shell of a hollow spherical layer or a hollow truncated cone, each having an upper smaller and a lower major passage is formed.

- Spray cans have long been known from practice and exist in a variety of embodiments.

- the can body is usually designed cylindrical, wherein the spray is arranged on one of the base surfaces of the cylinder.

- the spray is usually formed by a spray head with a spray valve.

- the lid is also often substantially cylindrical in shape with a base of the cylinder omitted to couple to the can body in the area of the sprayer.

- Spray cans of the type mentioned are often used for spraying colored paints.

- To detect the color of the paint absorbed in the can body is often either the lid completely colored according to the recorded paint or a part of the can body painted accordingly.

- the color of the recorded in the can body paint safely determined.

- a spray can with all features of the preamble of claim 1 is known.

- the can body is assigned a color recognition element for displaying the color of the spray material.

- the color recognition element is formed as a ring-like outer shell of a hollow spherical layer having an upper smaller and a lower major passage.

- the geometry of the color recognition element is chosen such that it is impossible to remove the color recognition element after the assignment without the color recognition element to break. A simple removal of the color detection element of the spray can is not possible.

- the DE 2 039 314 A shows a spray can in which the dome is painted with a coat of paint according to the paint content of the can.

- the US 3,075,673 shows a spray can with a protective cap to prevent inadvertent dropping of paint on the can.

- the known aerosol is assigned no color recognition element.

- DE-GM 69 28 235 shows a spray can with a color detection element, which is associated with a lid of the spray can.

- the GB 2 090 809 A shows a bottle with a label that can be arranged around the neck of the bottle.

- the present invention is therefore the object of a spray can of the type mentioned in such a way and further develop that a simple release of the color detection element is achieved by the can body or the lid with structurally simple means.

- the above object is achieved by a spray can with the features of claim 1.

- the spray can in question is designed such that the color detection element the can body thereby reversibly associated and can be removed again, that the inner diameter of the upper passage is slightly smaller than the outer diameter of a formed around the spray, annular sealing fold of the can body, the upper passage is slightly elastically stretchable under application of force against the sealing fold to a secure fit to reach the sealing fold or below the sealing fold after taking the original unstretched state of the upper passage and to be removed again accordingly.

- the above object is achieved by a spray can with the features of claim 1.

- the spray can in question is formed such that the color detection element is reversibly associated with the can body and can be removed again, that the inner diameter of the upper passage is slightly smaller than the outer diameter of a formed around the spray, annular sealing fold of the can body, said upper passageway is slightly elastically stretchable against the sealing fold in order to achieve a secure fit on the sealing fold or below the sealing fold after assuming the original unstretched condition of the upper passage and to be correspondingly removed again.

- the color recognition element is assigned reversibly to the can body. This makes it possible that the color detection element can be removed in case of accidental incorrect assignment to the can body and a correct color detection element can be assigned. Furthermore, with a view to recycling the spray can after use, it is possible to separate the components of the spray can - in this case a separation of the color recognition element from the can body. If the color recognition element is made of a different material than the can body, a material-specific disposal or reuse of the components can thus take place.

- the inner diameter of the upper passage slightly smaller than the outer diameter of the spray device formed around the annular sealing fold of the can body.

- a certain amount of force is needed to stretch the upper passage slightly elastically to ensure a secure fit on the sealing fold or a secure fit below the sealing fold after assuming the original unstretched state of the upper passage to reach.

- the sealing fold would have to have a region with a smaller outside diameter.

- the outer sheath could be guided along the sealing fold until the outer sheath arrives quasi below the sealing fold in a region of smaller diameter.

- the outer sheath could be assigned to the can body or arranged on the can body in such a way that the spraying device virtually protrudes from the upper smaller passage. In other words, in this case, the spray device would be surrounded by the outer jacket.

- the outer shell has a relatively large color detection area, which simplifies color detection as a whole.

- the outer sheath has a predefinable material thickness, which is to be turned off in the respective application.

- the outer sheath could have a certain elasticity.

- Spray cans for paints or varnishes usually have a sealing fold, which is finally formed ring-like directly around the spray. As a result, a seal between the can body and the spray is achieved, which is usually attached as a separate element to the can body. Furthermore, a conventional spray can have a further fold or sealing fold which is formed in the upper region of the can body and ultimately also as a reinforcement serves. With regard to a particularly simple assignment of the outer sheath to the can body, the inner edge of the upper passage of the outer sheath - could be bevelled - widening inwardly. When assigning the outer jacket to the can body, the outer shell thus slips easier due to the bevel on the annular sealing fold between the spray and can body.

- the outer shell in the region of the outer edge of the lower passage - to the lower passage or to its free end - tapered be sharpened.

- the outer sheath with the outer edge of the lower passage could preferably be arranged in a form-fitting manner on the inner circumference of the ring-shaped sealing fold formed in the upper region of the can body.

- This sealing fold forms a kind of connection between a side surface and an upper base surface of the can body.

- the outer diameter of the outer sheath could be slightly larger in the region of the lower passage than the inner diameter of the formed in the upper region of the can body, annular fold or Dichtfalzes the can body. In this way, in turn, a clamping action could be achieved due to an elasticity of the outer sheath in the region of the fold or sealing fold. This would result in a particularly secure arrangement of the outer jacket on the can body.

- the outer jacket could ultimately extend from the sealing fold around the spraying device to the fold or sealing fold in the upper region of the can body.

- the outer sheath could have a continuous slot extending substantially from the upper passage to the lower passage. hereby

- the outer sheath could simply be compressed or expanded to permit removal from the can body.

- the lid could be formed elastically.

- the lid could be formed in particular of plastic.

- the color recognition element could have a predetermined breaking point. After generating the predetermined fracture, the color detection element could then be easily detached from the can body or lid.

- the color recognition element could have an engagement passage or an engagement recess.

- the engagement passage or the engagement recess could be dimensioned such that the color detection element could be grasped either by hand or a finger or with a special instrument and detached from the can body or the lid.

- spray can also includes all known spray cans or aerosol cans.

- Fig. 1 shows a schematic side view of the embodiment of a spray can according to the invention.

- the spray can has a can body 1 for receiving the spray material, wherein the can body 1 is assigned a spraying device 2 for the spray material. Furthermore, the spray can has a cover 3 for protecting the spray device 2. With a view to a simplified production with reduced costs, the spray can is designed such that the can body 1 or the cover 3 is associated with a color detection element 4 for displaying the color of Sprühguts.

- the color recognition element 4 is painted with the spray material, at least in its outer area, so that ultimately the same spray material or the same paint is located on the color detection element 4 as in the can body 1.

- the lid 3 is transparent, so that the color detection element 4 even with the lid closed 3 is visible from the outside.

- the color recognition element 4 is reversibly associated with the can body 1.

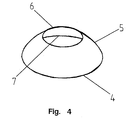

- the color recognition element 4 is finally formed as a closed ring, wherein the color recognition element 4 is more precisely formed as a ring-like outer shell 5 a hollow spherical layer, each having an upper smaller and a lower major passage 6 and 7. In other words, the color recognition element 4 is dish-shaped.

- the outer jacket 5 is elastically formed from plastic, so that a simple arrangement of the outer jacket 5 on the can body 1 is made possible.

- the inner edge 8 of the upper passage 6 is tapered inwardly widening.

- the outer jacket 5 is sharply tapered in the region of the outer edge 9 of the lower passage 7. This has the advantage that the outer jacket 5 can slide along a sealing fold 10 and a sealing fold 11 of the can body more easily when the outer jacket 5 is placed on the can body 1.

- the sealing fold 10 forms the transition from the upper part of the can body 1 to the spray 2.

- the sealing fold 11 forms the transition from the cylindrical shell of the can body 1 to the often conical upper part of the can body. 1

- the inner diameter of the upper passage 6 is slightly smaller than the outer diameter of the ring-like Dichtfalzes 10. D. h. That the outer shell 5 is snapped after its placement on the can body 1 almost below the Dichtfalzes 10 in a narrowed region below the Dichtfalzes 10.

- the outer jacket 5 is connected to the outer edge 9 of the lower passage 7 quasi form-fitting manner on the inner circumference of the sealing fold 11 of the can body.

- the outer diameter of the outer jacket 5 in the region of the lower passage 7 could be made slightly larger than the inner diameter of the sealing fold 11. This would almost a snuggling of the outer jacket 5 on the inner circumference of the sealing fold 11 realized.

- the outer jacket 5 extends substantially from the upper sealing fold 10 to the lower sealing fold 11.

- the cover 3 has recesses 12 for a color recognition element 4.

- the lid 3, a color detection element 4 could be assigned.

- the recesses 12 are formed in support webs 13 of the lid 3, which serve to rest on the can body 1.

- the lid 3 is also elastic and made of plastic.

- the Fig. 2 to 4 show the formed as an outer shell 5 color recognition element 4 in a schematic side view, in a schematic plan view and in a perspective view, each enlarged.

- the upper passage 6 and the lower passage 7 are particularly clearly visible.

Landscapes

- Chemical & Material Sciences (AREA)

- Dispersion Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Manufacturing Of Micro-Capsules (AREA)

- Nozzles (AREA)

- Catching Or Destruction (AREA)

- Acyclic And Carbocyclic Compounds In Medicinal Compositions (AREA)

Abstract

Description

Die Erfindung betrifft eine Sprühdose mit einem Dosenkörper zur Aufnahme des Sprühguts, wobei dem Dosenkörper eine Sprüheinrichtung für das Sprühgut zugeordnet ist, und einem Deckel zum Schutz der Sprüheinrichtung, wobei dem Dosenkörper ein Farberkennungselement zur Anzeige der Farbe des Sprühguts zugeordnet ist und wobei das Farberkennungselement als ringartiger Außenmantel einer hohlen Kugelschicht oder eines hohlen Kegelstumpfs mit jeweils einem oberen kleineren und einem unteren größeren Durchgang ausgebildet ist.The invention relates to a spray can with a can body for receiving the Sprühguts, wherein the can body is assigned a spraying device for the Sprühgut, and a lid for protecting the spraying device, wherein the can body is associated with a color detection element for displaying the color of the Sprühguts and wherein the color detection element as ring-like outer shell of a hollow spherical layer or a hollow truncated cone, each having an upper smaller and a lower major passage is formed.

Sprühdosen sind seit langem aus der Praxis bekannt und existieren in den unterschiedlichsten Ausführungsformen. Dabei ist der Dosenkörper meist zylinderförmig ausgestaltet, wobei die Sprüheinrichtung an einer der Grundflächen des Zylinders angeordnet ist. Die Sprüheinrichtung ist meist durch einen Sprühkopf mit einem Sprühventil gebildet. Der Deckel ist häufig ebenfalls im Wesentlichen zylinderförmig ausgebildet, wobei eine Grundfläche des Zylinders weggelassen ist, um an den Dosenkörper im Bereich der Sprüheinrichtung anzukoppeln.Spray cans have long been known from practice and exist in a variety of embodiments. In this case, the can body is usually designed cylindrical, wherein the spray is arranged on one of the base surfaces of the cylinder. The spray is usually formed by a spray head with a spray valve. The lid is also often substantially cylindrical in shape with a base of the cylinder omitted to couple to the can body in the area of the sprayer.

Sprühdosen der eingangs genannten Art werden häufig zum Versprühen von farbigen Lacken verwendet. Zur Erkennung des Farbtons des im Dosenkörper aufgenommenen Lacks ist häufig entweder der Deckel entsprechend der aufgenommenen Lackfarbe vollständig eingefärbt oder ein Teil des Dosenkörpers entsprechend lackiert. Hierdurch ist beispielsweise beim Kauf der Sprühdose der Farbton des im Dosenkörper aufgenommenen Lacks sicher bestimmbar.Spray cans of the type mentioned are often used for spraying colored paints. To detect the color of the paint absorbed in the can body is often either the lid completely colored according to the recorded paint or a part of the can body painted accordingly. As a result, for example, when purchasing the spray can the color of the recorded in the can body paint safely determined.

Aus der

Die

Die

Die DE-GM 69 28 235 zeigt eine Sprühdose mit einem Farberkennungselement, das einem Deckel der Sprühdose zugeordnet ist.DE-GM 69 28 235 shows a spray can with a color detection element, which is associated with a lid of the spray can.

Aus der

Aus der

Die

Bei den bekannten Sprühdosen ist häufig problematisch, das Farberkennungselement wieder von dem Dosenkörper oder dem Deckel - z. B. zur getrennten Wiederverwertung dieser Komponenten - zu lösen.In the known spray cans is often problematic, the color recognition element again from the can body or the lid - z. B. for separate recycling of these components - to solve.

Der vorliegenden Erfindung liegt daher die Aufgabe zugrunde, eine Sprühdose der eingangs genannten Art derart auszugestalten und weiterzubilden, dass ein einfaches Lösen des Farberkennungselements von dem Dosenkörper oder dem Deckel mit konstruktiv einfachen Mitteln erreicht ist.The present invention is therefore the object of a spray can of the type mentioned in such a way and further develop that a simple release of the color detection element is achieved by the can body or the lid with structurally simple means.

Erfindungsgemäß wird die voranstehende Aufgabe durch eine Sprühdose mit den Merkmalen des Patentanspruchs 1 gelöst. Danach ist die in Rede stehende Sprühdose derart ausgebildet, dass das Farberkennungselement dem Dosenkörper dadurch reversibel zugeordnet ist und wieder entfernt werden kann, dass der Innendurchmesser des oberen Durchgangs geringfügig kleiner ist als der Außendurchmesser eines um die Sprüheinrichtung ausgebildeten, ringartigen Dichtfalzes des Dosenkörpers, wobei der obere Durchgang unter Kraftaufwendung gegenüber dem Dichtfalz geringfügig elastisch dehnbar ist, um einen sicheren Sitz an dem Dichtfalz oder unterhalb des Dichtfalzes nach Einnehmen des ursprünglichen ungedehnten Zustands des oberen Durchgangs zu erreichen und um entsprechend wieder entfernt zu werden.According to the invention the above object is achieved by a spray can with the features of claim 1. Thereafter, the spray can in question is designed such that the color detection element the can body thereby reversibly associated and can be removed again, that the inner diameter of the upper passage is slightly smaller than the outer diameter of a formed around the spray, annular sealing fold of the can body, the upper passage is slightly elastically stretchable under application of force against the sealing fold to a secure fit to reach the sealing fold or below the sealing fold after taking the original unstretched state of the upper passage and to be removed again accordingly.

Erfindungsgemäß wird die voranstehende Aufgabe durch eine Sprühdose mit den Merkmalen des Patentanspruchs 1 gelöst. Danach ist die in Rede stehende Sprühdose derart ausgebildet, dass das Farberkennungselement dem Dosenkörper dadurch reversibel zugeordnet ist und wieder entfernt werden kann, dass der Innendurchmesser des oberen Durchgangs geringfügig kleiner ist als der Außendurchmesser eines um die Sprüheinrichtung ausgebildeten, ringartigen Dichtfalzes des Dosenkörpers, wobei der obere Durchgang unter Kraftaufwendung gegenüber dem Dichtfalz geringfügig elastisch dehnbar ist, um einen sicheren Sitz an dem Dichtfalz oder unterhalb des Dichtfalzes nach Einnehmen des ursprünglichen ungedehnten Zustands des oberen Durchgangs zu erreichen und um entsprechend wieder entfernt zu werden.According to the invention the above object is achieved by a spray can with the features of claim 1. Thereafter, the spray can in question is formed such that the color detection element is reversibly associated with the can body and can be removed again, that the inner diameter of the upper passage is slightly smaller than the outer diameter of a formed around the spray, annular sealing fold of the can body, said upper passageway is slightly elastically stretchable against the sealing fold in order to achieve a secure fit on the sealing fold or below the sealing fold after assuming the original unstretched condition of the upper passage and to be correspondingly removed again.

In erfindungsgemäßer Weise ist das Farberkennungselement dem Dosenkörper reversibel zugeordnet. Hierdurch ist ermöglicht, dass das Farberkennungselement bei einer versehentlich unrichtigen Zuordnung zu dem Dosenkörper wieder entfernt werden und ein korrektes Farberkennungselement zugeordnet werden kann. Des Weiteren ist im Hinblick auf ein Recycling der Sprühdose nach ihrer Benutzung ein Trennen der Komponenten der Sprühdose - in diesem Fall eine Trennung des Farberkennungselements von dem Dosenkörper - möglich. Falls das Farberkennungselement aus einem anderen Material als der Dosenkörper hergestellt ist, kann somit eine materialspezifische Entsorgung oder Wiederbenutzung der Komponenten erfolgen.In accordance with the invention, the color recognition element is assigned reversibly to the can body. This makes it possible that the color detection element can be removed in case of accidental incorrect assignment to the can body and a correct color detection element can be assigned. Furthermore, with a view to recycling the spray can after use, it is possible to separate the components of the spray can - in this case a separation of the color recognition element from the can body. If the color recognition element is made of a different material than the can body, a material-specific disposal or reuse of the components can thus take place.

Zur Erzeugung einer besonders sicheren Klemmwirkung zwischen Außenmantel und ringartigem Dichtfalz im Bereich der Sprüheinrichtung ist der Innendurchmesser des oberen Durchgangs geringfügig kleiner als der Außendurchmesser des um die Sprüheinrichtung ausgebildeten, ringartigen Dichtfalzes des Dosenkörpers. Zum Anordnen des Außenmantels um den Dichtfalz bzw. entlang dem Dichtfalz ist dabei eine gewisse Kraft aufzuwenden, die den oberen Durchgang geringfügig elastisch dehnt, um einen sicheren Sitz an dem Dichtfalz oder einen sicheren Sitz unterhalb des Dichtfalzes nach Einnehmen des ursprünglichen ungedehnten Zustands des oberen Durchgangs zu erreichen. Im letztgenannten Fall müsste der Dichtfalz einen Bereich mit geringerem Außendurchmesser aufweisen. Alternativ zu einem derartigen geringeren Außendurchmesser könnte der Außenmantel soweit entlang dem Dichtfalz geführt werden, bis der Außenmantel quasi unterhalb des Dichtfalzes in einem Bereich geringeren Durchmessers ankommt.To produce a particularly secure clamping action between outer sheath and ring-like sealing fold in the region of the spraying device, the inner diameter of the upper passage slightly smaller than the outer diameter of the spray device formed around the annular sealing fold of the can body. In order to place the outer sheath around the sealing fold or along the sealing fold, a certain amount of force is needed to stretch the upper passage slightly elastically to ensure a secure fit on the sealing fold or a secure fit below the sealing fold after assuming the original unstretched state of the upper passage to reach. In the latter case, the sealing fold would have to have a region with a smaller outside diameter. As an alternative to such a smaller outer diameter, the outer sheath could be guided along the sealing fold until the outer sheath arrives quasi below the sealing fold in a region of smaller diameter.

Der Außenmantel könnte derart dem Dosenkörper zugeordnet oder derart auf dem Dosenkörper angeordnet werden, dass die Sprüheinrichtung quasi aus dem oberen kleineren Durchgang herausragt. Mit anderen Worten wäre die Sprüheinrichtung in diesem Fall von dem Außenmantel umgeben. Der Außenmantel weist eine relativ große Farberkennungsfläche auf, was die Farberkennung insgesamt vereinfacht.The outer sheath could be assigned to the can body or arranged on the can body in such a way that the spraying device virtually protrudes from the upper smaller passage. In other words, in this case, the spray device would be surrounded by the outer jacket. The outer shell has a relatively large color detection area, which simplifies color detection as a whole.

Der Außenmantel weist eine vorgebbare Materialdicke auf, die auf den jeweiligen Anwendungsfall abzustellen ist. Insbesondere bei einer nicht zu dicken Ausgestaltung des Außenmantels könnte der Außenmantel eine gewisse Elastizität aufweisen. Hierbei bietet sich als Material für den Außenmaterial insbesondere ein Kunststoff an. Aufgrund einer vorhandenen Elastizität könnte der Außenmantel mit Bereichen des Dosenkörpers eine wechselseitige Klemmwirkung bereitstellen, die zu einer sicheren Zuordnung des Farberkennungselements zu dem Dosenkörper beiträgt. Mit anderen Worten ist dann ein unbeabsichtigtes Lösen des Farberkennungselements von dem Dosenkörper weitestgehend vermieden.The outer sheath has a predefinable material thickness, which is to be turned off in the respective application. In particular, in a not too thick configuration of the outer sheath, the outer sheath could have a certain elasticity. In this case, offers as a material for the outer material, in particular a plastic. Due to existing elasticity, the outer sheath could provide areas of the can body with a mutual clamping action that contributes to a secure association of the color detection element to the can body. In other words, unintentional release of the color recognition element from the can body is largely avoided.

Sprühdosen für Farben bzw. Lacke weisen meist einen Dichtfalz auf, der letztendlich direkt um die Sprüheinrichtung ringartig ausgebildet ist. Hierdurch wird eine Abdichtung zwischen dem Dosenkörper und der Sprüheinrichtung erreicht, die meist als separates Element an dem Dosenkörper befestigt wird. Des Weiteren kann eine herkömmliche Sprühdose einen weiteren Falz oder Dichtfalz aufweisen, der im oberen Bereich des Dosenkörpers ausgebildet ist und letztendlich auch als Verstärkung dient. Im Hinblick auf eine besonders einfache Zuordnung des Außenmantels zu dem Dosenkörper könnte der innere Rand des oberen Durchgangs des Außenmantels - sich nach innen erweiternd - angeschrägt sein. Beim Zuordnen des Außenmantels zu dem Dosenkörper rutscht der Außenmantel aufgrund der Anschrägung somit einfacher über den ringartigen Dichtfalz zwischen Sprüheinrichtung und Dosenkörper.Spray cans for paints or varnishes usually have a sealing fold, which is finally formed ring-like directly around the spray. As a result, a seal between the can body and the spray is achieved, which is usually attached as a separate element to the can body. Furthermore, a conventional spray can have a further fold or sealing fold which is formed in the upper region of the can body and ultimately also as a reinforcement serves. With regard to a particularly simple assignment of the outer sheath to the can body, the inner edge of the upper passage of the outer sheath - could be bevelled - widening inwardly. When assigning the outer jacket to the can body, the outer shell thus slips easier due to the bevel on the annular sealing fold between the spray and can body.

Ebenfalls im Hinblick auf ein vereinfachtes Zuordnen oder Anordnen des Außenmantels zu oder an dem Dosenkörper könnte der Außenmantel im Bereich des Außenrands des unteren Durchgangs - zum unteren Durchgang oder zu seinem freien Ende hin - sich verjüngend angespitzt sein. Eine derartige im Außenbereich des Außenmantels vorgesehene Anspitzung des Außenmantels quasi in Richtung seiner inneren Achse vereinfacht ein Entlangführen oder Entlangrutschen des Außenmantels entlang dem ringartigen Falz oder Dichtfalz im oberen Bereich des Dosenkörpers.Also with regard to a simplified allocation or arrangement of the outer shell to or on the can body, the outer shell in the region of the outer edge of the lower passage - to the lower passage or to its free end - tapered be sharpened. Such provided in the outer region of the outer shell tapering of the outer sheath quasi in the direction of its inner axis simplifies Entlangführen or slipping along the outer sheath along the annular fold or Dichtfalz in the upper region of the can body.

Im Konkreten könnte der Außenmantel mit dem Außenrand des unteren Durchgangs vorzugsweise formschlüssig an dem inneren Umfang des im oberen Bereich des Dosenkörpers ausgebildeten, ringartigen Dichtfalzes angeordnet sein. Dieser Dichtfalz bildet dabei quasi eine Verbindung zwischen einer Seitenfläche und einer oberen Grundfläche des Dosenkörpers.Specifically, the outer sheath with the outer edge of the lower passage could preferably be arranged in a form-fitting manner on the inner circumference of the ring-shaped sealing fold formed in the upper region of the can body. This sealing fold forms a kind of connection between a side surface and an upper base surface of the can body.

Der Außendurchmesser des Außenmantels könnte im Bereich des unteren Durchgangs geringfügig größer sein als der Innendurchmesser des im oberen Bereich des Dosenkörpers ausgebildeten, ringartigen Falzes oder Dichtfalzes des Dosenkörpers. Hierdurch könnte wiederum eine Klemmwirkung aufgrund einer Elastizität des Außenmantels im Bereich des Falzes oder Dichtfalzes erreicht werden. Dies hätte eine besonders sichere Anordnung des Außenmantels am Dosenkörper zur Folge.The outer diameter of the outer sheath could be slightly larger in the region of the lower passage than the inner diameter of the formed in the upper region of the can body, annular fold or Dichtfalzes the can body. In this way, in turn, a clamping action could be achieved due to an elasticity of the outer sheath in the region of the fold or sealing fold. This would result in a particularly secure arrangement of the outer jacket on the can body.

Der Außenmantel könnte sich letztendlich vom Dichtfalz um die Sprüheinrichtung bis zum Falz oder Dichtfalz im oberen Bereich des Dosenkörpers erstrecken.The outer jacket could ultimately extend from the sealing fold around the spraying device to the fold or sealing fold in the upper region of the can body.

Im Hinblick auf ein vereinfachtes Lösen des Außenmantels von dem Dosenkörper könnte der Außenmantel einen sich im Wesentlichen von dem oberen Durchgang zu dem unteren Durchgang erstreckenden durchgängigen Schlitz aufweisen. Hierdurch könnte der Außenmantel einfach zusammengedrückt oder erweitert werden, um ein Abnehmen von dem Dosenkörper zu ermöglichen.In view of a simplified release of the outer sheath from the can body, the outer sheath could have a continuous slot extending substantially from the upper passage to the lower passage. hereby For example, the outer sheath could simply be compressed or expanded to permit removal from the can body.

Im Hinblick auf eine sichere Anordnung des Deckels auf dem Dosenkörper könnte der Deckel elastisch ausgebildet sein. Dabei könnte der Deckel insbesondere aus Kunststoff ausgebildet sein.With regard to a secure arrangement of the lid on the can body, the lid could be formed elastically. In this case, the lid could be formed in particular of plastic.

Hinsichtlich eines einfachen Entfernens des Farberkennungselements von dem Dosenkörper oder dem Deckel könnte das Farberkennungselement eine Sollbruchstelle aufweisen. Nach Erzeugung des vorgegebenen Bruchs könnte das Farberkennungselement dann einfach von dem Dosenkörper oder Deckel gelöst werden.With regard to a simple removal of the color recognition element from the can body or the lid, the color recognition element could have a predetermined breaking point. After generating the predetermined fracture, the color detection element could then be easily detached from the can body or lid.

Weiterhin im Hinblick auf ein einfaches Lösen des Farberkennungselements von dem Deckel oder dem Dosenkörper könnte das Farberkennungselement einen Eingriffsdurchgang oder eine Eingriffsausnehmung aufweisen. Der Eingriffsdurchgang oder die Eingriffsausnehmung könnten dabei derart dimensioniert sein, dass das Farberkennungselement entweder mit der Hand bzw. einem Finger oder mit einem speziellen Instrument greifbar und von dem Dosenkörper oder dem Deckel lösbar wäre.Furthermore, with a view to easy release of the color recognition element from the lid or the can body, the color recognition element could have an engagement passage or an engagement recess. The engagement passage or the engagement recess could be dimensioned such that the color detection element could be grasped either by hand or a finger or with a special instrument and detached from the can body or the lid.

Mit dem Begriff "Sprühdose" sind auch sämtliche bekannten Spraydosen oder Aerosoldosen umfasst.The term "spray can" also includes all known spray cans or aerosol cans.

Es gibt nun verschiedene Möglichkeiten, die Lehre der vorliegenden Erfindung in vorteilhafter Weise auszugestalten und weiterzubilden. Dazu ist einerseits auf die dem Patentanspruch 1 nachgeordneten Ansprüche, andererseits auf die nachfolgende Erläuterung eines bevorzugten Ausführungsbeispiels der Erfindung anhand der Zeichnung zu verweisen. In Verbindung mit der Erläuterung des bevorzugten Ausführungsbeispiels der Erfindung anhand der Zeichnung werden auch im Allgemeinen bevorzugte Ausgestaltungen und Weiterbildungen der Lehre erläutert. In der Zeichnung zeigen

- Fig. 1

- in einer Seitenansicht, schematisch, das Ausführungsbeispiel einer erfindungsgemäßen Sprühdose,

- Fig. 2

- in einer Seitenansicht, schematisch und vergrößert, das Farberkennungselement des Ausführungsbeispiels aus

Fig. 1 , - Fig. 3

- in einer Draufsicht, schematisch und vergrößert, das Farberkennungselement des Ausführungsbeispiels aus

Fig.1 und - Fig. 4

- in einer perspektivischen Ansicht, schematisch und vergrößert, das Farberkennungselement des Ausführungsbeispiels aus

Fig. 1 .

- Fig. 1

- in a side view, schematically, the embodiment of a spray can according to the invention,

- Fig. 2

- in a side view, schematically and enlarged, the color detection element of the embodiment

Fig. 1 . - Fig. 3

- in a plan view, schematically and enlarged, the color detection element of the embodiment

Fig.1 and - Fig. 4

- in a perspective view, schematically and enlarged, the color recognition element of the embodiment

Fig. 1 ,

Das Farberkennungselement 4 ist zumindest in seinem Außenbereich mit dem Sprühgut lackiert, so dass sich letztendlich auf dem Farberkennungselement 4 dasselbe Sprühgut bzw. derselbe Lack befindet wie in dem Dosenkörper 1. Der Deckel 3 ist transparent ausgebildet, so dass das Farberkennungselement 4 auch bei geschlossenem Deckel 3 von außen sichtbar ist.The

Das Farberkennungselement 4 ist dem Dosenkörper 1 reversibel zugeordnet. Das Farberkennungselement 4 ist letztendlich als geschlossener Ring ausgebildet, wobei das Farberkennungselement 4 genauer gesagt als ringartiger Außenmantel 5 einer hohlen Kugelschicht mit jeweils einem oberen kleineren und einem unteren größeren Durchgang 6 und 7 ausgebildet ist. Mit anderen Worten ist das Farberkennungselement 4 schalenartig ausgebildet.The

Der Außenmantel 5 ist elastisch aus Kunststoff ausgebildet, so dass ein einfaches Anordnen des Außenmantels 5 auf dem Dosenkörper 1 ermöglicht ist. Der innere Rand 8 des oberen Durchgangs 6 ist sich nach innen erweiternd angeschrägt. Des Weiteren ist der Außenmantel 5 im Bereich des Außenrands 9 des unteren Durchgangs 7 sich verjüngend angespitzt. Dies hat den Vorteil, dass der Außenmantel 5 einfacher an einem Dichtfalz 10 und an einem Dichtfalz 11 des Dosenkörpers entlanggleiten kann, wenn der Außenmantel 5 auf den Dosenkörper 1 aufgesetzt wird. Der Dichtfalz 10 bildet dabei den Übergang vom oberen Teil des Dosenkörpers 1 zur Sprüheinrichtung 2. Der Dichtfalz 11 bildet den Übergang von dem zylinderförmigen Mantel des Dosenkörpers 1 zum oftmals konisch ausgebildeten oberen Teil des Dosenkörpers 1.The

Der Innendurchmesser des oberen Durchgangs 6 ist geringfügig kleiner als der Außendurchmesser des ringartigen Dichtfalzes 10. D. h., dass der Außenmantel 5 nach seiner Anordnung auf dem Dosenkörper 1 quasi unterhalb des Dichtfalzes 10 in einem verengten Bereich unterhalb des Dichtfalzes 10 eingerastet ist.The inner diameter of the

Der Außenmantel 5 liegt mit dem Außenrand 9 des unteren Durchgangs 7 quasi formschlüssig an dem inneren Umfang des Dichtfalzes 11 des Dosenkörpers an. Hierzu könnte der Außendurchmesser des Außenmantels 5 im Bereich des unteren Durchgangs 7 geringfügig größer ausgebildet sein als der Innendurchmesser des Dichtfalzes 11. Damit wäre quasi ein Anschmiegen des Außenmantels 5 am inneren Umfang des Dichtfalzes 11 realisiert.The

Der Außenmantel 5 erstreckt sich im Wesentlichen von dem oberen Dichtfalz 10 zu dem unteren Dichtfalz 11.The

Der Deckel 3 weist Ausnehmungen 12 für ein Farberkennungselement 4 auf. Insoweit könnte auch dem Deckel 3 ein Farberkennungselement 4 zugeordnet werden. Im Konkreten sind die Ausnehmungen 12 in Auflagestegen 13 des Deckels 3 ausgebildet, die zur Auflage auf dem Dosenkörper 1 dienen. Der Deckel 3 ist ebenfalls elastisch und aus Kunststoff ausgebildet.The

Die

Hinsichtlich weiterer vorteilhafter Ausgestaltungen und Weiterbildungen der erfindungsgemäßen Lehre wird zur Vermeidung von Wiederholungen einerseits auf den allgemeinen Teil der Beschreibung und andererseits auf die beigefügten Patentansprüche verwiesen.With regard to further advantageous embodiments and further developments of the teaching of the invention reference is made to avoid repetition on the one hand to the general part of the description and on the other hand to the accompanying claims.

Abschließend sei ganz besonders hervorgehoben, dass das zuvor rein willkürlich gewählte Ausführungsbeispiel lediglich zur Erörterung der erfindungsgemäßen Lehre dient, diese jedoch nicht auf dieses Ausführungsbeispiel einschränkt.Finally, it should be particularly emphasized that the previously purely arbitrary chosen embodiment is merely for the purpose of discussing the teaching of the invention, but this does not restrict to this embodiment.

Claims (12)

dadurch gekennzeichnet, dass das Farberkennungselement (4) dem Dosenkörper (1) dadurch reversibel zugeordnet ist und wieder entfernt werden kann, dass der Innendurchmesser des oberen Durchgangs (6) geringfügig kleiner ist als der Außendurchmesser eines um die Sprüheinrichtung (2) ausgebildeten, ringartigen Dichtfalzes (10) des Dosenkörpers (1), wobei der obere Durchgang (6) unter Kraftaufwendung gegenüber dem Dichtfalz (10) geringfügig elastisch dehnbar ist, um einen sicheren Sitz an dem Dichtfalz (10) oder unterhalb des Dichtfalzes (10) nach Einnehmen des ursprünglichen ungedehnten Zustands des oberen Durchgangs (6) zu erreichen und um entsprechend wieder entfernt zu werden.Spray can with a can body (1) for receiving the Sprühguts, wherein the can body (1) is assigned a spraying device (2) for the Sprühgut, and a lid (3) for protecting the spraying device (2), wherein the can body (1) a Color recognition element (4) is assigned to display the color of the Sprühguts and wherein the color detection element (4) as a ring-like outer jacket (5) of a hollow spherical layer or a hollow truncated cone, each with an upper smaller (6) and a lower major passage (7) is formed .

characterized in that the color recognition element (4) is reversibly associated with the can body (1) and can be removed again, that the inner diameter of the upper passage (6) is slightly smaller than the outer diameter of a ring-shaped Dichtfalzes formed around the spraying device (2) (10) of the can body (1), wherein the upper passageway (6) is slightly elastically stretchable against the sealing fold (10) to secure fit on the sealing fold (10) or underneath the sealing fold (10) after insertion of the original one to reach unstretched state of the upper passage (6) and to be removed again accordingly.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10126961A DE10126961B4 (en) | 2001-06-01 | 2001-06-01 | Spray can |

| EP04014923A EP1479620B1 (en) | 2001-06-01 | 2002-04-17 | Spray can |

| EP02008674A EP1262423B1 (en) | 2001-06-01 | 2002-04-17 | Spray can |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04014923A Division EP1479620B1 (en) | 2001-06-01 | 2002-04-17 | Spray can |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1982932A1 true EP1982932A1 (en) | 2008-10-22 |

| EP1982932B1 EP1982932B1 (en) | 2009-12-16 |

Family

ID=7687047

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04014923A Expired - Lifetime EP1479620B1 (en) | 2001-06-01 | 2002-04-17 | Spray can |

| EP02008674A Expired - Lifetime EP1262423B1 (en) | 2001-06-01 | 2002-04-17 | Spray can |

| EP08012577A Expired - Lifetime EP1982932B1 (en) | 2001-06-01 | 2002-04-17 | Spray can |

Family Applications Before (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04014923A Expired - Lifetime EP1479620B1 (en) | 2001-06-01 | 2002-04-17 | Spray can |

| EP02008674A Expired - Lifetime EP1262423B1 (en) | 2001-06-01 | 2002-04-17 | Spray can |

Country Status (7)

| Country | Link |

|---|---|

| EP (3) | EP1479620B1 (en) |

| AT (3) | ATE444245T1 (en) |

| CY (1) | CY1105150T1 (en) |

| DE (4) | DE10126961B4 (en) |

| DK (3) | DK1982932T3 (en) |

| ES (3) | ES2262724T3 (en) |

| PT (3) | PT1262423E (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10126961B4 (en) * | 2001-06-01 | 2009-04-02 | Progression Licensing Ag | Spray can |

| EP1571102A1 (en) * | 2004-02-25 | 2005-09-07 | Motip Dupli GmbH | System for spraying a lacquer |

| EP1852365A1 (en) * | 2006-04-10 | 2007-11-07 | Alessandro Lombardi | Aerosol canister for paints and the like, with color identification means |

| DE102017103080A1 (en) | 2017-02-15 | 2018-08-16 | Peter Kwasny Gmbh | Color marking with integrated spray protection |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3075673A (en) | 1960-06-15 | 1963-01-29 | American Can Co | Dispensing container |

| DE2039314B1 (en) | 1970-08-07 | 1971-07-01 | Kwasny Gmbh & Co P | Spray paint can with double cap |

| GB2090809A (en) | 1981-01-08 | 1982-07-21 | Precision Undersurface Ltd | Plastics labels |

| DE8402146U1 (en) * | 1984-01-26 | 1984-05-24 | FOMO-Schaumstoff GmbH & Co KG, 4353 Oer-Erkenschwick | Tanned steel tin can, especially tin can |

| DE9414679U1 (en) | 1994-09-09 | 1994-11-03 | Olga Tschechowa Kosmetik GmbH & Co. Vertriebs KG, 81373 München | Bottle-like container with a cap |

| DE29808332U1 (en) | 1998-05-12 | 1998-08-06 | Specht, Rolf F., 36037 Fulda | Container with label |

| ES1039242U (en) | 1998-01-16 | 1998-12-01 | Montana Colors S L | A color indicator for containers spray paint. (Machine-translation by Google Translate, not legally binding) |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE6928235U (en) * | 1969-07-16 | 1969-11-20 | Vogelsang K Gmbh | SPRAY CAN, IN PARTICULAR PAINT SPRAY CAN |

| EP1199255A1 (en) * | 2000-10-19 | 2002-04-24 | Montana Colors, S.L. | Indication system of the colour inside paint spray containers |

| DE10126961B4 (en) * | 2001-06-01 | 2009-04-02 | Progression Licensing Ag | Spray can |

-

2001

- 2001-06-01 DE DE10126961A patent/DE10126961B4/en not_active Expired - Fee Related

-

2002

- 2002-04-17 EP EP04014923A patent/EP1479620B1/en not_active Expired - Lifetime

- 2002-04-17 DK DK08012577.6T patent/DK1982932T3/en active

- 2002-04-17 PT PT02008674T patent/PT1262423E/en unknown

- 2002-04-17 PT PT04014923T patent/PT1479620E/en unknown

- 2002-04-17 EP EP02008674A patent/EP1262423B1/en not_active Expired - Lifetime

- 2002-04-17 AT AT04014923T patent/ATE444245T1/en not_active IP Right Cessation

- 2002-04-17 DE DE50206968T patent/DE50206968D1/en not_active Expired - Lifetime

- 2002-04-17 ES ES02008674T patent/ES2262724T3/en not_active Expired - Lifetime

- 2002-04-17 ES ES04014923T patent/ES2330433T3/en not_active Expired - Lifetime

- 2002-04-17 DE DE50213894T patent/DE50213894D1/en not_active Expired - Lifetime

- 2002-04-17 PT PT08012577T patent/PT1982932E/en unknown

- 2002-04-17 ES ES08012577T patent/ES2334077T3/en not_active Expired - Lifetime

- 2002-04-17 EP EP08012577A patent/EP1982932B1/en not_active Expired - Lifetime

- 2002-04-17 DE DE50214111T patent/DE50214111D1/en not_active Expired - Lifetime

- 2002-04-17 AT AT08012577T patent/ATE452079T1/en not_active IP Right Cessation

- 2002-04-17 DK DK02008674T patent/DK1262423T3/en active

- 2002-04-17 DK DK04014923T patent/DK1479620T3/en active

- 2002-04-17 AT AT02008674T patent/ATE327950T1/en active

-

2006

- 2006-08-11 CY CY20061101135T patent/CY1105150T1/en unknown

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3075673A (en) | 1960-06-15 | 1963-01-29 | American Can Co | Dispensing container |

| DE2039314B1 (en) | 1970-08-07 | 1971-07-01 | Kwasny Gmbh & Co P | Spray paint can with double cap |

| GB2090809A (en) | 1981-01-08 | 1982-07-21 | Precision Undersurface Ltd | Plastics labels |

| DE8402146U1 (en) * | 1984-01-26 | 1984-05-24 | FOMO-Schaumstoff GmbH & Co KG, 4353 Oer-Erkenschwick | Tanned steel tin can, especially tin can |

| DE9414679U1 (en) | 1994-09-09 | 1994-11-03 | Olga Tschechowa Kosmetik GmbH & Co. Vertriebs KG, 81373 München | Bottle-like container with a cap |

| ES1039242U (en) | 1998-01-16 | 1998-12-01 | Montana Colors S L | A color indicator for containers spray paint. (Machine-translation by Google Translate, not legally binding) |

| DE29808332U1 (en) | 1998-05-12 | 1998-08-06 | Specht, Rolf F., 36037 Fulda | Container with label |

Also Published As

| Publication number | Publication date |

|---|---|

| ES2330433T3 (en) | 2009-12-10 |

| CY1105150T1 (en) | 2009-11-04 |

| DE10126961B4 (en) | 2009-04-02 |

| ES2262724T3 (en) | 2006-12-01 |

| PT1982932E (en) | 2010-03-02 |

| ES2334077T3 (en) | 2010-03-04 |

| ATE444245T1 (en) | 2009-10-15 |

| EP1262423B1 (en) | 2006-05-31 |

| EP1262423A3 (en) | 2003-01-22 |

| DE50214111D1 (en) | 2010-01-28 |

| DK1479620T3 (en) | 2009-12-07 |

| DE10126961A1 (en) | 2002-12-12 |

| DK1262423T3 (en) | 2006-10-02 |

| DK1982932T3 (en) | 2010-03-01 |

| DE50206968D1 (en) | 2006-07-06 |

| PT1262423E (en) | 2006-08-31 |

| EP1479620A1 (en) | 2004-11-24 |

| EP1479620B1 (en) | 2009-09-30 |

| DE50213894D1 (en) | 2009-11-12 |

| PT1479620E (en) | 2010-01-04 |

| ATE452079T1 (en) | 2010-01-15 |

| EP1262423A2 (en) | 2002-12-04 |

| ATE327950T1 (en) | 2006-06-15 |

| EP1982932B1 (en) | 2009-12-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0754094B1 (en) | Discharge device for free-flowing liquids, in particular for discharge in only one stroke | |

| DE60004076T2 (en) | CLOSURE CONTAINING GOOD QUALITY, IN PARTICULAR FOR BOTTLES OF ALCOHOLIC BEVERAGES | |

| DE10002088B4 (en) | Lockable actuator for a dispenser of a liquid container | |

| DE69512440T2 (en) | DISPENSING BOTTLE | |

| DE1812451B2 (en) | Bottle cap | |

| DE2934334A1 (en) | CONTAINER SHELL CAP | |

| DE69603835T2 (en) | DISCHARGE DEVICE FOR FLOWABLE MEDIA | |

| DE2353520A1 (en) | DISPENSER FACILITIES | |

| WO2006131169A1 (en) | Dispensing closure with a plug-through sleeve for fixing it to a container | |

| EP1982932B1 (en) | Spray can | |

| WO2001046032A2 (en) | Hinged-lid closure with a tamperproof device | |

| EP1281634B1 (en) | Spray dispenser | |

| DE102016009483B4 (en) | Container closure system | |

| DE10114003A1 (en) | Closure, e.g. for tube of sweets, has removable toy or other object, e.g. bottle opener fitted over it | |

| DE19532980A1 (en) | Guarantee injection bottle seal | |

| DE29501421U1 (en) | Container closure | |

| DE2908111A1 (en) | Sealed snap-on lid for aerosol can - has flexible locking bead at can rim facing end with axially slidable break-off member | |

| EP4518951A1 (en) | Applicator for an ampoule | |

| DE3150532C2 (en) | Closure device for beverage bottles | |

| DE202005012686U1 (en) | Tube closure element for a connector piece of a tube holding pasty or liquid substances comprises a connector section which engages with one or more protrusions or edges of the connector piece | |

| EP3363749B1 (en) | Colour marking with integrated spray securing | |

| DE9218298U1 (en) | Atomizer pump with circlip lock | |

| DE20122123U1 (en) | Spray can has protective cap for spray head which carries integral ring indicating color of contents | |

| DE2656492A1 (en) | Disposable liquid spray can - has internal cross wall supporting suction pipe with union boss to spray pump | |

| EP2314979B1 (en) | Irritant spray device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 1262423 Country of ref document: EP Kind code of ref document: P Ref document number: 1479620 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| 17P | Request for examination filed |

Effective date: 20080918 |

|

| 17Q | First examination report despatched |

Effective date: 20090428 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| R17C | First examination report despatched (corrected) |

Effective date: 20090709 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RTI1 | Title (correction) |

Free format text: SPRAY CAN |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: KELLER, SILVIO |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 1479620 Country of ref document: EP Kind code of ref document: P Ref document number: 1262423 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 50214111 Country of ref document: DE Date of ref document: 20100128 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20100400094 Country of ref document: GR |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20100223 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2334077 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091216 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20100608 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20100520 Year of fee payment: 9 Ref country code: IT Payment date: 20100527 Year of fee payment: 9 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091216 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20100525 Year of fee payment: 9 |

|

| BERE | Be: lapsed |

Owner name: PROGRESSION LICENSING A.G. Effective date: 20100430 |

|

| 26 | Opposition filed |

Opponent name: PETER KWASNY GMBH Effective date: 20100915 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20101101 |

|

| EUG | Se: european patent has lapsed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100430 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20100417 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20110119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100417 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20101103 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100417 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100430 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100503 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110119 |

|

| PLBP | Opposition withdrawn |

Free format text: ORIGINAL CODE: 0009264 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 50214111 Country of ref document: DE Owner name: VOGELSANG-HOLDING AG, CH Free format text: FORMER OWNER: PROGRESSION LICENSING AG, ST. GALLEN, CH Effective date: 20110427 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20110714 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110704 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100418 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 452079 Country of ref document: AT Kind code of ref document: T Effective date: 20110417 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20111230 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110430 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110430 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110502 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110417 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110417 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100418 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100417 |

|

| PLBD | Termination of opposition procedure: decision despatched |

Free format text: ORIGINAL CODE: EPIDOSNOPC1 |

|

| PLBM | Termination of opposition procedure: date of legal effect published |

Free format text: ORIGINAL CODE: 0009276 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: OPPOSITION PROCEDURE CLOSED |

|

| 27C | Opposition proceedings terminated |

Effective date: 20130210 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091216 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20150626 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50214111 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161101 |