EP1033171B1 - Filtre electrostatique notamment pour le nettoyage de l'air d'échappement des tunnels routiers et d'autres choses semblables - Google Patents

Filtre electrostatique notamment pour le nettoyage de l'air d'échappement des tunnels routiers et d'autres choses semblables Download PDFInfo

- Publication number

- EP1033171B1 EP1033171B1 EP00890063A EP00890063A EP1033171B1 EP 1033171 B1 EP1033171 B1 EP 1033171B1 EP 00890063 A EP00890063 A EP 00890063A EP 00890063 A EP00890063 A EP 00890063A EP 1033171 B1 EP1033171 B1 EP 1033171B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- filter

- collector

- mat

- electrodes

- filter mat

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000004140 cleaning Methods 0.000 title description 6

- 238000002347 injection Methods 0.000 claims description 2

- 239000007924 injection Substances 0.000 claims description 2

- 238000007664 blowing Methods 0.000 claims 1

- 238000011144 upstream manufacturing Methods 0.000 claims 1

- 210000002268 wool Anatomy 0.000 abstract description 4

- 239000002245 particle Substances 0.000 description 11

- 238000000926 separation method Methods 0.000 description 10

- 230000000694 effects Effects 0.000 description 6

- 239000012717 electrostatic precipitator Substances 0.000 description 6

- 239000000725 suspension Substances 0.000 description 6

- 239000000463 material Substances 0.000 description 4

- 230000005684 electric field Effects 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 238000005406 washing Methods 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 238000004887 air purification Methods 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 239000004071 soot Substances 0.000 description 2

- 239000007921 spray Substances 0.000 description 2

- 238000005299 abrasion Methods 0.000 description 1

- 230000006978 adaptation Effects 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 239000000428 dust Substances 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 238000011086 high cleaning Methods 0.000 description 1

- 239000012212 insulator Substances 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000003595 mist Substances 0.000 description 1

- 239000004745 nonwoven fabric Substances 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 239000000779 smoke Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 238000004065 wastewater treatment Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C3/00—Separating dispersed particles from gases or vapour, e.g. air, by electrostatic effect

- B03C3/34—Constructional details or accessories or operation thereof

- B03C3/74—Cleaning the electrodes

- B03C3/78—Cleaning the electrodes by washing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C3/00—Separating dispersed particles from gases or vapour, e.g. air, by electrostatic effect

- B03C3/02—Plant or installations having external electricity supply

- B03C3/04—Plant or installations having external electricity supply dry type

- B03C3/12—Plant or installations having external electricity supply dry type characterised by separation of ionising and collecting stations

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C3/00—Separating dispersed particles from gases or vapour, e.g. air, by electrostatic effect

- B03C3/02—Plant or installations having external electricity supply

- B03C3/04—Plant or installations having external electricity supply dry type

- B03C3/14—Plant or installations having external electricity supply dry type characterised by the additional use of mechanical effects, e.g. gravity

- B03C3/155—Filtration

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C3/00—Separating dispersed particles from gases or vapour, e.g. air, by electrostatic effect

- B03C3/34—Constructional details or accessories or operation thereof

- B03C3/40—Electrode constructions

- B03C3/41—Ionising-electrodes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C3/00—Separating dispersed particles from gases or vapour, e.g. air, by electrostatic effect

- B03C3/34—Constructional details or accessories or operation thereof

- B03C3/86—Electrode-carrying means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F8/00—Treatment, e.g. purification, of air supplied to human living or working spaces otherwise than by heating, cooling, humidifying or drying

- F24F8/30—Treatment, e.g. purification, of air supplied to human living or working spaces otherwise than by heating, cooling, humidifying or drying by ionisation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C—MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03C2201/00—Details of magnetic or electrostatic separation

- B03C2201/10—Ionising electrode with two or more serrated ends or sides

Definitions

- the invention relates to an electrostatic precipitator, in particular for exhaust air purification for road tunnels, underground garages od.

- an electrostatic precipitator in particular for exhaust air purification for road tunnels, underground garages od.

- From at least one flow channel forming a filter cell with an inflow ionizing and an outflow collector, wherein the ionizing used in a frame, extending over the flow cross-section electrodes and a collector grounded, the flow cross-section covering filter mat made of wire wool od.

- Is provided US 4 222 748 A ).

- a road tunnel Like. Contains solid particles, such as diesel soot, tire or road surface abrasion, dust u. Like., And also liquid particles, which particles must be deposited for environmental reasons or for reuse of the purified air in the tunnel.

- Mechanical filter systems are less suitable because they are associated with large pressure losses and make high demands on the fan performance because of the considerable amounts of air required. Accordingly, electrostatic precipitators which operate on the Penney principle are used for this exhaust air purification, wherein an electric field for ionizing the particles to be separated is generated in an ionizing device by means of electrodes applied to a high DC voltage, whereby the charged particles are subsequently immersed in a collector Delivery of their cargo are knocked down.

- the collector is set to date by far from each other arranged, alternately positive and negative collector plates together, so that the ionized particles of the air flowing between the collector plates exhaust air are repelled depending on the charge from one collector plates and attracted by the other and by this distraction they settle collecting collector plates.

- the separation efficiency of these filters especially in terms of extremely small soot particles unsatisfactory.

- these electrostatic filters fail in case of fire, in which a smoke separation would be very important because of the visibility, since the operating temperature is usually about 65 ° C and the ionizer and the collector of a fire corresponding temperature load of about 250 ° C not withstand.

- the invention is therefore an object of the invention to provide an electrostatic precipitator of the type described above, which is characterized by its high separation efficiency and fire performance in relatively low-cost construction and can also be rationally clean beyond.

- the invention solves this problem in that the filter mat is associated with a blower comprising a Ausblasdüsenech on the downstream side of the filter mat and a suction hood unit at the inflow side, wherein the opposing Ausblasdüsen- and suction hood units are guided back and forth together along the mat surface.

- the electrodes can be configured as desired, as long as they produce an evenly distributed over the flow cross-section electric field, advantageously sheet metal strip stainless steel serve as electrodes, of which alternately one grounded and the other are connected to a high voltage source and the high voltage source connected sheet metal strip jagged edges for a Spitzenionmaschine form.

- the collector consists of a filter mat

- the ionized particles no longer need to be deflected transversely to the direction of flow to corresponding collector plates, because they must forcibly contact the grounded mat material when penetrating the filter mat and are thus deposited, as a filter material Wire wool or similar wire material, such as wire mesh and wire mesh, but also nonwovens u. Like. Of metal, ceramic, plastic or other suitable conductive materials is used.

- This filter mat is insensitive to temperature and brings with the failure of the ionization by collapse of the high voltage as a purely mechanical filter, a separation effect, without because of the looser Structure to cause higher pressure drops. Due to the interaction of lonisier Spur and filter mat sufficiently good separation performance are also guaranteed even at high flow rates, which are also largely independent of temperature because of the temperature capacity of the ionizer and the collector.

- the filter cells are usually arranged side by side in parallel, but also quite to achieve reinforced separation effects in series can be stringed.

- Several filter cells can also be combined to form a large filter cell, which forms a common flow channel and accommodates the ionizing units combined into an ionizing unit in a frame housing on the inflow side and the collectors of the individual filter cells combined to form a collector unit.

- the filter cell may further include a water injection device with spray nozzles provided in front of and / or behind the filter mat for additional air washing, so that not only the particle separation can be influenced by the resulting water mist or curtain, but also gas separation can be achieved.

- the spray nozzles can sit in adaptation to the particular conditions in front of the ionizing device, which is expedient for example in case of fire, or after the ionizing device so as not to impair the ionizing process, and they can also be arranged behind the collector and the water against the direction of flow through the filter mat, which in addition to the washing effect of the separation effect increases and a filter cleaning effect is achieved.

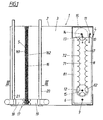

- a filter cell 1 of an electrostatic precipitator consists of a cell housing 2, which forms a flow-through channel 3 and on the inlet side an ionizing device 4 and on the outflow side a collector 5 receives.

- the ionizing device 4 has arranged in a frame 6 electrodes 7, 8, which extend at a mutual distance parallel to each other across the flow cross-section and alternately strip-shaped Erdungsblechen 81 and lonisierblechen 71 consist.

- the ground plates 81 are mounted at one end fixed to a support rod 9 of the frame 6 and suspended at the other end via a suspension spring 10 resiliently on a suspension rod 11, wherein there is a ground terminal for the frame 6 and the grounding plates 81.

- the formed with a serrated edge 72 lonisierbleche 71 are similar to the Erdungsblechen one end firmly mounted on a connecting rod 12 and the other suspended via a suspension spring 13 on a suspension rod 14, which lonisierbleche 71 but via the connecting rod 12 in a manner not shown with a high voltage source in line connection stand.

- This connecting rod 12 is insulated from the frame 6 by means of insulators 15, and passage openings 82 in the earthing plates 81 prevent electrical contact between grounding plates and connecting rod.

- a flow cross-section covering filter mat 16 made of wire wool od. Like. Used. If exhaust air flows through the filter cell 1, the particles contained in the exhaust air are ionized by the electric field generated by the electrodes 7, 8 in the ionizing device 4 and then reach the collector 5, where they are deposited and deposited in the grounded filter mat 16. Due to the spring-related stretchable suspension of the electrodes 7, 8 and when using a temperature-resistant material as a filter mat 16, the filter cell 1 is fire-safe and because of the filter mat as a collector results even for high flow rates a good separation efficiency.

- the collector 5 of the filter mat 16 is associated with a blower 17, which comprises a Ausblasdüsentician 18 on the downstream side 161 of the filter mat 16 and a suction hood unit 19 on the inflow side 162 of the filter mat 16, wherein the opposing Ausblasdüsen- and suction hood units 18, 19 means Screw spindles 20, 21 are guided back and forth along the mat surface.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Electrostatic Separation (AREA)

- Treating Waste Gases (AREA)

- Exhaust Gas Treatment By Means Of Catalyst (AREA)

- Filtering Materials (AREA)

Claims (2)

- Filtre électrostatique notamment pour le nettoyage de l'air d'échappement des tunnels routiers, des garages en sous-sol, ou analogues, composé d'au moins une cellule de filtre (1), formant un canal de passage d'écoulement (3), avec un dispositif d'ionisation (4) installé côté entrée d'écoulement, et un collecteur (5), installé côté sortie d'écoulement, le dispositif d'ionisation (4) présentant des électrodes (7, 8) insérées dans un cadre (6), s'étendant sur la section transversale offerte à l'écoulement, et, en tant que collecteur (5), est prévu un matelas filtrant (16), raccordé électriquement à la terre, recouvrant la section transversale offerte à l'écoulement, composé de laine métallique ou analogue, caractérisé en ce que les électrodes (7, 8) sont tendues, à une extrémité, rigidement et, à l'autre extrémité, de façon déformable élastiquement, dans le cadre (6), et en ce que, au matelas filtrant est associé un dispositif de ramonage par soufflage (17), comprenant une unité à buses de soufflage (18), sur le côté d'évacuation d'écoulement (161) du matelas filtrant (16), et une unité formant capot d'aspiration (19), à son côté arrivée d'écoulement (162), les unités à buses de soufflage et formant capot d'aspiration (18, 19) étant guidées conjointement, de façon à pouvoir se déplacer dans un sens et dans l'autre, le long de la surface du matelas.

- Filtre électrostatique selon la revendication 1, caractérisé en ce qu'à la cellule de filtre (1) appartient un dispositif de pulvérisation d'eau, muni de buses de projection, prévues en amont et/ou en aval du matelas filtrant (16), pour effectuer un lavage supplémentaire de l'air.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT00890063T ATE405349T1 (de) | 1999-03-01 | 2000-03-01 | Elektrofilter, insbesondere zur abluftreinigung für strassentunnel, tiefgaragen od. dgl. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT0033199A AT406737B (de) | 1999-03-01 | 1999-03-01 | Elektrofilter, insbesondere zur abluftreinigung für strassentunnel, tiefgaragen od. dgl. |

| AT33199 | 1999-03-01 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1033171A2 EP1033171A2 (fr) | 2000-09-06 |

| EP1033171A3 EP1033171A3 (fr) | 2001-03-28 |

| EP1033171B1 true EP1033171B1 (fr) | 2008-08-20 |

Family

ID=3487763

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00890063A Expired - Lifetime EP1033171B1 (fr) | 1999-03-01 | 2000-03-01 | Filtre electrostatique notamment pour le nettoyage de l'air d'échappement des tunnels routiers et d'autres choses semblables |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1033171B1 (fr) |

| AT (2) | AT406737B (fr) |

| DE (1) | DE50015313D1 (fr) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202011104657U1 (de) | 2011-08-15 | 2011-11-18 | Peter Oertmann | Elektronischer Feinstaubabscheider |

| DE102011110805A1 (de) | 2011-08-15 | 2013-02-21 | Peter Oertmann | Elektronischer Feinstaubabscheider |

| WO2013023644A1 (fr) | 2011-08-15 | 2013-02-21 | Peter Oertmann | Séparateur électronique de fines poussières |

| DE202021002126U1 (de) | 2021-06-18 | 2021-07-05 | Reinhard Stiebert | Anordnung zur Filterung und Desinfektion von Atemluft innerhalb von Schutzmasken, Schutzschildern und sonstigen Einrichtungen zur Durchleitung von Atemluft mittels Elektrofilterstrukturen und/oder Plasmaeinheiten und zusätzlichen Komponenten |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102018209993A1 (de) | 2018-06-20 | 2019-12-24 | ECOVAC Filteranlagen GmbH | Vorrichtung und Verfahren zur Reinigung schadstoffbelasteter Luft |

| DE102019207502A1 (de) | 2019-05-22 | 2020-11-26 | Christoph Kronhagel | Luftreinigungsanlage |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR865813A (fr) * | 1939-06-21 | 1941-06-05 | Louis Prat Soc | Perfectionnements aux appareils pour la récupération des poussières par voie électrostatique |

| GB553753A (en) * | 1941-12-12 | 1943-06-03 | Vauxhall Motors Ltd | Improved electrostatic gas cleaner |

| US4029482A (en) * | 1974-03-27 | 1977-06-14 | Battelle Memorial Institute | Electrostatic removal of airborne particulates employing fiber beds |

| US4222748A (en) * | 1979-02-22 | 1980-09-16 | Monsanto Company | Electrostatically augmented fiber bed and method of using |

| US4666474A (en) * | 1986-08-11 | 1987-05-19 | Amax Inc. | Electrostatic precipitators |

| US5391222A (en) * | 1993-04-15 | 1995-02-21 | The Babcock & Wilcox Company | In place discharge electrode replacement on rigid frame ESP's |

| US5698012A (en) * | 1995-03-28 | 1997-12-16 | Ajiawasu Kabushiki Kaisha | Exhaust gas purifying apparatus |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4147522A (en) * | 1976-04-23 | 1979-04-03 | American Precision Industries Inc. | Electrostatic dust collector |

| DE3173286D1 (en) * | 1980-05-06 | 1986-02-06 | Fleck Carl M | Electrostatic air filter |

| SE9200515L (sv) * | 1992-02-20 | 1993-07-12 | Tl Vent Ab | Tvaastegs elektrofilter |

| DE4207022A1 (de) * | 1992-03-06 | 1993-09-09 | Rolf Hertfelder | Elektrostatische filtereinrichtung fuer dunstabzugshauben |

-

1999

- 1999-03-01 AT AT0033199A patent/AT406737B/de not_active IP Right Cessation

-

2000

- 2000-03-01 DE DE50015313T patent/DE50015313D1/de not_active Expired - Fee Related

- 2000-03-01 AT AT00890063T patent/ATE405349T1/de not_active IP Right Cessation

- 2000-03-01 EP EP00890063A patent/EP1033171B1/fr not_active Expired - Lifetime

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR865813A (fr) * | 1939-06-21 | 1941-06-05 | Louis Prat Soc | Perfectionnements aux appareils pour la récupération des poussières par voie électrostatique |

| GB553753A (en) * | 1941-12-12 | 1943-06-03 | Vauxhall Motors Ltd | Improved electrostatic gas cleaner |

| US4029482A (en) * | 1974-03-27 | 1977-06-14 | Battelle Memorial Institute | Electrostatic removal of airborne particulates employing fiber beds |

| US4222748A (en) * | 1979-02-22 | 1980-09-16 | Monsanto Company | Electrostatically augmented fiber bed and method of using |

| US4666474A (en) * | 1986-08-11 | 1987-05-19 | Amax Inc. | Electrostatic precipitators |

| US5391222A (en) * | 1993-04-15 | 1995-02-21 | The Babcock & Wilcox Company | In place discharge electrode replacement on rigid frame ESP's |

| US5698012A (en) * | 1995-03-28 | 1997-12-16 | Ajiawasu Kabushiki Kaisha | Exhaust gas purifying apparatus |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202011104657U1 (de) | 2011-08-15 | 2011-11-18 | Peter Oertmann | Elektronischer Feinstaubabscheider |

| DE102011110805A1 (de) | 2011-08-15 | 2013-02-21 | Peter Oertmann | Elektronischer Feinstaubabscheider |

| WO2013023644A1 (fr) | 2011-08-15 | 2013-02-21 | Peter Oertmann | Séparateur électronique de fines poussières |

| DE102011110805B4 (de) | 2011-08-15 | 2019-02-14 | Peter Oertmann | Elektronischer Feinstaubabscheider |

| DE202021002126U1 (de) | 2021-06-18 | 2021-07-05 | Reinhard Stiebert | Anordnung zur Filterung und Desinfektion von Atemluft innerhalb von Schutzmasken, Schutzschildern und sonstigen Einrichtungen zur Durchleitung von Atemluft mittels Elektrofilterstrukturen und/oder Plasmaeinheiten und zusätzlichen Komponenten |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1033171A3 (fr) | 2001-03-28 |

| EP1033171A2 (fr) | 2000-09-06 |

| ATE405349T1 (de) | 2008-09-15 |

| DE50015313D1 (de) | 2008-10-02 |

| AT406737B (de) | 2000-08-25 |

| ATA33199A (de) | 2000-01-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3122515C2 (de) | Elektrostatische Filteranordnung | |

| DE102004022288B4 (de) | Elektrostatischer Abscheider mit internem Netzgerät | |

| DE19650585C2 (de) | Verfahren und Vorrichtung zur elektrischen Aufladung und Abtrennung schwierig abzuscheidender Partikel aus einem Gasfluid | |

| DE2810735C2 (de) | Elektrische Gasreinigungsvorrichtung | |

| CH574274A5 (en) | Electrostatic dust precipitator - with multiple plane electrodes axially parallel to air flow | |

| DE2727973C2 (de) | Verfahren zum Abscheiden hochohmiger Stäube aus Gasen | |

| DD257590A5 (de) | Anordnung zur erzeugung einer elektrischen koronaentladung in der luft | |

| EP1926558A1 (fr) | Etage d'ionisation electrostatique dans un dispositif de precipitation | |

| DE69009104T2 (de) | Fluidreiniger. | |

| EP1976639B1 (fr) | Dispositif d'epuration d'air, en particulier pour installations de ventilation ou de climatisation | |

| WO2013023644A1 (fr) | Séparateur électronique de fines poussières | |

| DE102011052946B4 (de) | Elektroabscheider | |

| EP1033171B1 (fr) | Filtre electrostatique notamment pour le nettoyage de l'air d'échappement des tunnels routiers et d'autres choses semblables | |

| EP1361927A1 (fr) | Depoussiereur electrostatique a tubes de filtration integres | |

| EP2189223A1 (fr) | Filtre électrique à nettoyage humide destiné au nettoyage des gaz d'échappement et procédé correspondant | |

| EP1771254B1 (fr) | Principe structurel d'un systeme de purification de gaz d'echappement, et procede pour purifier des gaz d'echappement a l'aide de celui-ci | |

| DE838594C (de) | Kollektor fuer elektrsische Gasreiniger | |

| DE102006033945B4 (de) | Steuern der Hochspannung einer Elektroluftfiltervorrichtung | |

| DE3802748A1 (de) | Elektrostatisches filter | |

| DE19841973C2 (de) | Aus Sprühelektroden und einer Niederschlagselektrode gebildete Elektro-Filterstufe | |

| DE3744677A1 (de) | Vorrichtung zur aufbereitung, insbesondere filtrierung, der raumluft | |

| DE3329638A1 (de) | Vorrichtung fuer die entstaubung von industriellen gasen | |

| DE2658510A1 (de) | Luftreinigungsgeraet | |

| DE2501463C2 (de) | Elektrostatisches Gerät zum Reinigen von Raumluft durch Ionisieren | |

| EP4000738B1 (fr) | Filtre de nettoyage d'un flux gazeux |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20010830 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| 17Q | First examination report despatched |

Effective date: 20070322 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50015313 Country of ref document: DE Date of ref document: 20081002 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081201 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080820 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080820 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080820 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080820 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090120 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20090525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080820 |

|

| BERE | Be: lapsed |

Owner name: AIGNER, HEINZ Effective date: 20090331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090331 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090301 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20091130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090331 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081120 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090331 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091001 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090301 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091123 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081121 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080820 |