EP1535860A1 - Kippventil mit variablem Durchfluss - Google Patents

Kippventil mit variablem Durchfluss Download PDFInfo

- Publication number

- EP1535860A1 EP1535860A1 EP04292631A EP04292631A EP1535860A1 EP 1535860 A1 EP1535860 A1 EP 1535860A1 EP 04292631 A EP04292631 A EP 04292631A EP 04292631 A EP04292631 A EP 04292631A EP 1535860 A1 EP1535860 A1 EP 1535860A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- valve

- opening

- product

- passage

- closing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers for dispensing liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant

- B65D83/44—Valves specially adapted for the discharge of contents; Regulating devices

- B65D83/48—Lift valves, e.g. operated by push action

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers for dispensing liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant

- B65D83/44—Valves specially adapted for the discharge of contents; Regulating devices

- B65D83/46—Tilt valves

Definitions

- the present invention relates to a valve for equipping a container pressurized.

- Such valves are used in particular in the field of cosmetics for the distribution of hair products (lacquers, styling sprays, etc.) of personal hygiene products, make-up products, or protection products against the harmful effects of the sun.

- valves in a most common configuration, include a Valve body having an opening / closing member thereon in the form of a valve stem, a portion of which emerges outside the body of valve.

- the valve stem is able to slide sealingly in engagement with a sealing element in the form of an annular seal.

- the other end of the channel opens radially via an inlet orifice, or several inlet ports arranged in the same axial position.

- the (or) orifice (s) of entry is (are) opposite of the sealing element.

- valve sink In response to an actuation command, the valve sinks axially, and the inlet port (s) of the valve stem is (are) placed in communication with the pressurized product inside the valve body.

- the product is then conveyed via the valve stem and the passage passing through the actuating member, towards the dispensing orifice. In the case of a multi-port valve of entry, these are put in communication simultaneously with the body of valve.

- valves besides actuating in response to axial movement, can be actuated in response to a force exerted laterally on the rod of valve. Such valves are called "tilting".

- the opening / closing element does not emerge not outside the valve body. In this case, a portion of the organ actuation is engaged inside the valve body, and control opening or closing the valve.

- valve in a different configuration is described for example in the FR 2 725 182.

- the valve body is crossed by a purge port for distribution, together with the product, or separate, from propellant.

- the actuation control causes a movement of the opening / closing element, and its passage from one position closing at an open position in which the product is dispensed according to a specific and unique flow rate.

- the first type of valve it is the section of the (or) orifice (s) of entry, and / or their number, which partly determines the output rate.

- a valve of type of that described in document FR 2 725 182, mentioned above it is the depth and / or the width, and / or the number of grooves formed on the internal surface of the valve body.

- Variable flow valves are described in US-A-3,292,827, US-A-3,195,569 and US-B-6,296,155. Because of their configuration, both positions at different rates are very close to each other. In particular, two flows are obtained by transmitting to the valve stem a force according to a same direction, more precisely by more or less the valve stem.

- US 4,139,128 discloses a variable flow tilt valve.

- This valve comprises a valve stem traversed by a channel opening, on the one hand, on an outlet of the product and, on the other hand, on a passage product inlet delimited between two parts of the valve stem.

- this passage is put into communication with the pressurized product inside the valve body.

- the two parts of the valve stem that delineate the passage the product inlet are separated from each other so as to enlarge the passage. Again, the two flows obtained are not clearly distinct.

- valve adapted to distribute a product at different rates, depending on the characteristics spraying, clearly distinguishing movements actuator for dispensing the product at different rates.

- valve of the type tilting for dispensing a product contained in a container said valve having a longitudinal axis and comprising a aperture / closing element fit, in response to a first command actuation, to move from a closed position to a first opening position in which the product under pressure is distributed according to a first rate via a first pass, and which, in response to a second actuation control different from the first, is able to move from the closed position to a second open position in which the product is distributed at a second rate, different from the first, via a second passage, the second passage being closed in the first open position and the first passage being closed in the second open position.

- the open / close element can move parallel to the X axis (y X-axis) in response to the first actuation command and deviate from the X axis in response to the second actuation command. So, the movement to move the opening / closing element to distribute the product at a first rate is relatively different from that for distribute the product at the second rate. Indeed, when the element opening / closing is directly accessible by the user, the first flow is achieved by toggling the open / close element while the second flow is obtained by pushing it down which allows the user to easily differentiate the two flows.

- both flow rates can also be easily identified by identifying for example two distinct surfaces on the push button, a first surface for transmitting to the element opening / closing a movement laterally to the X axis, and a second surface for transmitting to the opening / closing element a movement parallel to the X axis, including along the X axis.

- the product in a first open position, is distributed in a relatively low flow rate, in the form of a lacquer. In a second open position, the product is distributed at a higher rate, in the form of a spray.

- the same device can then be used for both modes of distribution.

- the opening / closing element can be traversed by an axial channel opening, on the one hand, outside the valve body via an outlet port and being able to open, on the other hand, inside the valve body via the first and second passages.

- the axial channel may comprise a necking situated axially between the first passage and the second pass.

- the opening / closing element may consist of a valve stem, one of which portion emerges outside a valve body.

- the opening / closing element may alternatively be a rod integral with a member external to the valve, in particular of an actuating member of the valve.

- the valve may comprise a sealing element, in particular in the form of a annular seal disposed within said valve body, the first passage opening laterally opposite said sealing member, in the position of closing.

- the first passage can lead to the inside of the valve body in the first open position.

- the valve may further comprise a nacelle provided with a suitable lip, in closing position, coming to rest on the sealing element, the nacelle further comprising a bottom bearing on one end of the element opening / closing in the closed position so as to close the second passage.

- the nacelle may include a pin able to be housed in the second passage to seal it tightly, especially in the closed position of the valve.

- the bottom of the nacelle may include a flat seal suitable for coming in sealing support on the end of the opening / closing element.

- the end of the opening / closing element is able to move away from the bottom of the nacelle when the opening / closing element is in the second position opening so as to clear the second passage.

- a device for packaging and distribution of a product in particular cosmetics, device comprising a pressurized container containing the product to be dispensed, and equipped with a valve according to the present invention.

- the product can be pressurized with compressed or liquefied gas.

- the gas propellant may be in contact with or separated from the product by a piston or a flexible pouch inside which the product is arranged.

- the device may further comprise a member for actuating the valve and dispensing the product under pressure via at least one orifice of distribution located for example inside a nozzle, in particular a nozzle to swirling effect.

- the actuating member may be integral with the opening / closing element.

- the actuating member may comprise two separate bearing surfaces for the actuation of the valve, a first bearing surface allowing axially moving the opening / closing element and a second surface support for laterally displacing the opening / closing element.

- the first bearing surface may for example be a surface passing through a plane substantially perpendicular to the X axis.

- the second bearing surface may for example pass in a plane parallel to the X axis or a surface passing in a plane substantially perpendicular to the X axis formed remotely of the X axis and which does not contain it.

- the device according to the invention can advantageously be used for packaging and dispensing under pressure of a cosmetic product, in particular a hair product, a personal care product, a product make-up, skin care product or protective product against the harmful effects of the sun.

- the device 100 is intended to distribute a composition, in particular capillary, through a dispensing orifice 31.

- the head of distribution 30 comprises two bearing surfaces 32 and 33 for the actuation of the valve.

- a removable cap 40 covers the head of distribution 30.

- valve 10 is mounted on a cup 60, which is dug on a rolled edge of a container Aluminum 20. The latter is only partially represented.

- the valve 10, of longitudinal axis X, comprises a cylindrical valve body 11 one end of which ends with an axial chimney 12 on which is forcibly mounted a dip tube 50.

- valve body 11 is closed by the valve holder cup 60, sealing at the closure being provided by an annular seal 13.

- a annular ring 11a formed inside the valve body 11 in the vicinity cup 60 is sealingly applied against the inner surface of the seal 13, thus ensuring both a holding in position thereof and the seal required.

- Inside the annular seal 13 slides axially a valve stem 14 of which a portion 14a emerges outside the valve body.

- the valve stem 14 is traversed axially by a channel 18, one end of which opens out of the valve body via an axial orifice 18a.

- the channel 18, in the vicinity of its other end opens radially via an orifice 18b which, in the closed position of the valve, is in sealing engagement against the inner edge of the annular seal 13.

- the channel 18 opens, at the second end 14b of the valve stem through a frustoconical shaped orifice 18c formed in the X axis.

- the lower end 14b of the valve stem 14 is located inside the body valve 11.

- a nacelle 15 having a bottom 15b surrounded by a lip 15a device is mounted inside the valve body, the bottom 15b being provided, in its middle, a frustoconical pin 15c.

- the nacelle 15 is formed in the extension of a rod portion 15d.

- a spring 16 surrounds the 15d rod portion and, in the absence of stress exerted on the valve stem, constrains the free end of the annular lip 15a in sealing engagement against the seal 13.

- An annular space 17 is then delimited by the nacelle 15, the lip 15a and the annular seal 13.

- the pin 15c comes to fit in the hole 18c of the valve stem so as to close it waterproof.

- the rod 14 is also pushed outwardly of the valve body by the spring, via the nacelle which bears on the end lower 14b of the stem. However, the rod 14 is held integral with the body of valve due to the presence of an annular ring 19 formed on the rod to near its lower end 14b, the rod 19 abutting against the annular seal 13.

- the pin 15c makes it easier to position the rod 14 with respect to the nacelle 15.

- a dispensing head 30 in the form of a pushbutton.

- the dispensing head 30 is crossed by a passage 34 one end of which is in communication with the channel 18 of the valve stem.

- the other end of the passage 34 opens, via a dispensing orifice 31, delimited, for example, by a vortex channel nozzle (which is not shown in detail).

- the dispensing head has a first bearing surface 32 formed to distance from the X axis and which makes it possible to actuate the valve by tilting.

- the head of distribution comprises a second bearing surface 33, passing through the X axis of the valve stem and preferably perpendicular to this axis X, which allows to actuate the valve by axial depression.

- the valve stem By exerting a force F 1 on the surface 33 of the dispensing head (FIG. 4), the valve stem penetrates axially by a distance such that the orifice 18b is no longer opposite the annular seal 13. against, the bottom 15b of the nacelle remains in abutment on the lower end 14b of the valve stem so that the orifice 18c remains closed sealingly by the pin 15c.

- the annular lip 15a moves away from the seal 13 over its entire circumference so that the product rushes into the channel 18 of the valve stem through the orifice 18b. It is then dispensed via the dispensing orifice 31, for example in the form of a spray, at a first rate determined by the section of the orifice 18b which is smaller than that of the channel 18.

- the product contained in the valve body then engulfs in the channel 18 of the valve stem 14 only through the orifice 18c. It goes up in the passage 34 of the dispensing head 30 and leaves in the form of a cloud of fine droplets, via the orifice 31 at a second flow rate, different from the first and which is determined by the section of the second orifice 18c.

- the second flow rate is determined by this section, regardless of the angle of inclination of the 14.

- the channel 18 has a narrowing 118 located axially between the first passage 18b and the second passage 18c whereas the orifice 18c may have a relatively large section, as shown in Figure 6.

- the second flow is then determined by the shrink 118. We then have a better control of the second flow.

- the spring 16 causes the raising of the nacelle 15 and the valve stem 14 in its position of the figure 3. The distribution of the product stops.

- the bottom 15b of the nacelle can be devoid of picot.

- the bottom is then only constituted by a surface plane which bears on the end 14b of the rod to close the orifice 18c.

- provision can be made for the bottom of the nacelle is provided with a flat gasket 15e, for example a gasket elastomer which improves the sealing of the orifice 18c.

- valve that has just been described may also make it possible to distribute the produced in a third rate. Indeed, it suffices to push the valve stem 14 and switch it once it is depressed so as to clear the two orifices 18b and 18c. The product can then be distributed in a third rate, different from the first two.

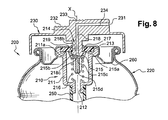

- the element opening / closing is a rod 214 secured to the pushbutton 230.

- the rod 214 can be made separately and welded push button, for example.

Landscapes

- Chemical & Material Sciences (AREA)

- Dispersion Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Nozzles (AREA)

- Sliding Valves (AREA)

- Check Valves (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0350898 | 2003-11-25 | ||

| FR0350898A FR2862623B1 (fr) | 2003-11-25 | 2003-11-25 | Valve a basculement a debits independants |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1535860A1 true EP1535860A1 (de) | 2005-06-01 |

| EP1535860B1 EP1535860B1 (de) | 2006-10-25 |

Family

ID=34451742

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04292631A Expired - Lifetime EP1535860B1 (de) | 2003-11-25 | 2004-11-05 | Kippventil mit variablem Durchfluss |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP1535860B1 (de) |

| JP (1) | JP4094003B2 (de) |

| AT (1) | ATE343532T1 (de) |

| DE (1) | DE602004002918T2 (de) |

| ES (1) | ES2274399T3 (de) |

| FR (1) | FR2862623B1 (de) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9662285B2 (en) | 2014-03-13 | 2017-05-30 | The Procter & Gamble Company | Aerosol antiperspirant compositions, products and methods |

| US10076474B2 (en) | 2014-03-13 | 2018-09-18 | The Procter & Gamble Company | Aerosol antiperspirant compositions, products and methods |

| US10076489B2 (en) | 2012-09-14 | 2018-09-18 | The Procter & Gamble Company | Aerosol antiperspirant compositions, products and methods |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5189411B2 (ja) * | 2008-05-30 | 2013-04-24 | 株式会社マンダム | エアゾール容器用バルブ、該バルブを備えたエアゾール容器、該エアゾール容器に内容物が充填されたエアゾール製品 |

| JP6416515B2 (ja) * | 2014-04-03 | 2018-10-31 | 株式会社ダイゾー | 吐出容器 |

| ES2885528T3 (es) | 2015-04-06 | 2021-12-14 | Johnson & Son Inc S C | Sistemas de dispensación |

| JPWO2023080095A1 (de) * | 2021-11-08 | 2023-05-11 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3404863A (en) * | 1966-06-24 | 1968-10-08 | Derek B. Green | Aerosol valve assembly |

| US3795350A (en) * | 1972-10-16 | 1974-03-05 | Scovill Manufacturing Co | Aerosol valve having selectable flow rate |

| US4139128A (en) * | 1976-06-10 | 1979-02-13 | Seaquist Valve Co., A Division Of Pittway Corporation | Variable spray valve assembly |

| DE10121425A1 (de) * | 2001-05-02 | 2002-11-07 | Wella Ag | Ventil für einen Druckgasbehälter |

-

2003

- 2003-11-25 FR FR0350898A patent/FR2862623B1/fr not_active Expired - Fee Related

-

2004

- 2004-11-05 ES ES04292631T patent/ES2274399T3/es not_active Expired - Lifetime

- 2004-11-05 DE DE602004002918T patent/DE602004002918T2/de not_active Expired - Lifetime

- 2004-11-05 EP EP04292631A patent/EP1535860B1/de not_active Expired - Lifetime

- 2004-11-05 AT AT04292631T patent/ATE343532T1/de not_active IP Right Cessation

- 2004-11-24 JP JP2004338359A patent/JP4094003B2/ja not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3404863A (en) * | 1966-06-24 | 1968-10-08 | Derek B. Green | Aerosol valve assembly |

| US3795350A (en) * | 1972-10-16 | 1974-03-05 | Scovill Manufacturing Co | Aerosol valve having selectable flow rate |

| US4139128A (en) * | 1976-06-10 | 1979-02-13 | Seaquist Valve Co., A Division Of Pittway Corporation | Variable spray valve assembly |

| DE10121425A1 (de) * | 2001-05-02 | 2002-11-07 | Wella Ag | Ventil für einen Druckgasbehälter |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10076489B2 (en) | 2012-09-14 | 2018-09-18 | The Procter & Gamble Company | Aerosol antiperspirant compositions, products and methods |

| US10076490B2 (en) | 2012-09-14 | 2018-09-18 | The Procter & Gamble Company | Aerosol antiperspirant compositions, products and methods |

| US9662285B2 (en) | 2014-03-13 | 2017-05-30 | The Procter & Gamble Company | Aerosol antiperspirant compositions, products and methods |

| US10076474B2 (en) | 2014-03-13 | 2018-09-18 | The Procter & Gamble Company | Aerosol antiperspirant compositions, products and methods |

Also Published As

| Publication number | Publication date |

|---|---|

| FR2862623B1 (fr) | 2006-01-20 |

| DE602004002918T2 (de) | 2007-04-26 |

| FR2862623A1 (fr) | 2005-05-27 |

| JP2005154013A (ja) | 2005-06-16 |

| JP4094003B2 (ja) | 2008-06-04 |

| DE602004002918D1 (de) | 2006-12-07 |

| ES2274399T3 (es) | 2007-05-16 |

| ATE343532T1 (de) | 2006-11-15 |

| EP1535860B1 (de) | 2006-10-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CA2368052C (fr) | Dispositif pressurise equipe d'une valve a basculement | |

| EP1035038B9 (de) | Einheit zur Aufbewahrung und Ausgabe eines unter Druck stehenden Produktes, insbesondere von Kosmetika | |

| EP0734969B1 (de) | Aerosolbehälter, versehen mit zwei Sprühdüsen | |

| EP1291293A1 (de) | Ventil mit variablem Durchfluss und Behälter mit einem solchen Ventil | |

| EP1048590B1 (de) | Ventilbetätigungsvorrichtung und Einrichtung mit einer solchen Vorrichtung | |

| EP1205403B1 (de) | Einheit zur Aufbewahrung und Ausgabe eines unter Druck stehenden Produktes | |

| EP1288142B1 (de) | Einheit zur Aufbewahrung und Ausgabe eines unter Druck stehenden Produktes | |

| EP0245172A1 (de) | Verpackung für zwei unter Druck stehende Behälter | |

| EP0688609B1 (de) | Vordruck-Handpumpe zur Zerstäuben einer Flüssigkeit und Abgabevorrichtung mit einer solchen Pumpe | |

| CA2363285A1 (fr) | Tete de distribution nettoyable, et distributeur ainsi equipe | |

| EP0939039A1 (de) | Ausgabekopf zur Ausgabe eines Stoffs sowie eine mit einem solchen Ausgabekopf versehene Ausgabevorrichtung | |

| FR2727162A1 (fr) | Pompe manuelle a precompression pour la pulverisation d'un liquide et ensemble de distribution equipe d'une telle pompe | |

| EP1535860B1 (de) | Kippventil mit variablem Durchfluss | |

| EP1302246B1 (de) | Einrichtung zum Zerstäuben von mindestens eines Produktes auf einem Substrat, insbesondere auf einem Keratinsubstrat wie Haut | |

| FR2925032A1 (fr) | Valve pour recipient sous pression de stockage et de distribution de produit et recipient pourvu d'une telle valve | |

| EP1400465B1 (de) | Kippventil mit variablem Durchfluss und Behälter mit einem solchen Ventil | |

| FR2814727A1 (fr) | Valve destinee a equiper un dispositif pour la distribution sous pression d'un produit, et dispositif ainsi equipe | |

| EP0863089B1 (de) | Ausgabekopf und Spender mit einem solchen Kopf | |

| EP1616632B1 (de) | Pumpe zum Ausbringen eines Produkts in verschiedenen Sprühpositionen und entsprechender Behälter | |

| FR2808258A1 (fr) | Recipient aerosol equipe d'une valve amelioree | |

| FR2835812A1 (fr) | Dispositif de distribution protege contre un fonctionnement accidentel | |

| FR2814726A1 (fr) | Valve destinee a equiper un dispositif pour la distribution sous pression d'un produit, et dispositif ainsi equipe | |

| EP1647501A1 (de) | Abgabevorrichtung für kosmetische Produkte | |

| FR2892277A3 (fr) | Contenant pour des produits cosmetiques |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK YU |

|

| 17P | Request for examination filed |

Effective date: 20051201 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20061025 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061130 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061130 |

|

| REF | Corresponds to: |

Ref document number: 602004002918 Country of ref document: DE Date of ref document: 20061207 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070125 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070125 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070125 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20070108 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070225 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070326 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2274399 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070726 |

|

| BERE | Be: lapsed |

Owner name: L'OREAL Effective date: 20061130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070126 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070426 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061105 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081130 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081130 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20131108 Year of fee payment: 10 Ref country code: GB Payment date: 20131030 Year of fee payment: 10 Ref country code: DE Payment date: 20131030 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20131011 Year of fee payment: 10 Ref country code: IT Payment date: 20131119 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602004002918 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20141105 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20150731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141105 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150602 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141201 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20151230 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141106 |