EP1288430A2 - Antriebs- und Verriegelungsaggregat - Google Patents

Antriebs- und Verriegelungsaggregat Download PDFInfo

- Publication number

- EP1288430A2 EP1288430A2 EP02018877A EP02018877A EP1288430A2 EP 1288430 A2 EP1288430 A2 EP 1288430A2 EP 02018877 A EP02018877 A EP 02018877A EP 02018877 A EP02018877 A EP 02018877A EP 1288430 A2 EP1288430 A2 EP 1288430A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- drive

- column tube

- bearing

- unit according

- locking unit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B11/00—Means for allowing passage through fences, barriers or the like, e.g. stiles

- E06B11/08—Turnstiles; Gates for control of entry or exit of persons, e.g. in supermarkets

- E06B11/085—Turnstiles; Gates for control of entry or exit of persons, e.g. in supermarkets non-rotary or with a limited angle of rotation, e.g. 90°

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05F—DEVICES FOR MOVING WINGS INTO OPEN OR CLOSED POSITION; CHECKS FOR WINGS; WING FITTINGS NOT OTHERWISE PROVIDED FOR, CONCERNED WITH THE FUNCTIONING OF THE WING

- E05F15/00—Power-operated mechanisms for wings

- E05F15/60—Power-operated mechanisms for wings using electrical actuators

- E05F15/603—Power-operated mechanisms for wings using electrical actuators using rotary electromotors

- E05F15/611—Power-operated mechanisms for wings using electrical actuators using rotary electromotors for swinging wings

- E05F15/614—Power-operated mechanisms for wings using electrical actuators using rotary electromotors for swinging wings operated by meshing gear wheels, one of which being mounted at the wing pivot axis; operated by a motor acting directly on the wing pivot axis

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2600/00—Mounting or coupling arrangements for elements provided for in this subclass

- E05Y2600/50—Mounting methods; Positioning

- E05Y2600/52—Toolless

- E05Y2600/522—Axial stacking

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2900/00—Application of doors, windows, wings or fittings thereof

- E05Y2900/40—Application of doors, windows, wings or fittings thereof for gates

Definitions

- the invention relates to a drive and locking unit (hereinafter abbreviated AVA) for a security gate for people passage control, with at least one by one in the assembly position, preferably essentially vertical axis of rotation rotatably and by means of one in an unlockable locking device in at least one Direction of rotation lockable against rotation or for rotation releasable locking element, for example a swivel wing, in particular a door leaf or a locking arm that by means of a drive from a pedestrian passage locking position in a passage releasing rotary position is actuated.

- AVA drive and locking unit

- Security gates with such drive and locking units are, for example, in the form of or turnstile systems become generally known. among them there is also a half-height swing door system Applicant, in which three swivel wings in the form of Glass panes at equal angular distances from each other 120 degrees each radially outward from the axis of rotation extend.

- the glass wings are free on the top cantilevered end of the drive and locking assembly by means of a suitable connecting flange connected.

- the glass wings protrude radially inside up to close to the axis of rotation and supported on the underside on a central rotary flange, which in turn via a pressure deep groove ball bearing on a non-rotatable supports the support tube connected to the ground.

- the glass wings each have a recess, protrude above the outer surface of the fixed one Support tube down.

- a Tooth clutch designed electromagnetically actuated brake, by means of which the rotating sash can be locked optionally can.

- cover plates designed in the shape of a segment of a circle firmly connected to the rotary wings, the Cover plates between the mutually facing vertical Side surfaces of the rotating wing and close to the ground, so overlapping over the central fixed standpipe extend.

- an electric gear motor In the stand and support tube is an electric gear motor. Its stator is fixed with the stand and support tube connected and its rotor is with connected to a central drive shaft, which in turn with the central rotary flange that supports the rotary wing is non-positively connected.

- the invention is the drive with a friction and / or positively engaging the rotating column tube and one Torque transmission to the rotating column tube or the least provide a locking element enabling active element.

- a frictional active element particularly quiet operation is possible.

- the two measures described above can For example, two standard units that can be manufactured at low cost, consisting of a drive unit, comprising the engine, the gearbox, a preferably as Crimp coupling designed active element and a Rotating column tube bearing and also a locking and monitoring unit, for example comprising a compensating coupling to be provided elsewhere and one Brake designed as a toothed clutch and a rotary encoder unit can be used to control the drive.

- a drive unit comprising the engine, the gearbox, a preferably as Crimp coupling designed active element and a Rotating column tube bearing and also a locking and monitoring unit, for example comprising a compensating coupling to be provided elsewhere and one Brake designed as a toothed clutch and a rotary encoder unit can be used to control the drive.

- the active element expediently engages on the inner circumference of the Rotating column. This makes it particularly simple and inexpensive manufacturable construction created and leave it particularly simple assembly and disassembly conditions in that, for example, that preferably on the geared motor comprehensive drive part simply into the the rotating column available as a standard part is inserted.

- the active element as Pinch coupling with a pressure exerted designed elastic and flexible deformable pressure element is that of the insertion of the pinch coupling and the position of the drive in the rotating column tube a frictionally against the inner circumference of the rotating column tube Location is transferable. This allows assembly or disassembly can be further simplified and it can a particularly low-noise operation of the AVA or with it equipped security gate by decoupling the engine vibrations reach from the rotating column tube.

- the pressure element with a Ring made of plastic or rubber, which is between arranged in the axis of rotation objected thrust washers is, of which at least one thrust washer by means of a the clamping element penetrating the ring in the direction of the rotary axis with simultaneous elastic deformation of the ring in Direction of the other thrust washer is movable.

- This construction is inexpensive to manufacture and particularly robust and allows easy replacement of the subject to wear over time Pressing element.

- Simple and space-saving storage conditions can be thereby achieve when the rotating column tube by itself can be turned at the front end into this extending journal is stored.

- a rotating column tube supports Bearing a coupling that compensates for angular and / or axial errors, so that corresponding manufacturing and / or assembly deviations are easily compensated for.

- This clutch expediently comprises preferably one on the front end of the vertical force support Rotary column tube rotatably and possibly axially fixed in the same received coupling sleeve with an internal toothing and one with the associated bearing pivot and optionally axially fixed hub part, the one in the positive engagement of the inner teeth of the coupling sleeve Has external teeth.

- Such a clutch allows for a variety of different ways designed swivel wing arrangements, without the associated storage and knitting units would have to be changed. This allows Achieve manufacturing and cost advantages. Also allows such a coupling a particularly precise storage of the rotating column tube.

- the hub part of the coupling and the coupling sleeve is the external toothing of the hub part of the coupling spherical, preferably teeth with partial spherical surfaces, hence as Curved tooth coupling designed.

- the bearing with a fixed, preferably integrally connected to the coupling sleeve, Ring bearing spherical surfaces is designed, the on a suitable bearing surface Ring counter bearing supports, with a hub part centrally extends through the ring bearing and the ring counter bearing.

- the ring bearing designed with spherical partial surfaces has a radius center point that has a radius center point the outer toothing of the hub part coincides.

- the rotating column tube in the area of its torque support end over a on the one hand on the inside and on the other a rotatably connected to a stator of the drive Bearing supporting bearing is rotatably mounted. This enables both simple assembly and disassembly conditions and also enables particularly stable storage of the rotating column tube to convey a long-term safe operation of the AVA and the associated security gate.

- Such a brake is useful with several Tooth-ring elements with opposite one another Interlocking teeth designed at least one of the tooth-ring elements to at least one further the tooth-ring elements in the direction of the axis of rotation of the rotary column tube is arranged to be axially displaceable a switchable engagement or disengagement of the opposite Allow teeth, going through the tooth-ring elements a rotatable and optionally axially fixed, preferably in one piece with one of the ends in the Rotating column tube connected bearing pin extending Hub part extends, the other with a rotary encoder Control of the drive is rotatably connected.

- the invention relates also a preferably designed as a tooth coupling Brake for an AVA, especially for a security gate for passage control, with at least one order an axis of rotation rotatably mounted and unlockable by means of an Locking device in at least one direction of rotation lockable against rotation or releasable for rotation Locking element, for example a swivel wing, in particular a door leaf or a locking arm, which by means of a Drive from a blocked position blocking the passage of people in a rotary position which enables the passage of people can be actuated, the brake being immediate, preferably rigid with an encoder to control the drive and / or the brake is connected. It is expedient if the hub part on his of the rotating column tube technological end has a pin on the the ring-shaped rotary encoder is plugged on, preferably frictionally, for example, by pressing.

- the fastening device is advantageously as one U-shaped mounting bracket designed a plate-shaped Fastening part with both ends at an angle from 90 degrees to this parallel mounting or has receiving legs.

- a mounting bracket can be conveniently with mounting tabs be provided, which are opposite to the column side Extend U-legs in the opposite direction, the attachment of the mounting bracket expediently on people guiding elements or passage limiting elements at the same time training support bodies of the security gate he follows.

- a particularly simple and robust mounting option as well as favorable assembly and disassembly conditions regarding the installation or removal of the at least one This enables swivel wing-bearing rotating column tube achieve that on the torque support side bearing element provided at the upper end of the rotating column tube is firmly connected to a fastener that for Purposes of assembling the rotating column tube by a first one Opening of the associated leg of the mounting bracket can be pushed through and for the purpose of non-rotatable fastening of the bearing element rotatable into one position is in which the fastener is positive, again detachable with the opening edges of a second opening in the associated leg is connected, the first opening and the second opening with at least one passing of the bearing element connecting path together are connected.

- first opening and the second opening a T-shaped or cross-shaped common opening train and if the fastener with a rectangular Plate is formed with little play is positively receivable in the second opening.

- the fastener by means of a displacement securing element, for example a bolt that can be secured for the purpose of a axially fixed securing of the bearing element from the fastening element releasing position in an overarching Position is displaceable.

- a displacement securing element for example a bolt that can be secured for the purpose of a axially fixed securing of the bearing element from the fastening element releasing position in an overarching Position is displaceable.

- the above measures carry both individually and in any combination to a compact and space-saving AVA, especially for a security gate or to a security gate with particularly compact and space-saving active elements, which results in the State-of-the-art arrangement and design options to extend such AVA. Furthermore is due to the measures described above inexpensive externally prefabricable, especially in common Units summarizable parts possible, so that thereby achieving a significant reduction in manufacturing costs can be. Finally, through the above Measures favorable assembly and disassembly conditions as well as a particularly quiet operation of the AVA or the reach the security gate equipped with it.

- the security gate shown in Fig. 1 for a security check is here as a double lock 21 designs and comprises four individual security gates 20.

- Each security gate 20 here also has a locking element unit designated AVA 26 with an about an axis of rotation 28 rotatably mounted and unlockable by means of an Locking device 29 in at least one direction of rotation 36 lockable against rotation or releasable for rotation Locking element 24, here in the form of a U-shape Pipe bracket 25 on.

- AVA 26 locking element unit designated AVA 26 with an about an axis of rotation 28 rotatably mounted and unlockable by means of an Locking device 29 in at least one direction of rotation 36 lockable against rotation or releasable for rotation Locking element 24, here in the form of a U-shape Pipe bracket 25 on.

- the scope the invention is not limited to such locking elements is, but that, for example, as locking elements also door leaves or other types of locking arms as Swivel wings can be used. It is understood that the Corresponding security gates 20 from FIG.

- Arrangement or the double lock arrangement shown in Fig. 1 are so meaningfully supplemented that one or several additional AVA 26 preferably on the same vertical Height horizontally adjacent in the pillars 22 and 23 to be arranged in this way to further control people and to be able to use guiding effects.

- Any locking element 24 is by means of a drive 32 from the people passage 37, 37 blocking blocking position 35 in a the passage 37, 37 releasing rotary position can be actuated.

- Each locking element 24 is fixed to one of these supporting rotating column, being in the embodiment each tube bracket is welded to the associated rotary column tube 27 is.

- two passageways 37 are consequently created, partially or entirely against the locking elements 24 a passage can be blocked, the locking elements 24 preferably by the drive 32 in both Rotation directions (double arrow 36) are rotatable.

- the admission is according to a particularly advantageous embodiment released with the help of card readers.

- the end AVA 26 shown in the figures with its locking elements 24 also allows a passage control and especially with increased personal capacities a quick go through of the respective people and is for integration in a parent Control unit suitable.

- Each security gate 20 is with a separately manageable or mountable locking element unit or an AVA 26 designed.

- This essentially consists of three standard units, namely rotating column unit 99, a drive unit 100 and a locking and monitoring unit 102, in turn by a fastener 81 added in the form of a mounting bracket 82 are (Fig. 7).

- the rotating column unit consists of the rotating column tube 27 with the locking element 24 attached to it.

- the drive unit 100 consists essentially of a received within the rotatable rotary column tube 27 Motor 33 with gear 34, the rotor of the motor 33 with an active element 42 designed in the form of a pinch coupling 44 which is a frictional torque transmission from the drive 32 on the rotary column tube 27 and thus that Locking element 24 mediates.

- the locking and monitoring unit 102 consists essentially of an angle and Axial error compensating clutch 40 and a Locking device 29 forming brake 30, which here as electromagnetic actuatable tooth coupling 31 is designed and that directly with a rotary encoder 72 for control of the drive 32 is provided.

- the torque support 38 of the drive 32 and the vertical force support 39 of the rotary column tube 27 take place in Range from in the direction of the axis of rotation 28 of the rotary column tube 27 spaced and facing ends 25, 41 of the rotating column tube 27.

- the stator is supported 64 of the motor 33 on the rotationally and axially fixed with this connected journal 50 via a form-releasable Connection to the mounting device 81 in the assembled Condition rotatable and axially fixed.

- the torque support side Bearing of the cylindrical rotating column tube 27 takes place of his upper one designed here as a deep groove ball bearing End 25 via a bearing 65, the one hand on the Supported column tube inside and that on the other hand on that firmly connected to the stator 64 of the drive 32 Bearing journal 50 supports.

- the pinch clutch connected to the rotor of the motor 33 44 includes a designed as a ring 46 made of plastic or rubber Pressure element 45, which is used to transmit the engine torque serves on the rotary column tube 27.

- a ring 46 made of plastic or rubber Pressure element 45 which is used to transmit the engine torque serves on the rotary column tube 27.

- Thrust washer 47 and 48 provided through bore, the means of being central through this as well extending through the ring 46 of the pressing element 45

- Clamping element 49 here in the form of a cylinder head screw, can be braced against each other.

- the bracing takes place starting from a relaxed position of the flexible and elastic pressure element 45, in which the outer diameter of the ring 46 is slightly smaller than that Inner diameter of the rotating column tube 27.

- the elastic and flexible ring 46 of the pressure element 45 due to the inclusion between the two thrust washers 47 and 48 substantially perpendicular to the axis of rotation 28 pressed radially outwards, so that in this way Friction between the peripheral surface of the ring 46 designed as Pressure element 45 and the inner surface or the Inner circumference 43 of the rotary column tube 27 are produced can.

- an angular and axial error compensating Coupling 40 provided at the vertical force support end 41 of the rotary column tube 27 .

- This consists of one of the lower end of the rotary column tube 27 can be inserted into this Coupling sleeve 52, which has an internal toothing 53 with teeth extending in the direction of the axis of rotation 28 having.

- One can be coupled to the internal toothing 53

- External teeth of a hub part comprising the bearing pin 51 54 the external toothing 55 being crowned is to enable an angular error compensation.

- the External toothing 55 of the hub part 54 also points in FIG Direction of the axis of rotation 28 extending teeth, which with the teeth of the internal toothing 53 of the coupling sleeve 52 correspond. Due to this tooth arrangement is in certain limits in the direction of the axis of rotation 28 an axial Displacement of the rotating column tube 27 relative to the bearing journal 51 of the hub part 54 allows so that on this An axial error compensation can also be achieved.

- the coupling sleeve 52 has at its opposite the insertion end End a ring shoulder on which the front end 41 of the rotary column tube 27 when inserted the coupling sleeve 52 strikes in the rotary column tube 27.

- the coupling sleeve 52 and the rotating column tube are in this area 27 preferably welded.

- the coupling sleeve 52 is in one piece in the exemplary embodiment connected to a spherical bearing ring bearing 57, that with a suitable plain bearing surface Ring counter bearing 60 to form a thrust bearing 66 interacts.

- the bearing elements 57 and 60 allow a vertical force support 39 of the rotary column tube 27 with the locking element 24 attached thereto such that the rotating column tube 27 a pendulum movement relative to the ring counter bearing 60 can execute.

- the external toothing is to enable angular error compensation 55 of the hub part 54 and the spherical part surfaces of the ring bearing 57 is designed so that they are coordinated with one another, that the radius center 62 of the spherical partial surfaces of the ring bearing 57 with the radius center of the partial spherical surface of the External teeth 55 of the hub part 54 coincide.

- the inside diameter of the central through hole of the Ring bearing 57 and the coupling sleeve 52 are in the embodiment larger than the radial outer circumference of the Screw head of the clamping screw 49 in such a way that this with the help of a through the mentioned central through holes can be inserted through an actuating tool Nut can be tightened or loosened.

- the ring counter bearing 60 is supported on a flange designed bearing element 80, which here in one piece with the Bearing pin 51 is connected.

- On the outer circumference of the ring flange of the bearing element 80 is one in the direction of Axis of rotation 28 of the rotary column tube 27 and over the circumference arranged longitudinal teeth provided with a suitable Internal toothing of a tooth-ring element 67 corresponds, that is received on the ring flange and that due to the longitudinal toothing compared to this in small Limits is axially displaceable.

- the tooth-ring element 67 forms the movable part of a toothed coupling 31 Brake 30 and points to it from the rotating column tube 27 technological front end with a toothing teeth extending in the radial direction about the axis of rotation 28 69 on.

- These teeth 69 correspond with it designed teeth 70 of a rotationally and axially fixed second tooth-ring element 68, which in turn a receiving leg 85 designed as a mounting bracket 82 Fastening device 81 rotatably and axially fixed supported.

- the bearings designed here as deep groove ball bearings are supported 78, which in turn are cone-shaped Support bearing element 80 and the rotation of the bearing element 80 and thus the rotary column tube 27 around the Allow axis of rotation 28 and ultimately also to Vertical force support 39 of the rotary column tube 27 with the Blocking element 26 serve.

- the tooth-ring element 67 is spring-assisted at not actuated tooth coupling 31 in the direction of the torque support side End 25 of the column tube 27 pressed, so that no clutch or brake intervention on the Teeth 69 and 70 are made.

- the electromagnets of the tooth coupling 31 Feeded electricity, so that due to the developing Magnetic field, the tooth-ring element 67 against the spring force is pulled against the tooth-ring element 68 until the opposite teeth 69 and 70 of the tooth-ring elements mentioned 67 and 68 come into mutual engagement and in this way, the rotary column tube 27 with the locking element 24 is blocked.

- the control of the drive 32 and the Tooth coupling 31 takes place by means of the rotary encoder 72 in the exemplary embodiment consists of an incremental disk 59 made of plastic with radially extending outwards Longitudinal slots.

- the incremental disk 59 is directly on a rotatable and axially fixed with the pin-like Bearing element 80, thus the hub part 51 is arranged.

- the incremental disk 59 is advantageous on the optionally also in one piece with the bearing element 80 connected pin 73 plugged on.

- To attach the Incremental disk 59 of the encoder 72 also serve Ring bushings 75 and 76, the inner diameter of which is slight is smaller than the outer diameter of the pin 73, so that the bushings 75 and 76 pressed onto the pin 73 by friction can be.

- the encoder 72 also includes a light barrier 74 with the on opposite sides of the Incremental disk 59 emitting or emitting light Light receiving elements.

- the security gate 20 is first the locking and monitoring unit 102 together with the bearing element 80 and attached to it Rotary encoder 72 on the vertical force support lower receiving leg 85 of the bracket 82 mounted and there for example with the help of suitable screws non-rotatably and axially fixed. Then that can rotary column tube 27 provided with the drive unit 100 in addition to locking element 24 while tilting the Rotary column tube 27 with its vertical force support side lower end 41 on the bearing pin 51 of the hub part 54 are plugged in until the ring ball bearing 57 on the designed ball pan provided with partial spherical surfaces Ring counter bearing 60 comes to rest.

- the opposite opening edges 91 of the second opening 90 arranged at a distance, which is slightly larger than the distance between the facing end edges of the plate 90 so that this in the final assembly position of the rotary column tube 27 little play positively in the second opening 90 of the receiving leg 84 of the fastening bracket 82 is included.

- the rotating column tube 27 with locking element 24 is in the final assembly position shown in the figures by means of a displacement locking element 94 against axial Displacement in the direction of the torque support side End 25 of the rotary column tube 27 can be secured.

Landscapes

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Power-Operated Mechanisms For Wings (AREA)

- Lock And Its Accessories (AREA)

- Vending Machines For Individual Products (AREA)

- Input Circuits Of Receivers And Coupling Of Receivers And Audio Equipment (AREA)

- Devices For Checking Fares Or Tickets At Control Points (AREA)

- Braking Arrangements (AREA)

Abstract

Description

- Fig. 1

- eine dreidimensionale Ansicht von zwei Personenschleusen, welche hier zu einer gemeinsamen Personenschleuse mit drei Standsäulen zusammengefaßt sind, wobei die mittlere Standsäule zwei AVA aufweist, die jeweils mit einem Drehsäulenrohr und einem daran befestigten Sperrelement in Form eines U-förmigen Rohrbügels gestaltet sind, während die beiden außenseitig angeordneten Standsäulen jeweils nur eine AVA aufweisen, wobei die Personenschleusen ein schnelles, jedoch kontrolliertes Passieren von Personen durch die Personendurchgangsbereiche der hier gezeigten Doppel- bzw. Vierfachpersonenschleuse ermöglicht;

- Fig. 2

- eine dreidimensionale Teildarstellung einer sinn vollen Anordnung von zwei zu einer Einheit zusammengefaßten AVA, bei dem sich die Sperrelemente in Sperrstellung in entgegengesetzte Richtungen erstrecken;

- Fig. 3

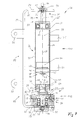

- eine Seitenansicht eines AVA mit einem Befestigungsbügel, einer Drehsäule mit einem daran befestigten, als Rohrbügel gestalteten Sperrelement sowie mit einer erfindungsgemäß als Zahnkupplung gestalteten Bremse mit integrierter Drehgeber-Einheit;

- Fig. 4

- eine Draufsicht auf das AVA gemäß Fig. 2 mit Teilschnitt durch den Rohrbügel;

- Fig. 5

- eine Unteransicht des AVA gemäß Fig. 2;

- Fig. 6

- eine Oberansicht des AVA gemäß Fig. 2;

- Fig. 7

- eine Seitenansicht des AVA der Personenschleuse gemäß Fig. 2 mit Längs-Querschnitt durch das Dreh säulenrohr nebst Lagern sowie durch die Bremse.

- 20

- Personenschleuse

- 21

- Doppelpersonenschleuse

- 22

- Standsäule

- 23

- Standsäule

- 24

- Sperrelement

- 25

- Rohrbügel

- 26

- AVA

- 27

- Drehsäulenrohr

- 28

- Drehachse von 27

- 29

- Sperrvorrichtung

- 30

- Bremse

- 31

- Zahnkupplung

- 32

- Antrieb

- 33

- Motor

- 34

- Getriebe

- 35

- Sperrstellung

- 36

- Drehrichtung (Doppelpfeil)

- 37

- Personendurchgang

- 38

- Drehmomentenabstützung

- 39

- Vertikalkraftabstützung

- 40

- Kupplung

- 41

- vertikalkraftabstützungsseitiges Ende von 27

- 42

- Wirkelement

- 43

- Innenumfang von 27

- 44

- Quetschkupplung

- 45

- Anpreßelement

- 46

- Ring

- 47

- Druckscheibe

- 48

- Druckscheibe

- 49

- Spannelement

- 50

- Lagerzapfen

- 51

- Lagerzapfen

- 52

- Kupplungshülse

- 53

- Innenverzahnung von 52

- 54

- Nabenteil

- 55

- Außenverzahnung von 54

- 57

- Ring-Lager

- 58

- drehmomentenabstützungs seitiges Ende von 27

- 59

- Inkrementalscheibe

- 60

- Ring-Gegenlager

- 62

- Radius-Mittelpunkt von 58

- 64

- Stator von 33

- 65

- Lager

- 66

- Drucklager

- 67

- Zahn-Ring-Element

- 68

- Zahn-Ring-Element

- 69

- Zahn von 67

- 70

- Zahn von 68

- 71

- Flansch

- 72

- Drehgeber

- 73

- Zapfen

- 74

- Lichtschranke

- 75

- Buchse

- 76

- Buchse

- 78

- Lager

- 79

- Lagerelement

- 80

- Lagerelement

- 81

- Befestigungsvorrichtung

- 82

- Befestigungsbügel

- 83

- Befestigungsteil

- 84

- Aufnahmeschenkel

- 85

- Aufnahmeschenkel

- 86

- Befestigungselement

- 87

- Platte

- 88

- erste Öffnung

- 89

- Öffnungskanten von 88

- 90

- zweite Öffnung

- 91

- Öffnungskanten von 90

- 92

- Verbindungspfad

- 93

- T- bzw. kreuzförmige Öffnung

- 94

- Verschiebe-Sicherungs-element

- 95

- Riegel

- 96

- Handgriff

- 97

- Profilteil

- 98

- Befestigungsschenkel

- 99

- Drehsäuleneinheit

- 100

- Antriebseinheit

- 102

- Verriegelungs- und Überwachungseinheit

Claims (25)

- Antriebs- und Verriegelungsaggregat, insbesondere für eine Personenschleuse (20) zur Personendurchgangskontrolle, mit wenigstens einem um eine Drehachse (28) drehbar gelagerten und mittels einer entriegelbaren Sperrvorrichtung (29) in wenigstens einer Drehrichtung (36) gegen Drehung sperrbaren bzw. zur Drehung freigebbaren Sperrelement (24), beispielsweise einem Schwenkflügel, insbesondere einem Türflügel oder einem Sperrarm, das mittels eines Antriebs (32) aus einer den Personendurchgang (37) sperrenden Sperrstellung (35) in eine den Personendurchgang (37) freigebenden Drehstellung betätigbar ist,

dadurch gekennzeichnet, daß der Antrieb (32) in einem um die Drehachse (28) drehbaren und das wenigstens eine Sperrelement (24) tragenden Drehsäulenrohr (27) angeordnet ist. - Antriebs- und Verriegelungsaggregat nach Anspruch 1,

dadurch gekennzeichnet, daß eine Drehmomentenabstützung (38) des Antriebs (32) und eine Vertikalkraftabstützung (39) des Drehsäulenrohrs (27) im Bereich von in Richtung der Drehachse (28) beabstandeten Enden (25, 41) des Drehsäulenrohrs (27) erfolgt. - Antriebs- und Verriegelungsaggregat nach einem der Ansprüche 1 oder 2, dadurch gekennzeichnet, daß der Antrieb (32) mit einem reib- und/oder formschlüssig an dem Drehsäulenrohr (27) angreifenden und eine Drehmomentenübertragung zu dem Drehsäulenrohr (27) bzw. dem wenigstens einen Sperrelement (24) ermöglichenden Wirkelement (42) versehen ist.

- Antriebs- und Verriegelungsaggregat nach Anspruch 3 dadurch gekennzeichnet, daß das Wirkelement (42) am Innenumfang (43) der Drehsäule (27) angreift.

- Antriebs- und Verriegelungsaggregat nach einem der Ansprüche 3 oder 4, dadurch gekennzeichnet, daß das Wirkelement (42) als Quetschkupplung (44) mit einem unter Ausübung von Druckkräften elastisch verformbaren Anpreßelmeent (45) gestaltet ist, das von einer das Einschieben der Quetschkupplung (44) und des Antriebs (32) in das Drehsäulenrohr (27) ermöglichenden Lage in eine reibschlüssig am Innenumfang (43) des Drehsäulenrohrs (27) anliegende Lage überführbar ist.

- Antriebs- und Verriegelungsaggregat nach Anspruch 5, dadurch gekennzeichnet, daß das Anpreßelement (45) mit einem Ring (46) aus Kunststoff bzw. Gummi gestaltet ist, der zwischen in Richtung der Drehachse (28) beabstandeten Druckscheiben (47, 48) angeordnet ist, von denen wenigstens eine Druckscheibe (48) mittels einem den Ring (46) in Richtung der Drehachse (28) durchsetzenden Spannelement unter gleichzeitiger elastischer Verformung des Rings (46) in Richtung der anderen Druckscheibe (47) bewegbar ist.

- Antriebs- und Verriegelungsaggregat nach einem der Ansprüche 1 bis 6, dadurch gekennzeichnet, daß die Vertikalkraftabstützung (39) des Drehsäulenrohrs (27) mittels eines im wesentlichen mit Druckkräften beaufschlagten Drucklager (66) erfolgt.

- Antriebs- und Verriegelungsaggregat nach einem der Ansprüche 1 bis 7, dadurch gekennzeichnet, daß das Drehsäulenrohr (27) mittels sich stirnendig in dieses hineinerstreckender Lagerzapfen (50, 51) drehbar gelagert ist.

- Antriebs- und Verriegelungsaggregat nach einem der Ansprüche 1 bis 8, dadurch gekennzeichnet, daß ein das Drehsäulenrohr (27) lagerndes Lager eine Winkel- oder Axialfehler ausgleichende Kupplung (40) umfaßt.

- Antriebs- und Verriegelungsaggregat nach Anspruch 9, dadurch gekennzeichnet, daß die Kupplung (40) aus einer vorzugsweise an dem vertikalkraftabstützungsseitigen Stirnende (41) des Drehsäulenrohrs (27) dreh- und gegebenfalls axialfest in demselben aufgenommene Kupplungshülse (52) mit einer Innenverzahnung und einem mit dem zugeordneten Lagerzapfen (50) dreh- und gegebenenfalls axialfest verbundenen Nabenteil (54) besteht, das eine in die Innenverzahnung (53) der Kupplungshülse (52) formschlüssig eingreifende Außenverzahnung (55) aufweist.

- Antriebs- und Verriegelungsaggregat nach Anspruch 10, dadurch gekennzeichnet, daß die Außenverzahnung (55) des Nabenteils (54) der Kupplung (40) ballig ausgebildet ist.

- Antriebs- und Verriegelungsaggregat nach einem der Ansprüche 10 oder 11, dadurch gekennzeichnet, daß die axiale Erstreckung des Nabenteils (54) kleiner ist als die der Kupplungshülse (52).

- Antriebs- und Verriegelungsaggregat nach einem der Ansprüche 9 bis 12, dadurch gekennzeichnet, daß das Drucklager (66) zur Vertikalkraftabstützung des Drehsäulenrohrs (27) die Winkel- und Axialfehler ausgleichende Kupplung (40) umfaßt.

- Antriebs- und Verriegelungsaggregat nach einem der Ansprüche 7 bis 12, dadurch gekennzeichnet, daß das Lager mit einem Kugelteilflächen aufweisenden Ringlager (57) gestaltet ist, das sich auf einem mit passenden Gleitlagerflächen versehenen Ring-Gegenlager (60) abstützt, wobei sich ein Nabenteil (54) zentral durch das Ring-Lager (57) und das Ring-Gegenlager (60) erstreckt.

- Antriebs- und Verriegelungsaggregat nach Anspruch 14 dadurch gekennzeichnet, daß das mit Kugelteilflächen gestaltete Ringlager (57) einen Radius-Mittelpunkt (62) aufweist, der mit einem Radius-Mittelpunkt der Außenverzahnung (55) des Nabenteils (54) zusammenfällt.

- Antriebs- und Verriegelungsaggregat nach einem der Ansprüche 2 bis 15, dadurch gekennzeichnet, daß das Drehsäulenrohr (27) im Bereich seines drehmomentenabstützungsseitigen Endes (58) über ein sich einerseits innenseitig an diesem und andererseits an einem drehfest mit dem Stator (64) des Antriebs (32) verbundenen Lagerzapfen (50) abstützenden Lagers (65) drehbar gelagert ist.

- Antriebs- und Verriegelungsaggregat nach einem der Ansprüche 1 bis 16, dadurch gekennzeichnet, daß das Drehsäulenrohr (27) mit einer als Zahnkupplung (31) gestalteten Bremse (30) gekoppelt ist, die vorzugsweise am vertikalkraftabstützungsseitigen Ende (41) des Drehsäulenrohrs (27) angeordnet ist.

- Antriebs- und Verriegelungsaggregat nach Anspruch 17, dadurch gekennzeichnet, daß die Bremse (30) mit mehreren Zahn-Ring-Elemen-ten (67, 68) mit sich gegenüberliegenden, einen gegenseitigen Eingriff ermöglichenden Zähnen (69, 70) gestaltet ist, wobei wenigstens einer der Zahn-Ring-Elemente (67) zu dem wenigstens einen weiteren Zahn-Ring-Element (68) in Richtung der Drehachse 28 des Drehsäulenrohrs (27) axialverschieblich angeordnet ist, um einen schaltbaren Eingriff bzw. Ausgriff der gegenüberliegenden Zähne (69, 70) zu ermöglichen, wobei sich durch die Zahn-Ring-Elemente (67, 68) ein dreh- und gegebebenenfalls axialfest, vorzugsweise einstückig mit einem der sich stirnseitig in das Drehsäulenrohr (27) hineinerstreckenden Lagerzapfen (51) verbundener Nabenteil (54) erstreckt, der andernends mit einem Drehgeber (72) zur Steuerung des Antriebs (32) drehfest verbunden ist.

- Antriebs- und Verriegelungsaggregat nach Anspruch 18, dadurch gekennzeichnet, daß der Nabenteil (54) an seinem von dem Drehsäulenrohr (27) wegweisenden Ende einen Zapfen (73) aufweist, auf den der ringförmige Drehgeber (72) aufgesteckt, vorzugsweise reibschlüssig befestigt ist.

- Antriebs- und Verriegelungsaggregat nach einem der Ansprüche 2 bis 19, dadurch gekennzeichnet, daß die Drehmomentabstützung (38) des Antriebs (32) und die Vertikalkraftabstützung (39) des Drehsäulenrohrs (27) über sich jeweils über die voneinander wegweisenden, in Richtung der Drehachse (28) beabstandeten Enden (25, 41) des Drehsäulenrohrs (27) hinauserstreckende Lagerelemente (79, 80) erfolgt, die jeweils an sich jeweils in Richtung des Drehsäulenrohrs (27) erstreckenden Schenkeln (84, 85) einer separat handhabbaren Befestigungsvorrichtung (81) befestigbar sind.

- Antriebs- und Verriegelungsaggregat nach Anspruch 20, dadurch gekennzeichnet, daß die Befestigungsvorrichtung (81) als ein U-förmiger Befestigungsbügel (82) gestaltet ist, der einen vorzugsweise plattenförmigen Befestigungsteil (83) mit sich beiderends in einem Winkel von etwa 90 Grad zu diesem erstreckenden parallelen Befestigungsschenkeln (84, 85) aufweist.

- Antriebs- und Verriegelungsaggregat nach einem der Ansprüche 20 und 21, dadurch gekennzeichnet, daß das an dem drehmomentenabstützungsseitigen Ende (58) des Drehsäulenrohrs (27) vorgesehene Lagerelement (79) fest mit einem Befestigungselement (86) verbunden ist, das zum Zwecke der Montage des Drehsäulenrohrs (27) durch eine erste Öffnung (88) des zugeordneten Schenkels (84) des Befestigungsbügels (82) hindurchsteckbar ist und das zum Zwecke der drehfesten Befestigung des Lagerelements (79) in eine Position verdrehbar ist, in der das Befestigungselement (86) formschlüssig, wieder lösbar mit den Öffnungskanten (91) einer zweiten Öffnung (90) in dem zugeordneten Schenkel (84) verbunden ist, wobei die erste Öffnung (88) und die zweite Öffnung (90) mit einem das Passieren zumindest des Lagerelements (79) ermöglichenden Verbindungspfad (92) miteinander verbunden sind.

- Antriebs- und Verriegelungsaggregat nach Anspruch 22, dadurch gekennzeichnet, daß eine drehfeste, formschlüssige Verbindung nach Absenken des Befestigungselements (86) in die zweite Öffnung (90) erreicht wird.

- Antriebs- und Verriegelungsaggregat nach einem der Ansprüche 22 oder 23, dadurch gekennzeichnet, daß die erste Öffnung (88) und die zweite Öffnung (90) eine T-bzw. kreuzförmige gemeinsame Öffnung (93) ausbilden und daß das Befestigungselement (86) mit einer rechteckigen Platte (87) gestaltet ist, die mit geringem Spiel formschlüssig in der zweiten Öffnung (90) aufnehmbar ist.

- Antriebs- und Verriegelungsaggregat nach einem der Ansprüche 22 bis 24, dadurch gekennzeichnet, daß das Befestigungselement (86) mittels eines Verschiebe-Sicherungselements (94) sicherbar ist, das zum Zwecke einer axialfesten Befestigung des Lagerelements (79) von einer das Befestigungselement (86) freigebenden Stellung in eine dieses sichernde Stellung verschiebbar ist.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP04018818A EP1475509B1 (de) | 2001-08-31 | 2002-08-24 | Antriebs- und Verriegelungsaggregat |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10142434A DE10142434A1 (de) | 2001-08-31 | 2001-08-31 | Antriebs- und Verriegelungsaggregat |

| DE10142434 | 2001-08-31 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1288430A2 true EP1288430A2 (de) | 2003-03-05 |

| EP1288430A3 EP1288430A3 (de) | 2004-04-28 |

Family

ID=7697067

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04018818A Expired - Lifetime EP1475509B1 (de) | 2001-08-31 | 2002-08-24 | Antriebs- und Verriegelungsaggregat |

| EP02018877A Withdrawn EP1288430A3 (de) | 2001-08-31 | 2002-08-24 | Antriebs- und Verriegelungsaggregat |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04018818A Expired - Lifetime EP1475509B1 (de) | 2001-08-31 | 2002-08-24 | Antriebs- und Verriegelungsaggregat |

Country Status (3)

| Country | Link |

|---|---|

| EP (2) | EP1475509B1 (de) |

| AT (1) | ATE460563T1 (de) |

| DE (2) | DE10142434A1 (de) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1605413A2 (de) | 2004-06-11 | 2005-12-14 | Axess AG | Einrichtung zur Zugangskontrolle |

| WO2011000908A1 (en) * | 2009-07-01 | 2011-01-06 | Somfy Sas | Expandable and damping motor mounting in a window covering headrail |

| EP1990777A3 (de) * | 2007-05-10 | 2012-04-04 | Axess AG | Zugangskontrollsperre |

| CN107653798A (zh) * | 2017-10-20 | 2018-02-02 | 四川省守望信息科技有限责任公司 | 适用于应急障碍的摆闸 |

| WO2020078887A1 (de) * | 2018-10-15 | 2020-04-23 | Dormakaba Deutschland Gmbh | Durchgangssperre |

| WO2020078883A1 (de) * | 2018-10-15 | 2020-04-23 | Dormakaba Deutschland Gmbh | Durchgangssperre sowie ein verfahren zur herstellung einer durchgangssperre |

| US11072976B2 (en) | 2017-02-06 | 2021-07-27 | Hunter Douglas, Inc. | Methods and apparatus to reduce noise in motor assemblies |

| CN116026857A (zh) * | 2023-03-28 | 2023-04-28 | 湖南省京湘电力开发有限公司 | 一种配电线异常检测装置 |

| US11821257B2 (en) | 2018-10-15 | 2023-11-21 | Dormakaba Deutschland Gmbh | Passage barrier and method for producing a passage barrier |

| US12338675B2 (en) * | 2021-08-03 | 2025-06-24 | Royal Boon Edam International B.V. | Door arrangement |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2890995B1 (fr) * | 2005-09-16 | 2009-02-13 | Norsk Hydro As | Ouverture de type fenetre, porte, porte-fenetre ou analogue, a ouvrant motorise de type battant |

| ATE399247T1 (de) * | 2006-02-23 | 2008-07-15 | Scheidt & Bachmann Gmbh | Durchgangssperre |

| DE102006024863B4 (de) * | 2006-05-24 | 2017-07-27 | Gottfried Ragg | Vereinzelungsanlage |

| DE102006030724B4 (de) * | 2006-06-30 | 2017-06-08 | Wanzl Metallwarenfabrik Gmbh | Anlage |

| DE102007023360A1 (de) * | 2007-05-18 | 2008-11-27 | Wanzl Metallwarenfabrik Gmbh | Anlage zum Verschließen eines Personendurchgangs |

| DE202008001066U1 (de) * | 2008-01-24 | 2009-06-18 | Gebr. Bode Gmbh & Co. Kg | Drehwegerfassungsvorrichtung |

| CN101793118A (zh) * | 2010-03-23 | 2010-08-04 | 张建新 | 安全通道的门翼摆动式控制方法 |

| DE202011003309U1 (de) * | 2011-02-28 | 2011-06-09 | Magnetic Autocontrol GmbH, 79650 | Durchgangssperre |

| NL2006465C2 (en) * | 2011-03-24 | 2012-09-25 | Royal Boon Edam Internat B V | Gateway for providing controlled access from an entrance point to an exit point. |

| CN107630654B (zh) * | 2017-10-20 | 2020-01-03 | 深圳市爱克信智能股份有限公司 | 多功能摆闸门禁系统 |

| DE102018125455B4 (de) * | 2018-10-15 | 2025-05-22 | Dormakaba Deutschland Gmbh | Durchgangssperre |

| DE102018125462A1 (de) * | 2018-10-15 | 2020-04-16 | Dormakaba Deutschland Gmbh | Durchgangssperre sowie ein Verfahren zur Herstellung einer Durchgangssperre |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE909428C (de) * | 1952-04-26 | 1954-04-15 | Eickhoff Geb | Rutschkupplung fuer Foerderbandantriebe |

| DE1290407B (de) * | 1964-05-06 | 1969-03-06 | Kalle Ag | Rutschkupplung fuer Aufwickelvorrichtungen |

| DE4039871A1 (de) * | 1990-12-13 | 1992-06-17 | Dautel Emil Gmbh | Transportfahrzeug mit wechselaufbau |

| DE4314026A1 (de) * | 1993-04-29 | 1994-11-03 | Wanzl Entwicklung Gmbh | Schwenktüre für einen Personendurchgang |

| DE19848324B4 (de) * | 1998-10-20 | 2007-03-22 | Sew-Eurodrive Gmbh & Co. Kg | Kupplung |

| FR2800122B1 (fr) * | 1999-10-20 | 2005-09-30 | Horizal | Portail ou portillon motorise s'adaptant a une pente |

| DE10011065A1 (de) * | 2000-03-07 | 2001-09-13 | Delphi Tech Inc | Kupplung zwischen zwei Wellen |

-

2001

- 2001-08-31 DE DE10142434A patent/DE10142434A1/de not_active Withdrawn

-

2002

- 2002-08-24 EP EP04018818A patent/EP1475509B1/de not_active Expired - Lifetime

- 2002-08-24 EP EP02018877A patent/EP1288430A3/de not_active Withdrawn

- 2002-08-24 DE DE50214273T patent/DE50214273D1/de not_active Expired - Lifetime

- 2002-08-24 AT AT04018818T patent/ATE460563T1/de active

Cited By (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1605413A3 (de) * | 2004-06-11 | 2006-09-27 | Axess AG | Einrichtung zur Zugangskontrolle |

| US7513423B2 (en) | 2004-06-11 | 2009-04-07 | Axess Ag | Device for controlling access in a passage lane |

| EP1605413A2 (de) | 2004-06-11 | 2005-12-14 | Axess AG | Einrichtung zur Zugangskontrolle |

| EP1990777A3 (de) * | 2007-05-10 | 2012-04-04 | Axess AG | Zugangskontrollsperre |

| WO2011000908A1 (en) * | 2009-07-01 | 2011-01-06 | Somfy Sas | Expandable and damping motor mounting in a window covering headrail |

| CN102472079A (zh) * | 2009-07-01 | 2012-05-23 | Somfy两合公司 | 安装在窗帘头轨中的可扩展式及阻尼式电机 |

| CN102472079B (zh) * | 2009-07-01 | 2015-04-01 | Somfy两合公司 | 安装在窗帘头轨中的可扩展式及阻尼式电机 |

| US11072976B2 (en) | 2017-02-06 | 2021-07-27 | Hunter Douglas, Inc. | Methods and apparatus to reduce noise in motor assemblies |

| US12152438B2 (en) | 2017-02-06 | 2024-11-26 | Hunter Douglas Inc. | Methods and apparatus to reduce noise in motor assemblies |

| CN107653798A (zh) * | 2017-10-20 | 2018-02-02 | 四川省守望信息科技有限责任公司 | 适用于应急障碍的摆闸 |

| CN107653798B (zh) * | 2017-10-20 | 2019-07-30 | 四川行之智汇知识产权运营有限公司 | 适用于应急障碍的摆闸 |

| WO2020078883A1 (de) * | 2018-10-15 | 2020-04-23 | Dormakaba Deutschland Gmbh | Durchgangssperre sowie ein verfahren zur herstellung einer durchgangssperre |

| CN112867839A (zh) * | 2018-10-15 | 2021-05-28 | 多玛凯拔德国有限公司 | 通道屏障 |

| US11613927B2 (en) | 2018-10-15 | 2023-03-28 | Dormakaba Deutschland Gmbh | Passage barrier and method for producing a passage barrier |

| CN112867839B (zh) * | 2018-10-15 | 2023-04-11 | 多玛凯拔德国有限公司 | 通道屏障 |

| US11821257B2 (en) | 2018-10-15 | 2023-11-21 | Dormakaba Deutschland Gmbh | Passage barrier and method for producing a passage barrier |

| WO2020078887A1 (de) * | 2018-10-15 | 2020-04-23 | Dormakaba Deutschland Gmbh | Durchgangssperre |

| US12338675B2 (en) * | 2021-08-03 | 2025-06-24 | Royal Boon Edam International B.V. | Door arrangement |

| CN116026857A (zh) * | 2023-03-28 | 2023-04-28 | 湖南省京湘电力开发有限公司 | 一种配电线异常检测装置 |

| CN116026857B (zh) * | 2023-03-28 | 2023-10-24 | 湖南省京湘电力开发有限公司 | 一种配电线异常检测装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE10142434A1 (de) | 2003-04-03 |

| DE50214273D1 (de) | 2010-04-22 |

| EP1475509B1 (de) | 2010-03-10 |

| EP1475509A1 (de) | 2004-11-10 |

| EP1288430A3 (de) | 2004-04-28 |

| ATE460563T1 (de) | 2010-03-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1288430A2 (de) | Antriebs- und Verriegelungsaggregat | |

| DE102010000970B4 (de) | Höhenverstellbare Betätigungs-Einrichtung | |

| DE2502052A1 (de) | Betaetigungsvorrichtung zum erzeugen einer geradlinigen bewegung | |

| DE102012013979A1 (de) | Linaearaktuator und Verfahren zum Herstellen eines Linearaktuators | |

| DE20023013U1 (de) | Vorschaltgetriebe an Motoren mit hoher Drehzahl für Hilfsantriebseinheiten | |

| DE202012009415U1 (de) | Industriegetriebe | |

| EP2671308B1 (de) | Rotorlagerung für eine elektrische maschine | |

| DE102007043984A1 (de) | Elektromotorischer Linearantrieb | |

| WO2009024127A2 (de) | Rotationsvorrichtung | |

| EP3807556B1 (de) | Rollengewindetrieb für einen aktuator einer steer-by-wire-lenkung sowie eine steer-by-wire-lenkung | |

| EP1398442A1 (de) | Antrieb für ein bewegliches Bauelement | |

| DE20313273U1 (de) | Antriebssystem für Verstelleinrichtungen in Kraftfahrzeugen | |

| EP2031175B1 (de) | Seitenteil für einen Rollladenkasten | |

| EP0958229B1 (de) | Seilzug mit vereinfachter montage | |

| EP1512211B1 (de) | Elektromotorischer antrieb mit einem stator und einem rotor in kombination mit einem exzentergetriebe | |

| EP3215312A1 (de) | Hub-schwenkeinheit | |

| EP1552149A1 (de) | Stator f r exzenterschneckenpumpe | |

| EP0657328B1 (de) | Antriebs- und Regelmechanismus für einen geradlinig ausfahrbaren Überrollbügel | |

| DE60003093T2 (de) | Kupplung für Pumpe und Motor | |

| DE202021003041U1 (de) | Kupplungseinrichtung für eine Linearantriebsvorrichtung und Linearantriebsvorrichtung und Möbelstück mit derselben | |

| DE102015201104B3 (de) | Oldhamkupplung | |

| WO2007017113A1 (de) | Adapter, planetengetriebe, antrieb und verfahren | |

| EP3109390B1 (de) | Antriebseinheit für eine automatische karusselltür | |

| DE102004044753B4 (de) | Neigungsverstellbeschlag für die Rückenlehne eines Kraftfahrzeugsitzes | |

| EP1335479A2 (de) | Schwingungsisolierende Halterung eines Elektromotors |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: 7E 05F 15/10 B Ipc: 7F 16D 7/02 B Ipc: 7F 16D 7/00 B Ipc: 7E 06B 11/08 A |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| AKX | Designation fees paid | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20041029 |