EP1535677A1 - Presswerkzeug - Google Patents

Presswerkzeug Download PDFInfo

- Publication number

- EP1535677A1 EP1535677A1 EP03405848A EP03405848A EP1535677A1 EP 1535677 A1 EP1535677 A1 EP 1535677A1 EP 03405848 A EP03405848 A EP 03405848A EP 03405848 A EP03405848 A EP 03405848A EP 1535677 A1 EP1535677 A1 EP 1535677A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- pressing

- press

- tool

- pressing jaw

- closed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25B—TOOLS OR BENCH DEVICES NOT OTHERWISE PROVIDED FOR, FOR FASTENING, CONNECTING, DISENGAGING OR HOLDING

- B25B27/00—Hand tools, specially adapted for fitting together or separating parts or objects whether or not involving some deformation, not otherwise provided for

- B25B27/02—Hand tools, specially adapted for fitting together or separating parts or objects whether or not involving some deformation, not otherwise provided for for connecting objects by press fit or detaching same

- B25B27/10—Hand tools, specially adapted for fitting together or separating parts or objects whether or not involving some deformation, not otherwise provided for for connecting objects by press fit or detaching same inserting fittings into hoses

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D39/00—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders

- B21D39/04—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders of tubes with tubes; of tubes with rods

- B21D39/048—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders of tubes with tubes; of tubes with rods using presses for radially crimping tubular elements

Definitions

- the invention relates to a pressing tool, in particular for pressing of pipe ends, with at least two pressing jaw elements, which form an opening gap with opposite ends, the is essentially closed after pressing.

- Pressing tools of the type mentioned have long been known and especially for pressing pipe ends in the sanitary area used. For example, by plastic compression Water pipes are connected with fittings. The pressing jaws when pressing by hand or with a hydraulic Drive closed. During the pressing process, the opening gap closed between the free ends of the pressing jaw elements.

- the pressed pipe end is thereby out of round, which has different disadvantages. For example can by the non-circular cross-section of the compressed pipe the Sealing effect should not be optimal.

- a pressing tool would be desirable, with the one most perfect centric and ensures round compression at different pipe cross sections is.

- a pressing tool of the type mentioned is, for example EP 1 036 608 A of the applicant.

- the pressing tool is designed here as a press loop, the three pressing jaw elements which are hinged together are.

- This press loop is around the pipe end to be pressed placed and provisionally closed with a strap.

- a hydraulic drive which on the two outer Pressing jaw elements is applied, the press loop is closed.

- a similar pressing tool is from the EP 0 671 984 A has become known.

- a pressing tool which also is designed as a press loop. This has press inserts on, which are kept floating in the press jaws and which are moved during the pressing in the circumferential direction. At the Pressing first come the free ends of the press inserts to the plant, while at the other ends a movement gap remains. This should make it possible to pipes with nominal diameters over 50 to press.

- this pressing tool is constructive comparatively complex and consists of many individual parts.

- the invention is based on the object, a pressing tool of called type to create the above-mentioned difficulties avoids and inexpensive to produce with ease of use is.

- the task is in a generic pressing tool characterized solved that at least one pressing jaw element a support means has, when applied pressing tool and in not yet compressed state on the outside of the object to be pressed bears radially supporting and together during pressing is moved with the pressing jaw elements in the circumferential direction.

- pressing tool according to the invention When pressing tool according to the invention is to be pressed Object before the pressing process and during the pressing process supported or guided in the opening gap by said support element, so that the object can not move radially. In order to it is ensured that in the opening gap no bulge or protrude. Thus, a centric and round Pressing guaranteed. It has surprisingly been found that with the invention, the force required for pressing force or the energy consumption is much smaller than before. The Pressing can thus be used in particular with a pressing tool Hand drive easier and faster.

- the support element is attached directly to the pressing jaw element and can as a simple finger-shaped extension of this pressing jaw element be educated. Additional elements and in particular Press inserts and means for moving these press inserts are avoided.

- the inventive pressing tool is not much more expensive to manufacture than previous ones Pressing tools or press slings.

- the support means is fixed connected to the pressing jaw member and preferably on this formed.

- a pressing jaw element is a support element as an extension and the opposite with this cooperating Pressing jaw member has a recess, in which the Extension can enter when closing the pressing tool.

- the proppant or the extension in cross-section U-shaped is U-shaped.

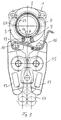

- the pressing tool 1 shown in FIG. 1 is a so-called Press sling, the middle pressing jaw element 2 and two having outer pressing jaw elements 3 and 4.

- the pressing jaw element 2 is with two hinge joints 5 with the other Pressing jaw elements 3 and 4 hingedly connected.

- a bracket 11 is pivotally mounted, with which the Pressing tool 1 according to Figure 2 are closed provisionally can.

- the disclosure is also hereby referred to EP 1 036 608 A of Applicant referenced, in which in particular the function of this Ironing 11 is disclosed.

- the pressing jaw elements 2, 3 and 4 each have an inner side 20, 21 and 22, respectively, which form the pressing surfaces and the with closed pressing tool in cross-section a round and form closed pressing surface.

- the insides 20, 21 and 22 may have protruding ribs extending in the circumferential direction extend and during the pressing process in the outside of the bury the object to be pressed.

- the press tool 1 shown is, as mentioned, in particular a Pressing loop. In principle, such a press loop also have more than three pressing jaw elements.

- the inventive Press tool is not limited to a press sling, but can for example be designed as pressing tongs be, which has only two pressing jaw elements and is closed by hand or motor.

- the one to be pressed The subject matter is preferably a tube 14 and in particular a pipe of sanitary engineering, basically can with the inventive pressing tool but also other objects be pressed.

- This support part 8 is part of the Pressing jaw element 3 and in particular integrally formed on this. In principle, this support member 8 could also be otherwise be firmly connected to the pressing jaw element 3.

- the support part 8 is formed according to Figure 6 U-shaped and has two parallel to each other side wall 10 and one of these bridge-like connecting wall 26. This wall 26 has projecting ribs 18, and is corresponding in the circumferential direction the inside 20 bent in a circle, as the figure 1 recognize leaves.

- the ribs 18 correspond to ribs 27 of the pressing jaw elements 2, 3 and 4 and each form a continuation of this.

- the pressing jaw element 4 has at its free end 7 a recess 9, which are formed corresponding to the support part 8 is and which receives this support member 8 in the closed state. If the pressing tool 1 according to FIG. 3 is applied to a tube 14, but not yet closed, the support member 8 engages preferably slightly into the recess 8 a. In the area of Opening gap 19 is thus the pipe to be pressed 14 at his Outside supported by the support member 8 and can during pressing do not dodge radially. If now the pressing tool 1 is closed, Thus, the support member 8 is pushed into the recess 9. The wall 26 slides on the outside 28 along the pipe 14 to be pressed. The thickness of the wall 26 is comparatively small and is for example 1 to 3 mm.

- the tube 14 is in particular a plastically deformable water pipe with a core layer 14b Aluminum and two layers 14a and 14c bonded thereto made of plastic.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Press Drives And Press Lines (AREA)

- Shaping Metal By Deep-Drawing, Or The Like (AREA)

- Measurement Of The Respiration, Hearing Ability, Form, And Blood Characteristics Of Living Organisms (AREA)

- Hand Tools For Fitting Together And Separating, Or Other Hand Tools (AREA)

Abstract

Description

- Figur 1

- eine teilweise geschnittene Ansicht eines erfindungsgemässen Presswerkzeuges in geöffnetem Zustand,

- Figur 2

- eine Ansicht eines erfindungsgemässen Presswerkzeuges, das um ein zu verpressendes Rohrende gelegt ist,

- Figur 3

- eine Ansicht eines erfindungsgemässen Presswerkzeuges, das um ein zu verpressendes Rohrende gelegt ist sowie ein Antrieb zum Schliessen des Presswerkzeuges,

- Figur 4

- eine Ansicht gemäss Figur 2, jedoch mit geschlossenem Presswerkzeug und somit nach der Durchführung der Verpressung,

- Figur 5

- eine Ansicht gemäss Figur 3, jedoch nach dem Pressvorgang und

- Figur 6

- ein Schnitt entlang der Linie VI-VI der Figur 5.

- 1.

- Presswerkzeug

- 2.

- Pressbackenelement

- 3.

- Pressbackenelement

- 4.

- Pressbackenelement

- 5.

- Gelenk

- 6.

- Ende

- 7.

- Ende

- 8.

- Stützteil

- 9.

- Ausnehmung

- 10.

- Seitenwand

- 11.

- Bügel

- 12.

- Leitung

- 13.

- Pressfitting

- 14.

- Rohr

- 15.

- Schliesszange

- 16.

- Nocken

- 17.

- Rollen

- 18.

- Rippen

- 19.

- Öffnungsspalt

- 20.

- Innenseite

- 21.

- Innenseite

- 22.

- Innenseite

- 23.

- Hebel

- 24.

- Anschlagfläche

- 25.

- Anschlagfläche

- 26.

- Wandung

- 27.

- Rippen

- 28.

- Aussenseite

- 29.

- Innenseite

Claims (4)

- Presswerkzeug, insbesondere zum Verpressen von Rohrenden, mit wenigstens zwei Pressbackenelemente (2, 3), die mit gegenüberliegenden Enden (6, 7) einen Öffnungsspalt (19) bilden, der nach dem Verpressen im Wesentlichen geschlossen ist, dadurch gekennzeichnet, dass wenigstens ein Pressbackenelement (3) ein Stützmittel (8) aufweist, das im angelegten und noch nicht verpressten Zustand an der Aussenseite (28) des zu verpressenden Gegenstandes radial stützend anliegt und beim Verpressen gemeinsam mit den Pressbackenelementen (2, 3) in Umfangsrichtung verschoben wird.

- Presswerkzeug nach Anspruch 1, dadurch gekennzeichnet, dass die Stützmittel (8) fest mit den Pressbackenelementen (2, 3) verbunden sind.

- Presswerkzeug nach Anspruch 1 oder 2, dadurch gekennzeichnet, dass die Stützmittel (8) wenigstens durch einen fingerartigen Fortsatz eines Pressbackenelementes (2, 3) gebildet ist.

- Presswerkzeug nach einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, dass wenigstens ein Pressbackenelement (4) an einem Ende eine Ausnehmung (9) aufweist, in die beim Schliessen ein Stützteil (8) der anderen Pressbacke (3) eingreift.

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03405848A EP1535677B1 (de) | 2003-11-27 | 2003-11-27 | Presswerkzeug |

| AT03405848T ATE372840T1 (de) | 2003-11-27 | 2003-11-27 | Presswerkzeug |

| DE50308188T DE50308188D1 (de) | 2003-11-27 | 2003-11-27 | Presswerkzeug |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03405848A EP1535677B1 (de) | 2003-11-27 | 2003-11-27 | Presswerkzeug |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1535677A1 true EP1535677A1 (de) | 2005-06-01 |

| EP1535677B1 EP1535677B1 (de) | 2007-09-12 |

Family

ID=34443148

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03405848A Expired - Lifetime EP1535677B1 (de) | 2003-11-27 | 2003-11-27 | Presswerkzeug |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1535677B1 (de) |

| AT (1) | ATE372840T1 (de) |

| DE (1) | DE50308188D1 (de) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202009009456U1 (de) * | 2009-07-15 | 2010-11-25 | Novopress Gmbh Pressen Und Presswerkzeuge & Co. Kommanditgesellschaft | Presswerkzeug zum Verbinden von insbesondere rohrförmigen Werkstücken |

| EP2272629A1 (de) * | 2009-07-08 | 2011-01-12 | Novopress GmbH Pressen und Presswerkzeuge & Co. KG | Presswerkzeug sowie Verfahren zum Verpressen von insbesondere rohrförmigen Werkstücken |

| CN103889659A (zh) * | 2011-08-19 | 2014-06-25 | 古斯塔夫.克劳克有限责任公司 | 压制设备 |

| DE202013007496U1 (de) * | 2013-08-21 | 2014-11-28 | Novopress Gmbh Pressen Und Presswerkzeuge & Co. Kg | Pressschlinge zum Verbinden von insbesondere rohrförmigen Werkstücken |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3338908B1 (de) * | 2016-12-21 | 2019-11-20 | Von Arx AG | Druckring mit länglichen löchern |

| DE202020102724U1 (de) | 2020-05-14 | 2021-08-17 | Novopress Gmbh Pressen Und Presswerkzeuge & Co. Kommanditgesellschaft | Antriebseinheit |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6044681A (en) * | 1997-03-11 | 2000-04-04 | Gustav Klauke Gmbh | Pressing tool |

| EP1036608A1 (de) * | 1999-03-17 | 2000-09-20 | Geberit Technik Ag | Verschluss an einem Presswerkzeug |

| EP1208949A2 (de) * | 2000-10-19 | 2002-05-29 | Gustav Klauke GmbH | Presswerkzeug |

-

2003

- 2003-11-27 AT AT03405848T patent/ATE372840T1/de active

- 2003-11-27 EP EP03405848A patent/EP1535677B1/de not_active Expired - Lifetime

- 2003-11-27 DE DE50308188T patent/DE50308188D1/de not_active Expired - Lifetime

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6044681A (en) * | 1997-03-11 | 2000-04-04 | Gustav Klauke Gmbh | Pressing tool |

| EP1036608A1 (de) * | 1999-03-17 | 2000-09-20 | Geberit Technik Ag | Verschluss an einem Presswerkzeug |

| EP1208949A2 (de) * | 2000-10-19 | 2002-05-29 | Gustav Klauke GmbH | Presswerkzeug |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2272629A1 (de) * | 2009-07-08 | 2011-01-12 | Novopress GmbH Pressen und Presswerkzeuge & Co. KG | Presswerkzeug sowie Verfahren zum Verpressen von insbesondere rohrförmigen Werkstücken |

| DE202009009456U1 (de) * | 2009-07-15 | 2010-11-25 | Novopress Gmbh Pressen Und Presswerkzeuge & Co. Kommanditgesellschaft | Presswerkzeug zum Verbinden von insbesondere rohrförmigen Werkstücken |

| CN103889659A (zh) * | 2011-08-19 | 2014-06-25 | 古斯塔夫.克劳克有限责任公司 | 压制设备 |

| CN103889659B (zh) * | 2011-08-19 | 2016-06-01 | 古斯塔夫.克劳克有限责任公司 | 链式压制设备、用于压合工件的方法和压力部件的组合件 |

| DE202013007496U1 (de) * | 2013-08-21 | 2014-11-28 | Novopress Gmbh Pressen Und Presswerkzeuge & Co. Kg | Pressschlinge zum Verbinden von insbesondere rohrförmigen Werkstücken |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1535677B1 (de) | 2007-09-12 |

| DE50308188D1 (de) | 2007-10-25 |

| ATE372840T1 (de) | 2007-09-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102009032113B4 (de) | Presswerkzeug sowie Verfahren zum Verpressen von insbesondere rohrförmigen Werkstücken | |

| DE69200259T2 (de) | Ausdehnbare Dichtungsanordnung. | |

| EP0671985A1 (de) | Presswerkzeug. | |

| DE2525313C2 (de) | Rohrmuffe | |

| DE2908935C2 (de) | Rohrverbindung mit zwei ineinandergeschobenen Teilen | |

| DE1652872B1 (de) | Verbindung zwischen einem zylindrischen rohr und einem auf dieses aufgeschobenen verbindungsteil | |

| DE102007051354A1 (de) | Verfahren zum Herstellen eines Profils aus flachem Metallband | |

| EP1535677B1 (de) | Presswerkzeug | |

| DE3328913A1 (de) | Einrichtung zur befestigung eines rohres in einer bohrung | |

| DE3718619C2 (de) | ||

| DE202007007827U1 (de) | Klemmfitting für ein Rohr | |

| DE19803536A1 (de) | Preßwerkzeug | |

| EP2791566B1 (de) | Verfahren zur herstellung einer rohrverbindung mittels pressfitting sowie presswerkzeug | |

| DE3422040A1 (de) | Stuelp-umformverfahren zur herstellung von doppelwandigen zylindrischen werkstuecken sowie umformwerkzeug hierfuer | |

| DE2332241B2 (de) | Rohrverbindung | |

| DE3617529C2 (de) | ||

| DE2513982B2 (de) | Rohrdichtung | |

| DE1806665B2 (de) | Verfahren und vorrichtung zum befestigen von muffen aus metall an gerippten bewehrungsstaeben und nach dem verfahren hergestellte stossverbindung | |

| DE102014112754A1 (de) | Stauchverfahren und Stauchvorrichtung | |

| EP1649948B1 (de) | Presswerkzeug | |

| EP1793155B1 (de) | Rohrschelle, insbesondere Anbohrschelle | |

| DE10202790A1 (de) | Rohrpresskupplung | |

| DE29517518U1 (de) | Preßwerkzeug | |

| DE29824956U1 (de) | Presswerkzeug | |

| DE19844878A1 (de) | Verfahren zur Herstellung einer Preßverbindung sowie Vorrichtung zur Durchführung des Verfahrens |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20050614 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20061108 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: CH Ref legal event code: NV Representative=s name: ISLER & PEDRAZZINI AG Ref country code: CH Ref legal event code: PCAR Free format text: ISLER & PEDRAZZINI AG;POSTFACH 1772;8027 ZUERICH (CH) |

|

| REF | Corresponds to: |

Ref document number: 50308188 Country of ref document: DE Date of ref document: 20071025 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070912 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071223 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070912 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071213 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070912 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080212 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070912 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070912 |

|

| BERE | Be: lapsed |

Owner name: GEBERIT TECHNIK A.G. Effective date: 20071130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070912 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071212 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071130 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070912 |

|

| 26N | No opposition filed |

Effective date: 20080613 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070912 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070912 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070912 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070912 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071212 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080313 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070912 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: GEBERIT INTERNATIONAL AG Free format text: GEBERIT TECHNIK AG#SCHACHENSTRASSE 77#8645 JONA (CH) -TRANSFER TO- GEBERIT INTERNATIONAL AG#SCHACHENSTRASSE 77#8645 JONA (CH) |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20101112 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20101127 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20111130 Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 372840 Country of ref document: AT Kind code of ref document: T Effective date: 20121127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121127 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 50308188 Country of ref document: DE Representative=s name: HOEGER, STELLRECHT & PARTNER PATENTANWAELTE, DE Ref country code: DE Ref legal event code: R082 Ref document number: 50308188 Country of ref document: DE Representative=s name: HOEGER, STELLRECHT & PARTNER PATENTANWAELTE MB, DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 50308188 Country of ref document: DE Representative=s name: HOEGER, STELLRECHT & PARTNER PATENTANWAELTE MB, DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20151119 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50308188 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20170601 |