EP1535860A1 - Variable-delivery tilt valve - Google Patents

Variable-delivery tilt valve Download PDFInfo

- Publication number

- EP1535860A1 EP1535860A1 EP04292631A EP04292631A EP1535860A1 EP 1535860 A1 EP1535860 A1 EP 1535860A1 EP 04292631 A EP04292631 A EP 04292631A EP 04292631 A EP04292631 A EP 04292631A EP 1535860 A1 EP1535860 A1 EP 1535860A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- valve

- opening

- product

- passage

- closing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers or packages with special means for dispensing contents for delivery of liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant for a product delivered by a propellant

- B65D83/44—Valves specially adapted therefor; Regulating devices

- B65D83/48—Lift valves, e.g. operated by push action

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D83/00—Containers or packages with special means for dispensing contents

- B65D83/14—Containers or packages with special means for dispensing contents for delivery of liquid or semi-liquid contents by internal gaseous pressure, i.e. aerosol containers comprising propellant for a product delivered by a propellant

- B65D83/44—Valves specially adapted therefor; Regulating devices

- B65D83/46—Tilt valves

Definitions

- the present invention relates to a valve for equipping a container pressurized.

- Such valves are used in particular in the field of cosmetics for the distribution of hair products (lacquers, styling sprays, etc.) of personal hygiene products, make-up products, or protection products against the harmful effects of the sun.

- valves in a most common configuration, include a Valve body having an opening / closing member thereon in the form of a valve stem, a portion of which emerges outside the body of valve.

- the valve stem is able to slide sealingly in engagement with a sealing element in the form of an annular seal.

- the other end of the channel opens radially via an inlet orifice, or several inlet ports arranged in the same axial position.

- the (or) orifice (s) of entry is (are) opposite of the sealing element.

- valve sink In response to an actuation command, the valve sinks axially, and the inlet port (s) of the valve stem is (are) placed in communication with the pressurized product inside the valve body.

- the product is then conveyed via the valve stem and the passage passing through the actuating member, towards the dispensing orifice. In the case of a multi-port valve of entry, these are put in communication simultaneously with the body of valve.

- valves besides actuating in response to axial movement, can be actuated in response to a force exerted laterally on the rod of valve. Such valves are called "tilting".

- the opening / closing element does not emerge not outside the valve body. In this case, a portion of the organ actuation is engaged inside the valve body, and control opening or closing the valve.

- valve in a different configuration is described for example in the FR 2 725 182.

- the valve body is crossed by a purge port for distribution, together with the product, or separate, from propellant.

- the actuation control causes a movement of the opening / closing element, and its passage from one position closing at an open position in which the product is dispensed according to a specific and unique flow rate.

- the first type of valve it is the section of the (or) orifice (s) of entry, and / or their number, which partly determines the output rate.

- a valve of type of that described in document FR 2 725 182, mentioned above it is the depth and / or the width, and / or the number of grooves formed on the internal surface of the valve body.

- Variable flow valves are described in US-A-3,292,827, US-A-3,195,569 and US-B-6,296,155. Because of their configuration, both positions at different rates are very close to each other. In particular, two flows are obtained by transmitting to the valve stem a force according to a same direction, more precisely by more or less the valve stem.

- US 4,139,128 discloses a variable flow tilt valve.

- This valve comprises a valve stem traversed by a channel opening, on the one hand, on an outlet of the product and, on the other hand, on a passage product inlet delimited between two parts of the valve stem.

- this passage is put into communication with the pressurized product inside the valve body.

- the two parts of the valve stem that delineate the passage the product inlet are separated from each other so as to enlarge the passage. Again, the two flows obtained are not clearly distinct.

- valve adapted to distribute a product at different rates, depending on the characteristics spraying, clearly distinguishing movements actuator for dispensing the product at different rates.

- valve of the type tilting for dispensing a product contained in a container said valve having a longitudinal axis and comprising a aperture / closing element fit, in response to a first command actuation, to move from a closed position to a first opening position in which the product under pressure is distributed according to a first rate via a first pass, and which, in response to a second actuation control different from the first, is able to move from the closed position to a second open position in which the product is distributed at a second rate, different from the first, via a second passage, the second passage being closed in the first open position and the first passage being closed in the second open position.

- the open / close element can move parallel to the X axis (y X-axis) in response to the first actuation command and deviate from the X axis in response to the second actuation command. So, the movement to move the opening / closing element to distribute the product at a first rate is relatively different from that for distribute the product at the second rate. Indeed, when the element opening / closing is directly accessible by the user, the first flow is achieved by toggling the open / close element while the second flow is obtained by pushing it down which allows the user to easily differentiate the two flows.

- both flow rates can also be easily identified by identifying for example two distinct surfaces on the push button, a first surface for transmitting to the element opening / closing a movement laterally to the X axis, and a second surface for transmitting to the opening / closing element a movement parallel to the X axis, including along the X axis.

- the product in a first open position, is distributed in a relatively low flow rate, in the form of a lacquer. In a second open position, the product is distributed at a higher rate, in the form of a spray.

- the same device can then be used for both modes of distribution.

- the opening / closing element can be traversed by an axial channel opening, on the one hand, outside the valve body via an outlet port and being able to open, on the other hand, inside the valve body via the first and second passages.

- the axial channel may comprise a necking situated axially between the first passage and the second pass.

- the opening / closing element may consist of a valve stem, one of which portion emerges outside a valve body.

- the opening / closing element may alternatively be a rod integral with a member external to the valve, in particular of an actuating member of the valve.

- the valve may comprise a sealing element, in particular in the form of a annular seal disposed within said valve body, the first passage opening laterally opposite said sealing member, in the position of closing.

- the first passage can lead to the inside of the valve body in the first open position.

- the valve may further comprise a nacelle provided with a suitable lip, in closing position, coming to rest on the sealing element, the nacelle further comprising a bottom bearing on one end of the element opening / closing in the closed position so as to close the second passage.

- the nacelle may include a pin able to be housed in the second passage to seal it tightly, especially in the closed position of the valve.

- the bottom of the nacelle may include a flat seal suitable for coming in sealing support on the end of the opening / closing element.

- the end of the opening / closing element is able to move away from the bottom of the nacelle when the opening / closing element is in the second position opening so as to clear the second passage.

- a device for packaging and distribution of a product in particular cosmetics, device comprising a pressurized container containing the product to be dispensed, and equipped with a valve according to the present invention.

- the product can be pressurized with compressed or liquefied gas.

- the gas propellant may be in contact with or separated from the product by a piston or a flexible pouch inside which the product is arranged.

- the device may further comprise a member for actuating the valve and dispensing the product under pressure via at least one orifice of distribution located for example inside a nozzle, in particular a nozzle to swirling effect.

- the actuating member may be integral with the opening / closing element.

- the actuating member may comprise two separate bearing surfaces for the actuation of the valve, a first bearing surface allowing axially moving the opening / closing element and a second surface support for laterally displacing the opening / closing element.

- the first bearing surface may for example be a surface passing through a plane substantially perpendicular to the X axis.

- the second bearing surface may for example pass in a plane parallel to the X axis or a surface passing in a plane substantially perpendicular to the X axis formed remotely of the X axis and which does not contain it.

- the device according to the invention can advantageously be used for packaging and dispensing under pressure of a cosmetic product, in particular a hair product, a personal care product, a product make-up, skin care product or protective product against the harmful effects of the sun.

- the device 100 is intended to distribute a composition, in particular capillary, through a dispensing orifice 31.

- the head of distribution 30 comprises two bearing surfaces 32 and 33 for the actuation of the valve.

- a removable cap 40 covers the head of distribution 30.

- valve 10 is mounted on a cup 60, which is dug on a rolled edge of a container Aluminum 20. The latter is only partially represented.

- the valve 10, of longitudinal axis X, comprises a cylindrical valve body 11 one end of which ends with an axial chimney 12 on which is forcibly mounted a dip tube 50.

- valve body 11 is closed by the valve holder cup 60, sealing at the closure being provided by an annular seal 13.

- a annular ring 11a formed inside the valve body 11 in the vicinity cup 60 is sealingly applied against the inner surface of the seal 13, thus ensuring both a holding in position thereof and the seal required.

- Inside the annular seal 13 slides axially a valve stem 14 of which a portion 14a emerges outside the valve body.

- the valve stem 14 is traversed axially by a channel 18, one end of which opens out of the valve body via an axial orifice 18a.

- the channel 18, in the vicinity of its other end opens radially via an orifice 18b which, in the closed position of the valve, is in sealing engagement against the inner edge of the annular seal 13.

- the channel 18 opens, at the second end 14b of the valve stem through a frustoconical shaped orifice 18c formed in the X axis.

- the lower end 14b of the valve stem 14 is located inside the body valve 11.

- a nacelle 15 having a bottom 15b surrounded by a lip 15a device is mounted inside the valve body, the bottom 15b being provided, in its middle, a frustoconical pin 15c.

- the nacelle 15 is formed in the extension of a rod portion 15d.

- a spring 16 surrounds the 15d rod portion and, in the absence of stress exerted on the valve stem, constrains the free end of the annular lip 15a in sealing engagement against the seal 13.

- An annular space 17 is then delimited by the nacelle 15, the lip 15a and the annular seal 13.

- the pin 15c comes to fit in the hole 18c of the valve stem so as to close it waterproof.

- the rod 14 is also pushed outwardly of the valve body by the spring, via the nacelle which bears on the end lower 14b of the stem. However, the rod 14 is held integral with the body of valve due to the presence of an annular ring 19 formed on the rod to near its lower end 14b, the rod 19 abutting against the annular seal 13.

- the pin 15c makes it easier to position the rod 14 with respect to the nacelle 15.

- a dispensing head 30 in the form of a pushbutton.

- the dispensing head 30 is crossed by a passage 34 one end of which is in communication with the channel 18 of the valve stem.

- the other end of the passage 34 opens, via a dispensing orifice 31, delimited, for example, by a vortex channel nozzle (which is not shown in detail).

- the dispensing head has a first bearing surface 32 formed to distance from the X axis and which makes it possible to actuate the valve by tilting.

- the head of distribution comprises a second bearing surface 33, passing through the X axis of the valve stem and preferably perpendicular to this axis X, which allows to actuate the valve by axial depression.

- the valve stem By exerting a force F 1 on the surface 33 of the dispensing head (FIG. 4), the valve stem penetrates axially by a distance such that the orifice 18b is no longer opposite the annular seal 13. against, the bottom 15b of the nacelle remains in abutment on the lower end 14b of the valve stem so that the orifice 18c remains closed sealingly by the pin 15c.

- the annular lip 15a moves away from the seal 13 over its entire circumference so that the product rushes into the channel 18 of the valve stem through the orifice 18b. It is then dispensed via the dispensing orifice 31, for example in the form of a spray, at a first rate determined by the section of the orifice 18b which is smaller than that of the channel 18.

- the product contained in the valve body then engulfs in the channel 18 of the valve stem 14 only through the orifice 18c. It goes up in the passage 34 of the dispensing head 30 and leaves in the form of a cloud of fine droplets, via the orifice 31 at a second flow rate, different from the first and which is determined by the section of the second orifice 18c.

- the second flow rate is determined by this section, regardless of the angle of inclination of the 14.

- the channel 18 has a narrowing 118 located axially between the first passage 18b and the second passage 18c whereas the orifice 18c may have a relatively large section, as shown in Figure 6.

- the second flow is then determined by the shrink 118. We then have a better control of the second flow.

- the spring 16 causes the raising of the nacelle 15 and the valve stem 14 in its position of the figure 3. The distribution of the product stops.

- the bottom 15b of the nacelle can be devoid of picot.

- the bottom is then only constituted by a surface plane which bears on the end 14b of the rod to close the orifice 18c.

- provision can be made for the bottom of the nacelle is provided with a flat gasket 15e, for example a gasket elastomer which improves the sealing of the orifice 18c.

- valve that has just been described may also make it possible to distribute the produced in a third rate. Indeed, it suffices to push the valve stem 14 and switch it once it is depressed so as to clear the two orifices 18b and 18c. The product can then be distributed in a third rate, different from the first two.

- the element opening / closing is a rod 214 secured to the pushbutton 230.

- the rod 214 can be made separately and welded push button, for example.

Landscapes

- Chemical & Material Sciences (AREA)

- Dispersion Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Nozzles (AREA)

- Sliding Valves (AREA)

- Check Valves (AREA)

Abstract

Description

La présente invention concerne une valve destinée à équiper un récipient pressurisé. De telles valves sont utilisées notamment dans le domaine de la cosmétique pour la distribution de produits capillaires (laques, sprays coiffants, etc...) de produits d'hygiène corporelle, de produits de maquillage, ou de produits de protection contre les effets néfastes du soleil.The present invention relates to a valve for equipping a container pressurized. Such valves are used in particular in the field of cosmetics for the distribution of hair products (lacquers, styling sprays, etc.) of personal hygiene products, make-up products, or protection products against the harmful effects of the sun.

De telles valves, selon une configuration la plus répandue, comprennent un corps de valve à l'intérieur duquel est monté un élément d'ouverture/fermeture sous forme d'une tige de valve dont une partie émerge à l'extérieur du corps de valve. La tige de valve est apte à coulisser de manière étanche en engagement avec un élément d'étanchéité sous forme d'un joint annulaire.Such valves, in a most common configuration, include a Valve body having an opening / closing member thereon in the form of a valve stem, a portion of which emerges outside the body of valve. The valve stem is able to slide sealingly in engagement with a sealing element in the form of an annular seal.

La tige de valve est traversée par un canal axial dont une extrémité débouche axialement à l'extérieur du corps de valve, et est destinée à être mise en communication avec un passage traversant un organe d'actionnement de la valve comportant au moins un orifice de sortie.The valve stem is crossed by an axial channel of which one end opens axially outside the valve body, and is intended to be communication with a passage passing through an actuating member of the valve having at least one outlet port.

L'autre extrémité du canal débouche radialement via un orifice d'entrée, ou plusieurs orifices d'entrée disposés selon la même position axiale.The other end of the channel opens radially via an inlet orifice, or several inlet ports arranged in the same axial position.

En position fermée de la valve, le (ou les) orifice(s) d'entrée est (sont) en regard de l'élément d'étanchéité.In the closed position of the valve, the (or) orifice (s) of entry is (are) opposite of the sealing element.

En réponse à une commande d'actionnement, la valve s'enfonce axialement, et le (ou les) orifice(s) d'entrée de la tige de valve est (sont) mis en communication avec le produit pressurisé à l'intérieur du corps de valve. Le produit est alors acheminé, via la tige de valve et le passage traversant l'organe d'actionnement, vers l'orifice de distribution. Dans le cas d'une valve à plusieurs orifices d'entrée, ceux-ci sont mis en communication simultanément avec le corps de valve. In response to an actuation command, the valve sinks axially, and the inlet port (s) of the valve stem is (are) placed in communication with the pressurized product inside the valve body. The product is then conveyed via the valve stem and the passage passing through the actuating member, towards the dispensing orifice. In the case of a multi-port valve of entry, these are put in communication simultaneously with the body of valve.

Lorsque cesse la commande d'actionnement, un ressort contenu à l'intérieur du corps de valve rappelle la tige de valve en position de fermeture. La distribution du produit s'interrompt.When the actuation command stops, a spring contained within the Valve body recalls the valve stem in the closed position. The distribution product stops.

Certaines valves, outre l'actionnement en réponse à un mouvement axial, peuvent être actionnées en réponse à une force exercée latéralement à la tige de valve. De telles valves sont dites "à basculement".Some valves, besides actuating in response to axial movement, can be actuated in response to a force exerted laterally on the rod of valve. Such valves are called "tilting".

Pour certaines valves, dites "femelles" l'élément d'ouverture/fermeture n'émerge pas à l'extérieur du corps de valve. Dans ce cas, une portion de l'organe d'actionnement est engagée à l'intérieur du corps de valve, et commande l'ouverture ou la fermeture de la valve.For some valves, called "females", the opening / closing element does not emerge not outside the valve body. In this case, a portion of the organ actuation is engaged inside the valve body, and control opening or closing the valve.

Une valve selon une configuration différente est décrite par exemple dans le brevet FR 2 725 182. Dans ce document, le corps de valve est traversé par un orifice de purge pour la distribution, conjointe avec le produit, ou séparée, de gaz propulseur.A valve in a different configuration is described for example in the FR 2 725 182. In this document, the valve body is crossed by a purge port for distribution, together with the product, or separate, from propellant.

Pour toutes ces valves connues, la commande d'actionnement provoque un mouvement de l'élément d'ouverture/fermeture, et son passage d'une position de fermeture à une position d'ouverture dans laquelle le produit est distribué selon un débit déterminé et unique.For all these known valves, the actuation control causes a movement of the opening / closing element, and its passage from one position closing at an open position in which the product is dispensed according to a specific and unique flow rate.

Pour le premier type de valve, c'est la section du (ou des) orifice(s) d'entrée, et/ou leur nombre, qui détermine en partie le débit de sortie. Pour une valve du type de celle décrite dans le document FR 2 725 182, mentionné ci-avant, c'est la profondeur et/ou la largeur, et/ou le nombre de rainures ménagées sur la surface interne du corps de valve.For the first type of valve, it is the section of the (or) orifice (s) of entry, and / or their number, which partly determines the output rate. For a valve of type of that described in document FR 2 725 182, mentioned above, it is the depth and / or the width, and / or the number of grooves formed on the internal surface of the valve body.

Ainsi, dans le domaine des produits de coiffage, pour une laque, on utilise un récipient équipé d'une valve permettant un premier débit. Quand il s'agit de pulvériser le produit sous forme d'un spray, on utilise un autre récipient équipé d'une autre valve permettant un second débit, supérieur au premier. Thus, in the field of styling products, for a lacquer, one uses a container equipped with a valve allowing a first flow. When it's about spray the product as a spray, use another container equipped another valve allowing a second flow, greater than the first.

Deux dispositifs distincts sont donc requis lorsque l'utilisatrice veut pouvoir choisir entre deux modes de pulvérisation différents d'un même produit.Two separate devices are required when the user wants to be able to choose between two different spray modes of the same product.

Des valves à débit variable sont décrites dans les documents US-A-3,292,827, US-A-3,195,569 et US-B-6,296,155. De par leur configuration, les deux positions à débits différents sont très proches l'une de l'autre. En particulier, les deux débits sont obtenus en transmettant à la tige de valve une force selon une même direction, plus précisément par enfoncement plus ou moins important de la tige de valve.Variable flow valves are described in US-A-3,292,827, US-A-3,195,569 and US-B-6,296,155. Because of their configuration, both positions at different rates are very close to each other. In particular, two flows are obtained by transmitting to the valve stem a force according to a same direction, more precisely by more or less the valve stem.

Le document US 4,139,128 décrit une valve à basculement à débit variable. Cette valve comporte une tige de valve traversée par un canal débouchant, d'une part, sur un orifice de sortie du produit et, d'autre part, sur un passage d'entrée du produit délimité entre deux parties de la tige de valve. Lorsque l'on enfonce axialement la tige de valve, ce passage est mis en communication avec le produit pressurisé à l'intérieur du corps de valve. Lorsque l'on bascule la tige de valve, les deux parties de la tige de valve qui délimitent le passage d'entrée du produit s'écartent l'une de l'autre de manière à agrandir le passage. Là encore, les deux débits obtenus ne sont pas clairement distincts.US 4,139,128 discloses a variable flow tilt valve. This valve comprises a valve stem traversed by a channel opening, on the one hand, on an outlet of the product and, on the other hand, on a passage product inlet delimited between two parts of the valve stem. When one depresses the valve stem axially, this passage is put into communication with the pressurized product inside the valve body. When we switch valve stem, the two parts of the valve stem that delineate the passage the product inlet are separated from each other so as to enlarge the passage. Again, the two flows obtained are not clearly distinct.

Aussi, est-ce un des objets de l'invention que de réaliser une valve apte à distribuer un produit selon des débits différents, en fonction des caractéristiques de pulvérisation recherchées, en distinguant clairement les mouvements d'actionnement permettant de distribuer le produit selon les débits différents.Also, is it an object of the invention to provide a valve adapted to distribute a product at different rates, depending on the characteristics spraying, clearly distinguishing movements actuator for dispensing the product at different rates.

C'est un autre objet de l'invention que de réaliser un dispositif qui soit simple et économique à réaliser.It is another object of the invention to provide a device which is simple and economic to achieve.

D'autres objets encore apparaítront dans la description détaillée qui suit.Still other objects will appear in the following detailed description.

Selon l'invention, ces objets peuvent être atteints en réalisant une valve de type à basculement pour la distribution d'un produit contenu dans un récipient pressurisé, ladite valve comportant un axe longitudinal et comprenant un élément d'ouverture/fermeture apte, en réponse à une première commande d'actionnement, à se déplacer d'une position de fermeture à une première position d'ouverture dans laquelle le produit sous pression est distribué selon un premier débit via un premier passage, et qui, en réponse à une seconde commande d'actionnement différente de la première, est apte à se déplacer de la position de fermeture à une seconde position d'ouverture dans laquelle le produit est distribué selon un second débit, différent du premier, via un second passage, le second passage étant obturé dans la première position d'ouverture et le premier passage étant obturé dans la seconde position d'ouverture.According to the invention, these objects can be achieved by making a valve of the type tilting for dispensing a product contained in a container said valve having a longitudinal axis and comprising a aperture / closing element fit, in response to a first command actuation, to move from a closed position to a first opening position in which the product under pressure is distributed according to a first rate via a first pass, and which, in response to a second actuation control different from the first, is able to move from the closed position to a second open position in which the product is distributed at a second rate, different from the first, via a second passage, the second passage being closed in the first open position and the first passage being closed in the second open position.

Ainsi, en utilisant deux passages distincts dont l'un seulement est ouvert à la fois, on peut parfaitement différencier les deux débits.So, using two separate passages of which only one is open to the time, one can perfectly differentiate the two flows.

L'élément d'ouverture/fermeture peut se déplacer parallèlement à l'axe X (y compris selon l'axe X) en réponse à la première commande d'actionnement et s'écarter de l'axe X en réponse à la seconde commande d'actionnement. Ainsi, le mouvement pour déplacer l'élément d'ouverture/fermeture afin de distribuer le produit selon un premier débit est relativement différent de celui pour distribuer le produit selon le second débit. En effet, lorsque l'élément d'ouverture/fermeture est directement accessible par l'utilisateur, le premier débit est obtenu en basculant l'élément d'ouverture/fermeture alors que le second débit est obtenu en l'enfonçant ce qui permet à l'utilisateur de facilement différencier les deux débits. Dans le cas où l'élément d'ouverture/fermeture est surmonté d'un organe d'actionnement, par exemple d'un bouton-poussoir, les deux débits peuvent également être facilement identifiés en identifiant par exemple deux surfaces distinctes sur le bouton-poussoir, une première surface permettant de transmettre à l'élément d'ouverture/fermeture un mouvement latéralement à l'axe X, et une seconde surface permettant de transmettre à l'élément d'ouverture/fermeture un mouvement parallèlement à l'axe X, y compris selon l'axe X.The open / close element can move parallel to the X axis (y X-axis) in response to the first actuation command and deviate from the X axis in response to the second actuation command. So, the movement to move the opening / closing element to distribute the product at a first rate is relatively different from that for distribute the product at the second rate. Indeed, when the element opening / closing is directly accessible by the user, the first flow is achieved by toggling the open / close element while the second flow is obtained by pushing it down which allows the user to easily differentiate the two flows. In case the element opening / closing is surmounted by an actuating member, for example of a push button, both flow rates can also be easily identified by identifying for example two distinct surfaces on the push button, a first surface for transmitting to the element opening / closing a movement laterally to the X axis, and a second surface for transmitting to the opening / closing element a movement parallel to the X axis, including along the X axis.

Ainsi, dans le cas par exemple d'un produit de coiffage, dans une première position d'ouverture, le produit est distribué selon un relativement faible débit, sous forme d'une laque. Dans une seconde position d'ouverture, le produit est distribué selon un débit plus important, sous forme d'un spray. Le même dispositif peut alors être utilisé pour les deux modes de distribution.Thus, in the case for example of a styling product, in a first open position, the product is distributed in a relatively low flow rate, in the form of a lacquer. In a second open position, the product is distributed at a higher rate, in the form of a spray. The same device can then be used for both modes of distribution.

L'élément d'ouverture/fermeture peut être traversé par un canal axial débouchant, d'une part, à l'extérieur du corps de valve via un orifice de sortie et étant apte à déboucher, d'autre part, à l'intérieur du corps de valve via le premier et le second passages.The opening / closing element can be traversed by an axial channel opening, on the one hand, outside the valve body via an outlet port and being able to open, on the other hand, inside the valve body via the first and second passages.

Le canal axial peut comporter un rétreint situé axialement entre le premier passage et le second passage.The axial channel may comprise a necking situated axially between the first passage and the second pass.

L'élément d'ouverture/fermeture peut être constitué d'une tige de valve dont une portion émerge à l'extérieur d'un corps de valve.The opening / closing element may consist of a valve stem, one of which portion emerges outside a valve body.

L'élément d'ouverture/fermeture peut alternativement être une tige solidaire d'un organe extérieur à la valve, notamment d'un organe d'actionnement de la valve.The opening / closing element may alternatively be a rod integral with a member external to the valve, in particular of an actuating member of the valve.

La valve peut comporter un élément d'étanchéité, notamment sous forme d'un joint annulaire, disposé à l'intérieur dudit corps de valve, le premier passage débouchant latéralement en regard dudit élément d'étanchéité, en position de fermeture.The valve may comprise a sealing element, in particular in the form of a annular seal disposed within said valve body, the first passage opening laterally opposite said sealing member, in the position of closing.

Le premier passage peut déboucher à l'intérieur du corps de valve dans la première position d'ouverture.The first passage can lead to the inside of the valve body in the first open position.

La valve peut en outre comporter une nacelle munie d'une lèvre apte, en position de fermeture, à venir en appui sur l'élément d'étanchéité, la nacelle comportant en outre un fond venant en appui sur une extrémité de l'élément d'ouverture/fermeture en position de fermeture de manière à obturer le second passage.The valve may further comprise a nacelle provided with a suitable lip, in closing position, coming to rest on the sealing element, the nacelle further comprising a bottom bearing on one end of the element opening / closing in the closed position so as to close the second passage.

La nacelle peut comporter un picot apte à se loger dans le second passage pour l'obturer de manière étanche, notamment en position de fermeture de la valve. The nacelle may include a pin able to be housed in the second passage to seal it tightly, especially in the closed position of the valve.

Alternativement, le fond de la nacelle peut comporter un joint plat apte à venir en appui étanche sur l'extrémité de l'élément d'ouverture/fermeture.Alternatively, the bottom of the nacelle may include a flat seal suitable for coming in sealing support on the end of the opening / closing element.

L'extrémité de l'élément d'ouverture/fermeture est apte à s'écarter du fond de la nacelle lorsque l'élément d'ouverture/fermeture est dans la seconde position d'ouverture de manière à dégager le second passage.The end of the opening / closing element is able to move away from the bottom of the nacelle when the opening / closing element is in the second position opening so as to clear the second passage.

Selon un autre aspect de l'invention, on réalise un dispositif pour le conditionnement et la distribution d'un produit, notamment cosmétique, le dispositif comprenant un récipient pressurisé contenant le produit à distribuer, et équipé d'une valve selon la présente invention.According to another aspect of the invention, a device for packaging and distribution of a product, in particular cosmetics, device comprising a pressurized container containing the product to be dispensed, and equipped with a valve according to the present invention.

Le produit peut être pressurisé au moyen d'un gaz comprimé ou liquéfié. Le gaz propulseur peut être au contact du produit ou séparé de ce dernier par un piston ou une poche souple à l'intérieur de laquelle est disposé le produit.The product can be pressurized with compressed or liquefied gas. The gas propellant may be in contact with or separated from the product by a piston or a flexible pouch inside which the product is arranged.

Le dispositif peut en outre comprendre un organe pour l'actionnement de la valve et la distribution du produit sous pression via au moins un orifice de distribution situé par exemple à l'intérieur d'une buse, notamment une buse à effet tourbillonnaire.The device may further comprise a member for actuating the valve and dispensing the product under pressure via at least one orifice of distribution located for example inside a nozzle, in particular a nozzle to swirling effect.

L'organe d'actionnement peut être solidaire de l'élément d'ouverture/fermeture.The actuating member may be integral with the opening / closing element.

L'organe d'actionnement peut comporter deux surfaces d'appui distinctes pour l'actionnement de la valve, une première surface d'appui permettant de déplacer axialement l'élément d'ouverture/fermeture et une seconde surface d'appui permettant de déplacer latéralement l'élément d'ouverture/fermeture. La première surface d'appui peut par exemple être une surface passant dans un plan sensiblement perpendiculaire à l'axe X. La seconde surface d'appui peut par exemple passer dans un plan parallèle à l'axe X ou encore une surface passant dans un plan sensiblement perpendiculaire à l'axe X formée à distance de l'axe X et qui ne le contient pas. The actuating member may comprise two separate bearing surfaces for the actuation of the valve, a first bearing surface allowing axially moving the opening / closing element and a second surface support for laterally displacing the opening / closing element. The first bearing surface may for example be a surface passing through a plane substantially perpendicular to the X axis. The second bearing surface may for example pass in a plane parallel to the X axis or a surface passing in a plane substantially perpendicular to the X axis formed remotely of the X axis and which does not contain it.

Le dispositif selon l'invention peut être utilisé avantageusement pour le conditionnement et la distribution sous pression d'un produit cosmétique, notamment d'un produit capillaire, d'un produit d'hygiène corporelle, d'un produit de maquillage, d'un produit de soin de la peau ou d'un produit de protection contre les effets néfastes du soleil.The device according to the invention can advantageously be used for packaging and dispensing under pressure of a cosmetic product, in particular a hair product, a personal care product, a product make-up, skin care product or protective product against the harmful effects of the sun.

L'invention consiste, mis à part les dispositions exposées ci-dessus, en un certain nombre d'autres dispositions qui seront explicitées ci-après, à propos d'exemples de réalisation non limitatifs, décrits en référence aux figures annexées, parmi lesquelles :

- la figure 1 illustre une vue d'ensemble d'un premier mode de réalisation d'un dispositif de conditionnement et de distribution selon l'invention ;

- la figure 2 représente une vue éclatée du dispositif illustré à la figure 1 ;

- les figures 3 à 5 représentent en coupe partielle le dispositif illustré à la figure 1 dans différentes positions ;

- les figures 6 et 7 représentent des variantes de réalisation du premier mode de réalisation du dispositif selon l'invention ; et

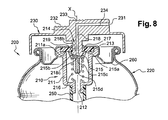

- la figure 8 représente un second mode de réalisation d'un dispositif de conditionnement et de distribution selon l'invention.

- FIG. 1 illustrates an overview of a first embodiment of a packaging and dispensing device according to the invention;

- Figure 2 shows an exploded view of the device shown in Figure 1;

- Figures 3 to 5 show in partial section the device shown in Figure 1 in different positions;

- Figures 6 and 7 show alternative embodiments of the first embodiment of the device according to the invention; and

- FIG. 8 represents a second embodiment of a packaging and dispensing device according to the invention.

Le dispositif 100 représenté dans son ensemble à la figure 1 comprend un

récipient cylindrique 20, notamment en aluminium ou en fer blanc, surmonté

d'une tête 30 pour l'actionnement d'une valve 10, qui sera décrite en détail

ultérieurement. Le dispositif 100 est prévu pour distribuer une composition,

notamment capillaire, au travers d'un orifice de distribution 31. La tête de

distribution 30 comprend deux surfaces d'appui 32 et 33 destinées à

l'actionnement de la valve. Un capuchon amovible 40 recouvre la tête de

distribution 30.The

Comme on le voit plus en détail sur les figures 3 à 5, la valve 10 est montée sur

une coupelle 60, laquelle est dudgeonnée sur un bord roulé d'un récipient en

aluminium 20. Ce dernier n'est représenté que partiellement. As seen in more detail in FIGS. 3 to 5, the

La valve 10, d'axe longitudinal X, comprend un corps de valve cylindrique 11

dont une extrémité se termine par une cheminée axiale 12 sur laquelle est

monté à force un tube plongeur 50.The

L'autre extrémité du corps de valve 11 est fermée par la coupelle porte-valve

60, l'étanchéité à la fermeture étant assurée par un joint annulaire 13. Une

couronne annulaire 11a formée à l'intérieur du corps de valve 11 au voisinage

de la coupelle 60 s'applique de manière étanche contre la surface intérieure du

joint 13, assurant ainsi à la fois un maintien en position de celui-ci et l'étanchéité

requise. A l'intérieur du joint annulaire 13 coulisse axialement une tige de valve

14 dont une portion 14a émerge à l'extérieur du corps de valve.The other end of the

La tige de valve 14 est traversée axialement par un canal 18 dont une extrémité

débouche à l'extérieur du corps de valve via un orifice axial 18a. Le canal 18,

au voisinage de son autre extrémité débouche radialement via un orifice 18b

qui, en position de fermeture de la valve, est en engagement étanche contre le

bord interne du joint annulaire 13. Enfin, le canal 18 débouche, à la seconde

extrémité 14b de la tige de valve par un orifice 18c de forme tronconique, formé

dans l'axe X.The valve stem 14 is traversed axially by a

L'extrémité inférieure 14b de la tige de valve 14 est située à l'intérieur du corps

de valve 11. Une nacelle 15 comportant un fond 15b entouré d'une lèvre

périphérique 15a est montée à l'intérieur du corps de valve, le fond 15b étant

pourvu, en son milieu, d'un picot 15c tronconique. La nacelle 15 est formée

dans le prolongement d'une portion de tige 15d. Un ressort 16 entoure la

portion de tige 15d et, en l'absence de contrainte s'exerçant sur la tige de valve,

contraint l'extrémité libre de la lèvre annulaire 15a en appui étanche contre le

joint 13. Un espace annulaire 17 est alors délimité par la nacelle 15, la lèvre

15a et le joint annulaire 13. En outre, dans cette position, le picot 15c vient se

loger dans l'orifice 18c de la tige de valve de manière à l'obturer de manière

étanche. La tige 14 est également poussée vers l'extérieur du corps de valve

par le ressort, par l'intermédiaire de la nacelle qui est en appui sur l'extrémité

inférieure 14b de la tige. Toutefois, la tige 14 est maintenue solidaire du corps

de valve grâce à la présence d'un jonc annulaire 19 formée sur la tige à

proximité de son extrémité inférieure 14b, le jonc 19 venant en butée contre le

joint annulaire 13.The

Outre le fait d'améliorer l'étanchéité de la fermeture de l'orifice 18c, le picot 15c

permet de faciliter le positionnement de la tige 14 par rapport à la nacelle 15.In addition to improving the sealing of the closure of the

Comme il apparaít sur les figures 3 et 5, sur la partie émergente 14a de la tige

de valve 14, est montée à force une tête de distribution 30 sous forme d'un

bouton poussoir. La tête de distribution 30 est traversée par un passage 34

dont une extrémité est en communication avec le canal 18 de la tige de valve.

L'autre extrémité du passage 34 débouche, via un orifice de distribution 31,

délimité, par exemple, par une buse à canaux tourbillonnaires (qui n'est pas

représentée de façon détaillée).As it appears in FIGS. 3 and 5, on the

La tête de distribution comporte une première surface d'appui 32 formée à

distance de l'axe X et qui permet d'actionner la valve par basculement. La tête

de distribution comporte une deuxième surface d'appui 33, passant par l'axe X

de la tige de valve et de préférence perpendiculaire à cet axe X, qui permet

d'actionner la valve par enfoncement axial.The dispensing head has a

En exerçant une force F1 sur la surface 33 de la tête de distribution (figure 4), la

tige de valve s'enfonce axialement d'une distance telle que l'orifice 18b n'est

plus en regard du joint annulaire 13. Par contre, le fond 15b de la nacelle reste

en appui sur l'extrémité inférieure 14b de la tige de valve de sorte que l'orifice

18c reste obturé de manière étanche par le picot 15c. La lèvre annulaire 15a

s'écarte du joint 13, sur toute sa circonférence si bien que le produit s'engouffre

dans le canal 18 de la tige de valve par l'orifice 18b. Il est alors distribué, via

l'orifice de distribution 31, par exemple sous forme d'un spray, selon un premier

débit déterminé par la section de l'orifice 18b qui est inférieure à celle du canal

18.By exerting a force F 1 on the

En exerçant une force F2 sur la surface 32 de la tête de distribution (figure 5),

une force latérale est transmise à la tige de valve 14 de sorte qu'elle est

basculée relativement à l'axe X. La lèvre annulaire 15a s'écarte du joint 13,

suivant une certaine étendue angulaire, ce qui permet d'établir une

communication entre l'intérieur du corps de valve et l'espace annulaire 17. En

outre, l'extrémité inférieure 14b de la tige s'écarte du fond 15b de la nacelle et

le picot 15c dégage l'orifice 18c de sorte que la communication est établie entre

l'intérieur du corps de valve et l'intérieur de la tige 14, via l'orifice 18c. Dans

cette position de la tige de valve, l'orifice 18b reste en regard du joint 13. Le

produit contenu dans le corps de valve s'engouffre alors dans le canal 18 de la

tige de valve 14 uniquement par l'orifice 18c. Il remonte dans le passage 34 de

la tête de distribution 30 et sort sous forme d'un nuage de fines gouttelettes, via

l'orifice 31 selon un second débit, différent du premier et qui est déterminé par

la section du second orifice 18c.By exerting a force F 2 on the

En outre, en choisissant un orifice 18c de section relativement faible, le second

débit est déterminé par cette section, quel que soit l'angle d'inclinaison de la

tige 14. Alternativement, le canal 18 comporte un rétreint 118 situé axialement

entre le premier passage 18b et le second passage 18c alors que l'orifice 18c

peut avoir une section relativement importante, comme on l'a représenté à la

figure 6. Le second débit est alors déterminé par le rétreint 118. On a alors une

meilleure maítrise du second débit.In addition, by choosing an

Depuis l'une ou l'autre des positions d'actionnement de la figure 4 ou 5, en

relâchant la pression sur la tête de distribution, le ressort 16 provoque la

remontée de la nacelle 15 et de la tige de valve 14 dans sa position de la figure

3. La distribution du produit s'interrompt.From one or other of the actuating positions of FIG. 4 or 5, in

releasing the pressure on the dispensing head, the

Selon une variante non représentée, le fond 15b de la nacelle peut être

dépourvu de picot. Le fond est alors uniquement constitué par une surface

plane qui vient en appui sur l'extrémité 14b de la tige pour obturer l'orifice 18c.According to a variant not shown, the bottom 15b of the nacelle can be

devoid of picot. The bottom is then only constituted by a surface

plane which bears on the

Selon une variante représentée en partie à la figure 7, on peut prévoir que le

fond de la nacelle est pourvu d'un joint plat 15e, par exemple un joint en

élastomère qui améliore la fermeture étanche de l'orifice 18c. According to a variant represented in part in FIG. 7, provision can be made for the

bottom of the nacelle is provided with a

La valve qui vient d'être décrite peut également permettre de distribuer le

produit selon un troisième débit. En effet, il suffit d'enfoncer la tige de valve 14

et de la basculer une fois qu'elle est enfoncée de manière à dégager les deux

orifices 18b et 18c. Le produit peut alors être distribué selon un troisième débit,

différent des deux premiers.The valve that has just been described may also make it possible to distribute the

produced in a third rate. Indeed, it suffices to push the

Selon un deuxième mode de réalisation illustré à la figure 8, l'élément

d'ouverture/fermeture est une tige 214 solidaire du bouton-poussoir 230. Elle

peut être obtenue de moulage à partir d'une seule pièce avec le bouton

poussoir. Alternativement, la tige 214 peut être réalisée séparément et soudée

au bouton poussoir, par exemple.According to a second embodiment illustrated in FIG. 8, the element

opening / closing is a

Dans la description détaillée qui précède, il a été fait référence à des modes de réalisation préférés de l'invention. Il est évident que des variantes peuvent y être apportées sans s'écarter de l'invention telle que revendiquée ci-après.In the above detailed description, reference has been made to modes of preferred embodiment of the invention. It is obvious that variants can to be made without departing from the invention as claimed hereinafter.

Claims (17)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR0350898 | 2003-11-25 | ||

| FR0350898A FR2862623B1 (en) | 2003-11-25 | 2003-11-25 | INDEPENDENT FLOW RATE VALVE |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1535860A1 true EP1535860A1 (en) | 2005-06-01 |

| EP1535860B1 EP1535860B1 (en) | 2006-10-25 |

Family

ID=34451742

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04292631A Expired - Lifetime EP1535860B1 (en) | 2003-11-25 | 2004-11-05 | Variable-delivery tilt valve |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP1535860B1 (en) |

| JP (1) | JP4094003B2 (en) |

| AT (1) | ATE343532T1 (en) |

| DE (1) | DE602004002918T2 (en) |

| ES (1) | ES2274399T3 (en) |

| FR (1) | FR2862623B1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9662285B2 (en) | 2014-03-13 | 2017-05-30 | The Procter & Gamble Company | Aerosol antiperspirant compositions, products and methods |

| US10076489B2 (en) | 2012-09-14 | 2018-09-18 | The Procter & Gamble Company | Aerosol antiperspirant compositions, products and methods |

| US10076474B2 (en) | 2014-03-13 | 2018-09-18 | The Procter & Gamble Company | Aerosol antiperspirant compositions, products and methods |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5189411B2 (en) * | 2008-05-30 | 2013-04-24 | 株式会社マンダム | Aerosol container valve, aerosol container equipped with the valve, and aerosol product filled with contents in the aerosol container |

| JP6416515B2 (en) * | 2014-04-03 | 2018-10-31 | 株式会社ダイゾー | Discharge container |

| AU2015390917A1 (en) | 2015-04-06 | 2017-10-12 | S.C. Johnson & Son, Inc. | Dispensing systems |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3404863A (en) * | 1966-06-24 | 1968-10-08 | Derek B. Green | Aerosol valve assembly |

| US3795350A (en) * | 1972-10-16 | 1974-03-05 | Scovill Manufacturing Co | Aerosol valve having selectable flow rate |

| US4139128A (en) * | 1976-06-10 | 1979-02-13 | Seaquist Valve Co., A Division Of Pittway Corporation | Variable spray valve assembly |

| DE10121425A1 (en) * | 2001-05-02 | 2002-11-07 | Wella Ag | Valve for releasing small quantities from a pressurized gas container comprises a spring-loaded tube having an axial discharge channel leading from a housing, and a valve disk |

-

2003

- 2003-11-25 FR FR0350898A patent/FR2862623B1/en not_active Expired - Fee Related

-

2004

- 2004-11-05 DE DE602004002918T patent/DE602004002918T2/en not_active Expired - Lifetime

- 2004-11-05 EP EP04292631A patent/EP1535860B1/en not_active Expired - Lifetime

- 2004-11-05 AT AT04292631T patent/ATE343532T1/en not_active IP Right Cessation

- 2004-11-05 ES ES04292631T patent/ES2274399T3/en not_active Expired - Lifetime

- 2004-11-24 JP JP2004338359A patent/JP4094003B2/en not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3404863A (en) * | 1966-06-24 | 1968-10-08 | Derek B. Green | Aerosol valve assembly |

| US3795350A (en) * | 1972-10-16 | 1974-03-05 | Scovill Manufacturing Co | Aerosol valve having selectable flow rate |

| US4139128A (en) * | 1976-06-10 | 1979-02-13 | Seaquist Valve Co., A Division Of Pittway Corporation | Variable spray valve assembly |

| DE10121425A1 (en) * | 2001-05-02 | 2002-11-07 | Wella Ag | Valve for releasing small quantities from a pressurized gas container comprises a spring-loaded tube having an axial discharge channel leading from a housing, and a valve disk |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10076489B2 (en) | 2012-09-14 | 2018-09-18 | The Procter & Gamble Company | Aerosol antiperspirant compositions, products and methods |

| US10076490B2 (en) | 2012-09-14 | 2018-09-18 | The Procter & Gamble Company | Aerosol antiperspirant compositions, products and methods |

| US9662285B2 (en) | 2014-03-13 | 2017-05-30 | The Procter & Gamble Company | Aerosol antiperspirant compositions, products and methods |

| US10076474B2 (en) | 2014-03-13 | 2018-09-18 | The Procter & Gamble Company | Aerosol antiperspirant compositions, products and methods |

Also Published As

| Publication number | Publication date |

|---|---|

| JP4094003B2 (en) | 2008-06-04 |

| ES2274399T3 (en) | 2007-05-16 |

| FR2862623A1 (en) | 2005-05-27 |

| ATE343532T1 (en) | 2006-11-15 |

| DE602004002918D1 (en) | 2006-12-07 |

| FR2862623B1 (en) | 2006-01-20 |

| DE602004002918T2 (en) | 2007-04-26 |

| JP2005154013A (en) | 2005-06-16 |

| EP1535860B1 (en) | 2006-10-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CA2368052C (en) | Pressurized device fitted with tilt valve | |

| EP1035038B9 (en) | Unit for storing and dispensing a product under pressure, especially cosmetics | |

| CA2172192C (en) | Aerosol container with double-outlet valve | |

| EP1291293A1 (en) | Valve with variable discharge and container having such valve | |

| EP1048590B1 (en) | Valve actuating device and assembly comprising such a device | |

| EP1288142B1 (en) | Unit for storing and dispensing a product under pressure | |

| EP1205403B1 (en) | Unit for storing and dispensing a product under pressure | |

| CA2257485A1 (en) | Outlet flow control valve, and container equipped with such a valve | |

| CA2363285A1 (en) | Washable dispensing head and dispenser equipped with said dispensing head | |

| EP0688609B1 (en) | Manually actuated precompression pump for spraying a liquid and dispensing assembly comprising such a pump | |

| CA2163483C (en) | Precompression manual pump for liquid pulverizing and dispensing assembly equipped with such pump | |

| EP0939039A1 (en) | Dispensing head for the dispensing of a material and assembly for dispensing under pressure equipped with such a head | |

| EP1201317B1 (en) | Spraying apparatus with at least two carrier gas outlets | |

| EP1302246B1 (en) | Device for spraying at least one product on a substrate, especially on a keratinous substrate such as skin | |

| EP1535860B1 (en) | Variable-delivery tilt valve | |

| EP1400465B1 (en) | Variable-delivery tiilt valve as well as container having such valve | |

| FR2814727A1 (en) | Pressurized container comprising a valve, useful for dispensing a spray, gel, mousse, cosmetic or pharmaceutical product, has spring holding it in closed position until actuator is depressed | |

| EP0863089B1 (en) | Dispensing head and dispenser with such head | |

| FR2808258A1 (en) | AEROSOL CONTAINER WITH IMPROVED VALVE | |

| EP1466669A1 (en) | Pump to spray a product in different positions and container therefor | |

| FR2814726A1 (en) | Pressurized container spray, useful for dispensing gel, mousse, a cosmetic or a pharmaceutical product, has cap with shutter covering valve outlet until depressed | |

| EP1647501A1 (en) | Dispensing device for cosmetic products |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK YU |

|

| 17P | Request for examination filed |

Effective date: 20051201 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20061025 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: FRENCH |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061130 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061130 |

|

| REF | Corresponds to: |

Ref document number: 602004002918 Country of ref document: DE Date of ref document: 20061207 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070125 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070125 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070125 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20070108 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070225 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070326 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2274399 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070726 |

|

| BERE | Be: lapsed |

Owner name: L'OREAL Effective date: 20061130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070126 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070426 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061105 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061025 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081130 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081130 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20131108 Year of fee payment: 10 Ref country code: GB Payment date: 20131030 Year of fee payment: 10 Ref country code: DE Payment date: 20131030 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20131011 Year of fee payment: 10 Ref country code: IT Payment date: 20131119 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602004002918 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20141105 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20150731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141105 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150602 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141201 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20151230 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141105 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141106 |