EP1614630B1 - Verfahren sowie Vorrichtung zum Sterilisieren von Behältern mit UV-Strahlung - Google Patents

Verfahren sowie Vorrichtung zum Sterilisieren von Behältern mit UV-Strahlung Download PDFInfo

- Publication number

- EP1614630B1 EP1614630B1 EP05011277A EP05011277A EP1614630B1 EP 1614630 B1 EP1614630 B1 EP 1614630B1 EP 05011277 A EP05011277 A EP 05011277A EP 05011277 A EP05011277 A EP 05011277A EP 1614630 B1 EP1614630 B1 EP 1614630B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- container

- radiation

- optical waveguide

- ultraviolet radiation

- ultraviolet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L2/00—Methods or apparatus for disinfecting or sterilising materials or objects other than foodstuffs or contact lenses; Accessories therefor

- A61L2/02—Methods or apparatus for disinfecting or sterilising materials or objects other than foodstuffs or contact lenses; Accessories therefor using physical phenomena

- A61L2/08—Radiation

- A61L2/10—Ultraviolet radiation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B55/00—Preserving, protecting or purifying packages or package contents in association with packaging

- B65B55/02—Sterilising, e.g. of complete packages

- B65B55/04—Sterilising wrappers or receptacles prior to, or during, packaging

- B65B55/08—Sterilising wrappers or receptacles prior to, or during, packaging by irradiation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C49/00—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor

- B29C49/42—Component parts, details or accessories; Auxiliary operations

- B29C49/42403—Purging or cleaning the blow-moulding apparatus

- B29C49/42405—Sterilizing

Definitions

- the invention relates to a method according to claim 1. Furthermore, the invention relates to a device according to the preamble. 7

- All known devices and methods for UV sterilization include i.a. common that for the radiation of UV radiation in the internal sterilization of containers, the UV source is introduced into the respective container through the container opening.

- the disadvantage here is at least that in the design of the UV source u.a.

- the type and shape of the container to be sterilized must be considered, and in particular the opening cross-section of the container, the structural design of the UV source so not only from the viewpoints of optimum radiation generation and the best possible efficiency can be made.

- the object of the invention is to provide a method which allows an internal sterilization of containers and / or packaging with UV radiation in a particularly simple and safe manner. To solve this problem, a method according to claim 1 is formed. An apparatus for carrying out the method is the subject of claim 7.

- the peculiarity of the invention is that the radiation of UV radiation, which is generated by a UV source outside the respective container, takes place inside the container by means of a flexible light guide element introduced into the container via the container opening.

- Containers within the meaning of the invention include bottles, but also made from flat packaging for example for drinks and other liquid foods.

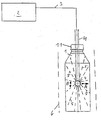

- 1 is a packaging or a container for a germ-susceptible liquid or pasty filling material, for example for a drink.

- the container 1 Prior to filling with the contents, the container 1 is sterilized internally by means of UV radiation in a wavelength range (for example 254 nm) which effects an optimal killing of the germs present on the container inner surface.

- the UV radiation is generated by a suitable radiation source 2, for example a mercury vapor discharge lamp, a UV laser and the like with sufficiently high power.

- the radiation source 2 is provided outside the respective container 1.

- the UV radiation is introduced into the container via a flexible light guide element 3.

- the light guide element 3 is introduced with a section 3.1 through the mouth opening 1.1 in the container interior and there provided with an optical radiating element 4, which is a spatial, i. e.g.

- Spherical radiation of UV radiation with an opening angle of 360 ° or nearly 360 ° in each space level allows, so that according to the lines of action or arrows 5, the entire inner surface of the container 1 is detected by the UV radiation.

- the radiating element 4 form such that the radiation direction is changed controlled during the sterilization process, wherein the UV radiation is preferably not spherical but for example radially from an over the entire circumference of the radiating element 4 reaching annular radiating outlet radially, wherein the exit angle the radiation controlled can be changed.

- the UV radiation is preferably not spherical but for example radially from an over the entire circumference of the radiating element 4 reaching annular radiating outlet radially, wherein the exit angle the radiation controlled can be changed.

- Mini mirrors moved by piezo elements are particularly suitable.

- a further, highly advantageous development of the present invention provides for the emitting element 4 to be embodied in such a way that the intensity of the spherically emitted UV radiation viewed over the spherical surface is not uniform but different. By doing so, there is the advantage that with unchanged or even reduced power of the UV source critical areas the container can be irradiated particularly intense. In order to form the radiation intensity unevenly over the surface, it is advisable, for example, not to arrange the outlet openings of the radiation regularly according to a pattern, but according to the intensity requirements.

- the light guide element 3 preferably consists of a bundle of optical fibers, this being e.g. can be made of glass or another, suitable for light guide material.

- the UV sterilization of the container 1 takes place in a sterilizer, which precedes in a production line of a local filling machine and which forms, for example, on a rotatably driven around a vertical axis machine rotor a plurality of container receptacles 6, which each at a container task to sterilizing container 1 are supplied, which are then removed at a container delivery the rotor and conveyed to the subsequent filling machine.

- Each receptacle 6 in this case has the optics 4 provided with the optical fiber end 3.1, which is then controlled for the sterilization process introduced into the interior of the container 1 and removed after treatment with the UV radiation from the container in question 1 again, for example by corresponding raising and lowering of the container 1.

- Each recording 6 is eg an independent UV source 2 assigned. In principle, it is also possible to provide a common UV source 2 for all images or in each case for a group of several images.

- the inventive construction has numerous advantages. As already mentioned, a relative movement between the end having the emission element 4 and the container 1 is possible due to the flexible light conductor element 3 in order to avoid areas not covered by the UV radiation. Due to the flexible design of the light guide element 3, it is also possible to arrange this within the machine (sterilizer) in an optimal manner to lay and assemble. Another advantage is that the flexible light guide element can follow the movements of the respective container with little mechanical effort. The UV radiation is reliably guided in the light guide element and a danger of injury avoiding shielding is easily possible.

- the light guide element 3 can be realized with a small outer diameter, this element can also be inserted into containers which have only a small diameter at the container mouth.

- the respective UV source 2 can have virtually any shape due to the design according to the invention, ie the construction of this radiation source can, for example, be as close as possible to the point of view Optimum generation of UV radiation with the greatest possible efficiency to be chosen following, and indeed completely independent of the specific type and / or shape of the container to be sterilized. 1

- the invention is suitable for the internal sterilization of containers of any kind, in particular for the internal sterilization of containers made of plastic and / or flat material or packaging.

Landscapes

- Health & Medical Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Toxicology (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Epidemiology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Apparatus For Disinfection Or Sterilisation (AREA)

- Filling Of Jars Or Cans And Processes For Cleaning And Sealing Jars (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102004032861A DE102004032861A1 (de) | 2004-07-07 | 2004-07-07 | Verfahren sowie Vorrichtung zum Sterilisieren von Behältern mit UV-Strahlung |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1614630A1 EP1614630A1 (de) | 2006-01-11 |

| EP1614630B1 true EP1614630B1 (de) | 2007-05-02 |

Family

ID=34993274

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05011277A Expired - Lifetime EP1614630B1 (de) | 2004-07-07 | 2005-05-25 | Verfahren sowie Vorrichtung zum Sterilisieren von Behältern mit UV-Strahlung |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7703262B2 (cg-RX-API-DMAC7.html) |

| EP (1) | EP1614630B1 (cg-RX-API-DMAC7.html) |

| JP (1) | JP2006021834A (cg-RX-API-DMAC7.html) |

| DE (2) | DE102004032861A1 (cg-RX-API-DMAC7.html) |

Families Citing this family (47)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2009009682A1 (en) * | 2007-07-11 | 2009-01-15 | Stokely-Van Camp, Inc. | Active sterilization zone for container filling |

| DE102008007428B4 (de) * | 2008-02-01 | 2016-02-11 | Khs Gmbh | Verfahren sowie Vorrichtung zum Sterilisieren von Packmitteln |

| DE102008023797A1 (de) | 2008-05-15 | 2009-11-19 | Krones Ag | Vorrichtung zum Sterilisieren von Behältnisverschlüssen |

| DE102008045187A1 (de) * | 2008-08-30 | 2010-03-04 | Krones Ag | Elektronenstrahlsterilisation für Behältnisse |

| IES20090400A2 (en) | 2009-05-22 | 2011-03-30 | Ann Marie Durkin | A sterilising apparatus |

| US9266633B2 (en) * | 2009-09-18 | 2016-02-23 | National Beef Packing Company, Llc | Antimicrobial packaging system |

| EP2482858B1 (de) | 2009-09-30 | 2014-04-02 | KHS GmbH | Verfahren und vorrichtung zur sterilisation von oberflächen |

| DE102009043496A1 (de) | 2009-09-30 | 2011-04-14 | Khs Gmbh | Verfahren und Vorrichtung zur Sterilisation von Oberflächen |

| DE102009043726A1 (de) | 2009-10-01 | 2011-04-07 | Khs Gmbh | Verfahren und Vorrichtung zur Sterilisation von Oberflächen |

| US9707306B2 (en) | 2010-06-01 | 2017-07-18 | Bluemorph, Llc | UV sterilization of containers |

| US9044521B2 (en) * | 2010-06-01 | 2015-06-02 | Alexander Farren | UV sterilization of containers |

| US9687575B2 (en) | 2010-06-01 | 2017-06-27 | Bluemorph, Llc | UV devices, systems and methods for UV sterilization |

| US9387268B2 (en) * | 2010-06-01 | 2016-07-12 | Alexander Farren | Compositions and methods for UV sterilization |

| US11260138B2 (en) | 2010-06-01 | 2022-03-01 | Bluemorph, Llc | UV sterilization of container, room, space or defined environment |

| US10046073B2 (en) | 2010-06-01 | 2018-08-14 | Bluemorph, Llc | Portable UV devices, systems and methods of use and manufacturing |

| DE102010044244A1 (de) * | 2010-09-02 | 2012-03-08 | Khs Gmbh | Verfahren sowie Vorrichtung zum Behandeln von Behältern |

| DE102010052207B4 (de) * | 2010-11-24 | 2017-08-31 | Khs Gmbh | Vorrichtung zum Sterilisieren von Verschlüssen für Behälter |

| DE102011056260A1 (de) * | 2011-12-12 | 2013-06-13 | Krones Ag | Behältnissterilisation mit UV-Strahlung |

| US20180104368A1 (en) * | 2012-04-16 | 2018-04-19 | Sensor Electronic Technology, Inc. | Ultraviolet-Based Sterilization |

| US9999782B2 (en) | 2012-04-16 | 2018-06-19 | Sensor Electronic Technology, Inc. | Ultraviolet-based sterilization |

| FR2990135B1 (fr) * | 2012-05-04 | 2016-05-06 | Sidel Participations | Ensemble pour la decontamination d'un moule de fabrication de recipient et procede de decontamination |

| WO2014164432A1 (en) * | 2013-03-13 | 2014-10-09 | Greenzapr, Inc. | Ultraviolet sanitizer with wand |

| DE102013013589A1 (de) * | 2013-08-19 | 2015-02-19 | Khs Corpoplast Gmbh | Vorrichtung und Verfahren zur Herstellung steriler Behälter |

| DE102013113784A1 (de) | 2013-12-10 | 2015-06-25 | Khs Gmbh | Verfahren zum Entkeimen von Gegenständen sowie Mittel zur Verwendung bei diesem Verfahren |

| US9931520B2 (en) * | 2013-12-19 | 2018-04-03 | Prs Medical Technologies, Inc. | Disinfection using light therapy |

| DE102014005650A1 (de) | 2014-04-17 | 2015-10-22 | Heuft Systemtechnik Gmbh | Behälterinspektion |

| JP6394214B2 (ja) * | 2014-09-12 | 2018-09-26 | 岩崎電気株式会社 | 殺菌用ランプ |

| SE539298C2 (en) * | 2015-10-28 | 2017-06-20 | Il Granito Ab | A method for decontamination and / or disinfection of carriers in a pneumatic tube transport system, and a decontamination / disinfection device for carriers |

| US10986852B2 (en) * | 2017-08-31 | 2021-04-27 | Sol-Ti, Inc. | Systems and methods of making cold processed juice beverages |

| CN108408673A (zh) * | 2018-03-08 | 2018-08-17 | 深圳食同源医用食品有限公司 | 液体灌装系统 |

| IT201900009591A1 (it) * | 2019-06-20 | 2020-12-20 | Smi Spa | Sistema per la disinfezione interna di contenitori |

| DE102020122472A1 (de) | 2020-08-27 | 2022-03-03 | Krones Aktiengesellschaft | Vorrichtung und Verfahren zum Erwärmen von Kunststoffvorformlingen mit Ausblaseinrichtung |

| CN113082240B (zh) * | 2021-04-02 | 2023-03-28 | 义利北冰洋(北京)食品有限公司 | 一种食品灌装金属罐体消毒杀菌处理方法 |

| US12011132B2 (en) | 2021-09-30 | 2024-06-18 | Midea Group Co., Ltd. | High speed reusable beverage container washing system |

| US12274409B2 (en) | 2021-09-30 | 2025-04-15 | Midea Group Co., Ltd. | Through opening air knife for high speed reusable beverage container washing system |

| US12029369B2 (en) | 2021-09-30 | 2024-07-09 | Midea Group Co., Ltd. | High speed reusable beverage container washing system with pop-up sprayer |

| US12036588B2 (en) | 2021-09-30 | 2024-07-16 | Midea Group Co., Ltd. | High speed reusable beverage container washing system with beverage container holder having retainer with lateral opening |

| US12035865B2 (en) | 2021-09-30 | 2024-07-16 | Midea Group Co., Ltd. | High speed reusable beverage container washing system with concentric housing members |

| US12201257B2 (en) | 2021-09-30 | 2025-01-21 | Midea Group Co., Ltd. | High speed reusable beverage container washing system with air knife chamber for supplying air to a rotatable air knife opening |

| US12022988B2 (en) | 2021-09-30 | 2024-07-02 | Midea Group Co., Ltd. | High speed reusable beverage container washing system with slip ring for supplying power to a rotatable ultraviolet light |

| US12193625B2 (en) | 2022-02-18 | 2025-01-14 | Midea Group Co., Ltd. | High speed reusable beverage container washing system with pop-up ultraviolet sanitizer |

| US12082761B2 (en) | 2022-06-24 | 2024-09-10 | Midea Group Co., Ltd. | Heated wash fluid circulation system for high speed reusable beverage container washing system |

| US12268346B2 (en) | 2022-06-30 | 2025-04-08 | Midea Group Co., Ltd. | High speed reusable beverage container washing system with themed lighting |

| US12285144B2 (en) | 2022-06-30 | 2025-04-29 | Midea Group Co., Ltd. | State machine and/or container-specific operational control of high speed reusable beverage container washing system |

| US12329340B2 (en) | 2022-09-30 | 2025-06-17 | Midea Group Co., Ltd. | High speed reusable beverage container washing system with spinning beverage container holder |

| US12193626B2 (en) | 2022-09-30 | 2025-01-14 | Midea Group Co., Ltd. | Auto-opening holder for high speed reusable beverage container washing system |

| DE102024106456A1 (de) * | 2024-03-06 | 2025-09-11 | Bausch + Ströbel SE + Co. KG | Anlage zum Verarbeiten pharmazeutischer Behälter und Verfahren zum Betreiben einer Anlage |

Family Cites Families (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1788906A (en) * | 1926-12-11 | 1931-01-13 | Gen Electric Vapor Lamp Co | Sterilizing system |

| US2175682A (en) * | 1937-07-12 | 1939-10-10 | Chaffee Edmund Lyman | Bottling apparatus |

| US2194463A (en) * | 1937-07-27 | 1940-03-26 | Powley & Sons Ltd R | Method for sterilizing empty vessels and apparatus therefor |

| US2384778A (en) * | 1941-04-04 | 1945-09-11 | Whitman Helen | Irradiating bottle filling machine |

| US4504114A (en) * | 1982-05-10 | 1985-03-12 | Raychem Corporation | Method of transmitting UV light through optical fibers |

| JP2519701B2 (ja) * | 1987-01-14 | 1996-07-31 | 住友電気工業株式会社 | 紫外線殺菌装置 |

| JPS63281936A (ja) * | 1987-05-14 | 1988-11-18 | Sumitomo Electric Ind Ltd | 容器の殺菌装置 |

| GB9107751D0 (en) * | 1991-04-12 | 1991-05-29 | Elopak Systems | Treatment of material |

| DE4232323A1 (de) * | 1992-09-26 | 1994-03-31 | Seitz Enzinger Noll Masch | Vorrichtung zur Überwachung der Wärmebehandlung bzw. Sterilisation von Flaschen o. dgl. Behälter bei einer Behälter-Behandlungsmaschine |

| JP2747961B2 (ja) * | 1992-12-25 | 1998-05-06 | 株式会社豊振科学産業所 | 容器殺菌装置 |

| DE4407183A1 (de) * | 1994-03-04 | 1995-09-07 | Bernd Uhlig | Verfahren und Vorrichtung zum Sterilisieren von Behältern |

| JPH0866462A (ja) * | 1994-08-27 | 1996-03-12 | Toppan Printing Co Ltd | 紫外線照射殺菌方法及び装置 |

| DE19513064B4 (de) * | 1995-04-07 | 2004-04-01 | Khs Maschinen- Und Anlagenbau Ag | Verfahren sowie System zum Füllen von Behältern mit einem flüssigen Füllgut sowie Füllmaschine und Etikettiereinrichtung zur Verwendung bei diesem Verfahren oder System |

| JPH0999921A (ja) * | 1995-10-03 | 1997-04-15 | Ishikawajima Harima Heavy Ind Co Ltd | 食品容器の殺菌方法及びその装置 |

| US5768853A (en) * | 1996-02-15 | 1998-06-23 | Purepulse Technologies, Inc. | Deactivation of microorganisms |

| US5958336A (en) * | 1996-04-26 | 1999-09-28 | Duarte; Raul | Surface sterilization device |

| FR2752386B1 (fr) * | 1996-08-14 | 1998-09-11 | Commissariat Energie Atomique | Procede de nettoyage ou de decontamination d'un objet au moyen d'un faisceau laser ultraviolet et dispositif pour sa mise en oeuvre |

| US5857309A (en) * | 1997-03-28 | 1999-01-12 | Tetra Laval Holdings & Finance, S.A. | Apparatus for sterilizing a spout assembly of a container |

| DE19731796A1 (de) * | 1997-07-24 | 1999-01-28 | Kronseder Maschf Krones | Verfahren und Vorrichtung zum hochreinen Abfüllen von Getränken in Flaschen |

| US6012267A (en) * | 1998-02-26 | 2000-01-11 | Tetra Laval Holdings & Finance, Sa | Hygienic packaging machine |

| DE19814625A1 (de) * | 1998-04-01 | 1999-10-07 | Khs Masch & Anlagenbau Ag | Vortisch für Gefäßbehandlungsmaschinen |

| FR2780288B1 (fr) * | 1998-06-26 | 2001-02-16 | Rene Wajsfelner | Procede de decapage et d'aseptisation de l'interieur d'un recipient et dispositif pour sa mise en oeuvre |

| US6536188B1 (en) * | 1999-02-02 | 2003-03-25 | Steuben Foods, Inc. | Method and apparatus for aseptic packaging |

| DE19909826A1 (de) * | 1999-03-05 | 2000-09-07 | Krones Ag | Verfahren zum Sterilisieren von Behältern und Füllvorrichtung |

| SE514083C2 (sv) * | 1999-04-21 | 2000-12-18 | Tetra Laval Holdings & Finance | Sätt att framställa förpackningsbehållare med låg bakteriebelastning |

| JP2001190565A (ja) * | 2000-01-06 | 2001-07-17 | Slt Japan:Kk | 生体へのレーザ光照射装置 |

| GB0001673D0 (en) * | 2000-01-26 | 2000-03-15 | Sheppard Raymond W | Ultra-violet container/closure sterilisation system |

| JP2001247108A (ja) * | 2000-03-08 | 2001-09-11 | Shokuhin Sangyo Denshi Riyo Gijutsu Kenkyu Kumiai | 容器殺菌方法及び装置 |

| US6868873B2 (en) * | 2000-06-23 | 2005-03-22 | Tetra Laval Holdings & Finance S.A. | Method for filling, apparatus for filling, and container for filling and packaging |

| US6517776B1 (en) * | 2000-11-03 | 2003-02-11 | Chevron Phillips Chemical Company Lp | UV oxygen scavenging initiation in angular preformed packaging articles |

| US7248769B2 (en) * | 2004-12-29 | 2007-07-24 | Corning Incorporated | Optical fiber bundles and devices including them |

-

2004

- 2004-07-07 DE DE102004032861A patent/DE102004032861A1/de not_active Ceased

-

2005

- 2005-05-25 EP EP05011277A patent/EP1614630B1/de not_active Expired - Lifetime

- 2005-05-25 DE DE502005000643T patent/DE502005000643D1/de not_active Expired - Lifetime

- 2005-07-04 JP JP2005195201A patent/JP2006021834A/ja active Pending

- 2005-07-05 US US11/175,118 patent/US7703262B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2006021834A (ja) | 2006-01-26 |

| DE502005000643D1 (de) | 2007-06-14 |

| US7703262B2 (en) | 2010-04-27 |

| US20060011263A1 (en) | 2006-01-19 |

| DE102004032861A1 (de) | 2006-02-02 |

| EP1614630A1 (de) | 2006-01-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1614630B1 (de) | Verfahren sowie Vorrichtung zum Sterilisieren von Behältern mit UV-Strahlung | |

| EP2371397B1 (de) | Vorrichtung zum Sterilisieren von Behältnissen | |

| EP2731631B1 (de) | Verfahren und vorrichtung zum herstellen von mit flüssigkeiten gefüllten getränkebehältnissen | |

| EP2491955B1 (de) | Verfahren und Vorrichtung zur Sterilisation von Behältnissen | |

| EP2431058B1 (de) | Aseptik-Sterilisationseinheit für Reinraum | |

| EP2604410B1 (de) | Vorrichtung, Getränkeabfüllanlage und Verfahren zum Umformen von Kunststoffvorformlingen | |

| EP2643025B1 (de) | Vorrichtung zum sterilisieren von verschlüssen für behälter | |

| EP2594493A2 (de) | Vorrichtung zur Innen- und Außensterilisierung von Kunststoffbehältnissen mittels Ladungsträgerstrahlen sowie entsprechendes Verfahren und Behandlungsanlage | |

| EP2275214A1 (de) | Vorrichtung zum Behandeln von Behältnissen mit Trägersterilisation | |

| DE102012110108A1 (de) | Vorrichtung zur Außensterilisation von Kunststoffvorformlingen | |

| EP2420258B1 (de) | Vorrichtung zum Behandeln von Verpackungen | |

| EP3330058A1 (de) | Vorrichtung und verfahren zur aussensterilisation von kunststoffvorformlingen | |

| DE102012017986A1 (de) | Vorrichtung und Verfahren zum Sterilisieren von Verschlüssen für Behälter | |

| EP2332845A2 (de) | Etikettiervorrichtung und Etikettierverfahren zur Etikettierung von Behältern mit Sterilisationseinrichtung | |

| EP4008364A2 (de) | Vorrichtung und verfahren zum sterilisieren von kunststoffvorformlingen | |

| DE102013106694A1 (de) | Verfahren und Vorrichtung zum Umformen von Kunststoffvorformlingen zu Kunststoffbehältnissen | |

| WO2018138374A1 (de) | Vorrichtung und verfahren zum sterilisieren von kunststoffvorformlingen mit vorangegangener prüfung der kunststoffvorformlinge | |

| EP1918208B1 (de) | Packstoff-Entkeimungsanlage | |

| EP2594492B1 (de) | Vorrichtung zum Sterilisieren eines Behältnisses, Getränkeabfüllanlage und/oder Getränkebehälterherstellanlage sowie Verfahren zum Sterilisieren eines ein von einer Innenwandung umgrenzten Volumen aufweisenden Behältnisses | |

| EP2650252B1 (de) | Behältnissterilisation mit UV-Strahlung | |

| EP2684674A1 (de) | Vorrichtung und Verfahren zum Erwärmen von Kunststoffvorformlingen mit Sterilraum | |

| DE102015103962B4 (de) | Vorrichtung zum Desinfizieren und Spülen von Behältern in einer Getränkeabfüllanlage | |

| DE19909488A1 (de) | Vorrichtung zur Überkopf-Behandlung von Flaschen | |

| DE102019118238A1 (de) | Verfahren und Vorrichtung zur Bestrahlung von Verpackungen und/oder Vorformlingen mittels Elektronenstahl | |

| EP4647237A2 (de) | Vorrichtung zum sterilisieren von kunststoffvorformlingen und verfahren hierzu |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: KHS AG |

|

| 17P | Request for examination filed |

Effective date: 20060711 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): BE DE FR GB IT NL |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE DE FR GB IT NL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20070508 |

|

| REF | Corresponds to: |

Ref document number: 502005000643 Country of ref document: DE Date of ref document: 20070614 Kind code of ref document: P |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20080205 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: TD Effective date: 20111114 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD Owner name: KHS GMBH Effective date: 20111122 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20180522 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20180518 Year of fee payment: 14 Ref country code: FR Payment date: 20180522 Year of fee payment: 14 Ref country code: IT Payment date: 20180530 Year of fee payment: 14 Ref country code: NL Payment date: 20180518 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20180518 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502005000643 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20190601 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190525 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20190531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20191203 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190525 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190601 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190531 |