EP1040918B1 - Procédé et dispositif pour amortir les vibrations de torsion d'une machine d'impression - Google Patents

Procédé et dispositif pour amortir les vibrations de torsion d'une machine d'impression Download PDFInfo

- Publication number

- EP1040918B1 EP1040918B1 EP00104762A EP00104762A EP1040918B1 EP 1040918 B1 EP1040918 B1 EP 1040918B1 EP 00104762 A EP00104762 A EP 00104762A EP 00104762 A EP00104762 A EP 00104762A EP 1040918 B1 EP1040918 B1 EP 1040918B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- torsional vibration

- printing machine

- mass

- machine according

- damping

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F13/00—Common details of rotary presses or machines

- B41F13/008—Mechanical features of drives, e.g. gears, clutches

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41P—INDEXING SCHEME RELATING TO PRINTING, LINING MACHINES, TYPEWRITERS, AND TO STAMPS

- B41P2213/00—Arrangements for actuating or driving printing presses; Auxiliary devices or processes

- B41P2213/40—Auxiliary devices or processes associated with the drives

- B41P2213/42—Vibration-dampers for machine parts

Definitions

- the invention relates to a method and a device for the eradication of the torsional vibrations a printing press, wherein at least one torsional vibration absorbing Element acts on the gear train of the printing press.

- Sources of vibration are cylinder channels as well Sheet transfer elements and other discontinuously working machine elements. This leads to bending vibrations in rollers and cylinders, but also to Torsional vibrations of cylinders or drums. The latter usually sit over the Gears of the gear train continue and usually reach with increasing Distance from the drive higher amplitudes. Such vibrations can be angularly synchronous or occur asynchronously.

- the invention is therefore based on the problem of speed-dependent duplication problems reduce as much as possible.

- the object is achieved in a method of the type mentioned in that the first mode shape and natural frequency of a printing machine is determined and that at least one of the shaft journals of the gears, on which the greatest amplitudes occur at the first natural frequency, one on the reductions of this first natural frequency coordinated passive torsional vibration damper is assigned.

- the object is achieved in a device of the type mentioned in that on at least one shaft journal of the cylinders driven by the gear train or drum a passive torsional vibration damper near the gear is arranged.

- the method according to the invention essentially causes the duplication problems specifically determined and with simple and effective means spatially and fought at the time of their appearance. Determining the first and where appropriate Further eigenmodes take place, for example, by measuring torsional vibrations and / or Calculation. The vibrations are in their resonance ranges, i.e. when they occur counteracted the eigenmodes and natural frequencies of the printing machine in such a way that they are harmless to the printing process and therefore no duplication errors occur can. This is done by appropriate tuning of the natural frequency of the Mass of the torsional vibration damper, its spring rate and, if applicable, its Damping, as well as by the arrangement of the torsional vibration damper on the critical Set the gear train.

- the device according to the invention provides the design and arrangement of a torsional vibration damper before the above To achieve effect.

- the Placement near the gear ensures that the harmful vibration is eliminated before it affects the cylinder or drum.

- the method and the device reduce the vibration in one Frequency band around the first natural frequency along the entire drive train of the Press. It unfolds without any technical control effort and without Sensors and actuators have an optimal effect at every set printing speed. This means that there are no changes in quality that depend on the printing speed due to vibrations in the drive train.

- a further development of the method provides that the second mode and Natural frequency of a printing press can be measured and that at least the shaft journal of the gears on which the greatest amplitudes of the second natural frequency occur, a passive tuned to the reduction of this second natural frequency Torsional vibration damper is assigned. This also reduces vibrations in a frequency band around the second natural frequency along the entire Drive train of the printing press.

- a passive tuned to the reduction of this second natural frequency Torsional vibration damper is assigned. This also reduces vibrations in a frequency band around the second natural frequency along the entire Drive train of the printing press.

- other orders of natural frequencies can also be combated, as a rule it is sufficient, however, the first and the second natural frequency in the proposed manner and Way to reduce.

- the properties of the torsional vibration absorbers are preferably corresponding to the measured values selected such that eradication and damping of the torsional vibrations is achieved.

- the device according to the invention provides for the eradication of the torsional vibrations that torsional vibration absorbers can be arranged at any point on the gear train can. However, it is preferably provided that at the points on the gear train Torsional vibration dampers are arranged on which the largest torsional vibration amplitudes occur. Since the amplitudes with increasing distance from the drive in the As a rule, it is advisable that the torsional vibration damper be attached to the Shafts of the cylinders or drums are arranged which continue from the drive are removed. For a machine with several printing units and a drive in Area of the machine center, it is suggested that each power transmission side at least a torsional vibration damper is assigned.

- At least one torsional vibration damper is expediently used to reduce the first frequency arranged and dimensioned.

- An optimal one Vibration reduction is achieved in that the torsional vibration damper dampened absorber.

- Such absorbers have a mass, which by means of spring and Damping elements is articulated at the critical points of the drive train.

- the damped absorber consists of at least one mass and at least one elastomer that exists between a carrier and the mass is inserted, the elastomer having spring and damping properties.

- a second embodiment provides that the damped absorber consists of at least one Mass and spring elements and damping elements exist between the Mass and a carrier are arranged.

- the damping elements expediently arranged acting in the circumferential direction.

- the damping elements can be cylinders with pistons, a damping medium can flow through a gap on the piston.

- the spring elements are also useful arranged acting in the circumferential direction.

- Further training provides for the reduction of the first and second mode and Natural frequency of the press a torsional vibration damper as a two-stage torsional vibration damper train.

- the first resilient and damping elements are arranged between the carrier and the mass and that second resilient and damping elements between the mass and another Mass are arranged, one of the resilient and damping elements with the associated mass to reduce the first and the other resilient and damping Element with the associated mass to reduce the second eigenmode and Natural frequency is formed and dimensioned.

- the damped torsional vibration dampers to combat the first and second Natural frequency can be arranged independently of each other on the cylinder journal. It it is also possible to arrange both absorbers next to each other on the same flange and to assign such a double damper to a cylinder or a drum.

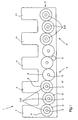

- the printing press 1 shows a printing press 1 with the torsional vibration damping according to the invention.

- the printing press 1 consists of five printing units 7, 7 ', 7 ", 7" “, 7” ", which are driven by a drive 8 via a gear train 2.

- the number of Printing units are of course only exemplary.

- the drive 8 is expedient arranged in the central region of the printing press 1 in order to transfer the data to be transferred To keep moments of force as low as possible.

- Each printing unit 7, 7 ', 7' ', 7' ', 7''', 7 ''''' is one Assigned printing cylinder 4 and there are drums 4 'between the printing units for transferring the sheets from one printing unit to another.

- the cylinders 4 and the drums 4 ' are equipped with gears 6, 6', 6 '', ... which pull the gears 2 forming interlocking. If there are 1 torsional vibrations in such a printing press, so these are usually low in the drive 8 and increase with increasing distance from the drive 8.

- the first of such a printing press 1 is measured by torsional vibration and possibly also the second mode and frequency as well as the location of the Occurrence of the same is determined in order to target this natural frequency and Use inherent shape of coordinated passive torsional vibration absorbers 5, 5 '.

- With such a Machine with the drive 8 in the middle area should regularly every power transmission side 9 and 9 'are assigned at least one torsional vibration damper 5, 5'.

- Fig. 2 shows the arrangement of a first embodiment of a torsional vibration damper 5 or 5 '.

- a cylinder 4 or a drum 4 ' is shown, which is mounted on both sides in the side walls 19 of the printing press by means of bearings 20.

- the side wall 19 of the drive side is shown.

- the gear 6, 6 ', 6'', ..., which is driven via the gear train 2 of the printing press 1, is located on the shaft journal 3 on this side. If corresponding amplitudes of the natural frequency have been measured for this cylinder 4 or this drum 4 ', the shaft journal 3 is provided according to the invention with a torsional vibration damper 5 or 5'.

- the illustrated first exemplary embodiment of a torsional vibration damper 5, 5 ' exists from a carrier 14, for example a flange, which is attached to the shaft journal 3 is.

- a carrier 14 On this carrier 14 there is an elastomer 11, which is a ring trained mass 10 carries.

- the elastomer 11 is designed such that it is amortization and Has damping properties.

- Fig. 3 shows a second embodiment of a torsional vibration damper 5, 5 '.

- the repayment properties are achieved by means of specific spring elements 12 and the damping properties are achieved by means of specific damping elements 13.

- these are arranged between a flange-like carrier 14 and the mass 10.

- the damping elements 13 consist of closed cylinders 15 in which pistons 16 run, the pistons 16 having a gap 18 through which a damping medium 17 can flow from one space to another.

- FIG. 4 shows a first exemplary embodiment of a two-stage torsional vibration damper 21.

- a carrier 14 with an elastomer 11 and a mass 10 is arranged on a shaft journal 3.

- a vibration which has amplitudes of the first and second orders can be reduced with a two-stage torsional vibration damper 21.

- FIG. 5 shows a second exemplary embodiment of a two-stage torsional vibration damper 21.

- the two torsional vibration dampers 5 and 5 ' are arranged next to one another on a carrier 14.

- the invention can be implemented with many other embodiments, for example the two-stage torsional vibration damper of FIGS. 4 and 5 in Art are formed like the torsional vibration damper 5, 5 ', which is shown in Fig. 3 and was explained above.

- torsional vibration damper 5 for the first and torsional vibration damper 5 'for the second mode shape and frequency of the pressure arrange the machine separately on the shaft journal 3. They can partially open the same shaft journal 3 or on different shaft journals 3.

- Further embodiments of the damping 13 and spring elements 12 are also conceivable or an embodiment in which a mass 10 or 10 'disc-shaped under Insertion of a repaying and / or damping element 11, 1 ', 12, 13 on the end face of the shaft journal 3 sits.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Rotary Presses (AREA)

- Vibration Prevention Devices (AREA)

- Inking, Control Or Cleaning Of Printing Machines (AREA)

- Rolls And Other Rotary Bodies (AREA)

- Accessory Devices And Overall Control Thereof (AREA)

Claims (16)

- Procédé pour amortir les vibrations torsionnelles d'une machine à imprimer (1), au moins un élément recevant les vibrations torsionnellcs agissant sur le train d'engrenages (2) de la machine à imprimer (1), caractérisé en ce que la première forme propre et la fréquence propre d'une machine à imprimer sont déterminées et en ce qu'un amortisseur de vibrations torsionnelles (5, 21) passif et adapté aux réductions de cette première fréquence propre est attribué à au moins l'un des tourillons d'arbre (3) des engrenages (6, 6', 6"...), sur lesquels apparaissent les amplitudes maximales de la seconde fréquence propre.

- Procédé selon la revendication 1, caractérisé en ce qu'également les secondes forme propre et fréquence propre d'une machine à imprimer sont mesurées et en ce qu'un amortisseur de vibrations torsionnelles (5') passif et adapté à la réduction de cette seconde fréquence propre est attribué à au moins l'un des tourillons d'arbre (3) des engrenages (6, 6', 6"...), sur lesquels apparaissent les amplitudes maximales de la seconde fréquence propre.

- Procédé selon la revendication 1 ou 2, caractérisé en ce que les propriétés des amortisseurs de vibrations torsionnelles (5, 5', 21) sont choisies en fonction des valeurs mesurées de telle sorte qu'on obtient un amortissement et une atténuation des vibrations torsionnelles.

- Machine à imprimer comprenant un dispositif pour l'amortissement des vibrations torsionnellcs, au moins un élément recevant les vibrations agissant sur le train d'engrenages (2) de la machine à imprimer (1), caractérisée en ce que sur au moins un tourillon d'arbre (3) des cylindres ou tambours (4, 4') entraínés par le train d'engrenages (2) est disposé un amortisseur passif de vibrations torsionnelles (5, 5', 21) à proximité de l'engrenage (6, 6', 6",...) qui est adapté à la première fréquence propre calculée.

- Machine à imprimer selon la revendication 4, caractérisée en ce que les amortisseurs de vibrations torsionnelles (5, 5', 21), sur lesquels apparaissent les amplitudes maximales des vibrations torsionnelles, sont disposés aux emplacements du train d'engrenages (2).

- Machine à imprimer selon la revendication 4 ou 5, caractérisée en ce que dans le cas d'une machine comprenant plusieurs groupes d'impression (7, 7', 7",...) et un entraínement (8), au moins un amortisseur de vibrations torsionnelles (5, 5', 21) est attribué à chaque côté de transmission de force (9, 9') dans le secteur du centre de la machine.

- Machine à imprimer selon l'une quelconque des revendications 4 à 6, caractérisée en ce qu'au moins un amortisseur de vibrations torsionnelles (5) est disposé et dimensionné pour la réduction de la première fréquence propre.

- Machine à imprimer selon la revendication 7, caractérisée en ce qu'au moins un autre amortisseur de vibrations torsionnelles (5') est disposé et dimensionné pour la réduction de la seconde fréquence propre.

- Machine à imprimer selon l'une quelconque des revendications 4 à 9, caractérisée en ce que l'amortisseur de vibrations torsionnelles (5, 5', 21) est un amortisseur amorti.

- Machine à imprimer selon la revendication 9, caractérisée en ce que l'amortisseur amorti de vibrations torsionnelles (5, 5', 21) comprend au moins une masse (10, 10') et au moins un élastomère (11, 11'), qui est inséré entre un support (12) et la masse (10, 10'), l'élastomère (11, 11') présentant des propriétés d'élasticité et d'amortissement.

- Machine à imprimer selon la revendication 9, caractérisée en ce que l'amortisseur (5, 5', 21) amorti comprend au moins une masse (10, 10') et des éléments de ressort (12) ainsi que des éléments d'amortissement (13), qui sont disposés entre la masse (10, 10') et un support (14).

- Machine à imprimer selon la revendication 11, caractérisée en ce que les éléments d'amortissement (13) sont disposés en agissant dans le sens périphérique.

- Machine à imprimer selon la revendication 12, caractérisée en ce que les éléments d'amortissement (13) sont des cylindres (15) avec piston (16), un fluide d'amortissement (17) pouvant circuler à travers une fente (18) sur le piston (16).

- Machine à imprimer selon l'une quelconque des revendications 11 à 13, caractérisée en ce que les éléments de ressort sont disposés en agissant dans le sens périphérique.

- Machine à imprimer selon l'une quelconque des revendications 4 à 14, caractérisée en ce que l'amortisseur de vibrations torsionnelles (5, 5') pour la réduction des premières et secondes forme propre et fréquence propre de la machine à imprimer sont conçues comme des amortisseurs de vibrations torsionnelles (21) à deux niveaux.

- Machine à imprimer selon la revendication 16, caractérisée en ce que des premiers éléments (11, 12, 13) faisant ressort et amortisseurs sont disposés entre le support (14) et la masse (10) et en ce que des seconds éléments (11', 12, 13) faisant ressort et amortisseurs sont disposés entre la masse (10) et une autre masse (10'), l'un des éléments (11, 12, 13, 11') faisant ressort et amortisseurs étant conçu et dimensionné avec la masse (10, 10') spécifique pour la réduction des premières forme propre et fréquence propre et l'autre élément (11, 12, 13 ; 11') faisant ressort et amortisseur étant conçu et dimensionné avec la masse (10 ; 10') spécifique pour la réduction des secondes forme propre et fréquence propre.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19914613A DE19914613A1 (de) | 1999-03-31 | 1999-03-31 | Verfahren und Vorrichtung zur Tilgung der Drehschwingungen einer Druckmaschine |

| DE19914613 | 1999-03-31 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1040918A1 EP1040918A1 (fr) | 2000-10-04 |

| EP1040918B1 true EP1040918B1 (fr) | 2004-07-14 |

| EP1040918B2 EP1040918B2 (fr) | 2012-01-25 |

Family

ID=7903081

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00104762A Expired - Lifetime EP1040918B2 (fr) | 1999-03-31 | 2000-03-04 | Procédé et dispositif pour amortir les vibrations de torsion d'une machine d'impression |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US6499401B1 (fr) |

| EP (1) | EP1040918B2 (fr) |

| JP (1) | JP2000313099A (fr) |

| AT (1) | ATE270967T1 (fr) |

| DE (2) | DE19914613A1 (fr) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19963945C1 (de) * | 1999-12-31 | 2001-07-19 | Koenig & Bauer Ag | Verfahren und Anordnung zur Kompensation von Schwingungen rotierender Bauteile |

| DE10249475A1 (de) | 2001-11-20 | 2003-09-11 | Heidelberger Druckmasch Ag | Verfahren und Vorrichtung zum Unterdrücken von Schwingungen in einer drucktechnischen Maschine |

| DE10248519B4 (de) * | 2002-10-17 | 2006-11-02 | Voith Patent Gmbh | Mittelwalze eines Kalanders und Kalander |

| DE102007015345A1 (de) * | 2007-03-30 | 2008-10-02 | Koenig & Bauer Aktiengesellschaft | Vorrichtung zur Reduzierung von Schwingungen einer Greiferwelle |

| DE102008054192A1 (de) | 2008-10-31 | 2010-05-06 | Manroland Ag | Druckeinheit |

| DE102009046745A1 (de) * | 2009-11-17 | 2011-05-19 | Man Diesel & Turbo Se | Kurbelwelle |

| DE102010026204A1 (de) * | 2010-07-02 | 2012-01-05 | Fakultät Ingenieurwissenschaften und Informatik Fachhochschule Onsabrück | Verfahren sowie Vorrichtung zur Kompensation von über den Umfang eines rotierenden insbesondere zylindrischen, Bauteils, insbesondere einer Walze, periodisch wiederkehrenden Störanregungen sowie Verfahren zur Bestimmung der Oberflächenstruktur eines ringförmigen Profils zur Kompensation der Störanregungen |

| DE102022212522A1 (de) | 2022-11-23 | 2024-05-23 | Zf Friedrichshafen Ag | Zahnrad oder Welle mit Schwingungstilger |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0585897A1 (fr) * | 1992-09-02 | 1994-03-09 | Konica Corporation | Appareil d'entrainement pour un corps rotatif dans un appareil de formation d'images |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE130321C (fr) | ||||

| US2581656A (en) * | 1947-04-25 | 1952-01-08 | Hoe & Co R | Bearing support for printing presses |

| US3058371A (en) * | 1960-11-29 | 1962-10-16 | Fred L Haushalter | Vibration dampener |

| DE2447602C3 (de) * | 1974-10-05 | 1980-10-30 | M.A.N.-Roland Druckmaschinen Ag, 6050 Offenbach | Dämpfungsvorrichtung |

| US4073047A (en) * | 1974-12-26 | 1978-02-14 | The Goodyear Tire & Rubber Company | Method of making vibration damper |

| DE2516462C3 (de) * | 1975-04-15 | 1981-01-08 | M.A.N.-Roland Druckmaschinen Ag, 6050 Offenbach | Gleichstromantrieb für Druckmaschinen |

| DD130321A1 (de) * | 1977-04-12 | 1978-03-22 | Wolfgang Mey | Vorrichtung zur tilgung von torsionsschwingungen |

| DE2907016C2 (de) * | 1979-02-23 | 1982-12-09 | Goetze Ag, 5093 Burscheid | Schwingungstilger für rotierende Wellen |

| DE3502029A1 (de) * | 1985-01-23 | 1986-07-31 | Fichtel & Sachs Ag, 8720 Schweinfurt | Torsionsdaempfer fuer kupplungsscheiben mit hydraulischer daempfung |

| DE3529687A1 (de) * | 1985-08-20 | 1987-03-05 | Opel Adam Ag | Drehschwingungstilger fuer eine antriebswelle |

| DE3626185A1 (de) * | 1986-08-01 | 1988-02-18 | Heidelberger Druckmasch Ag | Getriebe zur bildung einer zyklisch ablaufenden bewegung aus einer rotationsbewegung |

| DE3828638C1 (fr) * | 1988-08-24 | 1989-07-27 | Heidelberger Druckmaschinen Ag, 6900 Heidelberg, De | |

| JPH02146029U (fr) * | 1989-05-15 | 1990-12-11 | ||

| JP2895268B2 (ja) * | 1990-08-13 | 1999-05-24 | オイレス工業株式会社 | 塑性エネルギー吸収装置 |

| DE4033278C1 (fr) * | 1990-10-19 | 1992-03-12 | Heidelberger Druckmaschinen Ag, 6900 Heidelberg, De | |

| US5410228A (en) * | 1991-02-05 | 1995-04-25 | Kabushiki Kaisha Yaskawa Denki | Method and apparatus for suppressing torsional vibration in an electric motor speed control system |

| DE4234928A1 (de) * | 1992-10-16 | 1994-04-21 | Heidelberger Druckmasch Ag | Vorrichtung und Verfahren zur Dämpfung von mechanischen Schwingungen von Druckmaschinen |

| US5324248A (en) * | 1992-11-03 | 1994-06-28 | Composite Development Corporation | Composite machine roll and method of manufacture |

| FR2723625B1 (fr) * | 1994-08-09 | 1996-11-08 | Heidelberg Harris Sa | Procede et dispositif d'amortissement des vibrations en flexion des cylindres dans une presse a imprimer. |

| DE19508082C2 (de) † | 1995-03-08 | 2000-05-11 | Koenig & Bauer Ag | Hauptantrieb für eine Druckmaschine |

| US5752443A (en) | 1995-06-16 | 1998-05-19 | Heidelberger Druckmaschinen Ag | Mechanism for excluding critical speeds from normal operating ranges |

| JP3742143B2 (ja) * | 1996-04-19 | 2006-02-01 | 株式会社三共製作所 | 変動トルク相殺装置 |

| US5794529A (en) | 1996-05-02 | 1998-08-18 | Heidelberger Druckmaschinen Ag | Compliant drive for printing presses |

-

1999

- 1999-03-31 DE DE19914613A patent/DE19914613A1/de not_active Ceased

-

2000

- 2000-03-04 EP EP00104762A patent/EP1040918B2/fr not_active Expired - Lifetime

- 2000-03-04 DE DE50007037T patent/DE50007037D1/de not_active Expired - Lifetime

- 2000-03-04 AT AT00104762T patent/ATE270967T1/de not_active IP Right Cessation

- 2000-03-30 JP JP2000094016A patent/JP2000313099A/ja active Pending

- 2000-03-31 US US09/540,936 patent/US6499401B1/en not_active Expired - Lifetime

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0585897A1 (fr) * | 1992-09-02 | 1994-03-09 | Konica Corporation | Appareil d'entrainement pour un corps rotatif dans un appareil de formation d'images |

Also Published As

| Publication number | Publication date |

|---|---|

| DE19914613A1 (de) | 2000-10-05 |

| US6499401B1 (en) | 2002-12-31 |

| DE50007037D1 (de) | 2004-08-19 |

| ATE270967T1 (de) | 2004-07-15 |

| EP1040918A1 (fr) | 2000-10-04 |

| JP2000313099A (ja) | 2000-11-14 |

| EP1040918B2 (fr) | 2012-01-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1040917B1 (fr) | Procédé et dispositif à compensation de vibrations torsionelles d'une machine à imprimer | |

| EP0592850B1 (fr) | Dispositif et procédé pour amortir les vibrations mécaniques d'une machine à imprimer | |

| EP0462411B1 (fr) | Equilibrage du couple de deuxième ordre d'un moteur à combustion interne 5 cylindres en ligne | |

| EP2786042A1 (fr) | Pendule à force centrifuge | |

| EP0703384A2 (fr) | Amortisseur de vibrations | |

| WO2011141246A1 (fr) | Amortisseur de vibrations | |

| DE2358516A1 (de) | Schwingungsdaempfer, insbesondere fuer verbrennungskraftmaschinen | |

| EP1040918B1 (fr) | Procédé et dispositif pour amortir les vibrations de torsion d'une machine d'impression | |

| EP1411254B1 (fr) | Cylindre médial de calandre avec amortisseur comprennant un masse d'inertie | |

| DE4337554A1 (de) | Lithographische Offsetdruckmaschine | |

| WO2014202071A1 (fr) | Dispositif d'amortissement de vibrations de torsion dans un groupe motopropulseur d'un véhicule automobile | |

| DE10249475A1 (de) | Verfahren und Vorrichtung zum Unterdrücken von Schwingungen in einer drucktechnischen Maschine | |

| DE102017000193A1 (de) | Walze zur Bodenverdichtung sowie Verfahren zum Erzeugen eines Schwingungsbildes einer Walze zur Bodenverdichtung | |

| DE102017100457A1 (de) | Pendeldämpfungsvorrichtung | |

| DE102011084141B4 (de) | Antriebssystem mit einem Differentialdämpfer zur Drehungleichförmigkeitsreduktion | |

| DE102007035476A1 (de) | Verfahren zum Betreiben einer Druckmaschine | |

| EP1080315B1 (fr) | Element d'accouplement pour la liaison de deux arbres a axe parallele places coaxialement l'un derriere l'autre et avec un ecart transversal l'un par rapport a l'autre | |

| DE102010052822A1 (de) | Isolationsvorrichtung | |

| DE102008039543B4 (de) | Rollenmühle | |

| EP0411349A1 (fr) | Dispositif pour compacter le sol | |

| CH696360A5 (de) | Kämmaschine mit Schwingungsdämpfer. | |

| EP1182034B1 (fr) | Dispositif pour amortir des vibrations de torsion de l'entraînement d'une rotative d'impression offset pour feuilles | |

| DE102013101066A1 (de) | Rotationszylinder | |

| DE102010026204A1 (de) | Verfahren sowie Vorrichtung zur Kompensation von über den Umfang eines rotierenden insbesondere zylindrischen, Bauteils, insbesondere einer Walze, periodisch wiederkehrenden Störanregungen sowie Verfahren zur Bestimmung der Oberflächenstruktur eines ringförmigen Profils zur Kompensation der Störanregungen | |

| DE10040361C2 (de) | Druckwerk einer Druckmaschine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20000826 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| 17Q | First examination report despatched |

Effective date: 20010406 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040714 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040714 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040714 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 50007037 Country of ref document: DE Date of ref document: 20040819 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040811 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041014 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041014 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041014 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20041025 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050304 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050304 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20050318 Year of fee payment: 6 Ref country code: BE Payment date: 20050318 Year of fee payment: 6 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050331 |

|

| PLAQ | Examination of admissibility of opposition: information related to despatch of communication + time limit deleted |

Free format text: ORIGINAL CODE: EPIDOSDOPE2 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAQ | Examination of admissibility of opposition: information related to despatch of communication + time limit deleted |

Free format text: ORIGINAL CODE: EPIDOSDOPE2 |

|

| PLAR | Examination of admissibility of opposition: information related to receipt of reply deleted |

Free format text: ORIGINAL CODE: EPIDOSDOPE4 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| 26 | Opposition filed |

Opponent name: KOENIG & BAUER AKTIENGESELLSCHAFT Effective date: 20050413 |

|

| R26 | Opposition filed (corrected) |

Opponent name: KOENIG & BAUER AKTIENGESELLSCHAFT Effective date: 20050413 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060304 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060331 |

|

| BERE | Be: lapsed |

Owner name: *HEIDELBERGER DRUCKMASCHINEN A.G. Effective date: 20060331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041214 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20090326 Year of fee payment: 10 Ref country code: GB Payment date: 20090324 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20100304 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100331 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100304 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20120125 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 50007037 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 50007037 Country of ref document: DE Effective date: 20120125 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20120322 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20130419 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20141128 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140304 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20170331 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50007037 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20181002 |