EP1087067A1 - Abgabevorrichtung für die Abgabe eines Wirkstoffes - Google Patents

Abgabevorrichtung für die Abgabe eines Wirkstoffes Download PDFInfo

- Publication number

- EP1087067A1 EP1087067A1 EP00100895A EP00100895A EP1087067A1 EP 1087067 A1 EP1087067 A1 EP 1087067A1 EP 00100895 A EP00100895 A EP 00100895A EP 00100895 A EP00100895 A EP 00100895A EP 1087067 A1 EP1087067 A1 EP 1087067A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- dispensing

- chamber

- active ingredient

- dispensing device

- storage container

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000013543 active substance Substances 0.000 title claims description 16

- 238000004140 cleaning Methods 0.000 claims abstract description 24

- 239000008237 rinsing water Substances 0.000 claims abstract description 4

- 239000004480 active ingredient Substances 0.000 claims description 60

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 35

- 238000003860 storage Methods 0.000 claims description 31

- 239000007788 liquid Substances 0.000 claims description 13

- 238000011010 flushing procedure Methods 0.000 claims description 12

- 239000007787 solid Substances 0.000 claims description 7

- 238000005192 partition Methods 0.000 claims description 4

- 238000000034 method Methods 0.000 description 10

- 239000003205 fragrance Substances 0.000 description 8

- 239000000499 gel Substances 0.000 description 8

- 238000002360 preparation method Methods 0.000 description 5

- 239000000243 solution Substances 0.000 description 5

- 239000000126 substance Substances 0.000 description 5

- 239000004094 surface-active agent Substances 0.000 description 4

- 239000002304 perfume Substances 0.000 description 3

- 238000004659 sterilization and disinfection Methods 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000004061 bleaching Methods 0.000 description 2

- 239000012141 concentrate Substances 0.000 description 2

- 239000003814 drug Substances 0.000 description 2

- 229940079593 drug Drugs 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000006260 foam Substances 0.000 description 2

- 239000000203 mixture Substances 0.000 description 2

- 239000003921 oil Substances 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- ZAMOUSCENKQFHK-UHFFFAOYSA-N Chlorine atom Chemical compound [Cl] ZAMOUSCENKQFHK-UHFFFAOYSA-N 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 239000007853 buffer solution Substances 0.000 description 1

- 239000000460 chlorine Substances 0.000 description 1

- 229910052801 chlorine Inorganic materials 0.000 description 1

- 238000004332 deodorization Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 239000000645 desinfectant Substances 0.000 description 1

- 230000000249 desinfective effect Effects 0.000 description 1

- 239000003599 detergent Substances 0.000 description 1

- CEJLBZWIKQJOAT-UHFFFAOYSA-N dichloroisocyanuric acid Chemical compound ClN1C(=O)NC(=O)N(Cl)C1=O CEJLBZWIKQJOAT-UHFFFAOYSA-N 0.000 description 1

- 238000012377 drug delivery Methods 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- WJRBRSLFGCUECM-UHFFFAOYSA-N hydantoin Chemical class O=C1CNC(=O)N1 WJRBRSLFGCUECM-UHFFFAOYSA-N 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 150000007522 mineralic acids Chemical class 0.000 description 1

- 150000007524 organic acids Chemical class 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000005022 packaging material Substances 0.000 description 1

- 235000011837 pasties Nutrition 0.000 description 1

- -1 polypropylene Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 238000010926 purge Methods 0.000 description 1

- 230000000979 retarding effect Effects 0.000 description 1

- 230000035943 smell Effects 0.000 description 1

- 239000002562 thickening agent Substances 0.000 description 1

- 230000009974 thixotropic effect Effects 0.000 description 1

- 238000005406 washing Methods 0.000 description 1

- 238000009463 water soluble packaging Methods 0.000 description 1

- 230000004584 weight gain Effects 0.000 description 1

- 235000019786 weight gain Nutrition 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E03—WATER SUPPLY; SEWERAGE

- E03D—WATER-CLOSETS OR URINALS WITH FLUSHING DEVICES; FLUSHING VALVES THEREFOR

- E03D9/00—Sanitary or other accessories for lavatories ; Devices for cleaning or disinfecting the toilet room or the toilet bowl; Devices for eliminating smells

- E03D9/02—Devices adding a disinfecting, deodorising, or cleaning agent to the water while flushing

- E03D9/03—Devices adding a disinfecting, deodorising, or cleaning agent to the water while flushing consisting of a separate container with an outlet through which the agent is introduced into the flushing water, e.g. by suction ; Devices for agents in direct contact with flushing water

- E03D9/032—Devices connected to or dispensing into the bowl

Definitions

- the invention relates to the delivery device for the delivery at least an active ingredient, in particular in the form of a cleaning liquid or a cleaning gel, in a toilet bowl with an entry point for the Rinse water and with a reservoir for the active ingredient, which for the Delivery of the same has at least one passage point that contains the active ingredient passes on to a delivery chamber with an exit point.

- a generic dispensing device is known from EP 0 828 902 B1.

- the toilet flushing water occurs both through the refill opening for the active ingredient in the storage container one as well as via the exit point in the form of exit slots in the Dispensing chamber, which has further longitudinal slots as respective passage points is in fluid communication with the reservoir.

- a swamping of the active ingredient within the Dispenser wants to meet, this is due to the possible Rinse water inlet in the reservoir is insufficient.

- Much more it turns out that after a few flushing processes a clear one There is a decrease in wash-active substances of the active ingredient simultaneous weight gain due to the amount of active ingredient stored the rinse water storage in the active ingredient, among which the expert Understands sinking of the active ingredient.

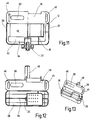

- a further development of the dispensing device provides that the storage container is divided into at least two individual chambers via at least one partition, in which different active substances can be stored.

- different active substances can be stored.

- differently acting cleaning liquids or cleaning gel compositions can be released together into the toilet bowl.

- media for example bleaching substances that contain chlorine or oxygen, together with oxidation-sensitive fragrances or surfactants, so that a kind of modular principle is achieved for drug delivery .

- certain disinfectants can be adjusted to the optimum pH value by adding a buffer solution in the further separated individual chamber at a predeterminable pH value which corresponds to their optimum effect and which have only a short shelf life in this area.

- Dispensing device is provided next to the storage container and outside of it at least one other receiving chamber inside to provide the delivery device in which a solid active ingredient can be stored is, the receiving chamber is an access point for the rinse water and has a delivery point to the delivery siphon.

- the receiving chamber is an access point for the rinse water and has a delivery point to the delivery siphon.

- the delivery device shown is used to deliver an active ingredient, in particular in the form of a cleaning liquid or a cleaning gel.

- the Cleaning gel can also have a pasty character.

- the active ingredient consists essentially of surfactants, in particular also from organic and / or inorganic acids and thickeners and optionally has a perfume oil as a fragrance.

- the viscosities of the thixotropic active ingredient, which is also referred to as an active ingredient preparation can be between 10 and 100,000 mPas, preferably between 100 up to 30,000 mPas, the relevant values using a Haake rotation viscometer VT500 are measured at an ambient temperature from 20 ° C and with the measuring system MV1 to MV3.

- the passing one Active ingredient is said to be particularly influenced by the rinse water a toilet bowl can be delivered for cleaning purposes.

- a toilet bowl can be delivered for cleaning purposes.

- a disinfection and deodorization of the toilet bowl possible; the latter in particular via the delivery of a fragrance or Fragrance, for example in the form of a substance incorporated into the active ingredient Perfume oils or the like ..

- the dispensing device has an entry point designated as a whole by 10 for the rinse water, with neither the rinse water nor the toilet are shown in more detail in the drawing.

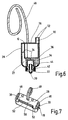

- the dispenser has a box-shaped storage container 12 for the storage of the active ingredient on. Seen in the direction of the figures and if the dispenser assumes the spatial position shown there, the reservoir 12 for the delivery of the active ingredient at its lower, horizontal End wall 14 passage points 16 for the passage of the stored Active ingredient. As FIG. 4 in particular shows, the passage points are 16 in the manner of perforations arranged in groups of rows within the lower end wall 14 of the reservoir 12 attached.

- the passage points 16 serve for the possible passage of the active ingredient for its forwarding from the storage container 12 into a delivery chamber 18 with an exit point designated as a whole by 20. How in particular 7 shows, the reservoir 12 is in operation of the dispenser completed against the rinse water, so that the Amount of active ingredient taken up in the storage container 12 before sumping is protected.

- the exit point 20 is in the dispensing chamber 18 Part of a delivery siphon 22.

- the exit point 20 can in particular Commissioning of the dispensing device, for example, currently on sale be provided with a cover cap 24 (see FIG. 1).

- the storage container 12 can be closed with an end cover 26, if the dispenser is made of a plastic material, in particular is made of injection-molded polypropylene, the end cover 26, as shown in the figures, with its one longitudinal edge pivotable, one-piece part of the other delivery device is.

- the free passage cross section of the passage points 16 in the lower one End wall 14 of the reservoir 12 is dependent on the viscosity of the active ingredient so dimensioned that in a time-definable

- the active substance can be delivered to the dispensing chamber 18 and the rinse water enters avoided in the reservoir 12 through the passage points 16 is. That way it can't go to a bog of the active ingredient within the storage container 12 by an unwanted Rinse water entering through the passage points 16.

- the dispensing chamber 18 includes at least partially maintaining one Distance 27 for the rinse water guide the reservoir 12 with their Side walls 28, being in the opposite end faces Side walls 28 each have three slot-like entry points 30 for the toilet flushing water available.

- the lower end of each bottom mentioned Entry point 30 defines one shown in dashed lines in FIG Fill level limit 32 for the rinse water within the dispensing chamber 18, the fill level limit 32 above the respective passage point 16 of the reservoir 12 is arranged. Seen in the direction of Fig.3 the lowest point of entry of the groups of three is at Entry points 30 formed by the slot shown on the far left.

- the exit point 20 of the dispensing siphon 22 is in turn with an axial Distance below this lower boundary wall 40 of the dispensing chamber 18 arranged on the dispenser.

- the dispensing siphon 22 is preferred trained as an independent plastic component and can in the kind of a cover with parts 42 of the dispensing chamber 18 clipped become.

- the parts 42 addressed for this form a kind Ring flange made on the underside of the lower boundary wall 40th the dispensing chamber 18 protrudes.

- the exit point 20 is off a riser pipe 44 formed for the effect of the dispensing siphon 22 in the siphon chamber 36 projects with its one free end in and in Direction of view of the figures or the installation position seen above the Side slots 38 opens into the siphon chamber 36.

- the other free end of the riser 44 for the actual exit point 20 projects below the Share 42 in the area.

- the end cover 26 has on its opposite end sides two slot-like inlet openings 46 for the in the dispensing chamber 18 over the distance 27 rinse water to be fed. Further the end cover 26 has bow-like fixing means on its upper side 48 for attaching the dispenser to the edge of a toilet bowl (not shown). For this purpose, the rolled up bracket 48 must be spread open and the free end of the fixing means 48 overlaps the edge of the Toilet bowl.

- Dispensing devices are common and are therefore not described in more detail.

- this can have a supply opening 50 have that in the manner of a key lock system only refilling from refill containers allowed, their discharge opening (not shown) corresponds to the supply opening 50, thus in the Type of widened dispensing nozzle are formed.

- the supply opening 50 therefore consists of an opening slot, the slot sides 52 on the one hand from the end cover 26 and on the other hand from a side wall 28 of the dispensing chamber are formed. It is important to ensure that the opening slot is outside the flushing flow.

- the dispensing device is explained in more detail based on its function.

- the storage container 12 is not filled with the active ingredient; but could also be filled, for example by the dispensing device being sealed with water-soluble packaging materials, in particular in the form of film.

- the end cover 26 is preferably closed by a clip connection and the interior of the storage container 12 is then closed without rinsing water from the environment via the end cover 26.

- the active ingredient drips from the storage container 12 onto the bottom of the dispensing chamber 18. If a toilet flushing process occurs, flushing water, as described, penetrates into the dispensing chamber 18 and dissolves the active ingredient .

- the relevant active substance liquid is then introduced via the side slots 38 into the siphon chamber 36, which fills in the manner of a siphon until the active substance solution reaches the upper edge of the riser pipe 44, with the result that the siphon chamber 36 is partially freed from the active substance solution, which then via the hollow riser pipe 44 and the exit point 20 into the environment, that is, into the toilet bowl for cleaning and scenting purposes.

- the dispensing device is designed such that a dispensing process begins Active ingredient in the toilet bowl only in the sense of a retarding The moment occurs when the rinsing process is almost complete and the Toilet user has left it. After the flushing process mentioned in turn, the dispensing chamber 18 is filled with the active ingredient for another subsequent rinsing process. A delivery of the active ingredient is therefore carried out in defined portions of the same concentration via the exit point 20. For example, finds a longer use due to vacation the toilet does not take place, so that there is no flushing process, the siphon chamber 36 fills exclusively with the active ingredient without Rinse water with the result that the active ingredient in pure form to the toilet is delivered via the exit point 20.

- a dispensing cartridge for the active ingredient can also be placed in the dispensing chamber 12 can be used, if used, against a new cartridge is replaceable in the form of refill containers.

- the storage container 12 via a centrally arranged, continuous and fluid-impermeable Partition wall 54 divided into two approximately equal individual chambers 56, which in turn down towards the dispensing siphon 22 for formation the passage points 16 are perforated.

- This can be done differently acting liquids or cleaning gels in the common dispensing chamber 18 in front of the dispensing siphon 22 and combined in such a way for a cleaning and / or disinfection process within insert the toilet bowl.

- Outlet openings in the form of the passage points 16 for each individual chamber 56 it is possible, as well as through differently selected viscosities of the two liquids or cleaning gels to be dosed Varying the ratio of the delivery quantities of the two active substance preparations.

- each individual chamber 56 in particular through the end cover 26 against accidental entry of the rinse water secured.

- a solid active ingredient for example in tablet form, as a cleaning block or can be stored as a toilet block.

- the relevant admission chamber 58 has an access point 60 for the rinse water and one Delivery point 62 for the active ingredient dissolved by the rinse water to the Dispensing siphon 22. Because of this arrangement, it is possible to use solid active ingredients to combine with liquid or with cleaning gels, with one Not shown embodiment of the reservoir 12 in turn can be divided into several individual chambers.

- a tablet with sodium dichloroisocyanurate or halogenated Hydantoine as a bleaching and disinfecting component with a liquid Mix phase with fragrance and surfactant can be done with a liquid scent or foam booster be upgraded.

- the further receiving chamber 58 can itself again be subdivided (not shown) and various active substances into Tablet form or the like stockpile.

- the embodiment according to Fig.11 to 13 is in any case the other receiving chamber 58 on the bottom via a Separator 64 divided.

- the flushing water entering via the access point 60 in operation of the dispensing device releases the stored solid active ingredient in the further receiving chamber 58 on and over the room-like delivery point 62 divided by the separating web 64 is delivered to the delivery siphon 22 and over this into the toilet bowl.

Landscapes

- Health & Medical Sciences (AREA)

- Public Health (AREA)

- Epidemiology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Hydrology & Water Resources (AREA)

- Water Supply & Treatment (AREA)

- Bidet-Like Cleaning Device And Other Flush Toilet Accessories (AREA)

- Feeding, Discharge, Calcimining, Fusing, And Gas-Generation Devices (AREA)

- Coating Apparatus (AREA)

- Sampling And Sample Adjustment (AREA)

- Automatic Analysis And Handling Materials Therefor (AREA)

Abstract

Description

Des weiteren können bestimmte Desinfektionsmittel bei einem vorgebbaren pH-Wert, der ihrem Wirkoptimum entspricht und die in diesem Bereich nur eine kurze Haltbarkeitsdauer aufweisen, mittels Zugabe einer Pufferlösung in der weiteren abgetrennten Einzelkammer auf den optimalen pH-Wert eingestellt werden.

- Fig.1

- teilweise in Ansicht, teilweise im Längsschnitt eine erste Ausführungsform der Abgabevorrichtung mit geöffnetem Abschlußdeckel;

- Fig.2

- einen Schnitt längs der Linie I ― I in Fig.1;

- Fig.3

- eine seitliche Ansicht gemäß dem Pfeil II in Fig.1;

- Fig.4

- eine Draufsicht auf die Abgabevorrichtung nach der Fig.1;

- Fig.5

- verkleinert dargestellt eine perspektivische Ansicht auf die Abgabevorrichtung gemäß den Fig.1 bis 4 mit geöffnetem Abschlußdeckel;

- Fig.6

- eine der Fig.2 entsprechende Schnittdarstellung mit geschlossenem Abschlußdeckel;

- Fig.7

- eine der Fig.5 entsprechende perspektivische Ansicht ebenfalls mit geschlossenem Abschlußdeckel:

- Fig.8,9,10

- teilweise in Ansicht, teilweise im Längsschnitt eine zweite Ausführungsform der Abgabevorrichtung mit geöffnetem Abschlußdeckel, eine Draufsicht auf dieselbe sowie eine perspektivische Ansicht von oben und

- Fig.11,12,13

- teilweise in Ansicht, teilweise im Längsschnitt eine dritte Ausführungsform der Abgabevorrichtung mit geöffnetem Abschlußdeckel, eine Draufsicht auf dieselbe sowie eine perspektivische Ansicht.

Bei der Erstausrüstung der Abgabevorrichtung ist der Vorratsbehälter 12 mit dem Wirkstoff nicht befüllt; könnte aber auch befüllt sein, beispielsweise indem die Abgabevorrichtung mit wasserlöslichen Verpackungsmaterialien, insbesondere in Form von Folie, verschlossen ist. Es ist aber auch an einen Verkauf der Abgabevorrichtung zusammen mit einem Nachfüllbehältnis als Gebinde gedacht mit der Möglichkeit, vor der ersten Inbetriebnahme die Vorratskammer 12 über das Nachfüllbehältnis zu füllen. Der Abschlußdeckel 26 wird vorzugsweise über eine Klippverbindung geschlossen und das Innere des Vorratsbehälters 12 ist dann spülwasserfrei gegenüber der Umgebung über den Abschlußdeckel 26 verschlossen. In Abhängigkeit von der gewählten Viskosität des Wirkstoffes und dem freien Durchtrittsquerschnitt der Durchtrittsstellen 16 tropft der Wirkstoff aus dem Vorratsbehälter 12 auf den Boden der Abgabekammer 18. Setzt ein Toilettenspülvorgang ein, dringt Spülwasser, wie beschrieben, in die Abgabekammer 18 ein und löst den Wirkstoff an. Die dahingehende Wirkstoffflüssigkeit wird dann über die Seitenschlitze 38 in die Siphonkammer 36 eingebracht, die sich in der Art eines Siphons füllt, bis die Wirkstofflösung die Oberkante des Steigrohres 44 erreicht mit der Folge, daß die Siphonkammer 36 von der Wirkstofflösung teilweise befreit wird, die dann über das hohle Steigrohr 44 und die Austrittsstelle 20 in die Umgebung, sprich in die Toilettenschüssel zu Reinigungs- und Beduftungszwecken gelangt.

Claims (11)

- Abgabevorrichtung für die Abgabe mindestens eines Wirkstoffes, insbesondere in Form einer Reinigungsflüssigkeit oder eines Reinigungsgels, in ein Toilettenbecken mit einer Eintrittsstelle (10) für das Spülwasser und mit einem Vorratsbehälter (12) für den Wirkstoff, der für die Abgabe desselben mindestens eine Durchtrittsstelle (16) aufweist, die den Wirkstoff an eine Abgabekammer (18) mit einer Austrittsstelle (20) weitergibt, dadurch gekennzeichnet, daß der Vorratsbehälter (12) im Betrieb der Abgabevorrichtung gegen über dem Spülwasser abgeschlossen ausgebildet ist und daß die Austrittsstelle (20) in der Abgabekammer (18) Teil eines Abgabesiphons (22) ist.

- Abgabevorrichtung nach Anspruch 1, dadurch gekennzeichnet, daß der Vorratsbehälter (12) über mindestens eine Trennwand (54) in mindestens zwei Einzelkammern (56) unterteilt ist, in denen unterschiedliche Wirkstoffe bevorratbar sind.

- Abgabevorrichtung nach Anspruch 1 oder 2, dadurch gekennzeichnet, daß der Vorratsbehälter (12) in der Art eines mit einem Abschlußdeckel (26) verschließbaren Kastens ausgebildet ist, an dessen Unterseite, insbesondere an seiner unteren Abschlußwand (14), eine Vielzahl von Durchtrittsstellen (16) angeordnet ist, deren freier Durchtrittsquerschnitt in Abhängigkeit von der Viskosität des Wirkstoffes derart bemessen ist, daß in einem zeitlich vorgebbaren Rahmen der Wirkstoff an die Abgabekammer (18) abgebbar und der Spülwassereintritt in den Vorratsbehälter (12) über die Durchtrittsstellen (16) vermieden ist.

- Abgabevorrichtung nach einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, daß die Abgabekammer (18) zumindest teilweise unter Beibehalten eines Abstandes (27) für die Spülwasserführung den Vorratsbehälter (12) mit ihren Seitenwänden (28) umfaßt und daß zumindest in einem Teil dieser Seitenwände (28) Eintrittsstellen (30) für das Spülwasser vorhanden sind.

- Abgabevorrichtung nach Anspruch 4, dadurch gekennzeichnet, daß das untere Ende einer jeden unteren Eintrittsstelle (30) unter Definieren einer Füllstandsgrenze (32) für das Spülwasser innerhalb der Abgabekammer (18) oberhalb der jeweiligen Durchtrittsstelle (16) des Vorratsbehälters (12) angeordnet ist.

- Abgabevorrichtung nach einem der Ansprüche 1 bis 5, dadurch gekennzeichnet, daß unterhalb des Vorratsbehälters (12) mit seiner jeweiligen Durchtrittsstelle (16) und in die Abgabekammer (18) hineinragend der Abgabesiphon (22) angeordnet ist, dessen Siphonkammer (36) an die abzugebende Menge an Wirkstoff von ihrer Größe her angepaßt ist.

- Abgabevorrichtung nach einem der Ansprüche 1 bis 6, dadurch gekennzeichnet, daß die Austrittsstelle (20) des Abgabesiphons (22) unterhalb der unteren Begrenzungswand (40) der Abgabekammer (18) angeordnet ist.

- Abgabevorrichtung nach einem der Ansprüche 3 bis 7, dadurch gekennzeichnet, daß der Abschlußdeckel (26) Eintrittsöffnungen (46) für das in die Abgabekammer (18) einzuspeisende Spülwasser aufweist und daß der Abschlußdeckel (26) mit Festlegemitteln (48) zum Befestigen der Abgabevorrichtung an einer Toilettenschüssel versehen ist.

- Abgabevorrichtung nach einem der Ansprüche 1 bis 8, dadurch gekennzeichnet, daß zum Nachfüllen des Vorratsbehälters (12) mit Wirkstoff dieser eine Versorgungsöffnung (50) aufweist, die in der Art eines Schlüssel-Schloßsystems nur das Nachfüllen aus Nachfüllbehältnissen erlaubt, deren Abgabeöffnung der Versorgungsöffnung (50) entspricht.

- Abgabevorrichtung nach Anspruch 9, dadurch gekennzeichnet, daß die Versorgungsöffnung (50) aus einem Öffnungsschlitz gebildet ist, dessen Schlitzseiten (52) zum einen aus dem Abschlußdeckel (26) und zum anderen aus einer Seitenwand (28) der Abgabekammer (18) gebildet sind.

- Abgabevorrichtung nach einem der Ansprüche 1 bis 10, dadurch gekennzeichnet, daß neben dem Vorratsbehälter (12) und außerhalb desselben mindestens eine weitere Aufnahmekammer (58) vorhanden ist, in der ein fester Wirkstoff bevorratbar ist und daß die Aufnahmekammer (58) eine Zutrittsstelle (60) für das Spülwasser und eine Abgabestelle (62) an den Abgabesiphon (22) aufweist.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE20023677U DE20023677U1 (de) | 1999-09-23 | 2000-01-18 | Abgabevorrichtung für die Abgabe eines Wirkstoffs |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19945598A DE19945598B4 (de) | 1999-09-23 | 1999-09-23 | Abgabevorrichtung für die Abgabe eines Wirkstoffes |

| DE19945598 | 1999-09-23 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1087067A1 true EP1087067A1 (de) | 2001-03-28 |

| EP1087067B1 EP1087067B1 (de) | 2005-10-26 |

Family

ID=7923031

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00100895A Expired - Lifetime EP1087067B1 (de) | 1999-09-23 | 2000-01-18 | Abgabevorrichtung für die Abgabe eines Wirkstoffes |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1087067B1 (de) |

| AT (1) | ATE307932T1 (de) |

| DE (3) | DE19945598B4 (de) |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2002064898A1 (en) * | 2001-02-09 | 2002-08-22 | Jeyes Group Limited | Lavatory cleansing devices |

| WO2003054311A1 (de) * | 2001-12-20 | 2003-07-03 | Jeyes Deutschland Gmbh | Vorrichtung zur abgabe eines flüssigen wirkstoffs in ein spülwasser |

| US6662380B1 (en) | 2002-08-29 | 2003-12-16 | S.C. Johnson & Son, Inc. | Dual action toilet rim mounted toilet bowl cleaner |

| EP1405956A3 (de) * | 2002-10-01 | 2004-04-21 | Skot S.A. Chemical Products | Vorrichtung zur Abgabe eines flüssigen Wirkstoffs in das Spülwasser eines Toilets |

| WO2004084697A1 (de) * | 2003-03-27 | 2004-10-07 | Henkel Kommanditgesellschaft Auf Aktien | Vorrichtung zur abgabe wenigstens einer wasserlöslichen wirksubstanz an eine reinigungsbürste |

| WO2004092493A1 (en) * | 2003-04-15 | 2004-10-28 | Re.Le.Vi.-S.P.A. | Liquid active substance dispenser for w.c. bowl |

| WO2007010311A1 (en) * | 2005-07-15 | 2007-01-25 | Csonka Matyas | External located device for feeding liquids |

| WO2009086948A1 (de) * | 2008-01-08 | 2009-07-16 | Henkel Ag & Co. Kgaa | Abgabevorrichtung zur abgabe wenigstens eines wirkstofffluids in das spülwasser eines toilettenbeckens sowie zur beduftung der umgebung |

| US20150345123A1 (en) | 2014-05-27 | 2015-12-03 | As Ip Holdco, Llc | Sanitaryware cleaning system |

| US10465366B2 (en) | 2014-05-27 | 2019-11-05 | As America, Inc. | Sanitaryware cleaning system |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2018140634A1 (en) | 2017-01-25 | 2018-08-02 | As Ip Holdco, Llc | Sanitaryware cleaning system |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4168551A (en) * | 1978-04-24 | 1979-09-25 | Globol-Werk Gmbh | Toilet flush water colorizer |

| US4555819A (en) * | 1982-08-26 | 1985-12-03 | Reckitt & Colman S.A. | Holder for cleaning and/or colorant products intended to be hooked from the edge of a WC bowl |

| EP0222607A2 (de) * | 1985-11-09 | 1987-05-20 | Reckitt And Colman Products Limited | Flüssigkeitsdosiervorrichtung |

| EP0878586A2 (de) * | 1997-05-15 | 1998-11-18 | Buck-Chemie GmbH & Co. | Abgabevorrichtung für Toilettenbecken |

| EP0828902B1 (de) | 1995-06-01 | 1999-06-02 | Henkel Kommanditgesellschaft auf Aktien | Wc-körbchen für flüssige oder pastöse wirkstoffzubereitungen |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2555253A1 (fr) * | 1983-11-18 | 1985-05-24 | Kamlay Serge | Dispositif de diffusion par diffraction d'un melange air-essence et son utilisation pour l'alimentation d'un moteur a combustion interne |

| FR2555216B1 (fr) * | 1983-11-23 | 1986-03-28 | Oreal | Support de produit, notamment colorant, destine a etre accroche sur le rebord d'une cuvette de toilettes |

-

1999

- 1999-09-23 DE DE19945598A patent/DE19945598B4/de not_active Expired - Fee Related

-

2000

- 2000-01-18 EP EP00100895A patent/EP1087067B1/de not_active Expired - Lifetime

- 2000-01-18 DE DE20023677U patent/DE20023677U1/de not_active Expired - Lifetime

- 2000-01-18 AT AT00100895T patent/ATE307932T1/de not_active IP Right Cessation

- 2000-01-18 DE DE50011426T patent/DE50011426D1/de not_active Expired - Lifetime

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4168551A (en) * | 1978-04-24 | 1979-09-25 | Globol-Werk Gmbh | Toilet flush water colorizer |

| US4555819A (en) * | 1982-08-26 | 1985-12-03 | Reckitt & Colman S.A. | Holder for cleaning and/or colorant products intended to be hooked from the edge of a WC bowl |

| EP0222607A2 (de) * | 1985-11-09 | 1987-05-20 | Reckitt And Colman Products Limited | Flüssigkeitsdosiervorrichtung |

| EP0828902B1 (de) | 1995-06-01 | 1999-06-02 | Henkel Kommanditgesellschaft auf Aktien | Wc-körbchen für flüssige oder pastöse wirkstoffzubereitungen |

| EP0878586A2 (de) * | 1997-05-15 | 1998-11-18 | Buck-Chemie GmbH & Co. | Abgabevorrichtung für Toilettenbecken |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2002064898A1 (en) * | 2001-02-09 | 2002-08-22 | Jeyes Group Limited | Lavatory cleansing devices |

| WO2003054311A1 (de) * | 2001-12-20 | 2003-07-03 | Jeyes Deutschland Gmbh | Vorrichtung zur abgabe eines flüssigen wirkstoffs in ein spülwasser |

| US6662380B1 (en) | 2002-08-29 | 2003-12-16 | S.C. Johnson & Son, Inc. | Dual action toilet rim mounted toilet bowl cleaner |

| US6854136B2 (en) | 2002-08-29 | 2005-02-15 | S. C. Johnson & Son, Inc. | Dual action toilet rim mounted toilet bowl cleaner |

| EP1405956A3 (de) * | 2002-10-01 | 2004-04-21 | Skot S.A. Chemical Products | Vorrichtung zur Abgabe eines flüssigen Wirkstoffs in das Spülwasser eines Toilets |

| WO2004084697A1 (de) * | 2003-03-27 | 2004-10-07 | Henkel Kommanditgesellschaft Auf Aktien | Vorrichtung zur abgabe wenigstens einer wasserlöslichen wirksubstanz an eine reinigungsbürste |

| WO2004092493A1 (en) * | 2003-04-15 | 2004-10-28 | Re.Le.Vi.-S.P.A. | Liquid active substance dispenser for w.c. bowl |

| WO2007010311A1 (en) * | 2005-07-15 | 2007-01-25 | Csonka Matyas | External located device for feeding liquids |

| WO2009086948A1 (de) * | 2008-01-08 | 2009-07-16 | Henkel Ag & Co. Kgaa | Abgabevorrichtung zur abgabe wenigstens eines wirkstofffluids in das spülwasser eines toilettenbeckens sowie zur beduftung der umgebung |

| US20150345123A1 (en) | 2014-05-27 | 2015-12-03 | As Ip Holdco, Llc | Sanitaryware cleaning system |

| US10465366B2 (en) | 2014-05-27 | 2019-11-05 | As America, Inc. | Sanitaryware cleaning system |

Also Published As

| Publication number | Publication date |

|---|---|

| DE19945598B4 (de) | 2008-03-13 |

| DE19945598A1 (de) | 2001-04-19 |

| DE50011426D1 (de) | 2005-12-01 |

| ATE307932T1 (de) | 2005-11-15 |

| DE20023677U1 (de) | 2005-06-09 |

| EP1087067B1 (de) | 2005-10-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE602004003101T2 (de) | Am rand eines toilettenbeckens angebrachte vorrichtung zur abgabe von zwei flüssigkeiten | |

| EP0828902B1 (de) | Wc-körbchen für flüssige oder pastöse wirkstoffzubereitungen | |

| DE60215465T2 (de) | Toilettenreinigungsvorrichtungen | |

| DE60015005T2 (de) | Reinigungs- und Erfrischungseinheit zum Hängen am Rand eines Toilettenbeckens | |

| DE60026590T2 (de) | Flüssigkeitsspender | |

| EP2123833B1 (de) | Abgabevorrichtung zur Abgabe von Wirkstofffluiden | |

| EP0878586B1 (de) | Abgabevorrichtung für Toilettenbecken | |

| DE19915322C1 (de) | Nachfüllbares WC-Körbchen für Flüssigreiniger | |

| DE102008003359A1 (de) | Abgabevorrichtung zur Abgabe wenigstens eines Wirkstofffluids in das Spülwasser eines Toilettenbeckens sowie zur Beduftung der Umgebung | |

| DE19912217A1 (de) | Vorrichtung zur Abgabe von Wirkstoffen in das Spülwasser insbesondere in Toilettenbecken | |

| EP2183439A1 (de) | Abgabevorrichtung zur abgabe wenigstens eines wirkstofffluids in das spülwasser eines toilettenbeckens sowie zur beduftung der umgebung | |

| EP1472419A1 (de) | ABGABEVORRICHTUNG ZUR ABGABE EINES WIRKSTOFFFLUIDS IN DIE SPÜmlFLÜSSIGKEIT IN EINEM TOILETTENBECKEN | |

| EP1087067B1 (de) | Abgabevorrichtung für die Abgabe eines Wirkstoffes | |

| EP0960984A2 (de) | Abgabevorrichtung | |

| DE8714172U1 (de) | Klosett od. Pissoir | |

| EP1334243B1 (de) | Abgabevorrichtung zur abgabe von wirkstofffluiden | |

| DE19930362C2 (de) | Vorrichtung zur Abgabe einer flüssigen Wirkstoffzubereitung in ein Toilettenbecken | |

| DE69104355T2 (de) | Dosiervorrichtung für einen Toiletten-Wasserkasten. | |

| DE10025972B4 (de) | Vorrichtung zur Abgabe einer flüssigen Wirkstoffzubereitung in ein Toilettenbecken | |

| WO1999017650A1 (de) | Vorrichtung für das ausgeben eines duftstoffes, reinigungsmittels oder eines desinfektionsmittels in eine wc-schüssel | |

| EP1587992B1 (de) | Abgabevorrichtung zur abgabe eines wirkstofffluids in die spülflüssigkeit in einem toilettenbecken | |

| EP2104773B1 (de) | System zur abgabe von wirkstofffluiden in die spülflüssigkeit eines toilettenbeckens | |

| EP1268948A1 (de) | Nachfüllbares wc-körbchen für flüssigreiniger | |

| EP1659228A1 (de) | Wirkstoffabgabevorrichtung | |

| DE2932449A1 (de) | Wasserkastenautomat |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20010412 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| 17Q | First examination report despatched |

Effective date: 20040510 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051026 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051026 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50011426 Country of ref document: DE Date of ref document: 20051201 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060118 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060126 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060126 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060126 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060131 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060131 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060131 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060131 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060206 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20060119 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060327 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| 26N | No opposition filed |

Effective date: 20060727 |

|

| BERE | Be: lapsed |

Owner name: BUCK-CHEMIE G.M.B.H. . Effective date: 20060131 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 20080111 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051026 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090119 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20110128 Year of fee payment: 12 Ref country code: IT Payment date: 20110118 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20110112 Year of fee payment: 12 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120118 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20120928 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120118 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120118 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120131 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20130131 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50011426 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50011426 Country of ref document: DE Effective date: 20140801 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140801 |