EP1530934B2 - Duvet - Google Patents

Duvet Download PDFInfo

- Publication number

- EP1530934B2 EP1530934B2 EP04405701A EP04405701A EP1530934B2 EP 1530934 B2 EP1530934 B2 EP 1530934B2 EP 04405701 A EP04405701 A EP 04405701A EP 04405701 A EP04405701 A EP 04405701A EP 1530934 B2 EP1530934 B2 EP 1530934B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- textile

- hydrophilic

- layers

- textile layer

- moisture

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000004753 textile Substances 0.000 claims abstract description 101

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 22

- 230000002209 hydrophobic effect Effects 0.000 claims abstract description 21

- 239000004744 fabric Substances 0.000 claims description 24

- 238000010521 absorption reaction Methods 0.000 claims description 4

- 239000000463 material Substances 0.000 abstract description 9

- 238000009958 sewing Methods 0.000 abstract 1

- 239000000126 substance Substances 0.000 description 10

- 238000009413 insulation Methods 0.000 description 9

- 238000012546 transfer Methods 0.000 description 8

- 239000011148 porous material Substances 0.000 description 7

- 238000000034 method Methods 0.000 description 6

- 238000010276 construction Methods 0.000 description 4

- 239000011257 shell material Substances 0.000 description 4

- 238000005406 washing Methods 0.000 description 4

- 241000238876 Acari Species 0.000 description 3

- 229920000742 Cotton Polymers 0.000 description 3

- 230000000295 complement effect Effects 0.000 description 3

- 239000000428 dust Substances 0.000 description 3

- 239000000835 fiber Substances 0.000 description 3

- 239000002245 particle Substances 0.000 description 3

- 229920002994 synthetic fiber Polymers 0.000 description 3

- 239000004758 synthetic textile Substances 0.000 description 3

- 241000272517 Anseriformes Species 0.000 description 2

- 239000013566 allergen Substances 0.000 description 2

- 239000004566 building material Substances 0.000 description 2

- 238000011835 investigation Methods 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 239000004745 nonwoven fabric Substances 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 241001669679 Eleotris Species 0.000 description 1

- 206010020751 Hypersensitivity Diseases 0.000 description 1

- 229920001410 Microfiber Polymers 0.000 description 1

- 239000004677 Nylon Substances 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 206010037660 Pyrexia Diseases 0.000 description 1

- 206010038743 Restlessness Diseases 0.000 description 1

- 238000005299 abrasion Methods 0.000 description 1

- 238000009825 accumulation Methods 0.000 description 1

- 230000006978 adaptation Effects 0.000 description 1

- 208000026935 allergic disease Diseases 0.000 description 1

- 230000000172 allergic effect Effects 0.000 description 1

- 230000007815 allergy Effects 0.000 description 1

- 208000010668 atopic eczema Diseases 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 210000000746 body region Anatomy 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 238000003795 desorption Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 230000003862 health status Effects 0.000 description 1

- 238000002955 isolation Methods 0.000 description 1

- 239000003658 microfiber Substances 0.000 description 1

- 229930014626 natural product Natural products 0.000 description 1

- 229920001778 nylon Polymers 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 238000005086 pumping Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 230000001932 seasonal effect Effects 0.000 description 1

- 238000001179 sorption measurement Methods 0.000 description 1

- 238000002336 sorption--desorption measurement Methods 0.000 description 1

- 238000009827 uniform distribution Methods 0.000 description 1

- 238000013022 venting Methods 0.000 description 1

- 230000036642 wellbeing Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47G—HOUSEHOLD OR TABLE EQUIPMENT

- A47G9/00—Bed-covers; Counterpanes; Travelling rugs; Sleeping rugs; Sleeping bags; Pillows

- A47G9/02—Bed linen; Blankets; Counterpanes

- A47G9/0207—Blankets; Duvets

Definitions

- the invention relates to a single or multi-part duvet, in particular a quilt or duvet cover provided with stitched chambers, according to the preamble of patent claim 1.

- the duvet Due to changed sleeping habits, the duvet, in particular its nature and quality, has gained a central importance for the well-being of the user during his resting periods. Due to the usual renunciation of linen sheets, the bed climate is determined primarily by the blanket. Essential for the duvet are their insulation properties, in particular the ability to regulate temperature and humidity, as well as the freedom from dust particles and organic allergens.

- DE-A-196 54 798 and FP-A-0 323 116 describes blankets which have a covering which makes it possible to effectively combat allergic phenomena in allergy sufferers.

- inner shell material which on the one hand is highly permeable to air and on the other hand highly captive for small particles.

- DE-A-196 54 798 is also proposed, in addition to this inner shell to use an outer shell having properties, such as mechanical structural strength, which are not provided in the inner shell.

- filling materials consisting of down of ducks and geese are preferably used. Down, which are typically filled in the blankets in amounts of 150-350 g / m 2 , are able to absorb larger amounts of moisture, thus resulting in a favorable regulation of the humidity of the bed climate.

- the ability to absorb moisture is also limited in down materials. Larger amounts of moisture, which typically occur locally in the area of certain areas of the user's body, usually can not be absorbed sufficiently quickly.

- Another disadvantage is that the insulation properties of the blanket change unfavorably after prolonged moisture transfer or after receiving larger amounts of moisture in the areas of increased humidity.

- the ceiling can be provided with openings that are closed with breathable fabrics and through which an exchange of dry and moist air can take place.

- the blanket is split into checkerboard-like fields with reduced air and moisture passages.

- a disadvantage of this solution is that the body areas of the sleeper are not uniformly insulated against the outside air abutting the outside of the ceiling. Therefore disturbing temperature gradients can occur in the body area. If necessary, sensitive parts of the body are not immediately noticeable, but are exposed to a lower temperature for a longer time. It is also possible that, when cuddling in the ceiling, the openings covered with moisture-permeable substances are closed so that a moisture accumulation results. It is also possible that disturbing moisture gradients arise.

- the present invention is therefore based on the object to provide an improved duvet.

- a blanket is to be created by means of which a more pleasant bed climate with low moisture values can be realized during the entire period of use.

- a blanket is to be created in which disturbing temperature and humidity gradients are avoided.

- the blanket according to the invention in particular a one- or multi-part quilted or duvet blanket, has a heat-insulating, hydrophilic filling which is trapped between two first textile layers in one or more chambers.

- both first textile layers preferably consist of a relatively hydrophobic first material which has the transport of pores and capillaries serving for water vapor and which is at least partially covered by a single or multi-layered second textile layer, which consists of a distinctly hydrophilic and water-vapor-permeable second material.

- the moisture released by the user is rapidly absorbed by absorption or adsorption / desorption, distributed over the pores of the relatively hydrophobic first textile layer to the hydrophilic, preferably down, filling, which has a high capacity for absorbing water vapor having.

- the relatively hydrophobic first fabric layer causes the moisture given off by the user and passed through the optional bedding to spread rapidly across the hydrophilic second fabric layer, whereafter, due to the resulting difference in vapor pressures on both sides of the first textile layer hydrophilic second textile layer stored water vapor through the relatively hydrophobic first textile layer is transferred and absorbed by the hydrophilic filling.

- the moisture is then released through the opposite relatively hydrophobic first textile layer and, if present, the subsequent hydrophilic second textile layer.

- the blanket according to the invention therefore results in a rapid transfer of moisture and thus a dry bed climate, disturbing moisture gradients are avoided.

- By avoiding larger openings for moisture transfer temperature and pressure gradients are further avoided, which could be perceived by the user as unpleasant.

- the solution of the problem is therefore not achieved by the local removal of materials, which partially increased breathability is achieved, but by the large-scale use of another textile layer. Particularly important is that the moisture does not evaporate on the skin of the user, resulting in a partial cooling of the skin surface, but is first absorbed by the adjacent textiles.

- the fabric of the two second textile layers also preferably has a water vapor transmission resistance Ret according to ISO standard 11092 of not more than 20 m 2 / Pa / W, preferably about 5 m 2 / Pa / W.

- Textile water vapor resistance can be measured, for example, by means of SGHP-8.2 and SGHP-10.5 measuring instruments of Measurement Technology Northwest, Seattle, WA 98199, which operate according to ISO 11092 and ASTM F-1868 standards.

- hydrophilic breathable substances are also usable for the second textile layers, in which the water vapor transfer does not take place primarily by adsorption and desorption.

- a substance is preferably used which has coarse mesh or pores whose diameter is at least twice as large as the diameter of the mesh or pores of the fabric of the first two textile layers.

- the second textile layer should cling as optimally as possible to the textile layers lying on one or both sides.

- substances whose shear stiffness is at most half as high as the shear stiffness of the fabric of the first two textile layers are selected for the second textile layer. This shows that the measurement of the shear stiffness correlates very well with the subjective grip assessment.

- the shear stiffness for example, the force required to subject a horizontally clamped textile strip to parallel displacement is measured. Further measuring methods are known from [3], page 30.

- the hydrophilic second textile layer is fixed by connecting means such as stitching, hook-and-loop fasteners, buttons or zippers, or releasably connected by the user to the associated relatively hydrophobic first textile layer. It is also possible to form an envelope with the hydrophilic second textile layers which is suitable for receiving a duvet cover formed from the first textile layers and the filling.

- a third, heat-insulating textile layer can be provided over the entire surface, which is preferably also made of a hydrophilic material, whereby the lateral transfer of moisture is still noticeably improved.

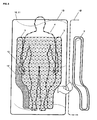

- the hydrophilic second textile layer completely covers the relatively hydrophobic first textile layer or is preferably provided only in the region which lies above the expected position of the body of the user.

- At least one breathable zone is provided outside the area of the blanket, which is above the expected position of the body of the user, which has no hydrophilic filling and the air exchange between the bed climate and the room climate allowed.

- the movements of the user result in pumping operations, by means of which dry air is sucked in and moist air is expelled.

- the user therefore forms a kind of drive, by means of which the regulation process is automatically driven and controlled.

- the regulation process In a user who suffers from fever, usually larger amounts of moisture occur. Due to the usually restless sleep and the resulting movements, however, there is an increased moisture output at the same time, so that the bed climate is regulated or stabilized within acceptable limits.

- the breathable zones are not above the user, disturbing temperature and pressure gradients are avoided. It is therefore prevented that the body of the user is partially cooled. Further, the breathable zones are not covered by the body of the user, so that the air exchange is not hindered.

- Preferably snake-shaped or narrow rectangular configured breathable zones are provided on both sides of the area, which is above the expected position of the body of the user, so that only a small and uniform, for the user quite pleasant heat flow can result.

- the breathable zones are through the first and / or the second textile layer; or alternatively covered by the first and / or the second textile layer and at least one heat-insulating third textile layer; so that disturbing air movements and isolation gaps are avoided.

- the breathable zones provided inside and / or outside the body region can be locked, so that an adaptation of the blanket to the seasonal climatic conditions is possible.

- individual end pieces can be provided, which can be fastened by means of Velcro fasteners, buttons or zippers on the edges of the breathable zones.

- Velcro fasteners buttons or zippers

- this causes a considerable effort, especially when installing the individual end caps.

- the storage of the individual end caps is rather unvorteilhaftrealisierbar.

- two mutually complementary cover parts which can be connected to one another by means of seams, Velcro fastenings, buttons or zippers are provided, of which the first is provided with the breathable zones and the second with correspondingly arranged end pieces.

- the two ceiling parts can therefore be rapidly connected or separated from one another in the manner of LEGO® building blocks.

- the storage of the complementary first or second ceiling part is much easier than the storage of the individual end caps.

- Particularly advantageous in this solution is also that three types of duvets can be realized. For example, in summer only the first ceiling part provided with the breathable zones can be used. In the transitional periods, in spring and autumn, the light second end piece provided with the end pieces can be used and in winter the combination of both ceiling parts is used. Furthermore, if necessary, the two ceiling parts can also be used separately. It is possible to use two parts of the ceiling which are only partially complementary to one another, during the connection of which the breathable zones are not or only partially filled.

- the distinctly hydrophilic second textile layer can be a single-layered or multi-layered, coarse-meshed, fine-meshed or microporous fabric, a knitted fabric, a knitted fabric or a non-woven fabric made of chemical and / or natural fibers.

- Advantageously usable for example, cotton, nylon or polyamide.

- Synthetic textiles including nonwovens, have been greatly improved in recent times, so that their properties have closely approximated those of natural products, such as cotton. Synthetic textiles also have a high degree of variability, which makes it possible to optimize the fabric for the present application. Synthetic textiles also have good mechanical strength in terms of abrasion, tearing and tearing, high breathability, isotropic properties (equally resilient in all directions with the advantages of traditional fabrics and knitted fabrics), a textile feel, good drape and a high ease of use.

- Mites and allergen-dense second textile layers with a maximum pore size of 0.5 ⁇ m are preferably used which have pronounced hydrophilic properties and at the same time prevent the ingress of mites.

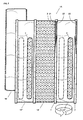

- the blanket consists of several parts, preferably a ceiling middle part, which is connected or connected by means of connecting devices, such as zippers, on one or both sides with ceiling side panels.

- the breathable zones for the regulation of the bed climate can be provided in the ceiling middle part or in the ceiling side parts.

- the breathable zones are preferably provided eccentrically, so that each ceiling side panel in a first and a second textile layer is connectable to the ceiling middle part, provided it is on both sides corresponding parts of Having connecting device. Users with a larger body circumference can therefore mount the ceiling side parts in such a way that a larger distance between the breathable zones results. For narrower users or quieter sleepers, a smaller distance between the openings may be preferable.

- the connecting devices are preferably covered by insulating flaps, so that they can not rest directly on the body of the user and can form disturbing thermal bridges.

- the insulating tabs are preferably connected to the ceiling middle part, so that they are facing away from the user, directed to the outside. It is possible to use one or more walls, optionally filled with insulating insulation laps, which are arranged on one or both sides of the blanket, the connecting devices preferably completely cover and optionally enclose annular.

- insulating laps are preferably provided on both sides of the ceiling side parts, so that it is prevented that parts of the connecting device can be exposed.

- each duvet is provided with two mutually interchangeable ceiling middle parts, by means of which the user can adjust the blanket to the respective needs, such as the health status, and possibly depending on the season room conditions.

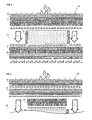

- FIG. 1 shows the structure of a cover blanket 1A according to the invention, which has a filling 10 consisting for example of down, hydrophobic or weakly hydrophilic first textile layers 11, 12 adjoining it on both sides and markedly hydrophilic second textile layers 13, 14 adjacent thereto.

- a filling 10 consisting for example of down, hydrophobic or weakly hydrophilic first textile layers 11, 12 adjoining it on both sides and markedly hydrophilic second textile layers 13, 14 adjacent thereto.

- the transfer of moisture from top to bottom, ie starting from the upper second textile layer 13 is described, which is applied to the user when using the blanket (see FIG. 5 ).

- the substances used for the first textile layers 11, 12 are not absolutely hydrophobic, but relatively hydrophobic in relation to the fabrics of the second textile layers 13, 14.

- the upper second textile layer 13 of FIG. 1 which consists of a single or multi-layered hydrophilic fabric or laminate, water drops are shown, which are absorbed by the hydrophilic second textile layer 13 and distributed flat along the fibers of the fabric or laminate.

- the provided under the hydrophilic second textile layer 13 relatively hydrophobic first textile layer 11 prevents that larger amounts of moisture locally enter the hydrophilic filling 10 and strongly moisten the down there, which affect their properties during use and then make a longer venting or drying necessary , As in FIG. 1 shown, the moisture or water vapor is then distributed with greatly reduced density on the relatively hydrophobic first textile layer 11 and can penetrate through the numerous channels or pores and capillaries 111 provided therein and into the hydrophilic filling 10.

- a hydrophilic third textile layer 15 is fixedly or detachably connected to the first or second textile layer 11 or 13.

- the first and second textile layers 11, 13 and 12, 14 are detachably connected to each other or form, firmly joined together, a laminate, as in FIG. 3 is shown.

- FIG. 3 further shows the construction of a duvet 1B, which has two breathable zones 3, in which no filling 10 is provided. If stronger air movements occur in these areas, the water vapor is thereby rapidly led to the outside.

- These breathable zones 3 are preferably located outside the area 4, which is above the expected position of the body of the user. For example, the breathable zones 3 are placed in the outer thirds or quarters of the blanket. This prevents the breathable zones 3 from being covered by the body of the user, thereby obstructing the air exchange.

- the peripheral arrangement of the breathable zones 3 also avoids disturbing temperature gradients that occur because the insulation properties of the blanket in the area of the breathable zones is changed, the user's body is exposed to barely perceptible air currents and moisture evaporates on the user's skin or clothing can.

- breathable zones 3 are bounded laterally by the filling 10, which is trapped for example by means of the sewn together upper and lower first textile layers 11, 12. Above and / or below the breathable zone 3 is covered by means of the first and / or the second textile layer 11, 12 or 13, 14 and optionally with an insulating third textile layer 15, through which the insulation value of the blanket in the breathable zones 3 largely is kept constant.

- the breathable zones 3 are covered on both sides by the first and second textile layers 11, 13 and 12, 14.

- the breathable zones 3 are covered on both sides by the hydrophilic second textile layer 13 and a hydrophilic, breathable third textile layer 15.

- FIG. 5 shows the over a symbolically illustrated user designed duvet 1A with a ceiling center part 1A 'and ceiling side panels 1A''on.

- the textile layers 11, ..., 15 of the ceiling middle part 1A ' are shown cut open.

- Shown is also a seam 18, by means of which the two relatively hydrophobic first textile layers 11, 12 are connected to one another. Further, a linen cover 99 is shown.

- the duvet 1A is therefore separable into individual parts, which can be easily stored in a washing machine and washed, which is particularly important in the use of hydrophilic substances.

- FIG. 6 shows the blanket 1B with the hydrophilic second textile layer 13, which is disposed within the area 4, which lies above the expected position of the body of the user and on both sides outside this area 4 lying breathable zones covered 3, Also shown is an insulating third textile layer 15 ' which only covers the breathable zones 3 and harmonizes the insulation properties. The moisture is therefore removed from the body area of the user and discharged laterally over the breathable zones 3.

- a closure piece 3 ' is shown by means of which one of the breathable zones 3 can be locked.

- the end piece 3 ' can be used individually, or be provided on a ceiling part 1B', which is connectable at its edges, for example by means of zipper or Velcro closures with the ceiling part 1B, so that the two ceiling parts 1B, 1B 'one above the other or next to each other.

- FIG. 7 shows the duvet 1A with a ceiling middle part 1A ', which is connected on both sides by means of zippers 2 with two cover side parts 1A'', 1A "'

- the zippers 21 consisting of two parts 21, 22 are covered by insulating tabs 7, the two sides are arranged on the ceiling side parts 1A '', 1A '''and connected to one another at their ends, so that they receive the associated zip fastener 2 in a pocket-like manner and surround it in a ring-like manner

- Ceiling middle part 1A 'replaceable which has a different room climate adapted insulation properties.

- the breathable zones 3 are arranged eccentrically, so that these, depending on the mounting of the ceiling side parts 1A '', 1A '' ', more or less spaced apart and thus adapted to the needs, possibly the body dimensions of the user can.

- the insulating tabs 7 are provided on both sides of the ceiling side parts 1A ", 1A" ', causes the zippers 2 are always reliably covered.

- the bed cover can be extended to a four-part cover by means of the additional ceiling middle part 1A', provided the ceiling side parts 1A ", 1A '' 'are provided on one side only with a portion 22 of the zipper 2, the insulating tabs 7 are preferably only on the central part 1 A' provided.

- the inventive blanket has been described and illustrated in preferred embodiments. On the basis of the teaching according to the invention, however, further expert designs can be realized. Especially Different dimensions of the duvet and the ceiling parts can be selected. Furthermore, various natural and synthetic substances and filling materials can be used. Furthermore, any other shapes and dimensions of the breathable zones 3 can be realized. It is also possible to use differently configured, possibly interlocking, filled or unfilled Isolierlappen. To connect the items and textile layers of the blanket also various types of connection devices, such as zippers, buttons, snaps, Velcro or cords are used.

Landscapes

- Bedding Items (AREA)

- Preparation Of Compounds By Using Micro-Organisms (AREA)

- Superconductors And Manufacturing Methods Therefor (AREA)

- Diaphragms For Electromechanical Transducers (AREA)

Claims (1)

- Couette de lit (lA; 1B), en particulier avec des alvéoles matelassées, en particulier couette matelassée ou duvet à une ou plusieurs parties, avec une garniture hydrophile, isolante à la chaleur (10), qui est prise entre deux premières couches textiles (11; 12) dans une ou plusieurs alvéoles, les premières couches textiles (11; 12) étant respectivement recouvertes d'une seconde couche textile (13; 14), caractérisée en ce que les deux premières couches textiles (11; 12) se composent d'une première matière relativement hydrophobe qui présente des capillaires servant au transport de la vapeur d'eau, et en ce que les secondes couches textiles (13; 14) se composent d'une seconde matière perméable à la vapeur d'eau particulièrement hydrophile en comparaison de la première matière, et que le ratio de la durée de l'absorption d'une goutte d'eau par la matière des deux premières couches de textile (11; 12) et la durée de l'absorption d'une goutte d'eau traversant la matière des deux secondes couches de textile (13, 14) est situé par un facteur 5.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH19602003 | 2003-11-15 | ||

| CH19602003 | 2003-11-15 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1530934A1 EP1530934A1 (fr) | 2005-05-18 |

| EP1530934B1 EP1530934B1 (fr) | 2007-02-28 |

| EP1530934B2 true EP1530934B2 (fr) | 2012-07-04 |

Family

ID=34427765

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04405701A Active EP1530934B2 (fr) | 2003-11-15 | 2004-11-12 | Duvet |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1530934B2 (fr) |

| AT (1) | ATE354998T1 (fr) |

| DE (1) | DE502004003017D1 (fr) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH696923A5 (de) * | 2004-12-24 | 2008-02-15 | Bss Downia Ag | Bettware und Verfahren zu deren Herstellung. |

| IT1397239B1 (it) * | 2009-12-01 | 2013-01-04 | Zecca | Sistema per accogliere un utente seduto o sdraiato. |

| US20230042399A1 (en) * | 2021-08-06 | 2023-02-09 | Misa Amano | Duvet cover having window opening and bedding set including such duvet cover |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB8730252D0 (en) * | 1987-12-29 | 1988-02-03 | Woodcock A | Bedding system |

| CH682977A5 (de) * | 1992-05-12 | 1993-12-31 | Albis Ag Bettwaren | Duvet-Decke. |

| DE19654798A1 (de) * | 1996-12-31 | 1998-07-02 | Kirchhoff International Gmbh M | Zellenkonstruktion für Bettmaterial und dgl. |

| UA76855C2 (uk) * | 2002-05-02 | 2006-09-15 | Сандерс Гмбх | Покривало |

-

2004

- 2004-11-12 AT AT04405701T patent/ATE354998T1/de active

- 2004-11-12 EP EP04405701A patent/EP1530934B2/fr active Active

- 2004-11-12 DE DE502004003017T patent/DE502004003017D1/de active Active

Also Published As

| Publication number | Publication date |

|---|---|

| EP1530934B1 (fr) | 2007-02-28 |

| EP1530934A1 (fr) | 2005-05-18 |

| ATE354998T1 (de) | 2006-03-15 |

| DE502004003017D1 (de) | 2007-04-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2303072B1 (fr) | Couverture et produits apparentés, ainsi que fabrication de ceux-ci | |

| DE69410963T2 (de) | Klimageregelte Bettdecke | |

| EP1499221B1 (fr) | Couverture | |

| DE19542210A1 (de) | Polsterteil, insbesondere Sitzpolster | |

| DE202011103351U1 (de) | Barrieretextilien | |

| EP1530934B2 (fr) | Duvet | |

| CH682977A5 (de) | Duvet-Decke. | |

| AT504387B1 (de) | Isolationsmaterial | |

| DE102009005783B4 (de) | Verfahren zur Herstellung eines Kassettensteppbettes und Kassettensteppbett | |

| DE102005046320B3 (de) | Permeables ABC-Schutzanzugsmaterial, diesbezügliche Verwendung und diesbezüglicher ABC-Schutzanzug | |

| CH698864B1 (de) | Bettdecke. | |

| EP2465390A1 (fr) | Couverture, sac de couchage, vêtement, coussin ayant une structure à extraction de chaleur et d'humidité adaptée au corps et fabrication de ces produits | |

| EP2670281A2 (fr) | Couette, notamment pour lits | |

| DE9201050U1 (de) | Waschbare Windelhose | |

| WO1991001101A1 (fr) | Couverture piquee | |

| DE102011016231B4 (de) | Betteinlage mit Hohlfasern | |

| WO2005116545A1 (fr) | Systeme de refroidissement pour refroidir des surfaces | |

| EP1350452A9 (fr) | Garniture de lit réglant la température et l'humidité | |

| AT391256B (de) | Zudecke mit einer fuellung aus naturfasern, federn und/oder synthetischen fuellmaterialien | |

| CH696923A5 (de) | Bettware und Verfahren zu deren Herstellung. | |

| AT526776A4 (de) | Gewebe | |

| DE202012101005U1 (de) | Schmiegsames Wärmegerät | |

| DE20111640U1 (de) | Belüftungssystem für Bekleidung | |

| EP3636111A1 (fr) | Système de couvre-lit | |

| DE202013105193U1 (de) | Bettdecke mit Feuchtigkeitssensor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK YU |

|

| 17P | Request for examination filed |

Effective date: 20051118 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070228 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070228 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070228 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070228 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 502004003017 Country of ref document: DE Date of ref document: 20070412 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070528 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070608 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: PETER RUTZ |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070628 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20070618 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070730 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070228 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: GEBRUEDER SANDERS GMBH & CO. KG Effective date: 20071126 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070228 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070228 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070228 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: GEBRUEDER SANDERS GMBH & CO. KG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070529 |

|

| PLAF | Information modified related to communication of a notice of opposition and request to file observations + time limit |

Free format text: ORIGINAL CODE: EPIDOSCOBS2 |

|

| BERE | Be: lapsed |

Owner name: ALBIS BETTWARENFABRIK A.G. Effective date: 20071130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071130 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070901 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070228 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20101122 Year of fee payment: 7 Ref country code: FR Payment date: 20101221 Year of fee payment: 7 Ref country code: NL Payment date: 20101122 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20101118 Year of fee payment: 7 Ref country code: IT Payment date: 20101125 Year of fee payment: 7 |

|

| PLBP | Opposition withdrawn |

Free format text: ORIGINAL CODE: 0009264 |

|

| PLAY | Examination report in opposition despatched + time limit |

Free format text: ORIGINAL CODE: EPIDOSNORE2 |

|

| PLBC | Reply to examination report in opposition received |

Free format text: ORIGINAL CODE: EPIDOSNORE3 |

|

| PLAY | Examination report in opposition despatched + time limit |

Free format text: ORIGINAL CODE: EPIDOSNORE2 |

|

| PLBC | Reply to examination report in opposition received |

Free format text: ORIGINAL CODE: EPIDOSNORE3 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20120601 |

|

| 27A | Patent maintained in amended form |

Effective date: 20120704 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AEN Free format text: AUFRECHTERHALTUNG DES PATENTES IN GEAENDERTER FORM |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20111112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120601 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20120731 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 502004003017 Country of ref document: DE Effective date: 20120704 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111112 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 354998 Country of ref document: AT Kind code of ref document: T Effective date: 20111112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111112 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20161121 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004003017 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: NEW ADDRESS: ALPENSTRASSE 14 POSTFACH 7627, 6302 ZUG (CH) |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180602 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20231201 Year of fee payment: 20 |