EP1516545A1 - Machine and method for simultaneously producing a number of cigarette rods - Google Patents

Machine and method for simultaneously producing a number of cigarette rods Download PDFInfo

- Publication number

- EP1516545A1 EP1516545A1 EP04090355A EP04090355A EP1516545A1 EP 1516545 A1 EP1516545 A1 EP 1516545A1 EP 04090355 A EP04090355 A EP 04090355A EP 04090355 A EP04090355 A EP 04090355A EP 1516545 A1 EP1516545 A1 EP 1516545A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- tobacco

- strands

- double

- strand

- double strand

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24C—MACHINES FOR MAKING CIGARS OR CIGARETTES

- A24C5/00—Making cigarettes; Making tipping materials for, or attaching filters or mouthpieces to, cigars or cigarettes

- A24C5/14—Machines of the continuous-rod type

- A24C5/18—Forming the rod

- A24C5/1835—Multiple rod making devices

Definitions

- the invention relates to a device for producing two tobacco rods, the parallel to each other to form a double strand out of at least a continuously supplied tobacco mat, namely cigarette rod machine with a plurality formed for the processing of a double strand Processing elements, essentially comprising a strand conveyor for Transport of the tobacco strands built up from the tobacco mat on two suction belts, Separating means for separating the excess tobacco from the tobacco strands, Corresponding to each suction belt of the strand conveyor, a format belt for molding the tobacco strands, means for feeding cigarette paper to each format strip, Gluing devices for gluing a respective protruding edge of the otherwise cigarette paper wrapped around the tobacco rod, measuring means for determining the cigarette paper Weight and / or the density of the individual tobacco strands of the double strand as well Release agent for separating cigarettes from the double strand.

- the invention relates to a process for the preparation of two Tobacco strands, which led parallel to each other to form a double strand be made of at least one continuously supplied tobacco mat, comprising the Steps: Transporting the tobacco strands built up from the tobacco fleece to two Saugbändem a strand conveyor in the direction of corresponding format strips, Separating the excess tobacco from the tobacco strands prior to forming the tobacco Tobacco strands, feeding cigarette paper on the format tapes, depositing the Tobacco strands on the size tapes or on the cigarette paper, forms the Tobacco strands, simultaneously wrapping the tobacco strands with the cigarette paper, Gluing a respective protruding edge of the otherwise around the tobacco rod wrapped cigarette papers, final closing of the cigarette paper, measuring the Weight and / or density of tobacco strands, and separating cigarettes from Double strand.

- Such devices and methods are commonly used in the tobacco processing industry used.

- the devices mentioned are Usually part of a production line that has a distributor for the tobacco, the actual cigarette rod machine, a transfer unit and a Filter attachment machine includes.

- the cigarette rod machine is from the distributor with a tobacco fleece, a kind of flat tab carpet, supplies.

- the well-known and generic cigarette rod making machines are for the production of a single Double strand formed from two pairs of individual strands, such that the two tobacco strands parallel next to each other as a pair with one for the Machining a double strand formed set of machining elements become.

- a device of the type mentioned achieved that the apparatus for producing at least two pairs arranged double strands is formed.

- the apparatus for producing at least two pairs arranged double strands is formed.

- the pairwise arrangement of Tobacco strands, each with a double strand namely on the one hand a particular dense arrangement of the tobacco strands of a double strand, so that for the processing of two strands (of a double strand) only one processing element necessary is.

- the inventive design also allows a dense Arrangement of the tobacco strands adjacent double strands, while at the same time sufficient Room for the required processing elements for the respective double strand is available.

- Another advantage is that substantially to known Components of a cigarette twin-strand machine can be used.

- the two double strands arranged one above the other which is also a space-saving construction of the Device guaranteed.

- the distance between the two double strands is greater than that Distance between the tobacco strands of a double strand. This will make it possible in a space-saving manner already existing and known (standard) processing elements to use without further adjustment.

- the double strands are driven separately from each other, such that the double strands formed from the tobacco strands independent of each other can be produced.

- the double strands formed from the tobacco strands independent of each other can be produced.

- the object is achieved by a method with the aforementioned Steps solved in that at least two double strands produced simultaneously become. This improves the performance over known methods of the generic type significantly increased, namely doubled.

- the two duplexes during processing offset in height to each other and side by side, so that a special cost-effective and space-saving production is possible.

- the same advantages apply for the variant in which the two double strands are superimposed.

- the two double strands during machining at a distance greater than that of each other Distance between the strands of a double strand. This is the nested Arrangement of the double strands on the one hand and the respective processing elements on the other hand possible in a particularly space-saving manner.

- Characterized in that the double strands driven separately in a further embodiment is an independent operation or an independent manufacture of Double strands in a device possible, so that e.g. different formats can be produced at the same time or with a time delay.

- the device serves for the parallel production of two double strands of tobacco, in which two tobacco strands are arranged in pairs next to each other.

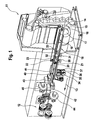

- a device 10 namely the cigarette rod machine with the respectively represented upstream and downstream components.

- the Device 10 On the input side is the Device 10 associated with a manifold 11, which is adapted to the device several streams of tobacco mat, preferably four streams, for further processing supply.

- Downstream of the device is an unspecified Transfer device 12, which produced the device 10 - usually - double-length cigarettes to a downstream processing station, e.g. one (not shown) Filteransetzmaschine passes.

- Each strand conveyor 18, 19 has two Suction belts 20, 21; 22, 23, wherein two suction belts 20, 21 and 22, 23 respectively for Forming one of two tobacco rods 24, 25 and 26, 27 existing Double strands 28, 29 serve.

- the double strands 28, 29 are arranged side by side and run parallel to each other.

- the double strands 28, 29 are in the vertical direction at different Layers arranged so that they are height offset from each other. With others In words, the transport and processing planes of each double strand 28, 29 run at different heights.

- the double strands 28, 29 are arranged directly above one another. This means that e.g. the tobacco rod 24 of the Double strand 28 vertically below the tobacco rod 26 of the double strand 29 and the Tobacco strand 25 of the double strand 28 vertically below the tobacco rod 27 of the Double strand 29 lies.

- Each double strand 28, 29 are each identical editing elements for Production of the four strands 24 to 27 assigned, the Machining elements are designed such that they parallel processing of a Double strands 28 and 29 ensure.

- the distance of the double strand 28 from Double strand 29 at least as large as the distance between individual strands 24, 25 or 26, 27 of a double strand 28, 29, but preferably larger.

- Words is the distance of the adjacent tobacco strands 25 and 26, each one are assigned to other double strand 28 or 29, greater than the distance between the Tobacco strands 24 and 25 or 26 and 27. This parallel guidance of the tobacco strands 24th to 27 or the double strands 28, 29 is during the entire transport and the maintained throughout processing by the device 10.

- the strand conveyors 18, 19 are in the embodiment shown as circumferential, endless belt conveyor designed such that the tobacco is preferably suspended in Transport direction 13 is conveyed. Other types of transport, such as the lying one Transportation is possible.

- the tobacco fleece is each suction belt 20 to 23 for Forming the respective tobacco rod 24 to 27 assigned in a separate lane. Below each suction belt 20 to 23 is a conventional release agent 30, 31, 32, 33 for Trimming the tobacco strands 24 to 27, more precisely, to separate the excess Tobacco, arranged.

- each Suction belt 20 to 23 a format strip 34, 35, 36, 37, wherein the format strips 34, 35 for the continuation of the double strand 28 and the format strips 36, 37 for Continuation of the double strand 29 serve.

- Two format bands 34, 35 and 36, 37, respectively each have a common drive.

- the format bands 34 to 37 are in a plane below the suction belts 20 to 23 arranged and also designed as endless circulating belt conveyor.

- the Format tapes 34 to 37 each run through a format (not shown) Shaping the tobacco strands 24 to 27, namely in particular for shaping cylindrical tobacco rods 24 to 27.

- In the range of size bands 34 to 37 are further means (not shown) for feeding cigarette paper to the Size bands 34 to 37 and gluing devices 38 and 39 serving as nozzles, Discs or the like are formed for gluing the cigarette paper, arranged. Behind the formats are then means 40, 41 for heating or drying the glue seams provided.

- each double strand 28, 29 a measuring means 42, 43 for weight and / or density determination of the tobacco strands 24th assigned to 27.

- the measuring means 42, 43 are parallel in the embodiment shown arranged side by side, but can also be offset from one another. Behind the Measuring means 42, 43 separating means 44 and 45 are arranged before the tobacco strands 24th to 27 of the transfer device 12 are handed over.

- the release agents 44, 45 are each for separating double-length cigarettes of a double strand 28, 29 educated.

- the device 10 is for manufacturing formed an even number of tobacco strands, wherein the tobacco strands respectively arranged in pairs and guided.

- the corresponding components, namely the upstream distributor and the downstream transfer device are then trained accordingly.

- By the separate drive are at least two of the tobacco strands 24 to 27 formed double strands 28, 29th independently producible.

- different formats e.g. different tobacco rod lengths and / or Tobacco stick diameter, producible.

- all double strands 28, 29 or sub-devices can also be driven jointly, e.g. through a overall drive.

- the process for producing two double strands proceeds in principle as follows: From the manifold 11 tobacco is fed in four streams to the device 10. Of the Tobacco is designed as a fleece. About the fluid beds 14 to 17 will each Strand conveyor 18, 19 or each suction belt 20 to 23 of the strand conveyor 18, 19 a uniform part of the nonwoven, wherein the nonwoven within the fluidized beds 14th to 17 by a circulating air flow to the bottom of the suction belts 20 to 23 is pressed or sucked.

- Shuddering of the tobacco is a uniform part of the nonwoven.

- the circumferentially driven suction belts 20 to 23 then transport the tobacco fleece or the tobacco strands 24 to 27 constructed therefrom hanging for further processing, wherein the hanging tobacco strands 24 to 27 by the release agent 30 to 33 are freed from excess tobacco.

- the trimmed Tobacco strands 24 to 27 are then on each of the format tape 34 to 37 placed placed cigarette paper.

- In this area are the format bands 34 to 37 with the cigarette paper positioned thereon and the suction belts 20 to 23 in the Synchronism.

- the cigarette paper is pulled off a bobbin by a Led printing unit and then stored on the respective format tape 34 to 37.

- the Size bands 34 to 37 transport each tobacco rod 24 to 27 and the Cigarette paper by the format in which the cigarette paper around the strand 24 to 27 is wound.

Landscapes

- Manufacturing Of Cigar And Cigarette Tobacco (AREA)

Abstract

Description

Die Erfindung betrifft eine Vorrichtung zur Herstellung von zwei Tabaksträngen, die parallel nebeneinander zur Bildung eines Doppelstranges geführt sind, aus mindestens einem kontinuierlich zugeführten Tabakvlies, nämlich Zigarettenstrangmaschine mit einer Mehrzahl für die Bearbeitung eines Doppelstranges ausgebildeten Bearbeitungselementen, im wesentlichen umfassend einen Strangförderer zum Transport der aus dem Tabakvlies aufgebauten Tabakstränge an zwei Saugbändern, Trennmittel zum Trennen des überschüssigen Tabaks von den Tabaksträngen, korrespondierend zu jedem Saugband des Strangförderers ein Formatband zum Formen der Tabakstränge, Mittel zum Zuführen von Zigarettenpapier auf jedes Formatband, Beleimungseinrichtungen zum Beleimen einer jeweils abstehenden Kante des ansonsten um den Tabakstrang gewickelten Zigarettenpapiers, Meßmittel zum Ermitteln des Gewichts und/oder der Dichte der einzelnen Tabakstränge des Doppelstranges sowie Trennmittel zum Trennen von Zigaretten vom Doppelstrang.The invention relates to a device for producing two tobacco rods, the parallel to each other to form a double strand out of at least a continuously supplied tobacco mat, namely cigarette rod machine with a plurality formed for the processing of a double strand Processing elements, essentially comprising a strand conveyor for Transport of the tobacco strands built up from the tobacco mat on two suction belts, Separating means for separating the excess tobacco from the tobacco strands, Corresponding to each suction belt of the strand conveyor, a format belt for molding the tobacco strands, means for feeding cigarette paper to each format strip, Gluing devices for gluing a respective protruding edge of the otherwise cigarette paper wrapped around the tobacco rod, measuring means for determining the cigarette paper Weight and / or the density of the individual tobacco strands of the double strand as well Release agent for separating cigarettes from the double strand.

Des weiteren betrifft die Erfindung ein Verfahren zur Herstellung von zwei Tabaksträngen, die parallel nebeneinander zur Bildung eines Doppelstranges geführt werden, aus mindestens einem kontinuierlich zugeführten Tabakvlies, umfassend die Schritte: Transportieren der aus dem Tabakvlies aufgebauten Tabakstränge an zwei Saugbändem eines Strangförderers in Richtung korrespondierender Formatbänder, Trennen des überschüssigen Tabaks von den Tabaksträngen vor der Formung der Tabakstränge, Zuführen von Zigarettenpapier auf die Formatbänder, Ablegen der Tabakstränge auf den Formatbändern bzw. auf dem Zigarettenpapier, Formen der Tabakstränge, gleichzeitiges Umwickeln der Tabakstränge mit dem Zigarettenpapier, Beleimen einer jeweils abstehenden Kante des ansonsten um den Tabakstrang gewickelten Zigarettenpapiers, endgültiges Schließen des Zigarettenpapiers, Messen des Gewichts und/oder der Dichte der Tabakstränge, und Trennen von Zigaretten vom Doppelstrang.Furthermore, the invention relates to a process for the preparation of two Tobacco strands, which led parallel to each other to form a double strand be made of at least one continuously supplied tobacco mat, comprising the Steps: Transporting the tobacco strands built up from the tobacco fleece to two Saugbändem a strand conveyor in the direction of corresponding format strips, Separating the excess tobacco from the tobacco strands prior to forming the tobacco Tobacco strands, feeding cigarette paper on the format tapes, depositing the Tobacco strands on the size tapes or on the cigarette paper, forms the Tobacco strands, simultaneously wrapping the tobacco strands with the cigarette paper, Gluing a respective protruding edge of the otherwise around the tobacco rod wrapped cigarette papers, final closing of the cigarette paper, measuring the Weight and / or density of tobacco strands, and separating cigarettes from Double strand.

Derartige Vorrichtungen und Verfahren kommen üblicherweise in der tabakverarbeitenden Industrie zum Einsatz. Die genannten Vorrichtungen sind üblicherweise Teil einer Produktionslinie, die einen Verteiler für den Tabak, die eigentliche Zigarettenstrangmaschine, eine Übergabeeinheit und eine Filteransetzmaschine umfaßt. Die Zigarettenstrangmaschine wird aus dem Verteiler mit einem Tabakvlies, einer Art flächigem Tabakteppich, beliefert. Die bekannten und gattungsgemäßen Zigarettenstrangmaschinen sind zur Herstellung eines einzelnen Doppelstranges aus insgesamt zwei paarweise angeordneten Einzelsträngen ausgebildet, derart, daß die zwei Tabakstränge parallel nebeneinander als Paar mit einem für die Bearbeitung eines Doppelstranges ausgebildeten Satz Bearbeitungselemente hergestellt werden. Dies hat gegenüber bekannten Zigarettenstrangmaschinen, bei denen mehrere einzelne und üblicherweise mit einem gleichen Abstand nebeneinander angeordnete Tabakstränge hergestellt werden, den Vorteil, daß eine kompaktere Bauform erreicht wird. Um mehr als zwei Zigarettenstränge parallel herstellen zu können, ist es grundsätzlich bekannt, mehrere einzelne Zigarettenstränge nebeneinander anzuordnen. Diese Lösung ist vor allem technisch sehr schwer realisierbar, da der Abstand zwischen den einzelnen Strängen sehr begrenzt ist und in der Regel nicht ausreicht, um die Bearbeitungselemente zu positionieren. Schafft man jedoch den erforderlichen Raum für die Bearbeitungselemente, führt dies zwangsläufig zu einem größeren Abstand und damit zu einer Vergrößerung der Bauform insgesamt, da jedem Strang separate Bearbeitungselemente zugeordnet werden müssen. Andernfalls ist der konstruktive Aufwand erheblich. Die Leistungsfähigkeit der bekannten Zigarettenstrangmaschinen zur Herstellung eines einzelnen Doppelstranges ist jedoch begrenzt.Such devices and methods are commonly used in the tobacco processing industry used. The devices mentioned are Usually part of a production line that has a distributor for the tobacco, the actual cigarette rod machine, a transfer unit and a Filter attachment machine includes. The cigarette rod machine is from the distributor with a tobacco fleece, a kind of flat tab carpet, supplies. The well-known and generic cigarette rod making machines are for the production of a single Double strand formed from two pairs of individual strands, such that the two tobacco strands parallel next to each other as a pair with one for the Machining a double strand formed set of machining elements become. This has over known cigarette rod making machines, where several single and usually arranged at an equal distance next to each other Tobacco strands are produced, the advantage that reaches a more compact design becomes. In order to produce more than two cigarette rods in parallel, it is basically known to arrange several individual cigarette rods next to each other. Above all, this solution is technically very difficult to implement, since the distance between the individual strands is very limited and usually insufficient to the Positioning editing elements. But if you manage the required space for the editing elements, this inevitably leads to a greater distance and thus to an increase in the overall design, since each strand separate Editing elements must be assigned. Otherwise, the constructive Effort considerably. The performance of the known cigarette rod making machines however, to produce a single duplex is limited.

Es ist daher Aufgabe der vorliegenden Erfindung, eine kompakte und einfach handhabbare Vorrichtung zur parallelen Herstellung von mehr als zwei Tabaksträngen zu schaffen. Des weiteren ist es Aufgabe der vorliegenden Erfindung, ein Verfahren vorzuschlagen, das auf einfache und kompakte Weise die Herstellung von mehr als zwei Tabaksträngen gleichzeitig ermöglicht. It is therefore an object of the present invention to provide a compact and simple Handleable device for the parallel production of more than two tobacco strands to accomplish. Furthermore, it is an object of the present invention, a method to propose, in a simple and compact way, the production of more than two Tobacco strands simultaneously allows.

Diese Aufgabe wird durch eine Vorrichtung der eingangs erwähnten Gattung dadurch erreicht, daß die Vorrichtung zur Herstellung von mindestens zwei paarweise angeordneten Doppelsträngen ausgebildet ist. Mit einer solchen Vorrichtung ist auf überraschend einfache Weise eine besonders kompakte Vorrichtung realisiert, die eine effektive Erhöhung der Leistungsfähigkeit gewährleistet. Die paarweise Anordnung der Tabakstränge zu je einem Doppelstrang ermöglicht nämlich zum einen eine besonders dichte Anordnung der Tabakstränge eines Doppelstranges, so daß zur Bearbeitung von zwei Strängen (eines Doppelstranges) jeweils nur ein Bearbeitungselement notwendig ist. Zum anderen ermöglicht die erfindungsgemäße Ausbildung auch eine dichte Anordnung der Tabakstränge benachbarter Doppelstränge, wobei zugleich ausreichend Raum für die erforderlichen Bearbeitungselemente für den jeweiligen Doppelstrang vorhanden ist. Ein weiterer Vorteil besteht darin, daß im wesentlichen auf bekannte Komponenten einer Zigarettendoppelstrangmaschine zurückgegriffen werden kann.This object is achieved by a device of the type mentioned achieved that the apparatus for producing at least two pairs arranged double strands is formed. With such a device is on Surprisingly simple way, a particularly compact device realized, the one effective increase in performance guaranteed. The pairwise arrangement of Tobacco strands, each with a double strand, namely on the one hand a particular dense arrangement of the tobacco strands of a double strand, so that for the processing of two strands (of a double strand) only one processing element necessary is. On the other hand, the inventive design also allows a dense Arrangement of the tobacco strands adjacent double strands, while at the same time sufficient Room for the required processing elements for the respective double strand is available. Another advantage is that substantially to known Components of a cigarette twin-strand machine can be used.

In einer besonders bevorzugten Ausführungsform der Erfindung sind zwei Doppelstränge höhenversetzt zueinander und nebeneinander angeordnet. Durch diese versetzte Anordnung ist eine besonders platzsparende Anordnung der Bearbeitungselemente gewährleistet, die eine leistungsstarke und sehr kompakte Vorrichtung ermöglicht.In a particularly preferred embodiment of the invention are two Double strands offset in height and arranged side by side. Through this staggered arrangement is a particularly space-saving arrangement of Machining elements ensures a powerful and very compact Device allows.

In einer weiteren vorteilhaften Ausführungsform sind die zwei Doppelstränge übereinander angeordnet, was ebenfalls eine platzsparende Konstruktion der Vorrichtung gewährleistet.In a further advantageous embodiment, the two double strands arranged one above the other, which is also a space-saving construction of the Device guaranteed.

Vorzugsweise ist der Abstand zwischen den beiden Doppelsträngen größer als der Abstand zwischen den Tabaksträngen eines Doppelstranges. Dadurch wird es möglich, in platzsparender Weise bereits vorhandene und bekannte (Standard-)Bearbeitungselemente ohne weitere Anpassung zu verwenden.Preferably, the distance between the two double strands is greater than that Distance between the tobacco strands of a double strand. This will make it possible in a space-saving manner already existing and known (standard) processing elements to use without further adjustment.

Vorteilhafterweise sind die Doppelstränge separat voneinander antreibbar, derart, daß die aus den Tabaksträngen gebildeten Doppelstränge unabhängig voneinander herstellbar sind. Dadurch können z.B. unterschiedliche Zigarettenmarken auch mit unterschiedlichen Formaten auf einer Vorrichtung hergestellt werden.Advantageously, the double strands are driven separately from each other, such that the double strands formed from the tobacco strands independent of each other can be produced. Thereby, e.g. different cigarette brands also with different formats are produced on a device.

Des weiteren wird die Aufgabe durch ein Verfahren mit den eingangs genannten Schritten dadurch gelöst, daß mindestens zwei Doppelstränge gleichzeitig hergestellt werden. Dadurch wird die Leistungsfähigkeit gegenüber bekannten Verfahren der gattungsgemäßen Art deutlich erhöht, nämlich verdoppelt.Furthermore, the object is achieved by a method with the aforementioned Steps solved in that at least two double strands produced simultaneously become. This improves the performance over known methods of the generic type significantly increased, namely doubled.

Vorteilhafterweise werden die beiden Doppelstränge während der Bearbeitung höhenversetzt zueinander und nebeneinander geführt, so daß eine besonders kostengünstige und platzsparende Herstellung ermöglicht ist. Dieselben Vorteile gelten für die Variante, in der die beiden Doppelstränge übereinander geführt werden.Advantageously, the two duplexes during processing offset in height to each other and side by side, so that a special cost-effective and space-saving production is possible. The same advantages apply for the variant in which the two double strands are superimposed.

In einer bevorzugten Weiterbildung der Erfindung werden die beiden Doppelstränge während der Bearbeitung in einem Abstand zueinander geführt, der größer ist als der Abstand zwischen den Strängen eines Doppelstranges. Dadurch ist die verschachtelte Anordnung der Doppelstränge einerseits und der jeweiligen Bearbeitungselemente andererseits in besonders platzsparender Weise möglich.In a preferred embodiment of the invention, the two double strands during machining at a distance greater than that of each other Distance between the strands of a double strand. This is the nested Arrangement of the double strands on the one hand and the respective processing elements on the other hand possible in a particularly space-saving manner.

Dadurch, daß die Doppelstränge in einer weiteren Ausführungsform separat angetrieben werden, ist ein unabhängiger Betrieb bzw. eine unabhängige Herstellung von Doppelsträngen in einer Vorrichtung möglich, so daß z.B. unterschiedliche Formate zeitgleich oder zeitversetzt hergestellt werden können.Characterized in that the double strands driven separately in a further embodiment is an independent operation or an independent manufacture of Double strands in a device possible, so that e.g. different formats can be produced at the same time or with a time delay.

Weitere bevorzugte Merkmale und Ausführungsformen ergeben sich aus den Unteransprüchen und der Beschreibung. Eine besonders vorteilhafte Ausführungsform sowie das Verfahren werden anhand der beigefügten Zeichnung näher erläutert. In der Zeichnung zeigt:

- Fig. 1

- eine schematische Darstellung einer Zigarettenstrangmaschine, bei der die Doppelstränge höhenversetzt zueinander und nebeneinander angeordnet sind, mit vorgeschaltetem Verteiler und nachgeordneter Übergabevorrichtung,

- Fig. 2

- eine Ausschnittsvergrößerung aus Figur 1, nämlich den Strangförderer mit den Trennelementen zum Trennen des überschüssigen Tabaks von den Tabaksträngen,

- Fig. 3

- eine Ausschnittsvergrößerung aus Figur 1, nämlich die Meßeinrichtung zur Ermittlung des Gewichts und/oder der Dichte der Stränge mit den Trennelementen zur Trennung von doppeltlangen Zigaretten von den Tabaksträngen sowie die Übergabevorrichtung, und

- Fig. 4

- eine schematische Darstellung einer weiteren Zigarettenstrangmaschine, bei der die Doppelstränge übereinander angeordnet sind.

- Fig. 1

- a schematic representation of a cigarette rod making machine, in which the double strands are offset in height and arranged side by side, with upstream distributor and downstream transfer device,

- Fig. 2

- 1 is an enlarged detail of FIG. 1, namely the strand conveyor with the separating elements for separating the excess tobacco from the tobacco strands;

- Fig. 3

- an enlarged detail of Figure 1, namely the measuring device for determining the weight and / or density of the strands with the separating elements for the separation of double-length cigarettes from the tobacco strands and the transfer device, and

- Fig. 4

- a schematic representation of another cigarette rod machine, in which the double strands are arranged one above the other.

Die Vorrichtung dient zur parallelen Herstellung von zwei Doppelsträngen aus Tabak, bei denen jeweils zwei Tabakstränge paarweise nebeneinander angeordnet sind.The device serves for the parallel production of two double strands of tobacco, in which two tobacco strands are arranged in pairs next to each other.

Aus der Figur 1 ist eine Vorrichtung 10, nämlich die Zigarettenstrangmaschine mit den

jeweils vor- bzw. nachgeordneten Komponenten dargestellt. Eingangsseitig ist der

Vorrichtung 10 ein Verteiler 11 zugeordnet, der dazu ausgebildet ist, der Vorrichtung

mehrere Ströme aus Tabakvlies, vorzugsweise vier Ströme, zur weiteren Bearbeitung

zuzuführen. Der Vorrichtung nachgeordnet ist eine nicht näher beschriebene

Übergabevorrichtung 12, die die auf der Vorrichtung 10 produzierten - üblicherweise -

doppeltlangen Zigaretten an eine nachgeordnete Bearbeitungsstation, z.B. eine (nicht

dargestellte) Filteransetzmaschine übergibt.From the figure 1 is a

An den Verteiler 11 schließen sich in Transportrichtung des Tabaks (siehe Pfeil 13) vier

Fließbetten 14, 15, 16 und 17 an. Die Fließbetten 14 bis 17 dienen zur kontinuierlichen

Förderung des als Vlies vorliegenden Tabaks an zwei in Transportrichtung 13

nachgeordnete Strangförderer 18 und 19. Jeder Strangförderer 18, 19 weist zwei

Saugbänder 20, 21; 22, 23 auf, wobei zwei Saugbänder 20, 21 bzw. 22, 23 jeweils zur

Bildung eines aus jeweils zwei Tabaksträngen 24, 25 bzw. 26, 27 bestehenden

Doppelstranges 28, 29 dienen. To the distributor 11 close in the transport direction of the tobacco (see arrow 13) four

Die Doppelstränge 28, 29 sind nebeneinander angeordnet und verlaufen parallel

zueinander. Die Doppelstränge 28, 29 sind in vertikaler Richtung auf unterschiedlichen

Ebenen angeordnet, so daß sie höhenversetzt zueinander ausgebildet sind. Mit anderen

Worten verlaufen die Transport- und Bearbeitungsebenen jedes Doppelstranges 28, 29

in unterschiedlicher Höhe. Alternativ ist es auch möglich, daß die Doppelstränge 28, 29

direkt übereinander angeordnet sind. Das bedeutet, daß z.B. der Tabakstrang 24 des

Doppelstrangs 28 vertikal unterhalb des Tabakstrangs 26 des Doppelstrangs 29 und der

Tabakstrang 25 des Doppelstrangs 28 vertikal unterhalb des Tabakstrangs 27 des

Doppelstrangs 29 liegt.The

Jedem Doppelstrang 28, 29 sind jeweils baugleiche Bearbeitungselemente zur

Herstellung der insgesamt vier Stränge 24 bis 27 zugeordnet, wobei die

Bearbeitungselemente derart ausgebildet sind, daß sie die parallele Bearbeitung eines

Doppelstranges 28 bzw. 29 gewährleisten. Insbesondere mit Bezug auf die in den

Figuren 1 bis 3 gezeigte Ausführungsform ist der Abstand des Doppelstranges 28 vom

Doppelstrang 29 mindestens so groß wie der Abstand zwischen einzelnen Strängen 24,

25 bzw. 26, 27 eines Doppelstranges 28, 29, vorzugsweise jedoch größer. Mit anderen

Worten ist der Abstand der benachbarten Tabakstränge 25 und 26, die jeweils einem

anderen Doppelstrang 28 bzw. 29 zugeordnet sind, größer als der Abstand zwischen den

Tabaksträngen 24 und 25 bzw. 26 und 27. Diese parallele Führung der Tabakstränge 24

bis 27 bzw. der Doppelstränge 28, 29 ist während des gesamten Transports und der

gesamten Bearbeitung durch die Vorrichtung 10 beibehalten.Each

Die Strangförderer 18, 19 sind in der gezeigten Ausführungsform als umlaufende,

endlose Bandförderer derart ausgebildet, daß der Tabak vorzugsweise hängend in

Transportrichtung 13 förderbar ist. Auch andere Transportarten, wie z.B. der liegende

Transport, sind möglich. Das Tabakvlies ist dabei jedem Saugband 20 bis 23 zur

Bildung des jeweiligen Tabakstranges 24 bis 27 in einer separaten Bahn zugeordnet.

Unterhalb jedes Saugbandes 20 bis 23 ist ein übliches Trennmittel 30, 31, 32, 33 zum

Trimmen der Tabakstränge 24 bis 27, genauer zum Abtrennen des überschüssigen

Tabaks, angeordnet. In Transportrichtung 13 kurz hinter den Trennmitteln 30 bis 33 und

kurz bevor die Saugbänder 20 bis 23 auslaufen, ist korrespondierend zu jedem

Saugband 20 bis 23 ein Formatband 34, 35, 36, 37 angeordnet, wobei die Formatbänder

34, 35 zur Weiterführung des Doppelstranges 28 und die Formatbänder 36, 37 zur

Weiterführung des Doppelstranges 29 dienen. Zwei Formatbänder 34, 35 bzw. 36, 37

haben jeweils einen gemeinsamen Antrieb. Im Bereich der Überschneidung der

Saugbänder 20 bis 23 einerseits und der Formatbänder 34 bis 37 andererseits erfolgt die

Übergabe des Tabakvlies von den Saugbändern 20 bis 23 auf die Formatbänder 34 bis

37.The strand conveyors 18, 19 are in the embodiment shown as circumferential,

endless belt conveyor designed such that the tobacco is preferably suspended in

Die Formatbänder 34 bis 37 sind in einer Ebene unterhalb der Saugbänder 20 bis 23

angeordnet und ebenfalls als endlos umlaufende Bandförderer ausgebildet. Die

Formatbänder 34 bis 37 laufen jeweils durch ein (nicht dargestelltes) Format zur

Formgebung der Tabakstränge 24 bis 27, nämlich insbesondere zur Formung

zylindrischer Tabakstränge 24 bis 27. Im Bereich der Formatbänder 34 bis 37 sind

weiterhin (nicht dargestellte) Mittel zur Zuführung von Zigarettenpapier auf die

Formatbänder 34 bis 37 sowie Beleimungseinrichtungen 38 und 39, die als Düsen,

Scheiben oder dergleichen zum Beleimen des Zigarettenpapiers ausgebildet sind,

angeordnet. Hinter den Formaten sind dann Mittel 40, 41 zum Heizen bzw. Trocknen

der Leimnähte vorgesehen. Weiter in Transportrichtung 13 ist jedem Doppelstrang 28,

29 ein Meßmittel 42, 43 zur Gewichts- und/oder Dichteermittlung der Tabakstränge 24

bis 27 zugeordnet. Die Meßmittel 42, 43 sind in der gezeigten Ausführungsform parallel

nebeneinander angeordnet, können jedoch auch versetzt zueinander liegen. Hinter den

Meßmitteln 42, 43 sind Trennmittel 44 und 45 angeordnet, bevor die Tabakstränge 24

bis 27 der Übergabevorrichtung 12 übergeben werden. Die Trennmittel 44, 45 sind

jeweils zum Trennen von doppeltlangen Zigaretten eines Doppelstranges 28, 29

ausgebildet.The

In weiteren nicht dargestellten Ausführungsformen können auch mehr als zwei

Doppelstrangpaare nebeneinander und/oder höhenversetzt zueinander oder auch

übereinander angeordnet sein. Vorteilhafterweise ist die Vorrichtung 10 zur Herstellung

einer geraden Anzahl von Tabaksträngen ausgebildet, wobei die Tabakstränge jeweils

paarweise angeordnet und geführt sind. Die korrespondierenden Komponenten, nämlich

der vorgeschaltete Verteiler und die nachgeordnete Übergabevorrichtung sind dann

entsprechend ausgebildet. In further embodiments, not shown, more than two

Double strand pairs next to each other and / or offset in height to each other or even

be arranged one above the other. Advantageously, the

Wie bereits zu der Ausführungsform gemäß der Figuren 1 bis 3 erwähnt, sind sämtliche

Bearbeitungselemente bzw. Funktionselemente oder Funktionen redundant vorhanden,

nämlich für jeden Doppelstrang 28, 29, wobei die Bearbeitungselemente, die jeweils zur

Bearbeitung eines Doppelstrangs 28, 29 ausgebildet sind, entsprechend der

übereinander angeordneten Doppelstränge 28, 29 ebenfalls übereinander angeordnet

sind.As already mentioned for the embodiment according to the figures 1 to 3, all are

Machining elements or functional elements or functions redundant,

namely for each

Für sämtliche Ausführungsformen ist der Betrieb der Vorrichtung 10, die in den

gezeigten Ausführungsformen quasi aus zwei Teilvorrichtungen, nämlich für jeden

Doppelstrang 28, 29 eine Teilvorrichtung, in einem gemeinsamen Gehäuse besteht,

variabel. Das bedeutet, daß die Doppelstränge 28, 29 bzw. die jeweiligen

Teilvorrichtungen dazu separat antreibbar sind. Das kann z.B. durch Zuordnung von

Einzelantrieben für jeden Doppelstrang 28, 29 erfolgen. Durch den getrennten Antrieb

sind mindestens zwei aus den Tabaksträngen 24 bis 27 gebildete Doppelstränge 28, 29

unabhängig voneinander herstellbar. Somit sind mit der Vorrichtung 10 zeitgleich oder

zeitversetzt unterschiedliche Formate, z.B. unterschiedliche Tabakstocklängen und/oder

Tabakstockdurchmesser, herstellbar. Selbstverständlich sind sämtliche Doppelstränge

28, 29 bzw. Teilvorrichtungen auch gemeinsam antreibbar, z.B. durch einen

übergeordneten Gesamtantrieb.For all embodiments, the operation of the

Das Verfahren zur Herstellung von zwei Doppelsträngen läuft prinzipiell wie folgt ab:

Aus dem Verteiler 11 wird Tabak in vier Strömen an die Vorrichtung 10 geführt. Der

Tabak ist als Vlies ausgebildet. Über die Fließbetten 14 bis 17 wird jedem

Strangförderer 18, 19 bzw. jedem Saugband 20 bis 23 der Strangförderer 18, 19 ein

gleichmäßiger Teil des Vlies zugeführt, wobei das Vlies innerhalb der Fließbetten 14

bis 17 durch eine zirkulierenden Luftstrom an die Unterseite der Saugbänder 20 bis 23

gedrückt bzw. gesogen wird. Man spricht in diesem Zusammenhang auch vom

Aufschauern des Tabaks. Die umlaufend angetriebenen Saugbänder 20 bis 23

transportieren das Tabakvlies bzw. die daraus aufgebauten Tabakstränge 24 bis 27 dann

hängend zur weiteren Bearbeitung, wobei die hängenden Tabakstränge 24 bis 27 durch

die Trennmittel 30 bis 33 von überschüssigem Tabak befreit werden. Die getrimmten

Tabakstränge 24 bis 27 werden dann auf das jeweils auf dem Formatband 34 bis 37

plazierte Zigarettenpapier gelegt. In diesem Bereich sind die Formatbänder 34 bis 37

mit dem darauf positionierten Zigarettenpapier sowie die Saugbänder 20 bis 23 im

Gleichlauf. Das Zigarettenpapier wird von einer Bobine abgezogen, durch ein

Druckwerk geführt und dann auf das jeweilige Formatband 34 bis 37 abgelegt. Die

Formatbänder 34 bis 37 transportieren jeden Tabakstrang 24 bis 27 und das

Zigarettenpapier durch das Format, in dem das Zigarettenpapier um den Strang 24 bis

27 gewickelt wird. Dabei wird eine Kante stehen gelassen, die von den

Beleimungsdüsen 38, 39 beleimt wird. Die zwei Kanten der Stränge 24, 25 bzw. 26, 27

eines Doppelstranges 28 bzw. 29 werden jeweils gemeinsam beleimt. Anschließend

wird die Klebnaht geschlossen und mittels der Mittel 40, 41 doppelstrangweise

getrocknet. Die so hergestellten Doppelstränge 28, 29 durchlaufen dann jeweils das

Meßmittel 42, 43, das die Trennmittel 30 bis 33 steuert. Im anschließenden Schritt

werden Zigaretten von jedem Tabakstrang 24 bis 27 abgetrennt, wobei das Abtrennen

wiederum paarweise erfolgt. Mit anderen Worten trennt das Trennmittel 44 die Stränge

24, 25 und das Trennmittel 45 die Stränge 26, 27. Mittels der Übergabevorrichtung

werden die Zigaretten zur nachfolgenden Bearbeitung überführt.The process for producing two double strands proceeds in principle as follows:

From the manifold 11 tobacco is fed in four streams to the

Claims (21)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL04090355T PL1516545T3 (en) | 2003-09-16 | 2004-09-16 | Machine and method for simultaneously producing a number of cigarette rods |

| EP04090355A EP1516545B1 (en) | 2003-09-16 | 2004-09-16 | Machine and method for simultaneously producing a number of cigarette rods |

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP03090297 | 2003-09-16 | ||

| EP03090297 | 2003-09-16 | ||

| EP04090024 | 2004-01-24 | ||

| EP04090024 | 2004-01-24 | ||

| EP04090355A EP1516545B1 (en) | 2003-09-16 | 2004-09-16 | Machine and method for simultaneously producing a number of cigarette rods |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1516545A1 true EP1516545A1 (en) | 2005-03-23 |

| EP1516545A8 EP1516545A8 (en) | 2005-06-15 |

| EP1516545B1 EP1516545B1 (en) | 2008-07-16 |

Family

ID=34198555

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04090355A Expired - Lifetime EP1516545B1 (en) | 2003-09-16 | 2004-09-16 | Machine and method for simultaneously producing a number of cigarette rods |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1516545B1 (en) |

| PL (1) | PL1516545T3 (en) |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1726223A3 (en) * | 2005-05-25 | 2007-08-15 | Hauni Maschinenbau Aktiengesellschaft | Apparatus for processing and/or producing rod-shaped articles of tobacco processing industry |

| EP1825767A1 (en) * | 2006-02-24 | 2007-08-29 | Hauni Maschinenbau AG | Strömungskörper einer Zigarettenstrangmaschine |

| EP1872671A1 (en) * | 2006-06-30 | 2008-01-02 | Hauni Maschinenbau AG | Valve body in a rod processing machine in the tobacco industry |

| EP2255681A1 (en) * | 2009-05-26 | 2010-12-01 | HAUNI Maschinenbau AG | String machine for the tobacco processing industry |

| EP2641489A2 (en) | 2012-03-20 | 2013-09-25 | HAUNI Maschinenbau AG | Measurement device, designed and configured to produce measurements of strands and/or strand sections in tobacco processing industry as well as a strand unit with such a measuring device |

| EP2641488A2 (en) | 2012-03-20 | 2013-09-25 | HAUNI Maschinenbau AG | Measuring assembly for measuring strands produced and conveyed in rod-making machines in the tobacco processing industry |

| DE102012102340A1 (en) | 2012-03-20 | 2013-09-26 | Hauni Maschinenbau Ag | Measuring arrangement i.e. 2-channel measuring arrangement, for measuring e.g. strands of tobacco processing industry, has measuring modules attached at base plate, and slots pluggable with module carriers according to slot selection |

| DE102012104613A1 (en) * | 2012-05-29 | 2013-12-05 | Hauni Maschinenbau Ag | Arrangement and method for producing article strands of coated fiber material of the tobacco processing industry |

| EP2674045A2 (en) | 2012-06-13 | 2013-12-18 | HAUNI Maschinenbau AG | Measurement module and measuring arrangement for measuring rods and/or rod sections manufactured in rod makers of the tobacco processing industry as well as rod makers with such measurement modules respectivley such a measuring arrangement |

| CN104621712A (en) * | 2013-11-11 | 2015-05-20 | 豪尼机械制造股份公司 | System and method for the manufacture of rod-shaped smoking articles with filters |

| DE102014107747A1 (en) | 2014-06-03 | 2015-12-03 | Hauni Maschinenbau Ag | Measuring module, measuring arrangement and stranding machine in the tobacco processing industry |

| EP2666372A3 (en) * | 2012-05-21 | 2015-12-09 | HAUNI Maschinenbau AG | Rod forming device and rod machine for the tobacco processing industry |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB216868A (en) * | 1923-05-30 | 1925-06-18 | Tescawi Zigaretten Vertriebsge | Multiple continuous rod cigarette machine |

| US4336812A (en) | 1979-05-22 | 1982-06-29 | G.D. Societa Per Azioni | Machine for simultaneously producing two continuous cigarette rods |

| US4848369A (en) | 1987-03-28 | 1989-07-18 | Korber Ag | Method of and machine for simultaneously making two or more rods from fibrous material |

| US4858626A (en) | 1986-12-17 | 1989-08-22 | G.D. Societa' Per Azioni | Method of optimizing the standard weight variation of cigarettes on a dual-rod cigarette manufacturing machine |

| US4889138A (en) | 1986-06-11 | 1989-12-26 | Korber Ag | Method of and apparatus for simultaneously making plural tobacco streams |

| US4893640A (en) * | 1987-12-12 | 1990-01-16 | Korber Ag | Multiple-rod cigarette making machine |

| US4924885A (en) * | 1987-11-25 | 1990-05-15 | Korber Ag | Method of and apparatus for building, guiding and trimming streams of fibrous material |

| EP0755636A1 (en) * | 1995-07-27 | 1997-01-29 | G.D Societa' Per Azioni | Method and machine for simultaneously producing a number of cigarette rods |

| EP1364588A1 (en) * | 2002-05-21 | 2003-11-26 | Hauni Maschinenbau AG | Arrangement and method for the formation of at least two tobacco rods in a cigarette rod making machine |

-

2004

- 2004-09-16 EP EP04090355A patent/EP1516545B1/en not_active Expired - Lifetime

- 2004-09-16 PL PL04090355T patent/PL1516545T3/en unknown

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB216868A (en) * | 1923-05-30 | 1925-06-18 | Tescawi Zigaretten Vertriebsge | Multiple continuous rod cigarette machine |

| US4336812A (en) | 1979-05-22 | 1982-06-29 | G.D. Societa Per Azioni | Machine for simultaneously producing two continuous cigarette rods |

| US4889138A (en) | 1986-06-11 | 1989-12-26 | Korber Ag | Method of and apparatus for simultaneously making plural tobacco streams |

| US4858626A (en) | 1986-12-17 | 1989-08-22 | G.D. Societa' Per Azioni | Method of optimizing the standard weight variation of cigarettes on a dual-rod cigarette manufacturing machine |

| US4848369A (en) | 1987-03-28 | 1989-07-18 | Korber Ag | Method of and machine for simultaneously making two or more rods from fibrous material |

| US4924885A (en) * | 1987-11-25 | 1990-05-15 | Korber Ag | Method of and apparatus for building, guiding and trimming streams of fibrous material |

| US4893640A (en) * | 1987-12-12 | 1990-01-16 | Korber Ag | Multiple-rod cigarette making machine |

| EP0755636A1 (en) * | 1995-07-27 | 1997-01-29 | G.D Societa' Per Azioni | Method and machine for simultaneously producing a number of cigarette rods |

| EP1364588A1 (en) * | 2002-05-21 | 2003-11-26 | Hauni Maschinenbau AG | Arrangement and method for the formation of at least two tobacco rods in a cigarette rod making machine |

Cited By (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1726223A3 (en) * | 2005-05-25 | 2007-08-15 | Hauni Maschinenbau Aktiengesellschaft | Apparatus for processing and/or producing rod-shaped articles of tobacco processing industry |

| EP1825767A1 (en) * | 2006-02-24 | 2007-08-29 | Hauni Maschinenbau AG | Strömungskörper einer Zigarettenstrangmaschine |

| CN101023809B (en) * | 2006-02-24 | 2012-06-27 | 豪尼机械制造股份公司 | Guiding member of cigarette rolling machine |

| EP1872671A1 (en) * | 2006-06-30 | 2008-01-02 | Hauni Maschinenbau AG | Valve body in a rod processing machine in the tobacco industry |

| EP2255681A1 (en) * | 2009-05-26 | 2010-12-01 | HAUNI Maschinenbau AG | String machine for the tobacco processing industry |

| DE102012102340A1 (en) | 2012-03-20 | 2013-09-26 | Hauni Maschinenbau Ag | Measuring arrangement i.e. 2-channel measuring arrangement, for measuring e.g. strands of tobacco processing industry, has measuring modules attached at base plate, and slots pluggable with module carriers according to slot selection |

| EP2641488A2 (en) | 2012-03-20 | 2013-09-25 | HAUNI Maschinenbau AG | Measuring assembly for measuring strands produced and conveyed in rod-making machines in the tobacco processing industry |

| DE102012102338A1 (en) | 2012-03-20 | 2013-09-26 | Hauni Maschinenbau Ag | Measuring arrangement for measuring strands produced and conveyed in extrusion machines of the tobacco processing industry |

| EP2641489A2 (en) | 2012-03-20 | 2013-09-25 | HAUNI Maschinenbau AG | Measurement device, designed and configured to produce measurements of strands and/or strand sections in tobacco processing industry as well as a strand unit with such a measuring device |

| EP2666372A3 (en) * | 2012-05-21 | 2015-12-09 | HAUNI Maschinenbau AG | Rod forming device and rod machine for the tobacco processing industry |

| DE102012104613A1 (en) * | 2012-05-29 | 2013-12-05 | Hauni Maschinenbau Ag | Arrangement and method for producing article strands of coated fiber material of the tobacco processing industry |

| WO2013178620A1 (en) * | 2012-05-29 | 2013-12-05 | Hauni Maschinenbau Ag | Arrangement and method for producing article rods from sheathed fibre material in the tobacco‑processing industry |

| EP2674045A2 (en) | 2012-06-13 | 2013-12-18 | HAUNI Maschinenbau AG | Measurement module and measuring arrangement for measuring rods and/or rod sections manufactured in rod makers of the tobacco processing industry as well as rod makers with such measurement modules respectivley such a measuring arrangement |

| DE102012105121A1 (en) | 2012-06-13 | 2013-12-19 | Hauni Maschinenbau Ag | Measuring module and measuring arrangement for measuring extrudates and / or strand sections produced in extrusion machines of the tobacco-processing industry, as well as a stranding machine with such measuring modules or such a measuring arrangement |

| CN104621712A (en) * | 2013-11-11 | 2015-05-20 | 豪尼机械制造股份公司 | System and method for the manufacture of rod-shaped smoking articles with filters |

| EP2883463A1 (en) * | 2013-11-11 | 2015-06-17 | HAUNI Maschinenbau AG | Assembly and method for the manufacture of rod-shaped smoking articles with filters |

| CN104621712B (en) * | 2013-11-11 | 2018-10-12 | 虹霓机械制造有限公司 | System and method for manufacturing the stick tobacco product for being equipped with filter tip |

| DE102014107747A1 (en) | 2014-06-03 | 2015-12-03 | Hauni Maschinenbau Ag | Measuring module, measuring arrangement and stranding machine in the tobacco processing industry |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1516545B1 (en) | 2008-07-16 |

| PL1516545T3 (en) | 2008-11-28 |

| EP1516545A8 (en) | 2005-06-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE19823954C2 (en) | Method and apparatus for forming air-applied absorbent fiber cores | |

| DE69307962T2 (en) | Process for the production of filter cigarettes | |

| EP1516545B1 (en) | Machine and method for simultaneously producing a number of cigarette rods | |

| EP2263956B9 (en) | Transport device for transporting printed products and assembly with such a transport device | |

| DE102010033871A1 (en) | Double lane machine and method for producing multiple filters for cigarettes, cigars or the like | |

| EP2363029A1 (en) | Transport drum for the tobacco processing industry | |

| EP1568288A1 (en) | Method and apparatus for removing foreign materials from tobacco | |

| EP1638419B1 (en) | Double-belt filter assembly machine, and production of filter cigarettes | |

| DE69720843T2 (en) | Object handling method | |

| DE102015001618A1 (en) | Method and device for producing a rod-shaped article made of vegetable foil | |

| EP0680916B1 (en) | Method for handling printed products | |

| EP1779739B1 (en) | Apparatus for feeding filters | |

| DE3432729C2 (en) | ||

| DE3509711A1 (en) | DEVICE FOR SUPPLYING CIGARETTES FOR THE COVERING DISTANCE OF A PACKING MACHINE | |

| DE102013222918B3 (en) | Arrangement and method for the production of filter-provided rod-shaped smoking articles | |

| DE3733435A1 (en) | METHOD FOR MOLDING, FOLDING, AND PRESSING BOOKS AND MACHINE FOR ITS IMPLEMENTATION | |

| EP2172345A1 (en) | Method for manufacturing book blocks joind together with adhesive and device for executing the method | |

| DE2614350B2 (en) | Device for conveying cylindrical rod-shaped objects in the tobacco industry | |

| WO2007062534A1 (en) | Method of, and apparatus for, optionally processing printed products | |

| DE102010019661A1 (en) | Apparatus and method for filling trays with rod-shaped articles and production machine for rod-shaped articles with such a device | |

| EP3415463B1 (en) | Arrangement of sections of a string of springs for the manufacture of a spring core | |

| EP3262959B1 (en) | Positioning of rod-shaped articles of the tobacco processing industry into an insertion device | |

| DE2540650A1 (en) | DEVICE FOR TRANSFERRING CROSS-AXIAL FILTER PLUGS IN LONG-AXIAL DIRECTION ON A STRIP OF COVERING MATERIAL | |

| WO2013178620A1 (en) | Arrangement and method for producing article rods from sheathed fibre material in the tobacco‑processing industry | |

| EP1629735B1 (en) | Apparatus for feeding filters |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: HAUNI MASCHINENBAU AG |

|

| TPAC | Observations filed by third parties |

Free format text: ORIGINAL CODE: EPIDOSNTIPA |

|

| 17P | Request for examination filed |

Effective date: 20050922 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20060324 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 502004007594 Country of ref document: DE Date of ref document: 20080828 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081027 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081216 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081016 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| BERE | Be: lapsed |

Owner name: HAUNI MASCHINENBAU A.G. Effective date: 20080930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080930 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 |

|

| 26N | No opposition filed |

Effective date: 20090417 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20090529 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080916 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081016 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080916 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090117 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080716 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081017 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20110922 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20110927 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20130401 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120930 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130401 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20130821 Year of fee payment: 10 Ref country code: GB Payment date: 20130925 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20130920 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20130930 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004007594 Country of ref document: DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20140916 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004007594 Country of ref document: DE Effective date: 20150401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150401 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140916 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140916 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: LAPE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140916 |