EP1049584B1 - Method and device for preventing an uncontrolled powder dispersion in a printing machine - Google Patents

Method and device for preventing an uncontrolled powder dispersion in a printing machine Download PDFInfo

- Publication number

- EP1049584B1 EP1049584B1 EP99908798A EP99908798A EP1049584B1 EP 1049584 B1 EP1049584 B1 EP 1049584B1 EP 99908798 A EP99908798 A EP 99908798A EP 99908798 A EP99908798 A EP 99908798A EP 1049584 B1 EP1049584 B1 EP 1049584B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- air

- powder

- sheet

- sheet delivery

- housing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F23/00—Devices for treating the surfaces of sheets, webs, or other articles in connection with printing

- B41F23/04—Devices for treating the surfaces of sheets, webs, or other articles in connection with printing by heat drying, by cooling, by applying powders

- B41F23/044—Drying sheets, e.g. between two printing stations

- B41F23/0443—Drying sheets, e.g. between two printing stations after printing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F23/00—Devices for treating the surfaces of sheets, webs, or other articles in connection with printing

- B41F23/04—Devices for treating the surfaces of sheets, webs, or other articles in connection with printing by heat drying, by cooling, by applying powders

- B41F23/06—Powdering devices, e.g. for preventing set-off

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H29/00—Delivering or advancing articles from machines; Advancing articles to or into piles

- B65H29/24—Delivering or advancing articles from machines; Advancing articles to or into piles by air blast or suction apparatus

- B65H29/245—Air blast devices

- B65H29/246—Air blast devices acting on stacking devices

- B65H29/247—Air blast devices acting on stacking devices blowing on upperside of the sheet

Definitions

- the invention relates to a method and an apparatus for Prevent an uncontrolled spread of powder in one Press.

- the invention relates in particular to a Process in which sheets printed in a sheet-fed printing machine by means of a sheet conveyor through a sheet delivery conveyed through a stack of sheets and with one Powder are dusted and one is uncontrolled Spread of excess powder is prevented, as well a device for preventing an uncontrolled Spreading powder in a sheet delivery case a sheet printing machine that a sheet conveyor for Transport of printed sheets via a sheet stack and a dusting device for dusting the printed Powder surrounds bow.

- the invention relates above also a sheet delivery for a sheet printing machine and a Sheet printing machine with such a device.

- a paper or chain conveyor Sheet delivery i.e. a chain conveyor with two parallel, connected by delivery gripper systems or sheet grippers Chains included and within a the sheet delivery and enclosing the printing units of the printing press housing transported a stack of sheets on which she then are stacked on top of each other. Since the printing ink at The sheets are not yet completely stacked on top of one another is dried at most on the market located sheetfed offset presses at least one Surface of each sheet before placing it on the stack with powdered on the printed areas of the Sheets of paper stick and a deposit, i.e.

- a sticking together the sheet of paper in the sheet stack prevents.

- Be as powder usually fine powdered potato starch or others powdered starch products used.

- To apply the Powder serves a so-called powder device or another Pollination facility, usually in a space between the leading leading the sheets Conveyor strand and the returning empty strand of the chain conveyor is arranged and the on the lower conveyor run of the Chain conveyor transported sheets from above with dusted the powder.

- High-speed sheetfed offset presses for printing high Requirements such as those under the label Heidelberg Speedmaster from Heidelberger Druckmaschinen AG sheetfed offset presses are usually sold with a high-stack sheet delivery to stack more sheets to be able to. With such sheet displays, this extends Chain conveyor conveyor run first diagonally upwards and is then redirected into the horizontal to the printed Sheets horizontally before releasing them above the sheet filing stack align.

- the pollination facility is common there just before the upper end of the sloping section of the Funding runs in the space between this and the empty run arranged of the chain conveyor.

- a sheet delivery is a Sheet printing machine disclosed in the housing near the Powder dusting device above the conveyor belt devices are provided to suck off excess powder and thus to prevent its uncontrolled spread.

- Such Devices suck a large part of the powder applied immediately, which often has the consequence that the Operating personnel increases the powder supply and so much more Powder is consumed.

- the problem of powder spread an air suction inside the housing, however unsolved.

- a sheet delivery is a Printing machine disclosed in the along an upper horizontal section of the empty run of a sheet conveyor a cleaning device is provided which has a housing, several brushes arranged in the housing and one Suction device includes the brushes from the Vacuum chains and gripper systems of cleaned powder.

- the cleaning device described is still suitable to transport powder-laden air in the direction to prevent the printing press, since both between the Housing of the cleaning device and the adjacent walls the sheet delivery as well as inside the case on both Wide open flow cross-sections on the sides of the brushes are present that have a passage of powdered Allow air along the movement path of the empty run.

- the invention is based on the object a method and a retrofittable and / or Factory assembled device of the type mentioned To provide a during printing Reduction of dust pollution in the vicinity of the Printing machine enables and the formation of powder deposits largely prevented within the housing.

- the invention provides that everyone along the movement path of the empty strand Existing flow path through which powder-contaminated air from the free end of the sheet delivery can flow to the printing press, at least one place between the free end of the Delivery and the printing press is blocked to allow the Formation of a running in the direction of the printing press Air flow and thus a transport of powder in it To prevent air flow to the press. It is for that required the entire free at the point of interruption Flow cross-section between an upper wall of the housing, the two side walls of the housing and one in the space arranged between the empty strand and the conveyor strand Partition or the like essentially completely block so that a passage of powdered air through this section of the flow path almost completely is prevented.

- the air flow is as close as possible to the free end of the Sheet delivery interrupted, i.e. expedient in an upper horizontal section of the sheet delivery and preferably above from a drive shaft of a lifting mechanism for the Sheet storage stack, where there is enough space for the required Facilities is available. Because the drive shaft is very turns slowly, it can also serve as a support or carrier for serve part of the facilities.

- the air flow can be interrupted with pneumatic and / or by mechanical means, one Combination is preferred.

- an interruption with pneumatic means is preferred air at the Interruption point sucked out of the housing and / or a Electricity cleaner, i.e. air not contaminated with powder so in that Housing of the sheet delivery fed that the flow path is blocked by an air curtain or airflow that the Empty strand is interspersed and is sufficiently wide and deep to a passage of powdered air between the top wall of the housing, the two side walls of the housing and that arranged between the empty run and the conveyor run Prevent partition or the like.

- an air supply device which Air sucked in from the environment and not contaminated with powder conducts into the housing so that it crosses the empty strand to it Flow direction vertical

- Air extraction device which is transverse to the direction of movement of the Empty strand sucks air from the flow path, preferably opposite the air supply device by at least one Part of the air introduced together with that from the chains and sheet grippers of the conveyor showered powder aspirate after passing through the flow path and expedient in a downstream separator from to clean carried powder.

- the air supplied is preferably from above into the housing passed and vacuumed below the empty strand to to discharge showered powder in the direction of gravity.

- a reverse arrangement is also conceivable.

- a particularly preferred embodiment of the invention is air from the environment behind a pair of brushes or Atmosphere from above through the empty strand into the Blown in housing of the sheet delivery and at least a part the blown air below the empty strand again aspirated, so that passed through the brushes air contaminated with powder by the air supplied from above carried along below and below the empty strand together with the detached from the chain conveyor by the brushes and / or by the air blowing in the showered powder is sucked off.

- Another preferred embodiment of the invention provides that in the area of the interruption point or in Direction of movement of the empty strand behind, not with powder contaminated air is fed into the housing from the outside. This prevents that in the direction of movement Vacuum runs behind the point of interruption a negative pressure trains, which in turn leads to a suction of powdered Air could lead to this area.

- the air supply and possibly the air extraction in the Range of the interruption point can also be set that the amount of air supplied is greater than that extracted Amount of air is, thereby creating a negative pressure avoid.

- the powder can not be loaded with the supply Air the air suction generated by the empty run can be used to this air if necessary together with that at the top of one too suction and air deflection device acting as a partition redirected blown air above the Pollination device past in the direction of the printing press conduct.

- This air which is not contaminated with powder, then forms between the pollination facility and the empty strand as well between the pollinator and the press Air cushion, which also helps spread to prevent the powder from getting close to the press.

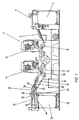

- Two-color sheetfed offset press 2 become paper sheets successively by means of an automated sheet feed 4 from one arranged in a sheet feeder 6 of the printing press 2 Paper stack 8 to a feed drum 10 of a first Transfer printing unit 12 and then through the first printing unit 12 and possibly transported a second printing unit 14 in order to or to print on both sides in one or more colors.

- a sheet delivery 22 of the printing machine 2 From an impression cylinder 16 of the second printing unit 14 take over delivery gripper systems 18 of a chain conveyor 20 a sheet delivery 22 of the printing machine 2, the printed sheets and transport them through a housing 24 of the sheet delivery 22 to a sheet stack 26 on which the sheet then are stacked on top of each other.

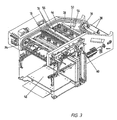

- the chain conveyor 20 is in the essentially two in opposite side Guide rails 28 (Fig. 3) guided parallel chains (not shown), which at regular intervals the gripper systems 18, also referred to as bow grippers are connected.

- the chain conveyor 20 has a lower one Bow conveyor conveyor (leading system) 30 on that of the two sprockets 31 one Delivery drum 32 moved obliquely upwards and then into the Horizontal is deflected before there are two drive sprockets 34 reached at the free end of the sheet delivery 22. His top Empty run (return system) 36 moves from the Sprockets 34 from horizontally towards the printing press 2 before it is turned diagonally down and to the delivery drum 32 is returned.

- Bow conveyor conveyor leading system

- each sheet is in Direction of movement of the conveyor run 30 through sheet baffles 38 non-contact on laterally adjustable guide arm blowers 40 over and via a sheet brake 42 arranged behind it guided and then reaches an arch exit opening 44 on the underside of the horizontal section of the housing 24 of the sheet delivery 22 to the sheet brake 42 transferred and braked sheet With the help of several arranged above the outlet opening 44 Delivery fan 46 down onto the sheet stack 26 blown. This rests on a lifting mechanism 48 that the Stack 26 in sync with the speed of the sheet feed lowers.

- a powder apparatus 50 is located horizontally above it in the space 52 between the conveyor run 30 and the empty run 36 arranged.

- the powder apparatus 52 pollinates the top of the held by the bow grippers 18 of the conveyor run 30 pressurized sheets with a fine powdered starch powder to a sticking together (putting on) of the sheets at the subsequent To prevent stacking.

- the powder apparatus 50 is made essentially from a transverse to the direction of movement of the Chain conveyor 20 through the space 52 extending tube 54, which has several powder outlet slots on its underside having.

- the starch powder is made using a pipe 54 connected blower (not shown) supplied, the Dosage of the size and color intensity of the printed Area is dependent. But not only that printed sheets, but also the chains and the sheet grabs 18 of the chain conveyor 20 dusted with the powder.

- the paper sheets carried by the chain conveyor 20 are in Direction of movement of the conveyor run 30 immediately behind the Powder apparatus 50 deflected from the inclines into the horizontal. This leads to the whip or flag effect, that is to a rocking or Flutter the back edges of the paper sheets 1. This in turn causes the powder emerging from the powder apparatus 50 is whirled up immediately after the exit. This Whirled up powder is caught by the suction of the chain conveyor 20 and by a suction-induced one in the direction of movement of the chain conveyor 20 entrained air flow.

- the Fresh air not contaminated with powder is supplied by a nozzle box 58 which over the powder suction and Air deflection trough 56 in the area of the nozzle box 58 closed upper wall of the housing 24 is inserted and the Fresh air blows down towards the Printing machine running powder-laden air flow interrupt and thus the transport of powder carried in Prevent the direction of the press.

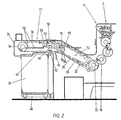

- the powder suction and air deflection tray 56 and the nozzle box 58 are arranged behind the point at which the conveyor run 30 in the horizontal is redirected, with the in the Figures 1 and 2 illustrated embodiment in Direction of movement of the conveyor run 30 before Sheet exit opening 44 and the one above it Display fans 46 are arranged while in the Fig. 3 illustrated embodiment with a shorter Sheet delivery 22 are immediately above.

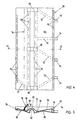

- the suction and air deflection tray 56 essentially from one thin-walled flat housing 62.

- the housing 62 extends below the side guides of the empty run 36 over the total clear width of the housing 24 of the sheet delivery 22 and forms a continuous partition between a lower, flow path running along the conveyor run 30 and a movement path of the empty run 36 arranged above it. This partition prevents the entire extent Air passes from top to bottom and vice versa.

- the housing 62 has a in the direction of movement Chain conveyor 20 upper housing wall 64 which has been bent several times, so that two shallow troughs 66 are formed by one Elevation 68 arranged between them are separated from one another.

- the upper housing wall 64 is also spaced apart arranged rows of suction slots 70 provided. While adjacent middle rows of suction slots 70 are located at the lowest points of the troughs 66 outer rows in the immediate vicinity of the opposite Arranged outer edges of the housing 62.

- Each of the rows of slots is arranged by a within the housing 62

- Suction channel 72 each connected to a suction port 74, which one of the outer edges are arranged.

- the suction nozzle 74 are each via directional and pressure control valves to control the extracted air quantities and the applied vacuum with connected to a suction fan, which a dust separator with a Centrifuge and a fine filter (not shown) is connected upstream. From the rows of suction slots 70 are the slots 70 on the outer edge on the side of the Powder apparatus 50 most heavily applied with negative pressure.

- the brush 76 is in of the trough 66 which extends from the housing 62 leaving empty strand 36 of the chain conveyor 20 first is swept over.

- the housing 62 also has a lower housing wall 80 which between the two troughs 66 and below the elevation 68 the upper housing wall 64 with a recessed upwards Bulge 82 is provided, the cross section of which is in the form of a reverse U has.

- this bulge 82 encloses the housing wall 80 between the empty strand 36 and the conveyor run 30 arranged transverse drive shaft 60, the top of which carries the housing 62.

- To reduce the Friction between the slow-running drive shaft 60 and the lower housing wall 80 is in the area of Provide bulge 82 with a Teflon coating.

- suction and air deflection tray 56 is supported the drive shaft 60 from, so that it with only a few Fastening screws on opposite side cheeks of the Chain conveyor 20 must be attached to them in place to keep.

- the Air outlet nozzles 86 are arranged in parallel rows, of which the middle one is just above the elevation 68 on the Top of the suction and air deflection tray 56 is.

- An edge 88 adjacent to the flat underside smaller lower part of the nozzle box 58 is chamfered and on its narrower faces with a series of Nozzle openings 90 provided for showering the chains of the Chain conveyor 20 serve.

- the larger top of the Nozzle box 58 is provided with a circumferential shoulder, whose narrow foreheads on the side cheeks of the Chain arm rest.

- On the bottom of the shoulder is a brush 92 is attached, the bristles 94 of which are down extend into the path of the empty run 36.

- the brush 92 also extends over the entire clear width of the Chain boom or the housing 24 and is in Direction of movement of the empty run 36 immediately behind the Brush 76 of the suction and air deflection tray 56 arranged.

- the application of compressed air to the nozzle box 58 with a Pressure between 1.5 and 3.5 bar occurs through two Air supply nozzle 96 on the top of the nozzle box 58, each communicating with a part of the nozzle rows 86.

- the amount of air supplied is such that only a part again through the suction slots 70 of the suction and Air deflector tray 56 can be sucked in while the rest Air in the top of the suction and air deflection tray 56 in Direction of the printing machine is deflected.

- the air is at a relatively low pressure of 1.5 to 2 bar supplied, while the air pressure at a downstream cleaning of the sheet delivery 22 to 3 to 3.5 bar is increased.

- Directional control valves in the to the air supply nozzle Allow 96 leading air supply lines (not shown) a clocked air supply or an optional air supply each one of the two air supply nozzles 96 or both together, i.e. to a part of each of the nozzles 86 or all nozzles 86.

- the air blown down from the nozzle box 58 flows in the sheet grippers 18 and on the chains of the chain conveyor 20 over, and shower this with clean fresh air, whereby adhering powder particles are carried down so that from the empty run 36 no further towards the printing press 2 can be transported.

- Suction slots 70 are formed as a result of the created there Vacuum also from fresh air vortex, at the Bottom of the air also in the opposite direction to Tub 56 flows back to the front and part of the whirled up powder with it, so that this through the Suction slots 70 on the adjacent outer edge of the tub 56 can be suctioned off.

- the Most of the air sucked in is from the suction of the empty run 36 carried along the same in the direction of the printing press 2, while a smaller part behind that which acts as an air switch Air suction pipe 75 down and along the press side of the powder apparatus 50 flows down.

- air can also be in front of the brushes 76, 92 be suctioned off, so that by one arising there Negative pressure a smaller part of that behind the brushes 76, 92 supplied air sucked forward through the brushes 76, 92 becomes.

- the brushes 76, 92 can also be omitted and the air flow running along the empty run 36 alone interrupted by the supply and / or extraction of air.

- the measures described above will in particular prevents powder from being whirled up by the Suction of the chain conveyor 20 entrained and over and over under the empty strand 36 generated air flow within the Housing 24 of the sheet delivery 22 in the direction of the printing press 2 is transported.

- the spread of powder is in the essentially to the area below the powder apparatus 50 and above the printed sheets below limited, which on the one hand significantly reduces powder consumption can be reduced and on the other hand both the Dust pollution in the ambient air as well as inside the Housing is significantly lower.

- both the Dust pollution in the ambient air as well as inside the Housing is significantly lower.

- the fresh air cushion accelerates between the Conveyor strand 30 and the empty strand 36 on that of the printing press 2 facing side of the powder apparatus 50 the oxidative drying of the printing inks due to the constant fresh air supply in them Area.

Description

Die Erfindung betrifft ein Verfahren und eine Vorrichtung zum Verhindern einer unkontrollierten Puderausbreitung in einer Druckmaschine. Die Erfindung betrifft insbesondere ein Verfahren, bei dem in einer Bogendruckmaschine bedruckte Bogen mittels einer Bogenfördereinrichtung durch eine Bogenauslage über einen Bogenablagestapel gefördert und dabei mit einem Puder bestäubt werden und bei dem eine unkontrollierte Ausbreitung von überschüssigem Puder verhindert wird, sowie eine Vorrichtung zum Verhindern einer unkontrollierten Ausbreitung von Puder in einem Gehäuse einer Bogenauslage einer Bogendruckmaschine, das eine Bogenfördereinrichtung zum Transport von bedruckten Bogen über einen Bogenablagestapel und eine Bestäubungseinrichtung zum Bestäuben der bedruckten Bogen mit einem Puder umgibt. Die Erfindung betrifft darüber hinaus eine Bogenauslage für eine Bogendruckmaschine und eine Bogendruckmaschine mit einer derartigen Vorrichtung.The invention relates to a method and an apparatus for Prevent an uncontrolled spread of powder in one Press. The invention relates in particular to a Process in which sheets printed in a sheet-fed printing machine by means of a sheet conveyor through a sheet delivery conveyed through a stack of sheets and with one Powder are dusted and one is uncontrolled Spread of excess powder is prevented, as well a device for preventing an uncontrolled Spreading powder in a sheet delivery case a sheet printing machine that a sheet conveyor for Transport of printed sheets via a sheet stack and a dusting device for dusting the printed Powder surrounds bow. The invention relates above also a sheet delivery for a sheet printing machine and a Sheet printing machine with such a device.

Beim Bogenoffsetdruck in größeren Bogenoffsetdruckmaschinen werden die ein- oder beidseitig bedruckten Papierbogen nach ihrem Durchlauf durch die Druckwerke der Druckmaschine gewöhnlich von einem Kettenförderer der Papier- oder Bogenauslage, d.h. einem Kettenförderer mit zwei parallelen, durch Auslagegreifersysteme oder Bogengreifer verbundenen Ketten aufgenommen und innerhalb eines die Bogenauslage und die Druckwerke der Druckmaschine umschließenden Gehäuses über einen Bogenstapel transportiert, auf dem sie anschließend übereinander abgelegt werden. Da die Druckfarbe beim Übereinanderstapeln der Bogen noch nicht vollständig getrocknet ist, wird bei den meisten auf dem Markt befindlichen Bogenoffsetdruckmaschinen mindestens eine Oberfläche jedes Bogens vor dem Ablegen auf dem Stapel mit einem Puder bestäubt, der auf den bedruckten Partien der Papierbogen haftet und ein Ablegen, d.h. ein Zusammenkleben der Papierbogen im Bogenstapel verhindert. Als Puder werden gewöhnlich feinpulverige Kartoffelstärke oder andere pulverförmige Stärkeprodukte verwendet. Zum Aufbringen des Puders dient ein sogenannter Puderapparat oder eine andere Bestäubungseinrichtung, die in der Regel in einem Zwischenraum zwischen dem die Bogen transportierenden vorlaufenden Fördertrum und dem rücklaufenden Leertrum des Kettenförderers angeordnet ist und die auf dem unten liegenden Fördertrum des Kettenförderers vorbeitransportierten Bogen von oben her mit dem Puder bestäubt.For sheetfed offset printing in larger sheetfed offset presses are the paper sheets printed on one or both sides after their passage through the printing units of the printing press usually from a paper or chain conveyor Sheet delivery, i.e. a chain conveyor with two parallel, connected by delivery gripper systems or sheet grippers Chains included and within a the sheet delivery and enclosing the printing units of the printing press housing transported a stack of sheets on which she then are stacked on top of each other. Since the printing ink at The sheets are not yet completely stacked on top of one another is dried at most on the market located sheetfed offset presses at least one Surface of each sheet before placing it on the stack with powdered on the printed areas of the Sheets of paper stick and a deposit, i.e. a sticking together the sheet of paper in the sheet stack prevents. Be as powder usually fine powdered potato starch or others powdered starch products used. To apply the Powder serves a so-called powder device or another Pollination facility, usually in a space between the leading leading the sheets Conveyor strand and the returning empty strand of the chain conveyor is arranged and the on the lower conveyor run of the Chain conveyor transported sheets from above with dusted the powder.

Schnellaufende Bogenoffsetdruckmaschinen für den Druck hoher Auflagen, wie beispielsweise die unter der Bezeichnung Heidelberg Speedmaster von der Fa. Heidelberger Druckmaschinen AG verkauften Bogenoffsetdruckmaschinen, sind gewöhnlich mit einer Hochstapelbogenauslage versehen, um mehr Bogen stapeln zu können. Bei derartigen Bogenauslagen erstreckt sich das Fördertrum des Kettenförderers zuerst schräg nach oben und wird dann in die Horizontale umgelenkt, um die bedruckten Bogen vor der Freigabe über dem Bogenablagestapel horizontal auszurichten. Die Bestäubungseinrichtung ist dort gewöhnlich kurz vor dem oberen Ende des schrägen Teilstücks des Fördertrums im Zwischenraum zwischen diesem und dem Leertrum des Kettenförderers angeordnet.High-speed sheetfed offset presses for printing high Requirements such as those under the label Heidelberg Speedmaster from Heidelberger Druckmaschinen AG sheetfed offset presses are usually sold with a high-stack sheet delivery to stack more sheets to be able to. With such sheet displays, this extends Chain conveyor conveyor run first diagonally upwards and is then redirected into the horizontal to the printed Sheets horizontally before releasing them above the sheet filing stack align. The pollination facility is common there just before the upper end of the sloping section of the Funding runs in the space between this and the empty run arranged of the chain conveyor.

Beim Betrieb derartiger Bogenoffsetdruckmaschinen hat man festgestellt, daß erheblich mehr Puder verbraucht wird, als zum Bestäuben der Papierbogen eigentlich erforderlich ist. Gleichzeitig weist die Umgebungsluft um die Bogenauslage herum einen stark erhöhten, durch Puderpartikel verursachten Staubgehalt auf, während sich im Inneren des Gehäuses der Bogenauslage auf beweglichen und unbeweglichen Teilen verstärkt Puderablagerungen bilden. Der höhere Staubgehalt in der Umgebungsluft, der teilweise fast als Pudernebel bezeichnet werden kann, wird vom Bedienungspersonal als äußerst unangenehm empfunden, während Puderablagerungen im Inneren des Gehäuses, insbesondere auf beweglichen Teilen, einen erhöhten Verschleiß und längere Stillstandszeiten der Maschine infolge häufiger Reinigungs- und Wartungsarbeiten zur Folge haben.When operating such sheetfed offset printing presses one has found that significantly more powder is consumed than is actually required for dusting the paper sheets. At the same time, the ambient air points around the sheet delivery a greatly increased, caused by powder particles Dust content while inside the case of the Sheet delivery on moving and immovable parts increasingly form powder deposits. The higher dust content in the ambient air, some of which is almost a powder mist can be referred to by the operating personnel as felt extremely uncomfortable, while powder deposits in the Interior of the housing, especially on moving parts, increased wear and longer downtimes Machine due to frequent cleaning and maintenance work Consequence.

Bei Untersuchungen des Anmelders zur Klärung der Ursachen der puderbedingten Staubbelastung in der Umgebungsluft sowie der Puderablagerungen im Gehäuse der Bogenauslage wurde festgestellt, daß in den Bogenauslagen herkömmlicher Offsetdruckmaschinen in großem Umfang Luftturbulenzen auftreten. Diese Luftturbulenzen werden unter anderem dadurch verursacht, daß jeweils unter- und oberhalb des Fördertrums und des Leertrums des Bogenauslegers durch die Sogwirkung der sich bewegenden Bogengreifer und Ketten Luft in Bewegungsrichtung des jeweiligen Trums mitgerissen wird, daß vom Fördertrum mitgeführte bedruckte Bogen flattern oder beim Umlenken aus der Schräge in die Horizontale mit ihrem hinteren Rand nach oben wippen (sogenannter Peitschen- oder Fahnen-Effekt), sowie dadurch, daß aus dem sogenannten Bogenleitblech Luft von unten her gegen den Bogen geblasen wird, um diesen berührungsfrei über das Leitblech zu führen, wobei jedoch ein Teil dieser Luft zwischen den benachbarten Bogen sowie seitlich an den Bogen vorbei nach oben strömt.In investigations by the applicant to clarify the causes of the powder-related dust pollution in the ambient air as well as the Powder deposits were in the housing of the sheet delivery found that more conventional in the sheet displays Large-scale offset printing machines air turbulence occur. This causes turbulence among other things causes that below and above the conveyor run and the empty run of the bow boom by the suction effect of the moving claws and chains air in Direction of movement of the respective run is carried away that printed sheets carried by the conveyor belt flutter or at Redirect from the slant to the horizontal with its rear Rock the edge upwards (so-called whip or flag effect), and in that from the so-called sheet guide plate Air is blown against the bow from below, around this to run without contact over the baffle, but with a Part of this air between the neighboring arches as well flows upwards past the arch.

Durch diese Luftturbulenzen wird ein großer Teil des aus der Puderbestäubungseinrichtung austretenden Puders verwirbelt und von der Luft mitgerissen, so daß er nicht wie gewünscht unmittelbar unterhalb der Puderbestäubungseinrichtung auf die Oberfläche des Bedruckstoffs gelangt. Statt dessen wird der Puder durch die Luftströmungen, insbesondere diejenigen entlang der beiden Trume des Bogenauslegers, über den gesamten Innenraum der Bogenauslage verteilt. Dies führt nicht nur zu einem erhöhten Verschleiß an beweglichen Teilen und längeren Stillstandszeiten zur Reinigung der Bogenauslage, sondern auch zu einer Belästigung des Bedienungspersonals, weil der aufgewirbelte Puder außerdem durch sämtliche Öffnungen der Bogenauslage, insbesondere durch die Bogenaustrittsöffnung und Luftaustrittsgitter auf der Oberseite des Gehäuses, in die Umgebung austritt.Due to this air turbulence, a large part of the Powder dusting device emerging and swirled carried away by the air, so that it does not work as desired immediately below the powdering device Surface of the substrate. Instead, the Powder through the air currents, especially those along the two strands of the bow boom, over the entire Distributed interior of the sheet delivery. This not only leads to increased wear on moving parts and longer ones Downtimes for cleaning the sheet delivery, but also to bother the operator because of whirled powder also through all openings of the Sheet delivery, especially through the sheet exit opening and Air outlet grille on the top of the housing, in the Environment emerges.

Um die hohe Staubbelastung der Umgebungsluft zu verringern und weitere, durch überschüssigen Puder verursachte Probleme zu beseitigen, wird in der US 5,265,563 eine oberhalb des Bogenstapels und einer Bogenaustrittsöffnung angeordnete Absaughaube vorgeschlagen, die dazu dient, puderbelastete Luft nach oben durch das Leertrum hindurch abzusaugen, um sie dann zu reinigen. Ein Teil der puderbelasteten Luft wird jedoch beim Hindurchtritt durch das Leertrum durch den Sog desselben mitgerissen und strömt entlang des Leertrums in Richtung der Druckmaschine.To reduce the high dust pollution in the ambient air and additional problems caused by excess powder eliminate, is in US 5,265,563 above the Sheet stack and a sheet exit opening arranged Extractor hood is proposed, which is used to remove air contaminated with powder aspirate upwards through the empty strand and then to clean. However, some of the air contaminated with powder becomes when passing through the empty run through the suction of the same swept along and flows along the empty strand towards the Press.

Weiter ist in der DE 42 07 118 A1 eine Bogenauslage einer Bogendruckmaschine offenbart, in deren Gehäuse in der Nähe der Puderbestäubungseinrichtung über dem Fördertrum Vorrichtungen vorgesehen sind, um überschüssigen Puder abzusaugen und damit dessen unkontrollierte Ausbreitung zu verhindern. Derartige Vorrichtungen saugen einen Großteil des ausgebrachten Puders sofort wieder ab, was jedoch häufig zur Folge hat, daß das Bedienungspersonal die Puderzufuhr steigert und so noch mehr Puder verbraucht wird. Das Problem einer Puderverbreitung durch einen Luftsog im Inneren des Gehäuses wird hingegen nicht gelöst.In DE 42 07 118 A1, a sheet delivery is a Sheet printing machine disclosed in the housing near the Powder dusting device above the conveyor belt devices are provided to suck off excess powder and thus to prevent its uncontrolled spread. such Devices suck a large part of the powder applied immediately, which often has the consequence that the Operating personnel increases the powder supply and so much more Powder is consumed. The problem of powder spread an air suction inside the housing, however unsolved.

Außerdem ist in der DE AS 2 148 757 eine Bogenauslage einer Druckmaschine offenbart, bei der entlang eines oberen horizontalen Teilstücks des Leertrums eines Bogenförderers eine Reinigungsvorrichtung vorgesehen ist, die ein Gehäuse, mehrere im Gehäuse angeordnete Bürsten und eine Absaugvorrichtung umfaßt, um den durch die Bürsten von den Ketten und Greifersystemen abgereinigten Puder abzusaugen. Jedoch wurde dort weder das Problem einer Puderausbreitung durch die vom Sog des Leertrums mitgerissene puderbelastete Luft erkannt, noch ist die beschriebene Reinigungsvorrichtung geeignet, einen Transport von puderbelasteter Luft in Richtung der Druckmaschine zu verhindern, da sowohl zwischen dem Gehäuse der Reinigungsvorrichtung und den benachbarten Wänden der Bogenauslage als auch innerhalb des Gehäuses auf beiden Seiten der Bürsten breite offene Strömungsquerschnitte vorhanden sind, die einen Hindurchtritt von puderbelasteter Luft entlang des Bewegungspfades des Leertrums ermöglichen.In addition, in DE AS 2 148 757 a sheet delivery is a Printing machine disclosed in the along an upper horizontal section of the empty run of a sheet conveyor a cleaning device is provided which has a housing, several brushes arranged in the housing and one Suction device includes the brushes from the Vacuum chains and gripper systems of cleaned powder. However, there was no problem of powder spreading there due to the powder load entrained by the suction of the empty run Air detected, the cleaning device described is still suitable to transport powder-laden air in the direction to prevent the printing press, since both between the Housing of the cleaning device and the adjacent walls the sheet delivery as well as inside the case on both Wide open flow cross-sections on the sides of the brushes are present that have a passage of powdered Allow air along the movement path of the empty run.

Ausgehend hiervon liegt der Erfindung die Aufgabe zugrunde, ein Verfahren und eine nachträglich montierbare und/oder fabrikmäßig montierte Vorrichtung der eingangs genannten Art bereitzustellen, die während des Druckbetriebs eine Verringerung der Staubbelastung in der Umgebung der Druckmaschine ermöglicht und die Bildung von Puderablagerungen innerhalb des Gehäuses weitgehend verhindert.Proceeding from this, the invention is based on the object a method and a retrofittable and / or Factory assembled device of the type mentioned To provide a during printing Reduction of dust pollution in the vicinity of the Printing machine enables and the formation of powder deposits largely prevented within the housing.

Diese Aufgabe wird erfindungsgemäß durch die in den beiliegenden Patentansprüchen 1 für das Verfahren, 14 für die Vorrichtung, sowie 32 für eine mit der Vorrichtung ausgestaltete Bogendruckmaschine angegebenen Merkmalskombinationen gelöst. Danach wird eine im Gehäuse der Bogenauslage entlang eines Leertrums der Bogenfördereinrichtung in Richtung der Druckmaschine verlaufende, durch den vorangehenden Vorbeitritt an der Bestäubungseinrichtung mit überschüssigem Puder belastete Luftströmung an mindestens einer Unterbrechungsstelle zwischen dem freien Ende der Bogenauslage und der Druckmaschine unterbrochen, um einen Transport von mitgeführtem Puder in Richtung der Druckmaschine zu verhindern.This object is achieved by the in the enclosed patent claims 1 for the method, 14 for the Device, and 32 for one designed with the device Sheet combinations specified feature combinations solved. Then one is in the housing along the sheet delivery an empty run of the sheet conveyor in the direction of Printing machine running through the previous pass at the pollinator with excess powder polluted air flow on at least one Interruption point between the free end of the sheet delivery and the printing machine is interrupted to carry out a transport of carried powder in the direction of the printing press prevent.

Die Erfindung sieht vor, daß jeglicher entlang des Bewegungspfades des Leertrums vorhandene strömungspfad, durch den puderbelastete Luft vom freien Ende der Bogenauslage zur Druckmaschine strömen kann, an mindestens einer Stelle zwischen dem freien Ende der Auslage und der Druckmaschine versperrt wird, um damit die Ausbildung einer in Richtung der Druckmaschine verlaufenden Luftströmung und damit einen Transport von Puder in dieser Luftströmung zur Druckmaschine zu verhindern. Dazu ist es erforderlich, an der Unterbrechungsstelle den gesamten freien Strömungsquerschnitt zwischen einer oberen Wand des Gehäuses, den beiden Seitenwänden des Gehäuses und einer im Zwischenraum zwischen dem Leertrum und dem Fördertrum angeordneten Trennwand oder dergleichen im wesentlichen vollständig zu versperren, so daß ein Hindurchtritt von puderbelasteter Luft durch diesen Abschnitt des Strömungspfades nahezu vollständig unterbunden wird.The invention provides that everyone along the movement path of the empty strand Existing flow path through which powder-contaminated air from the free end of the sheet delivery can flow to the printing press, at least one place between the free end of the Delivery and the printing press is blocked to allow the Formation of a running in the direction of the printing press Air flow and thus a transport of powder in it To prevent air flow to the press. It is for that required the entire free at the point of interruption Flow cross-section between an upper wall of the housing, the two side walls of the housing and one in the space arranged between the empty strand and the conveyor strand Partition or the like essentially completely block so that a passage of powdered air through this section of the flow path almost completely is prevented.

Gemäß einer weiteren bevorzugten Ausgestaltung der Erfindung wird die Luftströmung möglichst nahe am freien Ende der Bogenauslage unterbrochen, d.h. zweckmäßig in einem oberen horizontalen Teilstück der Bogenauslage und bevorzugt oberhalb von einer Antriebswelle eines Hubmechanismus für den Bogenablagestapel, wo ausreichend Platz für die benötigten Einrichtungen vorhanden ist. Da sich die Antriebswelle sehr langsam dreht, kann sie zudem gut als Auflager oder Träger für einen Teil der Einrichtungen dienen.According to a further preferred embodiment of the invention the air flow is as close as possible to the free end of the Sheet delivery interrupted, i.e. expedient in an upper horizontal section of the sheet delivery and preferably above from a drive shaft of a lifting mechanism for the Sheet storage stack, where there is enough space for the required Facilities is available. Because the drive shaft is very turns slowly, it can also serve as a support or carrier for serve part of the facilities.

Die Unterbrechung der Luftströmung kann mit pneumatischen und/oder mit mechanischen Mitteln erfolgen, wobei eine Kombination bevorzugt wird. Bei einer Unterbrechung mit pneumatischen Mitteln wird bevorzugt Luft an der Unterbrechungsstelle so aus dem Gehäuse abgesaugt und/oder ein Strom sauberer, d.h. nicht mit Puder belasteter Luft so in das Gehäuse der Bogenauslage zugeführt, daß der Strömungspfad durch einen Luftvorhang oder Luftstrom versperrt wird, der das Leertrum durchsetzt und ausreichend breit und tief ist, um einen Hindurchtritt von puderbelasteter Luft zwischen der oberen Wand des Gehäuses, den beiden Seitenwänden des Gehäuses und der zwischen Leertrum und Fördertrum angeordneten Trennwand oder dergleichen zu verhindern.The air flow can be interrupted with pneumatic and / or by mechanical means, one Combination is preferred. With an interruption with pneumatic means is preferred air at the Interruption point sucked out of the housing and / or a Electricity cleaner, i.e. air not contaminated with powder so in that Housing of the sheet delivery fed that the flow path is blocked by an air curtain or airflow that the Empty strand is interspersed and is sufficiently wide and deep to a passage of powdered air between the top wall of the housing, the two side walls of the housing and that arranged between the empty run and the conveyor run Prevent partition or the like.

Dazu umfassen die zur Unterbrechung der Luftströmung dienenden Einrichtungen vorzugsweise eine Luftzufuhreinrichtung, welche aus der Umgebung angesaugte und nicht mit Puder belastete Luft so in das Gehäuse leitet, daß sie das Leertrum quer zu dessen Bewegungsrichtung vertikal durchströmt, und/oder eine Luftabsaugeinrichtung, die quer zur Bewegungsrichtung des Leertrums Luft aus dem Strömungspfad saugt, vorzugsweise gegenüber von der Luftzufuhreinrichtung, um mindestens einen Teil der eingeleiteten Luft zusammen mit dem von den Ketten und Bogengreifern der Fördereinrichtung abgeduschten Puder nach dem Hindurchtritt durch den Strömungspfad abzusaugen und zweckmäßig in einem nachgeschalteten Abscheider von mitgeführtem Puder zu reinigen.For this purpose include those used to interrupt the air flow Devices preferably an air supply device, which Air sucked in from the environment and not contaminated with powder conducts into the housing so that it crosses the empty strand to it Flow direction vertical, and / or one Air extraction device, which is transverse to the direction of movement of the Empty strand sucks air from the flow path, preferably opposite the air supply device by at least one Part of the air introduced together with that from the chains and sheet grippers of the conveyor showered powder aspirate after passing through the flow path and expedient in a downstream separator from to clean carried powder.

Die zugeführte Luft wird bevorzugt von oben her in das Gehäuse geleitet und unterhalb des Leertrums abgesaugt, um abgeduschten Puder in Richtung der Schwerkraft abzuführen. Eine umgekehrte Anordnung ist jedoch ebenfalls denkbar.The air supplied is preferably from above into the housing passed and vacuumed below the empty strand to to discharge showered powder in the direction of gravity. A reverse arrangement is also conceivable.

Um eine möglichst ungestörte Ausbildung des Luftvorhangs sicherzustellen, sind vorzugsweise in Bewegungsrichtung des Leertrums vor der Luftzufuhreinrichtung mehrere Bürsten vorgesehen, die sich über die gesamte Breite des vorhandenen Strömungspfades erstrecken und deren Borsten von oben und unten in den Bewegungspfad des Leertrums ragen und sich dort berühren oder überlappen, um so den Strömungspfad auch über seine gesamte Höhe und zwischen den einzelnen Bogengreifern zu versperren und gleichzeitig die Bogengreifer und Ketten von anhaftendem Puder zu reinigen.To make the air curtain as undisturbed as possible ensure are preferably in the direction of movement Empty strand in front of the air supply device, several brushes provided that spanned the full width of the existing Extend flow paths and their bristles from above and protrude below in the path of movement of the empty run and there touch or overlap so the flow path also over its entire height and between the individual bow grabs too block and at the same time the bow grabs and chains from to clean adhering powder.

Die Reinigung der Ketten und Bogengreifer ist für eine Verhinderung der Puderausbreitung ebenfalls von Bedeutung, da sich auch vom Kettenförderer mitgeführter und später durch Vibrationen oder dergleichen freigesetzter Puder im Gehäuse der Bogenauslage ablagert und besonders in der Nähe einer letzten Druckstation der Druckmaschine zu einem erhöhten Verschleiß an empfindlichen Bauteilen sowie zu einer schlechteren Druckqualität führen kann. Cleaning the chains and bow grab is for one Prevention of powder spread also important because also carried by the chain conveyor and later on Vibrations or the like released powder in the housing of the sheet delivery and especially near one last printing station of the printing press to an elevated Wear on sensitive components as well as on one poor print quality.

Gemäß einer besonders bevorzugten Ausgestaltung der Erfindung wird hinter einem Bürstenpaar Luft aus der Umgebung oder Atmosphäre von oben her durch das Leertrum hindurch in das Gehäuse der Bogenauslage eingeblasen und mindestens ein Teil der eingeblasenen Luft unterhalb des Leertrums wieder abgesaugt, so daß durch die Bürsten hindurchgetretene puderbelastete Luft durch die von oben zugeführte Luft nach unten mitgerissen und unterhalb des Leertrums zusammen mit dem durch die Bürsten vom Kettenförderer gelösten und/oder durch die Lufteinblasung abgeduschtem Puder abgesaugt wird.According to a particularly preferred embodiment of the invention is air from the environment behind a pair of brushes or Atmosphere from above through the empty strand into the Blown in housing of the sheet delivery and at least a part the blown air below the empty strand again aspirated, so that passed through the brushes air contaminated with powder by the air supplied from above carried along below and below the empty strand together with the detached from the chain conveyor by the brushes and / or by the air blowing in the showered powder is sucked off.

Eine weitere bevorzugte Ausgestaltung der Erfindung sieht vor, daß im Bereich der Unterbrechungsstelle oder in Bewegungsrichtung des Leertrums dahinter nicht mit Puder belastete Luft von außen in das Gehäuse zugeführt wird. Dadurch wird verhindert, daß sich in Bewegungsrichtung des Leertrums hinter der Unterbrechungsstelle ein Unterdruck ausbildet, der wiederum zu einer Ansaugung von puderbelasteter Luft in diesen Bereich führen könnte. Alternativ oder zusätzlich können die Luftzufuhr und ggf. die Luftabsaugung im Bereich der Unterbrechungsstelle auch so eingestellt werden, daß die zugeführte Luftmenge größer als die abgesaugte Luftmenge ist, um dadurch die Entstehung eines Unterdrucks zu vermeiden.Another preferred embodiment of the invention provides that in the area of the interruption point or in Direction of movement of the empty strand behind, not with powder contaminated air is fed into the housing from the outside. This prevents that in the direction of movement Vacuum runs behind the point of interruption a negative pressure trains, which in turn leads to a suction of powdered Air could lead to this area. Alternatively or in addition, the air supply and possibly the air extraction in the Range of the interruption point can also be set that the amount of air supplied is greater than that extracted Amount of air is, thereby creating a negative pressure avoid.

Außerdem kann durch die Zufuhr der nicht mit Puder belasteten Luft der vom Leertrum erzeugte Luftsog genutzt werden, um diese Luft ggf. zusammen mit der an der Oberseite einer auch als Trennwand wirkenden Absaug- und Luftablenkeinrichtung umgelenkten eingeblasenen Luft oberhalb der Bestäubungseinrichtung vorbei in Richtung der Druckmaschine zu leiten. Diese nicht mit Puder belastete Luft bildet dann zwischen der Bestäubungseinrichtung und dem Leertrum sowie zwischen der Bestäubungseinrichtung und der Druckmaschine ein Luftpolster, das ebenfalls mit dazu beiträgt, eine Ausbreitung des Puders bis in die Nähe der Druckmaschine zu verhindern. In addition, the powder can not be loaded with the supply Air the air suction generated by the empty run can be used to this air if necessary together with that at the top of one too suction and air deflection device acting as a partition redirected blown air above the Pollination device past in the direction of the printing press conduct. This air, which is not contaminated with powder, then forms between the pollination facility and the empty strand as well between the pollinator and the press Air cushion, which also helps spread to prevent the powder from getting close to the press.

Darüber hinaus kommt es an der Unterseite des Luftpolsters zur Ausbildung von Luftwirbeln, an deren Unterseite Frischluft zurück in Richtung des freien Endes der Auslage strömt. Dies wiederum bewirkt, daß zwischen der Bestäubungseinrichtung und der Absaugeinrichtung ein Teil des aufgewirbelten Puders zu einer oder mehreren Ansaugöffnungen am hinteren Rand der Absaugeinrichtung gelenkt wird, wo er abgesaugt werden kann. Zwischen der Bestäubungseinrichtung und der Druckmaschine strömt hingegen Frischluft an der Unterseite der Wirbel zurück in Richtung der Bestäubungseinrichtung, wodurch der aufgewirbelte Puder unmittelbar oberhalb der bedruckten Bogen in Richtung des freien Endes der Auslage gedrückt wird. Überraschenderweise konnte dadurch eine gleichmäßigere beidseitige Bestäubung der Bogen erreicht werden.In addition, it occurs on the underside of the air cushion Formation of air vortices with fresh air on the underside flows back towards the free end of the delivery. This in turn causes between the pollinator and part of the whirled powder to the suction device one or more intake openings at the rear edge of the Suction device is steered where it can be suctioned off. Between the pollinator and the press fresh air, however, flows back at the bottom of the vortex towards the pollinator, causing the whirled up powder immediately above the printed sheets is pressed towards the free end of the delivery. Surprisingly, this allowed a more even one pollination of the sheets on both sides can be achieved.

Im folgenden wird die Erfindung anhand von in der Zeichnung

dargestellten Ausführungsbeispielen näher erläutert. Es

zeigen:

In der in Fig. 1 der Zeichnung schematisch dargestellten

Zweifarben-Bogenoffsetdruckmaschine 2 werden Papierbogen

nacheinander mittels einer automatisierten Bogenzufuhr 4 von

einem in einer Bogenanlage 6 der Druckmaschine 2 angeordneten

Papierstapel 8 an eine Anlegetrommel 10 eines ersten

Druckwerks 12 übergeben und dann durch das erste Druckwerk 12

und ggf. ein zweites Druckwerk 14 transportiert, um sie ein-

oder beidseitig ein- oder mehrfarbig zu bedrucken.Shown schematically in Fig. 1 of the drawing

Two-color sheetfed offset

Von einem Gegendruckzylinder 16 des zweiten Druckwerks 14

übernehmen Auslagegreifersysteme 18 eines Kettenförderers 20

einer Bogenauslage 22 der Druckmaschine 2 die bedruckten Bogen

und transportieren sie durch ein Gehäuse 24 der Bogenauslage

22 bis über einen Bogenablagestapel 26, auf dem die Bogen dann

übereinander abgelegt werden. Der Kettenförderer 20 besteht im

wesentlichen aus zwei in gegenüberliegenden seitlichen

Führungsschienen 28 (Fig. 3) geführten parallelen Ketten

(nicht dargestellt), welche in regelmäßigen Abständen durch

die auch als Bogengreifer bezeichneten Greifersysteme 18

verbunden sind. Der Kettenförderer 20 weist ein unteres, die

Bogen transportierendes Fördertrum (vorlaufendes System) 30

auf, das sich von den beiden Kettenrädern 31 einer

Auslagetrommel 32 aus schräg nach oben bewegt und dann in die

Horizontale umgelenkt wird, bevor es zwei Antriebskettenräder

34 am freien Ende der Bogenauslage 22 erreicht. Sein oberes

Leertrum (rücklaufendes System) 36 bewegt sich von den

Kettenrädern 34 aus horizontal in Richtung der Druckmaschine

2, bevor es schräg nach unten umgelenkt und zur Auslagetrommel

32 zurückgeführt wird.From an

Nach der Übergabe an die Bogengreifer 18 wird jeder Bogen in

Bewegungsrichtung des Fördertrums 30 durch Bogenleitbleche 38

berührungslos an seitlich verstellbaren Leitbügelbläsern 40

vorbei und über eine dahinter angeordnete Bogenbremse 42

geführt und erreicht anschließend eine Bogenaustrittsöffnung

44 auf der Unterseite des horizontalen Teilstücks des Gehäuses

24 der Bogenauslage 22. Dort werden die seitens der Greifer 18

an die Bogenbremse 42 übergebenen und abgebremsten Bogen mit

Hilfe mehrerer, über der Austrittsöffnung 44 angeordneter

Auslagelüfter 46 nach unten auf den Bogenablagestapel 26

geblasen. Dieser ruht auf einem Hubmechanismus 48, der den

Stapel 26 synchron zur Geschwindigkeit der Bogenzufuhr

absenkt.After delivery to the

In der Nähe des oberen Endes des schrägen Teilstücks des

Kettenförderers 20 kurz vor der Umlenkung des Fördertrums 30

in die Horizontale ist oberhalb desselben ein Puderapparat 50

im Zwischenraum 52 zwischen dem Fördertrum 30 und dem Leertrum

36 angeordnet. Der Puderapparat 52 bestäubt die Oberseite der

von den Bogengreifern 18 des Fördertrums 30 gehaltenen

druckfeuchten Bogen mit einem feinpulverigen Stärkepuder, um

ein Zusammenkleben (Anlegen) der Bogen beim anschließenden

Übereinanderstapeln zu verhindern. Der Puderapparat 50 besteht

im wesentlichen aus einem quer zur Bewegungsrichtung des

Kettenförderers 20 durch den Zwischenraum 52 verlaufenden Rohr

54, das auf seiner Unterseite mehrere Puderaustrittsschlitze

aufweist. Der Stärkepuder wird mit Hilfe eines mit dem Rohr 54

verbundenen Gebläses (nicht dargestellt) zugeführt, wobei die

Dosierung von der Größe und Farbintensität der bedruckten

Flächen abhängig ist. Dabei werden allerdings nicht nur die

bedruckten Bogen, sondern auch die Ketten und die Bogengreifer

18 des Kettenförderers 20 mit dem Puder bestäubt.Near the top of the sloping section of the

Die vom Kettenförderer 20 mitgeführten Papierbogen werden in

Bewegungsrichtung des Fördertrums 30 unmittelbar hinter dem

Puderapparat 50 aus der Schrägen in die Horizontale umgelenkt.

Dabei kommt es zu dem eingangs bereits erwähnten Peitschen-

oder Fahnen-Effekt, das heißt zu einem Hochwippen oder

Flattern der hinteren Ränder der Papierbogen 1. Dies wiederum

bewirkt, daß der aus dem Puderapparat 50 austretende Puder

unmittelbar nach dem Austritt stark verwirbelt wird. Dieser

aufgewirbelte Puder wird vom Sog des Kettenförderers 20 erfaßt

und durch eine vom Sog hervorgerufene, in Bewegungsrichtung

des Kettenförderers 20 verlaufende Luftströmung mitgeführt.The paper sheets carried by the

Um eine Verbreitung des aufgewirbelten Puders innerhalb des

Gehäuses 24 der Bogenauslage 22 und insbesondere entlang des

Bewegungspfades des Leertrums 36 in Richtung der Druckmaschine

2 zu verhindern, die durch Öffnungen des Gehäuses 24

austretenden Pudermengen zu reduzieren und die mit Puder

bestäubten Ketten und Bogengreifer 18 des Kettenförderers 20

zu reinigen, ist in Bewegungsrichtung des Fördertrums 30

hinter dem Puderapparat 50 eine von oben her durch das

Leertrum 36 hindurch mit Frischluft beaufschlagbare

kombinierte Absaug- und Luftablenkwanne 56 im Zwischenraum 52

zwischen dem Fördertrum 30 und dem Leertrum 36 angeordnet. Die

Zufuhr der nicht mit Puder belasteten Frischluft erfolgt durch

einen Düsenkasten 58, der über der Puderabsaug- und

Luftablenkwanne 56 in die im Bereich des Düsenkastens 58

geschlossene obere Wand des Gehäuses 24 eingesetzt ist und die

Frischluft nach unten bläst, um die in Richtung der

Druckmaschine verlaufende puderbelastete Luftströmung zu

unterbrechen und so den Transport von mitgeführtem Puder in

Richtung der Druckmaschine zu verhindern.In order to spread the whirled powder within the

Die Puderabsaug- und Luftablenkwanne 56 und der Düsenkasten 58

sind hinter der Stelle angeordnet, an der das Fördertrum 30 in

die Horizontale umgelenkt wird, wobei sie bei dem in den

Figuren 1 und 2 dargestellten Ausführungsbeispiel in

Bewegungsrichtung des Fördertrums 30 vor der

Bogenaustrittsöffnung 44 und den darüber angebrachten

Auslagelüftern 46 angeordnet sind, während sie sich bei dem in

Fig. 3 dargestellten Ausführungsbeispiel mit kürzerer

Bogenauslage 22 unmittelbar darüber befinden. The powder suction and

In beiden Fällen wird die Absaug- und Luftablenkwanne 56 von

einer im Zwischenraum 52 zwischen dem Leertrum 36 und dem

Fördertrum 36 angeordneten quer verlaufenden Antriebswelle 60

des Hubmechanismus 48 getragen.In both cases, the suction and

Wie am besten in den Figuren 3, 4 und 5 dargestellt, besteht

die Absaug- und Luftablenkwanne 56 im wesentlichen aus einem

dünnwandigen flachen Gehäuse 62. Das Gehäuse 62 erstreckt sich

unterhalb der seitlichen Führungen des Leertrums 36 über die

gesamte lichte Weite des Gehäuses 24 der Bogenauslage 22 und

bildet eine durchgehende Trennwand zwischen einem unteren,

entlang des Fördertrums 30 verlaufenden Strömungspfad und

einem darüber angeordneten Bewegungspfad des Leertrums 36.

Diese Trennwand verhindert über gesamte Erstreckung den

Hindurchtritt von Luft von oben nach unten und umgekehrt.As best shown in Figures 3, 4 and 5

the suction and

Das Gehäuse 62 besitzt eine in Bewegungsrichtung des

Kettenförderers 20 mehrfach abgeknickte obere Gehäusewand 64,

so daß zwei flache Mulden 66 gebildet werden, die durch eine

dazwischen angeordnete Erhebung 68 voneinander getrennt sind.

Die obere Gehäusewand 64 ist weiter mit im Abstand voneinander

angeordneten Reihen von Ansaugschlitzen 70 versehen. Während

sich benachbarte mittlere Reihen von Ansaugschlitzen 70

jeweils an den tiefsten Stellen der Mulden 66 befinden, sind

äußere Reihen in unmittelbarer Nähe der entgegengesetzten

Außenränder des Gehäuses 62 angeordnet. Jede der Schlitzreihen

ist durch einen innerhalb des Gehäuses 62 angeordneten

Saugkanal 72 mit je einem Saugstutzen 74 verbunden, die an

einem der Außenränder angeordnet sind. Die Saugstutzen 74 sind

jeweils über Wege- und Druckregelventile zur Steuerung der

abgesaugten Luftmengen und des angelegten Unterdrucks mit

einem Sauggebläse verbunden, dem ein Staubabscheider mit einer

Zentrifuge und einem Feinfilter (nicht dargestellt)

vorgeschaltet ist. Von den Reihen von Ansaugschlitzen 70

werden die Schlitze 70 an dem Außenrand auf der Seite des

Puderapparats 50 am stärksten mit Unterdruck beaufschlagt. The

Auf der Oberseite der oberen Gehäusewand 64 ist weiter eine

Reinigungsbürste 76 angebracht, die sich über die gesamte

lichte Weite des Gehäuses 62 erstreckt, wobei sich ihre nach

oben weisenden und in Bewegungsrichtung des Leertrums 36 etwas

angewinkelten Borsten 78 bis in den Bewegungspfad des

Leertrums 36 erstrecken. Die Bürste 76 befindet sich in

derjenigen Mulde 66, die von dem über das Gehäuse 62

hinwegtretenden Leertrum 36 des Kettenförderers 20 zuerst

überstrichen wird.On the top of the

Das Gehäuse 62 besitzt weiter eine untere Gehäusewand 80, die

zwischen den beiden Mulden 66 und unterhalb der Erhebung 68

der oberen Gehäusewand 64 mit einer nach oben eingetieften

Ausbuchtung 82 versehen ist, deren Querschnitt die Form eines

umgekehrten U besitzt. Im Bereich dieser Ausbuchtung 82

umschließt die Gehäusewand 80 die zwischen dem Leertrum 36 und

dem Fördertrum 30 angeordnete quer verlaufende Antriebswelle

60, deren Oberseite das Gehäuse 62 trägt. Zur Minderung der

Reibung zwischen der langsam laufenden Antriebswelle 60 und

der unteren Gehäusewand 80 ist diese im Bereich der

Ausbuchtung 82 mit einem Teflonüberzug versehen.The

Das heißt, die Absaug- und Luftablenkwanne 56 stützt sich auf

der Antriebswelle 60 ab, so daß sie nur mit wenigen

Befestigungsschrauben an gegenüberliegenden Seitenwangen des

Kettenförderers 20 befestigt werden muß, um sie in ihrer Lage

zu halten.That is, the suction and

Wie am besten in den Figuren 5 bis 7 dargestellt, besteht der

als Luftzufuhreinrichtung dienende Düsenkasten 58 aus einem

flachen Metallgehäuse, das auf seiner dem Leertrum 36

zugewandten ebenen Unterseite mit einer Vielzahl von

Luftaustrittsdüsen 86 versehen ist, durch welche die unter dem

Düsenkasten 58 hindurchtretenden Bogengreifer 18 des

Kettenförderers 20 mit Luft beduscht werden können. Die

Luftaustrittsdüsen 86 sind in parallelen Reihen angeordnet,

von denen die mittlere genau über der Erhebung 68 auf der

Oberseite der Absaug- und Luftablenkwanne 56 liegt.As best shown in Figures 5 through 7, the

serving as air supply

Ein an die ebene Unterseite angrenzender Rand 88 eines

kleineren Unterteils des Düsenkastens 58 ist abgeschrägt und

an seinen schmaleren Stirnseiten jeweils mit einer Reihe von

Düsenöffnungen 90 versehen, die zum Beduschen der Ketten des

Kettenförderers 20 dienen. Der größere Oberteil des

Düsenkastens 58 ist mit einer umlaufenden Schulter versehen,

deren schmale Stirnenden auf den Seitenwangen des

Kettenauslegers aufliegen. Auf der Unterseite der Schulter ist

eine Bürste 92 angebracht, deren Borsten 94 sich nach unten

bis in den Pfad des Leertrums 36 erstrecken. Die Bürste 92

erstreckt sich ebenfalls über die gesamte lichte Weite des

Kettenauslegers bzw. des Gehäuses 24 und ist in

Bewegungsrichtung des Leertrums 36 unmittelbar hinter der

Bürste 76 der Absaug- und Luftablenkwanne 56 angeordnet.An

Von dem Düsenkasten 58 bzw. einer um diesen herum angeordneten

geschlossenen oberen Gehäusewand oder Abdeckung, der Absaugund

Luftablenkwanne 56 im Zwischenraum zwischen dem Leertrum

36 und dem Fördertrum 30 und den beiden, die Führungen 28

tragenden Seitenwänden der Bogenauslage 22 wird unterhalb des

Düsenkastens 58 ein Strömungspfad begrenzt, der quer zur

Bewegungsrichtung des Leertrums 36 durch die Bürsten 76, 92

und einen vom Düsenkasten 58 zur Absaug- und Luftablenkwanne

56 strömenden Luftvorhang vollständig versperrt wird, wobei

die Begrenzungen des Strömungspfades ein seitliches Ausweichen

der puderbelasteten Luftströmung verhindern.From the

Die Beaufschlagung des Düsenkastens 58 mit Druckluft mit einem

Druck zwischen 1,5 und 3,5 bar erfolgt durch zwei

Luftzufuhrstutzen 96 auf der Oberseite des Düsenkastens 58,

die jeweils mit einem Teil der Düsenreihen 86 kommunizieren.

Die zugeführte Luftmenge ist so bemessen, daß nur ein Teil

wieder durch die Ansaugschlitze 70 der Absaug- und

Luftablenkwanne 56 angesaugt werden kann, während die übrige

Luft an der Oberseite der Absaug- und Luftablenkwanne 56 in

Richtung der Druckmaschine abgelenkt wird.The application of compressed air to the

Während des Betriebs der Druckmaschine 2 und der Bogenauslage

22 wird die Luft mit einem verhältnismäßig geringen Druck von

1,5 bis 2 bar zugeführt, während der Luftdruck bei einer

nachgeschalteten Reinigung der Bogenauslage 22 auf 3 bis 3,5

bar erhöht wird. Wegeventile in den zu den Luftzufuhrstutzen

96 führenden Luftzufuhrleitungen (nicht dargestellt) gestatten

eine getaktete Luftzufuhr bzw. eine wahlweise Luftzufuhr zu

jedem einzelnen der beiden Luftzufuhrstutzen 96 oder zu beiden

gemeinsam, d.h. zu jeweils einem Teil der Düsen 86 oder zu

sämtlichen Düsen 86.During the operation of the

Die aus dem Düsenkasten 58 nach unten geblasene Luft strömt an

den Bogengreifern 18 und an den Ketten des Kettenförderers 20

vorbei, und beduscht diese mit sauberer Frischluft, wobei

anhaftende Puderpartikel nach unten mitgeführt werden, so daß

sie vom Leertrum 36 nicht weiter in Richtung der Druckmaschine

2 transportiert werden können. Gleichzeitig bildet der nach

unten geführte Luftstrom in diesem Bereich der Bogenauslage 22

zwischen der geschlossenen Gehäuseoberseite, den Seitenwänden

der Bogenauslage 22 und der Absaug- und Luftablenkwanne 56 auf

der Unterseite eine Sperre, die verhindert, daß durch die

Bürsten 76, 92 hindurchgetretene puderbelastete Luft entlang

des Leertrums 36 in Richtung der Druckmaschine 2 strömt.The air blown down from the

Während ein Teil der zugeführten Luft mit den abgereinigten

Puderpartikeln durch die Ansaugschlitze 70 der beiden

mittleren Schlitzreihen auf der Oberseite der Absaug- und

Umlenkwanne 56 und die zugehörigen Saugkanäle 72 abgesaugt und

im nachgeschalteten Staubabscheider gereinigt wird, wird bei

der Bogenauslage 22 in Fig. 1 die restliche Luft an der

Oberseite der Wanne 56 in Bewegungsrichtung des Leertrums 36

umgelenkt, wobei sie oberhalb des Puderapparats 50 vorbei in

Richtung der Druckmaschine strömt. Dadurch wird zwischen dem

zum Puderapparat 50 benachbarten Außenrand der Absaug- und

Luftablenkwanne 56 und der Oberseite des Puderapparats 50

unterhalb des Leertrums 36 ein Frischluftpolster gebildet (in

Figuren 1 durch Pfeile dargestellt), das sich über den

Puderapparat 50 hinaus bis weit in das schräge Teilstück des

Kettenauslegers hinein erstreckt und die Ausbreitung von

aufgewirbeltem Puder in dieser Richtung verhindert.While part of the air supplied with the cleaned

Powder particles through the

Zwischen dem Puderapparat 50 und der Druckmaschine 2 bilden

sich an der dem Fördertrum 30 zugewandten Unterseite des

Luftpolsters Luftwirbel aus, vermutlich infolge des Luftsogs

des Fördertrums 30, die unmittelbar über den bedruckten Bogen

eine Umkehr der Frischluftströmung in Richtung des freien

Endes der Auslage 22 zur Folge haben und den aus dem

Puderapparat 50 austretenden Puder in der Nähe des Fördertrums

30 von der Druckmaschine 2 weg in Richtung der Umlenkung des

Fördertrums 30 drücken. Dadurch wird auch dort eine

Ausbreitung von aufgewirbeltem Puder sicher verhindert und der

Puder in der Nähe des Puderapparats gehalten.Form between the

Zwischen dem Puderapparat 50 und den auf dem benachbarten

Außenrand der Absaug- und Luftablenkwanne 56 angeordneten

Ansaugschlitzen 70 bilden sich infolge des dort angelegten

Unterdrucks ebenfalls Frischluftwirbel aus, an deren

Unterseite die Luft ebenfalls in umgekehrter Richtung zur

Wanne 56 zurück nach vorne strömt und einen Teil des

aufgewirbelten Puders mit sich führt, so daß dieser durch die

Ansaugschlitze 70 am benachbarten Außenrand der Wanne 56

abgesaugt werden kann.Between the

Durch die Unterbrechung der Luftströmung entlang des Leertrums

36 kann es druckmaschinenseitig von den Bürsten 76, 92 zur

Entstehung eines Unterdrucks Kommen, dessen Stärke von der

durch den Düsenkasten 58 zugeführten Luftmenge abhängt. Um zu

verhindern, daß durch diesen Unterdruck puderbelastete Luft

von der Puderbestäubungseinrichtung her angesaugt wird, ist

bei der in Fig. 2 dargestellten Bogenauslage 22 am oberen Ende

des schrägen Teilstücks des Gehäuses 24 in der oberen Wand des

Gehäuses 24 ein Lüftungsgitter 95 angeordnet, durch das aus

der Umgebung der Bogenauslage 22 nicht mit Puder belastete

Luft ins Innere des Gehäuses 24 gesaugt werden kann. Der

größte Teil der angesaugten Luft wird vom Sog des Leertrums 36

entlang desselben in Richtung der Druckmaschine 2 mitgeführt,

während ein kleinerer Teil hinter dem als Luftweiche wirkenden

Luftabsaugrohr 75 nach unten und druckmaschinenseitig entlang

des Puderapparats 50 nach unten strömt. Der an der Oberseite

der Absaug- und Luftablenkwanne 56 umgelenkte Teil der durch

den Düsenkasten 58 eingeblasenen Luft strömt auf der von der

Druckmaschine 2 abgewandten Seite des Puderapparats 50 nach

unten, wobei die beiden Luftströmungen ebenfalls dazu

beitragen, den Puder aus dem Puderapparat nach unten zur

Oberfläche der vorbeitransportierten Bogen zu fördern und eine

Aufwirbelung und Ausbreitung von Puder zu verhindern.By interrupting the air flow along the empty run

36 it can be on the printing machine side from the

An Stelle eines über der Absaug- und Luftablenkwanne 56

angeordneten Düsenkastens 58 zum Einblasen von Luft und einer

im Abstand dahinter angeordneten Lufteintrittsöffnung 95 kann

auch eine oberhalb der Absaug- und Luftablenkwanne 56

angeordnete Lufteintrittsöffnung (nicht dargestellt)

vorgesehen sein. Infolge der Luftansaugung auf der Unterseite

des Leertrums 36 wird durch diese Öffnung nicht mit Puder

belastete Luft aus der Umgebung der Bogenauslage 22 ins Innere

des Gehäuses 24 angesaugt, worauf sie den Bewegungspfad des

Leertrums 36 in vertikaler Richtung durchströmt.Instead of one above the suction and

Weiter kann zusätzlich auch vor den Bürsten 76, 92 Luft

abgesaugt werden, so daß durch einen dort entstehenden

Unterdruck ein kleinerer Teil der hinter den Bürsten 76, 92

zugeführten Luft nach vorne durch die Bürsten 76, 92 gesaugt

wird. Weiter können die Bürsten 76, 92 auch weggelassen und

die entlang des Leertrums 36 verlaufende Luftströmung allein

durch Zufuhr und/oder Absaugung von Luft unterbrochen werden.In addition, air can also be in front of the

Durch die vorangehend beschriebenen Maßnahmen wird

insbesondere verhindert, daß aufgewirbelter Puder durch den

Sog des Kettenförderers 20 mitgerissen und von einer über und

unter dessen Leertrum 36 erzeugten Luftströmung innerhalb des

Gehäuses 24 der Bogenauslage 22 in Richtung der Druckmaschine

2 transportiert wird. Die Ausbreitung von Puder wird im

wesentlichen auf den Bereich unterhalb des Puderapparats 50

und oberhalb der darunter vorbeitretenden bedruckten Bogen

begrenzt, wodurch zum einen der Puderverbrauch erheblich

verringert werden kann und zum anderen sowohl die

Staubbelastung in der Umgebungsluft als auch im Inneren des

Gehäuses bedeutend niedriger ist. Durch die Beschränkung des

Puders auf den genannten Bereich kann außerdem bei beidseitig

bedruckten Bogen die gleichmäßige Bestäubung von deren Vorder-

und Rückseite verbessert werden.The measures described above will

in particular prevents powder from being whirled up by the

Suction of the

Weiter beschleunigt das Frischluftpolster zwischen dem

Fördertrum 30 und dem Leertrum 36 auf der der Druckmaschine 2

zugewandten Seite des Puderapparats 50 die oxidative Trocknung

der Druckfarben durch die stetige Frischluftzufuhr in diesen

Bereich.The fresh air cushion accelerates between the

Durch die Beduschung mit Luft bleiben darüber hinaus die

Ketten und Führungsschienen 28 des Kettenförderers 20 sauber

und mit Fett gesättigt, so daß ein puderbedingter Verschleiß

verhindert werden kann.By showering with air, the

Chains and

Mit Hilfe der beiden Bürsten 76 und 92 werden fester an den

Ketten oder Bogengreifern 18 anhaftende Puderpartikel oder

Puderagglomerate abgebürstet, die dann nach unten in die

Mulden 66 der Absaug- und Luftablenkwanne 56 fallen und durch

die beiden Ansaugschlitze 70 der beiden mittleren

Schlitzreihen abgesaugt werden.With the help of the two

Claims (33)

- Method wherein, in a printing press (2) comprising at least one printing unit (12, 14), printed sheets are conveyed through a sheet delivery (22) to a location above a sheet deposit pile (26) by means of a sheet conveyor (20) and are dusted with a powder in the process, and wherein a powder-laden air flow flowing in a housing (24) of the sheet delivery (22) in the direction of motion of an empty strand (36) of the sheet conveyor (20) in a direction towards the printing unit (12, 14) is surrounded at all sides and interrupted at at least one interruption location between the free end of the sheet delivery (22) and the printing unit (12, 14) by devices (56, 58, 76, 92) comprising mechanical and/or pneumatic means (58, 76, 92) in combination with the side walls of the housing, the flow path of the powder-laden air being blocked substantially completely over the entire clear width of the housing (24) of the sheet delivery (22) by means of the devices (56, 68, 76, 92) comprising mechanical and/or pneumatic means, so that excess powder entrained by the air flow is prevented from being transported into the direction of the printing unit (12, 14) and from spreading in an uncontrolled manner, and the air flow being interrupted above a part (56) of the devices (56, 58, 76, 92) arranged between the empty strand (36) and a conveying strand (30) of the sheet conveyor (20) and acting as a dividing wall.

- Method according to claim 1, characterized in that the air flow is interrupted in an upper horizontal section of the sheet delivery (22).

- Method according to claim 1 or 2, characterized in that the air flow is interrupted substantially above a drive shaft (60) of a lifting mechanism (48) for the sheet deposit pile (26).

- Method according to one of claims 1 to 3, characterized in that in order to interrupt the air flow, air not laden with powder is supplied to the housing in such a way that it flows through the empty strand (36) transversely to the direction of motion of the latter.

- Method according to claim 4, characterized in that the air is supplied to the housing from above.

- Method according to claim 4 or 5, characterized in that the air is supplied downstream of a brush arrangement (76, 92) in the direction of motion of the empty strand (36), the brush arrangement (76, 92) at least partially blocking the flow path.

- Method according to one of claims 4 to 6, characterized in that at least part of the supplied air is deflected in the direction of the printing unit (12, 14).

- Method according to claim 7, characterized in that at least part of the deflected air is directed into the direction of the printing unit (12, 14) so as to pass above a dusting device (50) dusting the sheets with a powder.

- Method according to one of claims 1 to 8, characterized in that in order to interrupt the air flow in the region of the interruption location powder-laden air is removed by suction.

- Method according to claim 9, characterized in that at least part of the air supplied into the housing is removed by suction after passing through the empty strand (36).

- Method according to claim 10, characterized in that the air is removed by suction at a location located substantially opposite the location where the air is supplied to the housing.

- Method according to one of claims 9 to 11, characterized in that the powder-laden air is removed by suction in the region of a brush arrangement (76, 92) blocking the flow path of the powder-laden air at least partially or substantially completely.

- Method according to one of claims 1 to 12, characterized in that in the region of the interruption location and/or downstream of said location in the direction of motion of the empty strand (36) additional air is drawn into the housing (24) from outside by suction through at least one air opening (95).