EP1064110B1 - Biegemaschine für flachmaterial - Google Patents

Biegemaschine für flachmaterial Download PDFInfo

- Publication number

- EP1064110B1 EP1064110B1 EP00904892A EP00904892A EP1064110B1 EP 1064110 B1 EP1064110 B1 EP 1064110B1 EP 00904892 A EP00904892 A EP 00904892A EP 00904892 A EP00904892 A EP 00904892A EP 1064110 B1 EP1064110 B1 EP 1064110B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- bending

- machine

- bending tool

- tool

- bending machine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D5/00—Bending sheet metal along straight lines, e.g. to form simple curves

- B21D5/04—Bending sheet metal along straight lines, e.g. to form simple curves on brakes making use of clamping means on one side of the work

- B21D5/042—With a rotational movement of the bending blade

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D5/00—Bending sheet metal along straight lines, e.g. to form simple curves

- B21D5/04—Bending sheet metal along straight lines, e.g. to form simple curves on brakes making use of clamping means on one side of the work

Definitions

- the invention relates to a bending machine for flat material, comprising a Machine frame, arranged on the machine frame lower beam with a lower clamping tool and arranged on the machine frame Upper cheek with an upper clamping tool with which the flat material can be fixed in a clamping plane, a lower bending tool movement device, which is associated with the lower cheek and with which one Lower bending tool carrier with a lower bending tool for bending of the sheet around an upper bending edge relative to the clamping plane movable between a rest position and a plurality of bending positions is an upper bending tool moving device, which is the upper beam is assigned and with which an upper bending tool carrier with a upper bending tool for bending the sheet about a lower bending edge relative to the clamping plane between a rest position and a plurality is movable by bending positions.

- the invention is therefore based on the object, a bending machine of generic type to improve such that the type of possible bending operations as few restrictions as possible.

- the advantage of the solution according to the invention is the fact that with this a bending space is available, which in the known machines did not exist, either in the direction of the clamping plane of the clamping tools away still around the respective effective bending edge.

- the solution according to the invention also makes it possible to through the bending space free of machine elements of the bending machine, use additional devices, such as handling devices to be able to, who now have the opportunity in the bending free space unhindered through the machine elements of the bending machine with the Flat material to interact, for example, on the sheet access to perform additional functions, such as handling to be able to without a risk of collision with the acting bending tool consists.

- the bending machine according to the invention has in particular for each of the bending tools not a bending operation disturbing machine element in one Angular range of at least 110 °, so that with each of the two bending tools Bending operations are feasible, far beyond a right Going angle and thus complex bending parts with multiple bends in Different directions can be produced in one operation.

- Such a bending clearance can be inventively realized then, if the bending tool carrier in the rest position near a front surface of the respective Cheek stands, that is as far as possible away from the front plane and is arranged in the direction of the respective cheek.

- the bending space is dimensioned so that it is around the effective bending edge over an angular range of at least 120 ° extends. It is even more advantageous when the bending clearance around the bending edge extends over an angular range of at least 130 °.

- An optimal Biegehow having embodiment of a bending machine according to the invention provides that the bending tool movement device of standing at rest bending tool outside of the defined by the angular range bending space is.

- a bending machine in that the bending tool movement device for the respective bending tool in all bending positions of the bending tool exclusively on the side of the clamping level is, on which the Biegeguidingswolf of the bending tool is located.

- the bending tool movement device in all bending positions between one passing through the bending tool and perpendicular at the clamping level, the front boundary plane and the machine frame extends.

- Such a training the bending tool moving device has the great advantage that before the Frontbegrenzungsebene no element of Biegewerkmaschineschis worn and also of the machine frame is present, so that in this area the flat material survive unhindered, taken over by other machines or otherwise manipulated.

- Such a structure allows an inventive Bending machine also the ability to shape several machines to arrange a production line successively, the means that there is a possibility that this over the front boundary level on a machine frame opposite Side protruding flat material from another Machine can be taken in a simple way.

- the Bending tool itself is the element that on one Machine frame opposite side of the clamping tools farthest over the machine frame and all other machine parts of the bending machine, in particular the machine frame itself and the bending tool movement device, on the machine frame side facing lie the front boundary level.

- the bending machine when the bending tool moving device is in all possible bending positions between one by the bending edge extending and perpendicular to the clamping level Front level and the machine frame extends. Because the front plane even closer to the machine frame than the front boundary plane, is in this case an even greater freer Room on the side opposite the machine frame created the frontal plane, which on the one hand for a Variety of bending operations and on the other hand but also for exploit a manipulation of the bent sheet material leaves.

- the bending tool carrier is in all possible bending positions between one by the Bending edge extending and perpendicular to the clamping plane standing front plane and the machine frame extends, and thus arranged even closer to the machine frame, so that only the bending tool on the front plane on the machine frame opposite side protrudes.

- the bending tools are identical and each with one provided for each bending tool driven identical bending tool moving device.

- This solution includes all the applications in which Use one of the bending tools the other bending tool always in the rest position. But this solution closes nor, if appropriate, that special operations, for example, to folding operations or other special Bending operations or manipulation operations both bending tools be used and at the same time or directly shortly after the attack on the flat material.

- the bending tool movement device all conceivable and hitherto used in bending machines Capture realization forms that the invention Meet requirements.

- a particularly advantageous Execution of the bending tool movement device provides that these a plurality of facing in a bending tool Area of the bending tool carrier attacking and in a direction parallel to the longitudinal direction of the bending edge in Has fixed distances from each other arranged holding elements, which the bending tool carrier against the Support machine frame.

- the retaining elements can not only be used for this purpose be that the stability of the bending tool carrier itself can be reduced. Rather, the holding elements can be advantageously also use it as guides for a defined movement of an attack point on the same To serve bending tool carrier and thus also for fixing contribute to the path on which the bending tool at Passing through the individual bending positions moves.

- the holding elements are formed so that they lead the point of attack on a given path that, superimposed with other movements that contribute to the orbit which moves the bending tool.

- Such a guide of the bending tool carrier can be mechanical especially just form when the holding elements articulated on the bending tool carrier attack.

- the holding elements represent handlebars, on the one hand hinged to the machine frame and on the other hand hinged to the bending tool carrier attack, so that over the handlebars a web movement of the Defining the same point of application on the bending tool carrier in a simple manner leaves and also on the handlebars in a simple way large forces of the bending tool carrier are transferred to the machine frame In order to provide the bending tool carrier with sufficient dimensional stability To lend bending.

- Such a point of attack can be chosen particularly favorably if the Attatch holding elements on the cheek, which the respective bending tool assigned.

- the bending tool expediently also be positioned in a rest position is, for example, conceivable by moving the entire bending tool movement device between a Biegeguidings ein and the rest position to the rest position to reach. It is particularly favorable, however, if that Bending tool by the bending tool carrier drive units also between the rest position and the bending start position is movable.

- Overlay of this defined predetermined path with additional Path movements, for example by the holding elements given orbits, can be the according to the invention required movement of the bending tool reach the defined predetermined course appropriate.

- the web by a pivoting movement about a machine frame fixed Swivel axis can be specified.

- the bending tool carrier drive units are designed so that they carry out the web movements are driven by a drive.

- each of the bending tool carrier drive units can be driven by its own drive.

- each of the bending tool carrier drive units a pivotally drivable drive arm comprises, which on a first end pivotable about a machine frame fixed axis is and pivotable at a second end via a knee joint connected to the bending tool carrier.

- Such Formation of the bending tool carrier drive units has the Advantage that this in a simple manner a definable movement of the bending tool carrier for fixing realize the path of the bending tool.

- each of the bending tool carrier drive units is a toggle drive system for moving the bending tool carrier, there with such a toggle drive system in easy way to complex movements by setting the Lengths of the knee lever can be generated.

- a first lever of the toggle drive system to a machine frame fixed axis is pivotable.

- This translation movement can be used to, the provided for the bending tool path from the Biegeguidings ein for bending end position additionally with path corrections to provide.

- the drive arm via a Drive variable in length is adjustable.

- a Drive can in principle be a separate drive, with which at any time the length of the drive arm adjustable is. This would be particularly advantageous if by the Length adjustment also path corrections during the movement the path of the bending tool between the bending start position and the bending end position to be made.

- the drive for pivoting the drive arm as a drive for Length adjustment of the drive arm is used. so that the length adjustment - For example, to move the bending tool between the resting position and the bending start position - and moving the bending tool on the desired path a drive can be realized.

- the length adjustment of the drive arm could in principle for example, by a spindle adjustment or each other adjusting mechanism done.

- a particularly cheap Solution provides, however, that the drive arm due to a Toggle mechanism is variable in length.

- An implementation of such a toggle mechanism provides that the drive arm extends from the first end up to a center joint extending arm and a extending from the center joint to the second end Part arm covers.

- toggle mechanism is the length adjustment the drive arm particularly easy then feasible, when the toggle mechanism setting different Lengths of the drive arm in different Elongated positions can be specified.

- Such a determination of different extended positions can in the simplest case by blocking the movement of the Partial arms relative to each other or by a blockage of the center joint in different positions.

- a blocking device which is preferably either on the sub-arms themselves or acting on the center joint.

- the pivot drive is designed so that it attacks the center joint.

- a mechanically particularly favorable solution in which the Biegewerkmaschine Wegmikwith with as a second lever of the toggle drive system acts, provides that the bending tool carrier with Armfort arrangementsn extending in the direction of the drive arm is provided, each of which with the bending tool carrier forms the second lever of the toggle drive system. It is particularly favorable when the arm extensions rigid are connected to the bending tool carrier and thus each form a unity with this.

- a further advantageous support of the bending tool movement device is preferably carried out in that the Biegewerkmaschinectionnovantriebsaku on the Wangenarme the respective cheek is arranged and thus also in a suitable Saving space on the machine frame positioned is.

- the Movement of the knee joint relative to the first partial arm and also to the machine frame is not fixed, is preferably provided that the knee joint in the change in length of Drive arm is movable along a predetermined path.

- the web is straight runs.

- the realization of the guidance of the knee joint along a track can be particularly easily achieved in that on the Knee joint a track follower is arranged, which along a the course predetermining backdrop runs, preferably the Setting is arranged on the machine frame.

- the scenery in different positions is adjustable relative to the machine frame.

- the leadership of the knee joint along the track to use the movement between the Rest position and the bending start position of the bending tool set. For this reason, it is preferably provided that the track follower when moving the bending tool of the Rest position in the bending start position along the scenery is movable.

- elongated flat material with a to be able to edit the bending machine according to the invention is preferably provided that the machine frame at least one of its transverse sides for the introduction of flat material in the longitudinal direction of the bending edge and between the Upper cheek and the lower cheek is formed laterally open.

- Such a construction of the machine frame is in particular for flat sheet withdrawn from a coil or for long, laterally supplied flat material parts in one Production line advantageous.

- the clamping plane extending and transverse to the bending edge limited opening is present, which is greater than one Extension of the supplied sheet in this direction. It is particularly favorable, however, when the machine frame in the area of the clamping tools for inserting Flat material also formed open between the clamping tools is, so that also flat material, the transverse to the bending edge has a greater extent than, for example the distance between a guide of upper beam and lower beam relative to each other and the bending edge already side can be inserted between the clamping tools.

- a particularly advantageous embodiment of the machine frame provides that this essentially only between lateral End faces of the upper and lower cheeks extends.

- An advantageous type of training of the machine frame provides that the machine frame at least two in one Direction parallel to the longitudinal direction of the bending edge in succession having progressively arranged rack units, which the lower cheek and the upper cheek relative to each other keep moving.

- Interspaces arranged between the rack units Interspaces arranged.

- These spaces can, for example also be used, handling devices to provide for the sheet during bending, the intervene in the interstices and thus in a simple manner may be formed so that they the flat material advantageous grab and position to bend.

- each rack unit has a guide for one defined movement of the lower beam and the upper beam relative has to each other, so that the leadership of Oberwange and Lower cheek relative to each other on each of the rack units he follows.

- the frame units also the lower cheek and the upper cheek structurally advantageous form, since the rack units in each case a stabilization of lower cheek and upper cheek represent relative to each other, so that the stability of the Under cheek and the upper cheek in the longitudinal direction of the bending edge far less large than in machines in which cantilever and upper cheek self-supporting between side frame units of the machine frame extend.

- the guide of lower cheek and upper cheek relative to each other can be configured as desired.

- the pivot axis is such that they are in a distance from the clamping tools on a bending tool the same is arranged opposite side thereof.

- each rack unit has a lower beam carrier and has a main beam through the guide are movable relative to each other and each lower cheek or wear the upper cheek, so that the guide in sufficient be arranged at a large distance from the lower beam and upper beam can.

- a coherent Machine frame to form these are to connect with each other, although she already has a continuous under cheek and a continuous upper cheek connect with each other exhibit.

- the lower beam support the rack units rigidly connected are, preferably in addition to the lower cheek still another continuous rigid connection between the upper beam carriers the rack units is provided.

- each of the rack units has a bending tool carrier drive unit for the respective bending tool assigned.

- Particularly favorable can be with a machine frame of at least two Such frame units a side frame free trained machine frame in that the frame units between lateral end faces the upper cheek and the lower cheek are arranged and thus the Machine frame inevitably in the range of at least one transverse side open to this, flat material between the upper cheek and the To insert the lower cheek.

- a simple bending kinematics is when the bending tool a bending nose with a curved pressure surface for applying having a side of the sheet.

- An advantageous embodiment provides that the bending tool through the bending tool movement device between a bending start position and a bending end position on a path around the respective bending edge is movable, which is defined defined such that the domed Pressure surface and the applied side of the sheet relative to each other in the form of a substantially sliding free rolling on each other.

- the web of the bending tool by a mechanical web guide is defined, so that no precise path control the bending tool with the help of large forces necessary is, but only a drive of the bending tool such, that it follows the web guide.

- the web guide can be realized in many different ways be. For example, it would be conceivable to this purpose a slide track to create a train follower. Such Sliding track is on the one hand consuming to manufacture and on the other hand associated with considerable size.

- a pivoting movement has the great advantage that this in a simple way for realize large forces suitable and in particular in simple way without much mechanical effort lesser signs of wear is afflicted than a Guidance by means of a slide track.

- the inventive web can then realize when the web of the bending tool by overlaying given at least two pivoting movements, with respect to the advantage of the pivoting movements over Slotted guides on the above Reference is made.

- an advantageous embodiment provides that the Bend nose with a bending nose tip in all bending positions at least one of the clamping tools facing, wherein in such an orientation of the bending nose only Simple movements of the same are required to enter inventive way to bend the sheet.

- a particularly advantageous embodiment of the printing surface sees before that this faces away from the bending tool carrier lying front partial pressure surface, of the Crest line goes away.

- Such a type of printing surface is particularly suitable for performing Bends of the flat material by angles of up to 90 °.

- the pressure surface is a bending tool carrier having facing rear partial pressure surface, that of the front partial pressure surface opposite of the Crest line goes away.

- Such a training of Pressure surface has the advantage that in particular also large bending angle, in particular bending angle of more than 90 °, with simple movement of the Let bending tool be realized.

- the contact line between the printing surface and the loaded side of the sheet material in the area of the front partial pressure surface lies and moves in bending towards the crest line.

- the bending nose in such a bending end position is movable, in which the contact line in the area of the rear Partial pressure surface is, so that the largest possible pressure surface during the bending process can be used and in particular with a simple motion kinematics a bending of the sheet material is movable by more than 90 °.

- An embodiment of a bending machine according to the invention includes a whole 10 with machine frame, which is a variety of rack units 12a to 12c, which in a Longitudinal direction 14 are arranged successively so that between the individual rack units 12a and 12b and 12b and 12c each gaps 16a, 16b remain.

- the rack units 12 are firmly connected to each other, for example through on a base 16 for the bending machine lying on and in the longitudinal direction 14th extending side members 18a, b, on which the individual Rack units sit and which also over the Between spaces 16 imparterumblen.

- Each of the rack units 12 includes, as in Figs. 1 to 3 recognizable, a Unterwangenarme 20, which on the longitudinal beams 18 rests and over this with a Unterwangenarme endeavor 22 rises, at which one in the longitudinal direction 14 over all frame units 12 extending lower beam 24 is held, in turn, a lower clamping tool 26 carries.

- the lower cheek body 22 is constructed so that this between the lower beam 24 and the front side member 18a has a front wall 28, which in the direction of one of these formed opposite to the rear wall 30 is and so between the lower beam 24 and the front side member 18a creates a freely accessible front room 32.

- the front wall 28 has a lower area 34 on, with respect to a bottom part 36 of the lower beam carrier body 22 is inclined at an angle of less than 90 ° and thus starting from the front side member 18a in Direction of the rear wall 30 rises and then rises into a upper area 38 passes, in which the front wall 28th turn away from the rear wall 30 in the direction of the lower cheek 24 extends to a lower cheek 24 receiving cutout 40 of the lower beam carrier body 22.

- the lower beam support body 22 still with an upper part 42nd provided, which is a support 44 for sheet to be bent 46 carries.

- the lower beam carrier 20 is still two at a distance arranged side walls 48 and 50, which over the rear wall 30 and preferably also the upper part 42 survive and in a projecting region 52 a pivot bearing 54 wear, with which a top beam 60 swivel is mounted opposite the lower beam carrier 20.

- the top beam support 60 includes a top beam support body 62, which in turn has a top cheek 64 with an upper one Clamping tool 66 carries, wherein the upper beam 64 with the upper clamping tool 66 on one of the lower beam 24 with the lower clamping tool 26 opposite side a workpiece receiving space 70 lies, in which the flat material 46 is positionable to this between the top Clamping tool 66 and the lower clamping tool 26 for Bend in.

- the upper beam carrier body 62 is preferably designed such that it has a lower part 72, which is located on a the upper part 42 of the lower beam carrier body 22 opposite Side of the workpiece receiving space 70 extends, and a front wall 74, which is at an acute angle to the lower part 72 extending above this rises and up to a rear wall 76 extends, which the lower part 72 with the Front wall 74 connects.

- the upper beam support body 62 still comprises each other opposite side walls 78, 80 which extend over the Upper beam carrier body 62 also extend between the side walls 48, 50 in their over the lower beam carrier body 22 extending range and on the Engage pivot bearing 54, so that the entire upper beam carrier body 62 about a pivot axis 82 of the pivot bearing 54th pivotable relative to the lower beam carrier body 22 to store.

- the side walls 78 and 80 extend with lower portions 84 in the direction of the rear side member 18b and hold a bearing 86, to which a drive 90th attacks, in turn, by means of a bearing 92 in the Lower beam carrier body 22 is mounted and, for example acts on the bearing 86 by means of a drive rod 88.

- the drive 90 serves to the upper beam carrier body 62 relative to the lower beam carrier body 22 about the pivot axis 82 to pivot and thus the upper beam 64 with the upper Clamping tool 66 from the lower beam 24 with the lower Clamping tool 26 to move away to the clamping of the To release flat material 46 and this or other flat material subsequently again between the clamping tools 26, 66 to clamp.

- the drive 90 is as an actuating cylinder formed, which either hydraulically or pneumatically is operable.

- each of the clamping tools 26, 66 is parallel to the longitudinal direction 14 defines extending bending edge 104 and 106, which then, if this is effective, the umbiegende portion 102 of the sheet 46 bendable is.

- a bending over of the portion 102 to be bent takes place, as shown in FIG. 2, for example, by means of a lower bending tool 110, which a lower bending tool carrier 112 is held, wherein the lower Bending tool 110 extends in the longitudinal direction 14 and the lower bending tool carrier 112 preferably in the longitudinal direction 14 over the entire Length of the lower cheek 24 extends.

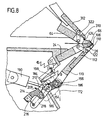

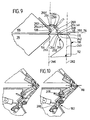

- a bending tool 110 For bending is the lower bending tool 110, starting from a in Fig. 5 illustrated rest position, in which the bending tool 110 in a withdrawn relative to the bending edge 104 of the lower clamping tool 26 Rest position stands, toward a clamping level 114 for the Flat material 46 first in a bending start position shown in Fig. 6 movable, in which the bending tool 110 on an underside 116 of the Flat material 46 is applied and then further in in Fig. 7 and Fig. 8 shown Bending positions movable, causing a bending around the effective bending edge 106 of the upper clamping tool to that shown by way of example in FIG Biegeend ein done.

- the bending tool movement device includes, how Shown in Fig. 1 to 8, a plurality of in the longitudinal direction 14 spaced from each other retaining brackets 122, which in the region of a first end 124 by means of a Swivel bearings 126 are pivotally mounted on the lower cheek and in the region of a second end 128 by means of a pivot bearing 130 in a near the bending tool 110 lying Area 132 of the lower bending tool carrier 112.

- the first end 124 is each of the retaining links 122 in a recess 134 of the lower beam 24 so that the Retaining rod 122 at least with its second end 128 via the recess 134 protrudes and into a recess 136 in engages the portion 132 of the bending tool carrier 112, wherein the second end 128 supporting pivot bearing 130 preferably is also disposed in the recess 136.

- the retaining rod 122 is each with its ends 124th and 128 in the recesses 134 and 136 of the lower beam 24th or of the bending tool carrier 112 and the retaining link 122 extends with a central, between the ends 124 and 128 lying area 138 via a gap 140 between the lower beam 24 and the lower bending tool carrier 112th

- pivot bearings 126 and 130 is a by a Swivel axis 142 of the pivot bearing 130 defined point of the respective retaining link 122 on the bending tool carrier 112 on a track 144 about a pivot axis 146 of Swivel bearing 126 guided around, wherein the web 144 a Circular path with respect to a machine frame fixed center represents.

- the retaining rods 122 are over the entire length of the bending tool carrier 112 distributed at constant intervals arranged from each other and store this movable opposite the lower cheek 24, wherein the plurality of retaining rods 122nd the bending tool carrier 112 in the region 132 due to multiple support against the lower beam 24 an improved Bending stiffness against bending of the Biegewerkmaschine Wegns 112 with partial enlargement of the Gap 140 represents, so that thereby the entire Biegewerkmaschine Wegmik Wegmant, the bending tool carrier 112 also stabilized.

- the distance between successive Retainers 122 in the longitudinal direction 14 less than 50cm.

- the bending tool moving device comprises 120 also still several bending tool carrier drive units 150, preferably each a bending tool carrier drive unit 150 of the one Frame units 12 is assigned.

- Each bending tool carrier drive unit 150 comprises, as in FIG 6 to 8, a toggle drive system 152, which in turn by a first lever forming Drive arm 154 and one with this via a knee joint 156th connected to a second lever forming arm 158 is formed is.

- the drive arm 154 is in turn in a first storage area 160 via a pivot bearing 162 about an axis 164th pivotally mounted relative to the lower beam carrier body 22, wherein the pivot bearing 162 on the lower beam support body 22nd engages, so that the pivot axis 164 fixed against the lower beam carrier body 22 and thus to the Machine frame is arranged.

- the drive arm 154 is in a second storage area 166 pivotally connected to the arm 158 via the knee joint 156, which extends from the knee joint 156 to the pivot axis 142 of the pivot bearing 130 extends.

- the arm 158 is partially by a from the pivot axis 142 in Direction of the knee joint 156 extending portion 168 of formed lower bending tool carrier 112 and a on arm extension 170 following this section 168.

- the drive arm 154 is the through the knee joint 156th defined point of attack on the arm 158 on a circular path 172nd about the axis 164 movable and thereby movement of the lower bending tool 110 can be fixed, which also through the path 144 of the point of attack 142 of the retaining rods 122nd on the bending tool carrier 112 and the lever length between the Knee joint 156 and the point of application 142 and the distance of the bending tool 110 from the point 142 set is.

- the drive arm 154 by variation of a Distance between the pivot bearing 162 and the knee joint 156 variable in length, by a toggle mechanism 182, which by one from the first Storage area 160 up to a center joint 184 of the drive man 154 extending first partial arm 186 is formed, and a from the center joint 184 to the knee joint 156 of the Knee lever drive system 152 extending second arm 188th

- a pivot drive 190 which, for example is designed as a control cylinder 192 and a Operating rod 194 acts on the center joint 184, wherein the actuating rod preferably also hinged on Center joint 184 attacks.

- the knee joint 156 is provided with a track follower 196 in FIG Form provided a role, which in all knee joint positions the toggle mechanism 182 until reaching an extended position on a whole designated 198 Sliding track can be applied, wherein the slide track 198 by a running rail is formed, against which as a role trained track follower 196 can be applied and along a surface 200, preferably formed as a plane, in the longitudinal direction 202 of the slide track 198 is movable.

- the slide track 198 is in turn on one of the front wall 28 of the Lower beam carrier body 22 facing end via a hinge 204 pivotally mounted on the lower beam carrier body 22 and on the other hand via an adjusting 206 in the direction of Track successor 196 or adjustable away from it, so that ever after setting the slide track 198 of the tracker 196 in different positions of the toggle drive system 152 at the backdrop path 198 comes to the plant, if by one defined length adjustment of the drive arm 154 assumed becomes.

- the blocking device 208 comprises a Blocking lever 210, which relative to the pivot axis 164 to the first arm 186 is pivotally mounted on this.

- the blocking arm 210 further includes a direction towards the first sub-arm 186 and via this and the center joint 184th extending blocking finger 212, which at the second arm 188 can be applied.

- the blocking arm 210 includes a on a the Blocking finger 212 opposite side over the pivot axis 164 extending drive arm 214, in turn is connected to an actuator 216, wherein the Actuator 216 acts on a support arm 218, the one-piece is connected to the first arm 186, but in opposite Direction to the first arm on the pivot bearing 162 personallyerstreckt and parallel to the drive arm 214th the blocking arm 210 runs.

- the actuator 216 is used to the blocking finger 212 relative to the first arm 186th to pivot in different positions, so that the Blocking finger 212 in different extended positions of the second sub-arm 188 relative to the first sub-arm 186 on the second arm 188 comes to rest and one about this Extended position extending extension position of the second part of the arm Blocked 188 relative to the first arm 186.

- a connecting line 220 runs between the pivot bearing 162 and the center joint 184 in FIG an angle of less than 180 ° to a connecting line 222 between the center joint 184 and the knee joint 156, so that the drive arm 154 a by the distance between the Pivot bearing 162 and the knee joint 156 has defined length, which is smaller than the maximum by the toggle mechanism 182 adjustable length, which is given then when the connecting line 220 between the pivot bearing 162 and the center joint 184 with the connection line 222 between the center joint 184 and the knee joint 156 flees.

- This second extended position is shown for example in FIG. 2.

- the blocking device 208 of the toggle mechanism 182 is further arranged so that the position of the blocking device 208 a buckling of the toggle mechanism in one Kinking when moving the center joint 184 in the direction the pivot drive 190 is not prevented, so that when moving of the center joint 184 in the direction of the pivot drive 190th a shown in Fig. 5 minimum length of the drive arm 154 is reachable.

- minimum length of the drive arm in which the connecting lines 220 and 222 a Enclose angles of preferably less than 90 ° with each other, is the lower bending tool 110 in its maximum retracted or rest position, in which the bending tool 110 preferably in a recess 224 provided for this purpose which is for receiving the bending tool 110 in the Rest position is provided in the lower beam 24.

- the Rest position are simultaneously the retaining link 122 in one opposite the lower cheek 24 and also the bending tool carrier 112 strongly inclined position, so that the lower bending tool carrier 112 with his over the lower cheek 24th extending area as close as possible.

- the slide track 198 is preferably by the actuator 206 adjusted so that in the initial bending position of the track following 196 still rests on the slide track 198, also but in the initial bending position by the blocking device 208 predetermined extended position of the toggle mechanism 182 is reached, so that the drive arm 154 the for the bending operation and thus the path of the bending tool having provided maximum length.

- predetermined extension position By blocking the toggle mechanism 182 in the by the blocking device 208 predetermined extension position further moves the first sub-arm 186 in the Pivoting direction 226 for pivoting the drive arm 154 in the pivoting direction 226 in total, which then after Reaching the bending start position of the bending tool 110 also the Bahndecier 196 lifts off from the slide track 198 and moves according to the path 172 of the knee joint 156 and Although against the action of the energy storage 230.

- This moves the bending tool 110 in the subsequent bending positions and acts against the underside 116 of the sheet 46 in such a way that this in a first bending direction 232 from the clamping plane 114 upwards, the is bent in the direction of the upper beam 64.

- the bending of the flat material 46 can, as in Fig. 8 shown, as long as the flat material 46, such as shown in Fig. 8, on a at an acute angle to Einspannesebene 114 extending oblique front surface 234 of the upper clamping tool 66 is applied.

- the bending tool 110 has a neck 240 which extends connects to the bending tool carrier 112.

- the neck 240 wears in turn, a bending nose 242, which to the actual Performing the bending operation is used.

- the bending nose 242 extends from the neck 240 in the direction of Clamping tools 26, 66, that a bending tip 244 always at least one of the clamping tools 26, 66 faces and starting from the bending tip of the nose, the bending nose 242 from the respective clamping tool 26 and / or 66 extends.

- the bending nose 242 carries as a whole 246 designated printing surface, with which the bottom 116th of the flat material 46 can be acted upon.

- the printing surface 246 comprises a bending tool carrier 112 facing away from arranged upper partial pressure surface 248, with which the bending nose 242 in the bending start position first the bottom 116 of the Flat material 46 touched.

- the front partial pressure surface 248 is bent to one at the bending tip 244 lying crest line 250. Starting from the crest line 250 then still extends a rear partial pressure surface 252nd the pressure surface 246 on a bending tool carrier 112 facing side of the bending nose 242 of the bending nose tip Away.

- the Biegenase 242 plant at the bottom in this case 116 of the sheet 46 is a substantially linear Plant, which predetermined by a contact line 254 is, which is parallel to the longitudinal direction 14 and thus also extends in the longitudinal direction of the bending tool 110.

- a contact line 254 is, which is parallel to the longitudinal direction 14 and thus also extends in the longitudinal direction of the bending tool 110.

- the Biegeusings ein is, as shown in Fig. 9, the Contact line 254 on the front partial pressure surface 248, and while at a maximum distance from the apex line 250.

- the flat material 46 bent out of the clamping plane 114 so migrates the contact line 254 on the front partial pressure surface 248 in the direction of the crest line 250 and then coincides with the Crest line 250 together when the sheet 46, for example by an angle of the order of 90 ° the clamping level 114 has been bent out.

- the sheet 46 passes over this angle the contact line 254 across the crest line 250 and then migrates to the rear partial pressure surface 252 at which it rests in all bending positions in which a bend of the flat material 46 with respect to the clamping plane 114 um an angle of more than 90 ° is done.

- the determination of the web 260, with which the bending nose 242 from the initial bending position to the final bending position moves takes place by appropriate determination of the dimensions the knee lever drive system 152, in particular the lengths of Drive arm 154 and the arm 158 and the dimensions the retaining rod 122 and the distance of the bending nose 242 of the pivot axis 142.

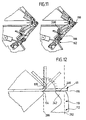

- the blocking device 208 allows, as already described, different extended positions of the toggle mechanism Adjust 182, as in Fig. 10 and 11 again clearly is shown.

- the toggle mechanism 182 In the first, in Fig. 10 shown extended position the toggle mechanism 182 is not in its maximum Extended position, but has a length that is less as the maximum possible length while, for example, in the second, in Fig. 11 shown extended position, the Length of the toggle mechanism 182 is maximum.

- the bending tool 110 each in the initial bending position should stand. For this reason is at the second extended position of the toggle mechanism 182 the Sliding link 198 set with the actuator 206 so that this closer to the upper portion 38 of the front wall 28 of the Lower beam carrier body 22 is than in the first extended position.

- the bending machine does not only include the lower one Bending tool 110 and the lower bending tool carrier 112 with a associated bending tool moving device 120, but also still in addition, an upper bending tool 310, which on an upper bending tool carrier 312 is held, wherein the upper bending tool 310 by a bending tool moving device 320 is movable, in the same preferably identical manner is formed, as the bending tool movement device 120th

- the bending tool moving device 320 also includes Retaining rods 322, which function in the same way as the retainer 122, and attack the upper cheek 64 in this case.

- the bending tool carrier drive units 350 are formed in the same way, like the bending tool carrier drive units 150, but in this case the upper beam carrier body 62 is arranged.

- the upper bending tool 310 is capable of the same Perform bending operations, such as those associated with the lower bending tool 110 have been described.

- a bending operation performed with the lower bending tool 110 so is the upper bending tool 310 in the rest position, in which it in a depression 224 corresponding recess 424 engages in the upper beam 64.

- the upper bending tool 310, the upper Bending tool carrier 312 and also the upper bending tool movement device 320 are near the upper cheek 64 and lie close to the front wall 74 of the upper beam carrier body 62,

- There is a bending clearance above the effective bending edge 106 280 between the upper bending tool moving means 320, the upper bending tool carrier 312 and the upper Bending tool 310 and the clamping level 114 which is starting from the clamping level 114 over an angular range ⁇ of about 135 °.

- the lower bending tool carrier 112 does not move in the form of a pivoting movement about the effective bending edge 106 - as is the case in the prior art - but remains in all possible bending positions of the lower bending tool 110 in a between a perpendicular to Clamping level 114 and by the lower bending tool 110 extending Front Begrenzungssebene 282 and the lower beam support 20 lying Action space and also the bending tool movement device 120 remains in this action space without reaching beyond, so that so for example the flat 46 can be handled easily or a shortcut several machines in a simple manner is possible.

- the action space is even smaller and lies between one the respective effective bending edge 104, 106 therethrough and perpendicular to the clamping plane 114 extending front plane 286 and the Unterwangenarri 20th

- the lower bending tool 110 with the bending tool carrier 112 into the rest position which, for example, in Fig. 5 is shown. Also in this rest position of the lower bending tool 110 exists between the clamping plane 114 and the lower bending tool moving means 120, the lower bending tool carrier 112 as well the lower bending tool 110, a bending space 284, which is also over an angular range ⁇ of approximately 135 ° with respect to the clamping plane 114 extends, so that even with the upper bending tool 310, a bending of the Flat material 46 opposite the clamping plane 114 to the bending edge 104th of the lower clamping tool 26 by an angle of up to 135 ° possible is.

- the flat material is thus with the bending machine according to the invention 46 from the clamping level 114 in two opposite Directions, namely toward 290 above or in the direction 292 down from the clamping level 114 out possible, where to bend in the direction of 290 the lower bending tool 110 and for bending in the direction 292 the upper bending tool 310 are used, while the respective other bending tool 310 or 110 for creating the respective Biegeokraums 280, 284 is at rest and the respectively active bending tool carrier 112, 312 remains together with the associated bending tool movement device in the Action space between the front level 286 and the respective Wang bearer 20, 60.

- the bending machine according to the invention allows the Performing multiple bends of flat material, for example first in the direction of 290 and then in Direction 292, and then possibly back towards 290, wherein each of the bending clearances 280 and 284 between the front plane 282 and the other bending tool carrier 312 and 112 are advantageous, since so despite existing bends in the same direction, an additional Bend without hindrance is feasible.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Bending Of Plates, Rods, And Pipes (AREA)

- Shaping Of Tube Ends By Bending Or Straightening (AREA)

- Veneer Processing And Manufacture Of Plywood (AREA)

- Wrappers (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19901797 | 1999-01-19 | ||

| DE19901797A DE19901797A1 (de) | 1999-01-19 | 1999-01-19 | Biegemaschine |

| PCT/EP2000/000124 WO2000043140A1 (de) | 1999-01-19 | 2000-01-11 | Biegemaschine |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1064110A1 EP1064110A1 (de) | 2001-01-03 |

| EP1064110B1 true EP1064110B1 (de) | 2003-05-07 |

Family

ID=7894630

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00904892A Expired - Lifetime EP1064110B1 (de) | 1999-01-19 | 2000-01-11 | Biegemaschine für flachmaterial |

Country Status (10)

| Country | Link |

|---|---|

| US (1) | US6427511B1 (da) |

| EP (1) | EP1064110B1 (da) |

| JP (1) | JP2002535144A (da) |

| AT (1) | ATE239566T1 (da) |

| CA (1) | CA2324368A1 (da) |

| DE (2) | DE19901797A1 (da) |

| DK (1) | DK1064110T3 (da) |

| ES (1) | ES2198283T3 (da) |

| PT (1) | PT1064110E (da) |

| WO (1) | WO2000043140A1 (da) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2014381A2 (en) | 2007-07-13 | 2009-01-14 | Franze Reinhard | Sheet-metal bending machine, preferentially hydro-powered machine, and a method of its operation |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7444880B2 (en) * | 2003-12-12 | 2008-11-04 | California Institute Of Technology | Method and apparatus for measuring the mechanical response of micro-electro-mechanical systems |

| WO2007102176A1 (en) * | 2006-03-08 | 2007-09-13 | Pro Form S.R.L. | Device and method for bending a metallic strip |

| DE102011103383A1 (de) * | 2011-06-03 | 2012-12-06 | Weinbrenner Maschinenbau Gmbh | Biegepresse |

| AT515280B1 (de) * | 2014-06-10 | 2015-08-15 | Trumpf Maschinen Austria Gmbh | Biegepresse mit Biegeeinheit sowie Verfahren zur Umformung |

| ITUB20154609A1 (it) * | 2015-09-22 | 2017-03-22 | Tecnoma Automazioni Ind Srl | Macchina multifunzione atta ad eseguire pieghe, curve aperte e chiuse in lamiera, sequenzialmente, in unica struttura. |

| EP3706930B1 (en) | 2017-11-06 | 2024-06-19 | Hershberger, Nelson Dwayne | Bending machine |

| DE102018000344B3 (de) | 2018-01-17 | 2019-05-23 | Nikolaus Franz Duscher | Biegemaschine, Biegeeinheit, elektronische Steuereinrichtung und Verfahren zum Biegen eines Werkstücks aus Flachmaterial |

| CN108856383A (zh) * | 2018-06-29 | 2018-11-23 | 厦门正黎明冶金机械有限公司 | 折弯机构及折弯设备 |

| DE102021117488A1 (de) | 2021-07-07 | 2023-01-12 | EVOBEND GmbH | Bearbeitungsmaschine, Werkstücktisch und Verfahren zur Bearbeitung eines Werkstücks |

| KR102650530B1 (ko) * | 2023-07-03 | 2024-03-22 | (주)동양모터스 | 판재 자동절곡기 |

| CN116921513B (zh) * | 2023-09-14 | 2023-12-12 | 广州市德晟机械有限公司 | 一种自动化吊耳折弯机 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2307592A1 (fr) * | 1975-04-16 | 1976-11-12 | Lamendour Andre | Machine automatique de pliage de toles |

| CH622447A5 (en) * | 1977-11-14 | 1981-04-15 | Thalmann Konstruktionen Ag | Bending machine |

| AT363757B (de) * | 1980-04-24 | 1981-08-25 | Voest Alpine Ag | Vorrichtung zum abkanten von blechtafeln |

| FR2509204A1 (fr) * | 1981-07-07 | 1983-01-14 | Jouanel Sa Ets Y | Plieuse automatique de toles |

| DE4019881A1 (de) * | 1990-06-22 | 1992-01-09 | Horst Warneke | Schwenkbiegepresse zum abkanten und verformen von blechtafeln |

| DE4206417A1 (de) * | 1992-02-29 | 1993-09-02 | Edgar Griebel | Schwenkbiegemaschine |

| JPH06226354A (ja) * | 1993-01-29 | 1994-08-16 | Amada Co Ltd | 板材折曲げ加工装置 |

-

1999

- 1999-01-19 DE DE19901797A patent/DE19901797A1/de not_active Ceased

-

2000

- 2000-01-11 DE DE50002044T patent/DE50002044D1/de not_active Expired - Lifetime

- 2000-01-11 ES ES00904892T patent/ES2198283T3/es not_active Expired - Lifetime

- 2000-01-11 JP JP2000594589A patent/JP2002535144A/ja active Pending

- 2000-01-11 EP EP00904892A patent/EP1064110B1/de not_active Expired - Lifetime

- 2000-01-11 AT AT00904892T patent/ATE239566T1/de active

- 2000-01-11 CA CA002324368A patent/CA2324368A1/en not_active Abandoned

- 2000-01-11 PT PT00904892T patent/PT1064110E/pt unknown

- 2000-01-11 WO PCT/EP2000/000124 patent/WO2000043140A1/de active IP Right Grant

- 2000-01-11 DK DK00904892T patent/DK1064110T3/da active

- 2000-09-19 US US09/665,152 patent/US6427511B1/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2014381A2 (en) | 2007-07-13 | 2009-01-14 | Franze Reinhard | Sheet-metal bending machine, preferentially hydro-powered machine, and a method of its operation |

Also Published As

| Publication number | Publication date |

|---|---|

| ES2198283T3 (es) | 2004-02-01 |

| WO2000043140A1 (de) | 2000-07-27 |

| DK1064110T3 (da) | 2003-08-25 |

| ATE239566T1 (de) | 2003-05-15 |

| DE19901797A1 (de) | 2000-07-27 |

| JP2002535144A (ja) | 2002-10-22 |

| EP1064110A1 (de) | 2001-01-03 |

| PT1064110E (pt) | 2003-09-30 |

| DE50002044D1 (de) | 2003-06-12 |

| US6427511B1 (en) | 2002-08-06 |

| CA2324368A1 (en) | 2000-07-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1064108B1 (de) | Biegemaschine | |

| EP1064110B1 (de) | Biegemaschine für flachmaterial | |

| EP1064109B1 (de) | Biegemaschine für flachmaterial | |

| EP3370892B1 (de) | Greifersystem für eine biegepresse | |

| EP2756891B1 (de) | Vorrichtung zum Biegen strangförmiger Werkstücke | |

| DE69805631T2 (de) | Biegepresse für metallblech | |

| EP0934131B1 (de) | Biegemaschine | |

| DD153404A5 (de) | Gleisstopfmaschine | |

| WO2019001982A1 (de) | Verfahren zur herstellung eines biegeteils und biegemaschine zur durchführung des verfahrens | |

| AT519221B1 (de) | Fertigungsanlage mit einem Klemmwerkzeug sowie Verfahren zur Anpassung einer Gesamtlänge einer Biegekante des Klemmwerkzeugs | |

| EP3365122B1 (de) | Fertigungsanlage zur fertigung von werkstücken aus blech | |

| EP1748855A1 (de) | Vorrichtung zum schrittweisen verschieben von werkstücken | |

| AT515407A4 (de) | Biegewerkzeug sowie Wechseleinheit hierfür | |

| DE20310428U1 (de) | Biegewerkzeug mit einstellbaren Werkstückwiderlagersegmenten sowie Biegemaschine mit einem derartigen Biegewerkzeug | |

| DE69507627T2 (de) | Abkantpresse zur herstellung u-foermiger abkantungen an den vier kanten eines tafelbleches | |

| DE19701830C2 (de) | Vorrichtung zur Bewegung eines Körpers im Raum | |

| DE10214275A1 (de) | Biegemaschine für Profile und Rundrohre | |

| EP3427853B1 (de) | Hinteranschlageinheit sowie damit ausgestattete fertigungsanlage | |

| EP0894550A2 (de) | Biegemaschine zum Mehrseitigen Biegen | |

| DE19640124A1 (de) | Biegemaschine | |

| DE102004041024A1 (de) | Verfahren und Vorrichtung zum Herstellen eines längsnahtgeschweißten Hohlprofils | |

| EP1584385B1 (de) | Biegewerkzeug zum Biegen von Werkstücken, insbesondere von Blechen sowie Biegemaschine mit einem derartigen Biegewerkzeug | |

| EP3041618B1 (de) | Biegemaschine, sowie verfahren zum biegen eines blechwerkstückes | |

| DE102020124126B3 (de) | Blechbiegemaschine mit Anschlagsystem | |

| WO2007093356A2 (de) | Vorrichtung zum kippen von steinen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20001017 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| 17Q | First examination report despatched |

Effective date: 20010118 |

|

| RTI1 | Title (correction) |

Free format text: BENDING MACHINE FOR FLAT MATERIAL |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030507 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030507 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50002044 Country of ref document: DE Date of ref document: 20030612 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: KIRKER & CIE SA |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030807 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20030807 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D Ref document number: 1064110E Country of ref document: IE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040111 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040131 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2198283 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20040210 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050111 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20081118 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20081117 Year of fee payment: 10 |

|

| PGRI | Patent reinstated in contracting state [announced from national office to epo] |

Ref country code: IT Effective date: 20091201 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20100712 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20100111 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100111 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100712 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20150112 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 50002044 Country of ref document: DE Representative=s name: HOEGER, STELLRECHT & PARTNER PATENTANWAELTE MB, DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 17 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160131 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20171211 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20180115 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20180115 Year of fee payment: 19 Ref country code: DK Payment date: 20180110 Year of fee payment: 19 Ref country code: FI Payment date: 20180110 Year of fee payment: 19 Ref country code: ES Payment date: 20180201 Year of fee payment: 19 Ref country code: DE Payment date: 20180226 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20171228 Year of fee payment: 19 Ref country code: SE Payment date: 20180111 Year of fee payment: 19 Ref country code: IT Payment date: 20180122 Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 50002044 Country of ref document: DE Representative=s name: HOEGER, STELLRECHT & PARTNER PATENTANWAELTE MB, DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50002044 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20190131 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20190201 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 239566 Country of ref document: AT Kind code of ref document: T Effective date: 20190111 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190112 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190111 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190131 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190801 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190131 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190111 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190111 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20200309 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190112 |