EP1471610A2 - Steckerteil einer Steckverbindung - Google Patents

Steckerteil einer Steckverbindung Download PDFInfo

- Publication number

- EP1471610A2 EP1471610A2 EP04008036A EP04008036A EP1471610A2 EP 1471610 A2 EP1471610 A2 EP 1471610A2 EP 04008036 A EP04008036 A EP 04008036A EP 04008036 A EP04008036 A EP 04008036A EP 1471610 A2 EP1471610 A2 EP 1471610A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- sleeve

- plug part

- spring

- spring element

- plug

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/46—Bases; Cases

- H01R13/502—Bases; Cases composed of different pieces

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/648—Protective earth or shield arrangements on coupling devices, e.g. anti-static shielding

- H01R13/658—High frequency shielding arrangements, e.g. against EMI [Electro-Magnetic Interference] or EMP [Electro-Magnetic Pulse]

- H01R13/6591—Specific features or arrangements of connection of shield to conductive members

- H01R13/65912—Specific features or arrangements of connection of shield to conductive members for shielded multiconductor cable

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/46—Bases; Cases

- H01R13/502—Bases; Cases composed of different pieces

- H01R13/5025—Bases; Cases composed of different pieces one or more pieces being of resilient material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/46—Bases; Cases

- H01R13/502—Bases; Cases composed of different pieces

- H01R13/504—Bases; Cases composed of different pieces different pieces being moulded, cemented, welded, e.g. ultrasonic, or swaged together

- H01R13/5045—Bases; Cases composed of different pieces different pieces being moulded, cemented, welded, e.g. ultrasonic, or swaged together different pieces being assembled by press-fit

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/62—Means for facilitating engagement or disengagement of coupling parts or for holding them in engagement

- H01R13/622—Screw-ring or screw-casing

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R2107/00—Four or more poles

Definitions

- the invention relates to a plug part of a plug connection with a core part made of plastic, which forms an insertion section for insertion into a Insertion opening of a mating plug part, contact elements of the core part with mating contact elements of the insertion opening in an electrically conductive Connect to each other with a cap assigned to the core part made of metal, which has a thread to connect to a Mating thread of the mating connector part, with a rearward the insertion section subsequent guide section of the core part an electrical carries conductive sleeve which can be connected to a shield of a cable, which is in electrical connection with the union.

- the invention is based, a generic connector part in the task To improve with a view to higher operational safety.

- Claim 1 initially and essentially provides that the lead connection between sleeve and cap by means of an annular spring element, for example in the form of a spring washer.

- This spring element is supported preferably in an annular recess in the inner wall of the cap. according to a spring bias then other sections of the spring element spring loaded on the sleeve. Regardless of the axial position the union to the sleeve is the electrical lead connection via the spring element ensured between sleeve and cap.

- the assembly of the Plug with the mating connector part is made in that the insertion section of the plug is inserted into the insertion cavity of the mating connector part.

- the contact elements come into electrical contact with the counter-contact elements.

- the contact elements can be pins or sleeves act.

- the inner wall the insertion sleeve of the mating connector part is made of metal and has an internal thread.

- the union can be screwed into this internal thread become.

- the union has an external thread.

- the spring ring in a ring recess in the inner wall the throw is secured against losing.

- the spring ring preferably has a V shape. But it can also have a cross-sectional shape that corresponds to that of a U or a wave.

- the ring It lies touching with its end edges on the bottom of the ring recess and lies with a certain preload with its apex on the outer wall of the sleeve.

- the ring is not closed, but forms a gap.

- the region of the apex is corrugated in the circumferential direction.

- the section of the sleeve on which the spring washer is in the screwed position comes to rest, is also curled. This provides security against vibrations, because a certain locking force is overcome to turn the cap must become.

- the corrugation on the sleeve can be ripped or

- Grooves can be achieved, which alternate in the circumferential direction. In the screwed Position, the two corrugations interlock.

- the spring element of a helical spring in particular helical compression spring, is formed.

- the spring element is designed as a coil spring, so it can also in a Ring recess between the union and sleeve can be arranged. It can one end of the helical compression spring at one step of this ring recess support. The other end of the compression coil spring can be on one shoulder support the sleeve. If the cap is moved relative to the sleeve, so the electrical connection between the sleeve and the cap remains exist, only the helical compression spring is tensioned or relaxed yourself.

- one end of the helical compression spring or an area of the helical compression spring protrudes radially.

- This radially protruding End or the radially protruding area of the helical compression spring can enter a niche, for example a further, stepped ring recess.

- the helical compression spring is axially tied to the union.

- the coil spring does not necessarily have to be a compression spring.

- the turns of the coil spring can also be tightly wound. The contact to the sleeve is then a sliding contact of the turns of the other end the coil spring. These turns of the coil spring are tight the outer surface of the sleeve.

- the spring element is designed as a sheet metal sleeve. Of this Sheet metal sleeve go out spring tongues. These spring tongues extend in the radial direction inside and / or outside. It can also be provided here that the spring element is bound by a shoulder of the sleeve in the axial direction.

- the contacts can also have forms be formed. It is preferably in the forms around inward-looking features that come into contact with the sleeve.

- the contact tongues can extend in the axial direction. It is also provided that the contact tongues extend in the circumferential direction. In The circumferential direction can be directed radially outwards and radially inwards Alternate contact tongues. Even in the axial direction can be radially outward directed tongues opposite radially inward tongues.

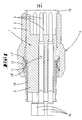

- the plug is in Essentially from a plastic core part 1, which with its free end 2 forms an insert part, which in an insertion cavity a mating connector part, not shown, can be inserted.

- the contact elements designated by the reference number 3 which in the exemplary embodiment are formed by pins in a conductive connection with corresponding ones Contact elements of the mating connector part.

- the contact elements 3 are via clamping sleeves 15 or the like connected to wires 9 of a cable 8.

- the cable 8 has a screen 7 which is electrically conductive with a guide section 6 of the Core part 1 surrounding sleeve 10 is connected.

- the screen is between the sleeve 10 and a clamping shell 16.

- the clamping shell 16 is surrounded by a plastic encapsulation 17.

- the sleeve 10 can be placed on the guide section 6 assigned to the core part 1 be pressed on. However, it is also possible to injection-mold the entire core part 1 produce, wherein the sleeve 10 is part of the mold.

- the front end of the insertion section 2 forms a bead 18.

- a cap screw 4 can be mounted on this bead. It is through Exerting a force pushed over the bead and locked behind it.

- the Cap screw 4 has an external thread 5, which in a corresponding Mating thread of the mating connector part can be screwed in.

- the cap screw 4 overlaps a portion of the sleeve 10. Inside this overlapping partial area has the inner wall of the cap screw 4 an annular recess 12. In this annular recess 12 lies a spring washer 11 bent from a leaf spring. This spring ring has a circumferential recess (see FIG. 3).

- the cross section of the spring ring 11 is V-shaped, the two edge edges 11 "of the spring ring 11 on the floor Support 12 'of the ring recess 12.

- the apex 11 'of the spring ring 11 rests under spring tension on the outer wall of the sleeve 10. hereby is in each axial position of the cap screw 4 to the sleeve 10 conductive connection between sleeve 10 and union 4 given.

- FIGS. 5 and 6 has at least the portion of the sleeve 10 on which the spring ring 11 in the screwed position is a corrugation or corrugation.

- the apex 11 'of the spring ring has a corresponding corrugation 13.

- the wave crests of the waves 13 of the spring ring 11 can be in the Depress the corrugation 14 of the sleeve 10.

- the spring element 11 is as Helical compression spring designed. One end 11 'of the helical compression spring lies against a step 19 of the ring recess 12. The other end 11 "of the spring element 11 is supported on a shoulder 22 which is assigned to the sleeve 10 is, from. If the cap 4 is displaced in the axial direction relative to the sleeve 10, so the spring element 11 relaxes or tensions, the end 11 'in electrical Lead connection to stage 19 and the other end 11 "in conductive connection to shoulder 22 remains.

- the inner wall has the cap 4, which is directed towards the ring recess 12, a niche in the form of another ring recess 20.

- this ring recess 20 is a radially projecting section 11 'of the coil spring 11.

- the other end 11 "of the coil spring is in contact with the Outer wall of the sleeve 10.

- the Coil spring 11 is not necessarily a compression spring.

- the turns of the Coil spring 11 can also be close together. But it is preferred that the turns of the coil spring forming the end 11 "are tight on the Apply sleeve 10. It need not only be the turns 11 "that are close to the Apply sleeve 10. It can be all turns of the coil spring 10.

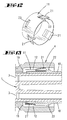

- the spring element a sheet metal sleeve.

- Contact tongues 21 are cut radially outward from the sheet. These contact tongues 21 are in contact with the inner wall of throw 4. This will make contact between the spring element 11 and cap 4 produced.

- the contact between spring element 11 and sleeve 10 is formed in this embodiment of features 23. These features 23 are made from the spring element 11

- the sheet metal part is marked radially inwards and lies in contact with the system the outer surface of the sleeve 10.

- the axial movement of the Spring element 11 is also in this embodiment by a shoulder 22, which is integrally formed on the sleeve 10.

- the spring element 11 also formed by a sheet metal part which is shaped into a sleeve.

- contact tongues 21 protrude both radially outside to come into contact with the cap 4, as well as in the form of the contact tongues 21 'radially inward to come into contact with the sleeve 10.

- the contact to the cap 4 is made by projecting radially outwards Contact tongues 21 in contact with the sleeve 10 by projecting radially inwards Contact tongues 21 'ensured.

Landscapes

- Details Of Connecting Devices For Male And Female Coupling (AREA)

Abstract

Description

- Fig. 1

- einen Schnitt durch einen Teil eines ersten Ausführungsbeispiels der Erfindung;

- Fig. 2

- den in Fig. 1 dargestellten Teil einer Seitenansicht;

- Fig. 3

- einen Schnitt gemäß der Linie III - III in Fig. 2;

- Fig. 4

- eine Frontalansicht auf den Stecker;

- Fig. 5

- ein zweites Ausführungsbeispiel der Erfindung in einer Darstellung ähnlich Fig. 1;

- Fig. 6

- eine Schnittdarstellung gemäß der Linie VI - VI in Fig. 5;

- Fig. 7

- ein drittes Ausführungsbeispiel der Erfindung in einer Darstellung gemäß Fig. 1;

- Fig. 8

- ein weiteres Ausführungsbeispiel der Erfindung in einer Darstellung gemäß Fig. 1;

- Fig. 9

- ein weiteres Ausführungsbeispiel der Erfindung in einer Darstellung gemäß Fig. 1;

- Fig. 10

- den Schnitt gemäß der Linie X - X;

- Fig. 11

- ein weiteres Ausführungsbeispiel in einer Darstellung gemäß Fig. 1, jedoch vergrößert;

- Fig. 12

- ein Federelement in perspektivischer Darstellung gehörend zum Ausführungsbeispiel gemäß Fig. 11;

- Fig. 13

- ein weiteres Ausführungsbeispiel in einer vergrößerten Darstellung gemäß Fig. 1;

- Fig. 14

- das Federelement zum Ausführungsbeispiel gemäß Fig. 13 in vergrößerter Darstellung;

- Fig. 15

- ein weiteres Ausführungsbeispiel gemäß Fig. 1 in einer vergrößerten Darstellung;

- Fig. 16

- einen Schnitt gemäß der Linie XVI - XVI in Fig. 15 und

- Fig. 17

- die perspektivische Darstellung eines Federelementes gehörend zum Ausführungsbeispiel der Fig. 15 und 16.

Claims (12)

- Steckerteil einer Steckverbindung mit einem Kernteil (1) aus Kunststoff, der einen Einsteckabschnitt (2) ausbildet zum Einstecken in eine Einstecköffnung eines Gegensteckteiles, wobei Kontaktelemente (3) des Kernteiles (2) mit Gegenkontaktelementen der Einstecköffnung in eine elektrisch leitende Verbindung zueinander treten, mit einem dem Kernteil (1) zugeordneten Überwurf (4) aus Metall, der ein Gewinde (5) aufweist zum in Verbindung bringen mit einem Gegengewinde des Gegensteckerteils, wobei ein rückwärtig sich dem Einsteckabschnitt (2) anschließender Führungsabschnitt (6) des Kernteiles (1) eine elektrisch leitende, mit einem Schirm (7) eines Kabels (8) in Verbindung bringbare Hülse (10) trägt, die in elektrischer Leitverbindung zum Überwurf steht, dadurch gekennzeichnet, dass die Leitverbindung zwischen Hülse (10) und Überwurf (4) mittels eines ringförmigen Federelementes (11) erfolgt.

- Steckerteil nach Anspruch 1 oder insbesondere danach, dadurch gekennzeichnet, dass das Federelement (11) in einer Ringaussparung (12) der Innenwandung des Überwurfs (4) liegt.

- Steckerteil nach einem oder mehreren der vorhergehenden Ansprüche oder insbesondere danach, dadurch gekennzeichnet, dass das als Federring ausgebildete Federelement (11) einen V-förmigen, U-förmigen oder wellenförmigen Querschnitt besitzt, wobei der Scheitel (11') des Profils auf der Hülse (10) aufliegt.

- Steckerteil nach einem oder mehreren der vorhergehenden Ansprüche oder insbesondere danach, dadurch gekennzeichnet, dass der Scheitel (11') des U-Profils eine Wellenumfangskontur (13) aufweist und der Abschnitt der Hülse (4), auf der der Federring (11) in mit dem Gegensteckerteil zusammengeschraubtem Zustand liegt, ebenfalls in Umfangsrichtung gewellt (14) ist oder in Achsrichtung verlaufende Rippen bzw. Nuten aufweist.

- Steckerteil nach einem oder mehreren der vorhergehenden Ansprüche oder insbesondere danach, dadurch gekennzeichnet, dass das Federelement (11) eine Schraubenfeder, insbesondere Schraubendruckfeder ist, die mit einem Abschnitt, vorzugsweise mit ihrem einen Ende (11') in elektrisch leitendem Kontakt mit dem Überwurf (4) und mit einem davon entfernten Abschnitt, vorzugsweise mit ihrem anderen Ende (11") in elektrisch leitendem Kontakt mit der Hülse (10) steht.

- Steckerteil nach einem oder mehreren der vorhergehenden Ansprüche oder insbesondere danach, dadurch gekennzeichnet, dass sich das Ende (11') der Schraubendruckfeder (11) gegen eine Stufe (19) des Überwurfs (4) und das Ende (11") der Schraubendruckfeder (11) gegen eine Schulter (22) der Hülse (4) abstützt.

- Steckerteil nach einem oder mehreren der vorhergehenden Ansprüche oder insbesondere danach, dadurch gekennzeichnet, dass ein radial abstehendes Ende (11') des Federelementes (11) in einer Nische, insbesondere in Form einer Ringaussparung des Überwurfs (4) einliegt und das andere Ende (11") insbesondere die Hülse eng umschliesst.

- Steckerteil nach einem oder mehreren der vorhergehenden Ansprüche oder insbesondere danach, dadurch gekennzeichnet, dass das als Hülse ausgebildete Federelement (11) radial abragende Kontaktzungen (21, 21') aufweist.

- Steckerteil nach einem oder mehreren der vorhergehenden Ansprüche oder insbesondere danach, dadurch gekennzeichnet, dass das als Hülse ausgebildete Federelement (11) radial abragende Ausprägungen (23) aufweist.

- Steckerteil nach einem oder mehreren der vorhergehenden Ansprüche oder insbesondere danach, dadurch gekennzeichnet, dass die Kontaktzungen (21) in Achsrichtung abragen.

- Steckerteil nach einem oder mehreren der vorhergehenden Ansprüche oder insbesondere danach, dadurch gekennzeichnet, dass die Kontaktzungen (21, 21') sich in Umfangsrichtung abwechseln und insbesondere radial einwärts abragende Kontaktzungen sich in Umfangsrichtung mit radial auswärts abragenden Kontaktzungen abwechseln.

- Steckerteil nach einem oder mehreren der vorhergehenden Ansprüche oder insbesondere danach, dadurch gekennzeichnet, dass je eine radialeinwärts abragende Kontaktzunge (21') in Achsrichtung benachbart liegt zu einer radial auswärts abragenden Kontaktzunge (21).

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10318509 | 2003-04-24 | ||

| DE10318509 | 2003-04-24 | ||

| DE10356044 | 2003-12-01 | ||

| DE10356044A DE10356044A1 (de) | 2003-04-24 | 2003-12-01 | Steckerteil einer Steckverbindung |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1471610A2 true EP1471610A2 (de) | 2004-10-27 |

| EP1471610A3 EP1471610A3 (de) | 2005-12-21 |

Family

ID=32963535

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04008036A Withdrawn EP1471610A3 (de) | 2003-04-24 | 2004-04-02 | Steckerteil einer Steckverbindung |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP1471610A3 (de) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7406017B2 (en) | 2003-06-12 | 2008-07-29 | Samsung Electronics Co., Ltd. | Apparatus for reproducing data from information storage medium having multiple storage layers with optimal power control (OPC) areas and buffer areas |

| WO2008061572A3 (de) * | 2006-03-16 | 2008-12-31 | Escha Bauelemente Gmbh | Geschirmter steckverbinder und verfahren zu seiner herstellung |

| EP2051340A1 (de) * | 2007-10-19 | 2009-04-22 | ITT Manufacturing Enterprises, Inc. | Elektrischer Steckverbinder |

| WO2015172866A1 (de) * | 2014-05-14 | 2015-11-19 | Eisele Pneumatics Gmbh & Co. Kg | Anschlusseinheit für eine kupplungsvorrichtung, insbesondere eine mehrfachkupplung |

| CN110854580A (zh) * | 2019-11-28 | 2020-02-28 | 瓯锟科技温州有限公司 | 一种具有可靠持久复位功能的弹簧型插座 |

| DE102015212660B4 (de) * | 2015-07-07 | 2020-10-08 | Volkswagen Aktiengesellschaft | Ladestecker |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3275970A (en) * | 1964-02-06 | 1966-09-27 | United Carr Inc | Connector |

| GB2066591B (en) * | 1979-12-13 | 1983-12-21 | Bunker Ramo | Electrical connector shell and method of making same |

| US4593964A (en) * | 1983-03-15 | 1986-06-10 | Amp Incorporated | Coaxial electrical connector for multiple outer conductor coaxial cable |

| US4598959A (en) * | 1983-11-04 | 1986-07-08 | International Telephone And Telegraph Corporation | Electrical connector grounding ring |

| DE4307728C2 (de) * | 1993-03-11 | 1995-01-19 | Contact Gmbh | Steckverbinder |

| EP0622872A3 (de) * | 1993-04-08 | 1997-01-22 | Amphenol Tuchel Elect | Rundsteckverbinder mit Filter. |

| IT1275681B1 (it) * | 1993-12-04 | 1997-10-17 | Interconnectron Gmbh | Connettore da innesto elettrico con dispositivo di contatto per la schermatura emv del cavo. |

| US5478254A (en) * | 1994-10-03 | 1995-12-26 | Rolls-Royce, Plc | Electrical connector |

| US5823803A (en) * | 1996-06-17 | 1998-10-20 | Conxall Corporation | Electrical cable connector |

-

2004

- 2004-04-02 EP EP04008036A patent/EP1471610A3/de not_active Withdrawn

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7406017B2 (en) | 2003-06-12 | 2008-07-29 | Samsung Electronics Co., Ltd. | Apparatus for reproducing data from information storage medium having multiple storage layers with optimal power control (OPC) areas and buffer areas |

| WO2008061572A3 (de) * | 2006-03-16 | 2008-12-31 | Escha Bauelemente Gmbh | Geschirmter steckverbinder und verfahren zu seiner herstellung |

| US7976341B2 (en) | 2006-03-16 | 2011-07-12 | Escha Bauelemente Gmbh | Shielded connector and method for producing the same |

| EP2051340A1 (de) * | 2007-10-19 | 2009-04-22 | ITT Manufacturing Enterprises, Inc. | Elektrischer Steckverbinder |

| WO2015172866A1 (de) * | 2014-05-14 | 2015-11-19 | Eisele Pneumatics Gmbh & Co. Kg | Anschlusseinheit für eine kupplungsvorrichtung, insbesondere eine mehrfachkupplung |

| CN106463864A (zh) * | 2014-05-14 | 2017-02-22 | 艾泽勒气动有限责任两合公司 | 用于离合器设备、尤其是多重离合器的接头单元 |

| US9935386B2 (en) | 2014-05-14 | 2018-04-03 | Eisele Pneumatics Gmbh & Co. Kg | Connection unit for a coupling device, in particular a multiple coupling |

| DE102015212660B4 (de) * | 2015-07-07 | 2020-10-08 | Volkswagen Aktiengesellschaft | Ladestecker |

| CN110854580A (zh) * | 2019-11-28 | 2020-02-28 | 瓯锟科技温州有限公司 | 一种具有可靠持久复位功能的弹簧型插座 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1471610A3 (de) | 2005-12-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69705170T2 (de) | Verbinder | |

| DE2724862C2 (de) | Koaxialsteckverbinder | |

| EP0598261B1 (de) | Kabelverschraubung für Erdungs- oder Abschirm-Kabel | |

| EP3047544B1 (de) | Kontaktfederring und steckverbinder | |

| DE102010061067A1 (de) | Vorrichtung zur Fixierung eines Kabels an einen Kabelabgangsstutzen | |

| DE19846440A1 (de) | Steckverbinder für Koaxialkabel mit ringgewelltem Außenleiter | |

| DE1590030A1 (de) | Kupplung fuer Koaxialkabel | |

| EP1891710A1 (de) | Elektrische steckverbindung, steckerteil und buchsenteil | |

| DE4226904C2 (de) | Crimphülse | |

| DE102008036399A1 (de) | Datenkabel | |

| EP0431408A2 (de) | Steckeranordnung für ein mehradriges Kabel | |

| WO2019134828A1 (de) | Kabelschirm-kontaktierungseinrichtung und elektrischer steckverbinder | |

| EP2515387B1 (de) | Stecker | |

| EP1471610A2 (de) | Steckerteil einer Steckverbindung | |

| DE102004012883A1 (de) | Steckverbinder für den elektrischen Anschluss von Solarpanels | |

| DE3905024A1 (de) | Anschlussvorrichtung fuer elektrische kabel | |

| DE102011050574A1 (de) | Anschlussverbinder | |

| EP1737094B1 (de) | Muffe zum auszugssicheren Einführen eines gewellten Rohres | |

| WO2016026834A1 (de) | Elektrisches gerät | |

| DE3008772C2 (de) | Zigarettenanzünder, insbesondere für Kraftfahrzeuge | |

| DE10356044A1 (de) | Steckerteil einer Steckverbindung | |

| DE3302924C3 (de) | Elektrische Steckverbindung | |

| EP1432061B1 (de) | Diagnosesonde für eine Mehrzellen-Batterie | |

| EP3435494B1 (de) | Verbinder und verwendung | |

| EP1667284B9 (de) | Kontaktierungseinrichtung für einen Kabelschirm |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: 7H 01R 9/03 B Ipc: 7H 01R 13/502 B Ipc: 7H 01R 13/658 A |

|

| AKX | Designation fees paid | ||

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20060622 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |