EP1007446B1 - Klappschachtel für zigaretten - Google Patents

Klappschachtel für zigaretten Download PDFInfo

- Publication number

- EP1007446B1 EP1007446B1 EP98924221A EP98924221A EP1007446B1 EP 1007446 B1 EP1007446 B1 EP 1007446B1 EP 98924221 A EP98924221 A EP 98924221A EP 98924221 A EP98924221 A EP 98924221A EP 1007446 B1 EP1007446 B1 EP 1007446B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- collar

- box

- front wall

- webs

- lid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D85/00—Containers, packaging elements or packages, specially adapted for particular articles or materials

- B65D85/07—Containers, packaging elements or packages, specially adapted for particular articles or materials for compressible or flexible articles

- B65D85/08—Containers, packaging elements or packages, specially adapted for particular articles or materials for compressible or flexible articles rod-shaped or tubular

- B65D85/10—Containers, packaging elements or packages, specially adapted for particular articles or materials for compressible or flexible articles rod-shaped or tubular for cigarettes

- B65D85/1036—Containers formed by erecting a rigid or semi-rigid blank

- B65D85/1045—Containers formed by erecting a rigid or semi-rigid blank having a cap-like lid hinged to an edge

Definitions

- the invention relates to a hinged box (so-called hinge-lid pack), especially for cigarettes, from a one-piece blank made of thin cardboard to form a box part with Box front wall, box rear wall, box side walls as well as bottom wall and a lid with lid front wall, Lid rear wall, lid side walls and end wall and further with a collar made of the front wall and side flaps, the collar in the area of the collar front wall with the box front wall over remaining connections or webs is connected, the Z-shaped when folding the blank are foldable in such a way that the remaining connections or webs lie against the inside of the front of the box.

- hinge-lid pack especially for cigarettes, from a one-piece blank made of thin cardboard to form a box part with Box front wall, box rear wall, box side walls as well as bottom wall and a lid with lid front wall, Lid rear wall, lid side walls and end wall and further with a collar made of the front wall and side flaps, the collar in the area of the collar front wall with the box front wall over remaining connections or webs is

- Hinged boxes made from blanks in which the collar is in one piece with a main cut for the box part and lid connected are known in various designs.

- the box front wall webs are on the upright sides the box front wall webs as a connection to the collar arranged. This is done by changing the relative position in the packaged position opposite the front of the box folded, the webs being given a Z-shaped folding position.

- the folding box according to DE 27 59 178 is designed similarly, the foldable connection between the front of the box and Collar front wall extends over the entire width of the box front wall extends.

- the invention is based, folding boxes the task to further develop and implement the embodiment described above improve, such that the production is simplified and that improved appearance of the finished folding box is.

- the hinged box according to the invention characterized in that the inside on the (Z-shaped) pleated webs adjacent collar front wall in the area the webs has a recess or depression into which the relevant web occurs at least partially.

- the hinged box according to the invention is based on the knowledge that that the remaining connections or webs in the folded Position, i.e. in the position between the front of the collar and Box front wall, an additional layer of material and thus create a thickening. According to the invention, this is entirely or partially eliminated by the recess in the Collar front wall in the area of the folded web, so that this is at least predominantly in the recess and such local thickening of material is avoided.

- the position and dimension of the recess are according to the invention adapted the dimension and position of the webs in the folded position.

- a special design of the webs namely through a transverse partial cut in the area of a folding joint, can the folded web a clamping position in the recess occupy the collar front wall and so the folded position fix the collar or webs.

- Another special feature of the invention is one special type of folding boxes, namely with rounded ones Longitudinal edges or beveled long edges (octagonal cross-section) a one-piece blank construction to propose.

- a typical folding box consists of a (larger) Box part 10, a lid 11 and a collar 12.

- the Box part 10 forms a box front wall 13, one Box rear wall 14 and narrow, elongated box side walls 15 and 16. Below the box part 10 is through limited a floor 17.

- the cover 11 is analogous to this made of cover front wall 18, cover rear wall 19, cover side walls 20, 21 and an upper end wall 22.

- the lid 11 is with the box part 10 pivotally connected, via a Line of articulation 23 between box rear wall 14 and lid rear wall 19th

- the typical structure of a hinged box also includes that the box side walls 15, 16 and the lid side walls 20, 21 are double-layered, namely each of inner Box side tabs 24 and outer box side tabs 25 exists.

- the lid side walls 20 and 21 are analogous double-layered, namely consist of an inner Lid side tab 26 and an outer lid side tab 27.

- the side tabs 24, 25 of the box part 10 on the one hand and the side tabs 26, 27 of the lid 11 are on the other hand delimited from one another by oblique closing edges 28, 29.

- the collar is still an important part of the hinged box 12 with a collar front wall 30 and transverse collar side tabs 31 and 32.

- the collar 12 sits with a lower one Area in the box part 10 and is anchored in this. A protruding from the box part 10 upper part of the The collar is in the closed position of the hinged box from the lid 11 enclosed.

- the collar front wall 30 lies on the inside the box front wall 13, while the collar side tabs 31, 32 on the inside of the box side walls 15, 16 concerns.

- the folding box is made up of a whole, including the collar 12, from a one-piece blank (from thin cardboard). Box part 10 and lid 11 form a main blank 33.

- the collar 12 is with this main blank 33 in the area of Box front wall 13 connected, namely via residual connections, namely webs 34 and 35.

- the rectangular or strip-shaped Bars 34 and 35 are in the side area of the box front wall 13 on the one hand and the collar front wall 30 on the other positioned.

- each web 34, 35 limited by punch cuts 36, 37. Extend across fold lines 38, 39.

- the lower or the box front wall 13 facing fold line 39 is in the upper limit the box front wall 13, that is, in the extension of a free one Transverse edge 40 of the box front wall 13.

- the position of the collar 12 is this compared to the spread 3 relative to the main blank 33 moved, namely towards the floor 17.

- the Web 34, 35 lies on the back of the box front wall 13 on.

- the upper fold line 39 after folding is with the Cross edge 40 flush.

- the fold line 38 lies at a distance below it.

- the webs 34, 35 are dimensioned so that in this folded position (Fig. 2) the collar 12 overall corresponding to the pack Relative to the main cut 33 receives.

- the collar front wall 30 is to be avoided at least partially in the area of the webs 34, 35 with a stamped Recess 41, 42 provided.

- the recesses 41, 42 are like this positioned, designed and dimensioned so that an (upper) part of the folded webs 34, 35 into the associated recess 41, 42 occurs (Fig. 2). This results in this upper area the webs 34, 35 a two-layer construction, as in remaining area of the system of the collar front wall 30 on the Box front wall 13.

- the recesses are 41, 42 rectangular, preferably slightly greater width than that of the webs 34, 35.

- the total width 43 of the cut larger (e.g. 98 mm) than the collar width 44 (95 mm).

- the wall width 45 is 55 mm, for example.

- the width of the webs 34, 35 can be 6 mm, that of the associated recesses 41, 42 6.5 mm.

- the bridge length 46 (from fold line 38 to fold line 39) is 7.5 mm in FIGS. 1 to 3.

- a distance 47 between the (originally upper) fold line 38 and one of them removed lying edge of the recess 41, 42 is provided with 7 mm.

- the distance between the fold line 38 and the facing edge the recess 41, 42 here is approximately 3 mm.

- the collar 12 is in the folded position (Fig. 1, Fig. 2) connected to the box part 10.

- there are 30 glue points in the area of the collar front wall namely two glue points 51, 52 are provided, approximately in Height of the recesses 41, 42.

- the collar front wall 30 is with With the help of these glue points 51, 52 on the inside of the box front wall 13 anchored.

- the bridges 34, 35 can on the facing, inner side of the box front wall 13 be glued.

- the webs 34, 35 are at this version wider than in the embodiment of FIG. 1 to FIG. 3.

- the recesses 41, 42 are also corresponding dimensioned with a larger width, namely slightly wider than the webs 34, 35.

- In the longitudinal direction of the blank have the Recesses 41, 42 smaller dimensions, namely clearly shorter length than that of the webs 34, 35.

- the webs 34, 35 are delimited by fold lines 39, which extend in extension of the transverse edge 40.

- the opposite fold line facing the recess 41, 42 is modified.

- the end edge 55 extends between narrow, lateral residual webs 56, 57.

- One of the fold lines runs in the area of these remaining webs 56, 57 38 corresponding fold line.

- the end edge 55 thus formed or a facing region of the Bars 34, 35 on the back and inside of the collar front wall 30 on (Fig. 5).

- the web 34, 35 is anchored to the collar by the clamping position of the upper area.

- An additional gluing of the webs 34, 35 in the Folded position (on the box front wall 13) can be provided 4, but in the embodiment according to FIGS omitted.

- hinged box and blank correspond to this exemplary embodiment that of FIGS. 1 to 3.

- 7 and 8 show folding boxes of special design, namely with rounded longitudinal edges, namely round edges 58, 59 (Fig. 7) or with beveled edges, i.e. beveled edges 60, 61 (Fig. 8).

- the A special feature is the use of one-piece blanks for these types of packs and the resulting special features.

- 7 and 8 is an example of a Package contents each shown a cigarette block 62 (dash-dotted). This consists of a group of cigarettes made by is surrounded by an inner covering, namely a tinfoil or Paper cutting.

- Both hinged boxes consist of one piece Cut.

- the collar 12 is in each case via webs 34, 35 connected to the main blank 33.

- the recesses 41, 42 are also present. However, these can also be omitted.

- the Cuts in accordance with the in connection with Fig. 4 to Fig. 6 details described be formed.

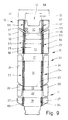

- FIG. 9 An advantageous embodiment of a blank for a Hinged box according to FIG. 7 is shown in FIG. 9.

- the round edges 58, 59 are defined by folding strips 63, 64 which a central portion of the main blank 33 from the side Delimit folding tabs, namely box front wall 13, box rear wall 14, bottom 17, cover front wall 18, cover rear wall 19 and end wall 22 on the one hand from the box side tabs 24, 25 and lid side tabs 26, 27 on the other hand.

- the folding strip 63, 64 corresponds in width to the dimension the round edges 58, 59.

- the folding strip 63, 64 consists of grooves 65, which is parallel and with in the longitudinal direction of the blank run a short distance from each other. The grooves 65 will through appropriate embossing tools in the packaging machine or attached outside of it.

- the collar also has 12 round edges 58, 59, there are folding strips 66, 67 also attached in the region of the collar 12, and although preferably simultaneously with the folding strips 63, 64 in Area of the main cut 33.

- the special feature is that that the folding strips 63, 64 on the one hand and 66, 67 on the other run flush on the sides facing each other.

- the difference in dimensions is expediently a groove 65.

- the webs 34, 35 are like this in this type of hinged box positioned that the outer punch cuts 37 a (small) Distance from the facing grooves 65 or folding strips 63, 64 or 66, 67. This distance can be 1.5 to 2 mm. This distance ensures that the grooves the folding strip 63 .. does not run in the area of the webs 34, 35.

- Bottom 17 and end wall 22 fit in by rounded corners the shape of the round edges 58, 59 occur.

- the box side tabs 24 and 25 and the lid side tabs 26 and 27 are only in the area outside the round edges 58, 59 or overlap each other. In this area are the mentioned Side tabs connected by gluing.

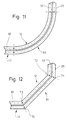

- the cut according to FIG. 10 is analogous for one Hinged box formed with bevelled edges 60, 61.

- these inclined edges 60, 61 are in the region of the cut two parallel fold lines 70, 71 are formed. These extend continuously in the area of the main cut 33, including the lid.

- the collar 12 is also on the (octagonal) cross-sectional shape of the package coordinated.

- two parallel fold lines are provided. At but these are parallel perforation lines 72, 73.

- the respective outer perforation lines 72 are in an upper or outer area by a C-shaped punch 74 interrupted. This forms a projection or Overhang of the collar on the front of the pack Fixing the lid 11 in the closed position.

- the perforation lines 72, 73 as pre-designed fold lines in the area of the Collar 12 are arranged so that the inner lines of perforation 73 are closer together than the inner ones, fold lines 70 facing each other.

- the distance of the fold lines 70 from each other 51.3 mm and the distance of the perforation lines 73 from each other are 50.3 mm.

- the position of the outer perforation lines then also results from this 72.

- Their distance from the neighboring inner one Perforation line 73 can be 7.9 mm, the distance of the two mutually associated fold lines 70, 71 8.9 mm.

- the outer fold lines 71 are opposite the outer perforation lines 72 moved outwards.

- FIG. 11 shows a section of the package according to FIG. 7 in the area of overlap of collar 12 and box front wall 13.

- the areas of the box front wall shaped as a quarter circle 13 and collar 12 are concentric with each other, with the same (imaginary) center. This effect will guaranteed by the dimensions described.

- In the area of the collar 12 therefore has a smaller round edge 58, 59 Diameter than that of the box front wall 13.

- the hinged box according to FIG. 8 is analogous in this area educated. Formed by fold lines 70, 71 (upright) Edges of the box front wall 13 lie on a line with the edges formed by the perforation lines 72 and 73.

- the hinged boxes according to FIGS. 7 to 12 be designed in a known manner or with all details of the folding boxes according to FIGS. 1 to 6, namely with regard to the connection of the collar 12 to the main blank 33.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cartons (AREA)

- Packaging Of Annular Or Rod-Shaped Articles, Wearing Apparel, Cassettes, Or The Like (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19718821A DE19718821A1 (de) | 1997-05-05 | 1997-05-05 | Klappschachtel für Zigaretten |

| DE19718821 | 1997-05-05 | ||

| PCT/EP1998/002477 WO1998050287A1 (de) | 1997-05-05 | 1998-04-25 | Klappschachtel für zigaretten |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1007446A1 EP1007446A1 (de) | 2000-06-14 |

| EP1007446B1 true EP1007446B1 (de) | 2001-11-21 |

Family

ID=7828593

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP98924221A Expired - Lifetime EP1007446B1 (de) | 1997-05-05 | 1998-04-25 | Klappschachtel für zigaretten |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US6302322B1 (zh) |

| EP (1) | EP1007446B1 (zh) |

| JP (1) | JP2001523199A (zh) |

| CN (1) | CN1097001C (zh) |

| AU (1) | AU7649798A (zh) |

| BR (1) | BR9809229A (zh) |

| DE (2) | DE19718821A1 (zh) |

| ES (1) | ES2166164T3 (zh) |

| WO (1) | WO1998050287A1 (zh) |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT1308982B1 (it) * | 1999-01-21 | 2002-01-15 | Gd Spa | Pacchetto rigido con coperchio incernierato |

| US6276600B1 (en) | 2000-04-18 | 2001-08-21 | Westvaco Corporation | Hinged-lid pack for cigarettes or the like |

| ITBO20010554A1 (it) * | 2001-09-14 | 2003-03-14 | Gd Spa | Contenitore rigido per articoli da fumo con spigoli trasversali e longitudinali arrotondati o smussati |

| ITBO20010747A1 (it) * | 2001-12-11 | 2003-06-11 | Gd Spa | Contenitore rigido per articoli da fumo |

| TWI253430B (en) * | 2003-07-16 | 2006-04-21 | Japan Tobacco Inc | Hard pack for rod shaped smoking article |

| ITBO20030469A1 (it) * | 2003-08-01 | 2005-02-02 | Gd Spa | Confezione rigida con coperchio incernierato di articoli di fumo e relativo sbozzato. |

| EP1724210B1 (en) * | 2004-03-12 | 2010-04-07 | Japan Tobacco, Inc. | Hinged lid type package of rod-like smoking article and its blank |

| DE102004025261A1 (de) * | 2004-05-19 | 2005-12-08 | Focke & Co.(Gmbh & Co. Kg) | Klappschachtel für Zigaretten |

| ITBO20050098A1 (it) * | 2005-02-24 | 2005-05-26 | Gd Spa | Pacchetto di sigarette composito con coperchio incernierato |

| GB0806700D0 (en) * | 2008-04-14 | 2008-05-14 | British American Tobacco Co | Package for smoking articles |

| US20100059395A1 (en) * | 2008-05-02 | 2010-03-11 | John England | Pack for Smoking Articles |

| ITBO20130133A1 (it) * | 2013-03-28 | 2014-09-29 | Gd Spa | Pacchetto di sigarette rigido con coperchio incernierato e con apertura a scorrimento. |

| ES2721502T3 (es) * | 2015-05-27 | 2019-08-01 | Philip Morris Products Sa | Recipiente con borde biselado mejorado |

| RU2711862C2 (ru) * | 2015-07-31 | 2020-01-23 | Филип Моррис Продактс С.А. | Бигованная заготовка для образования емкости с закругленными или скошенными кромками |

| JP2017089227A (ja) * | 2015-11-10 | 2017-05-25 | スリーエム イノベイティブ プロパティズ カンパニー | 吸音積層体並びにその製造方法及び取付方法、吸音積層体を含む道路用吸音ユニット、並びに吸音積層体が取り付けられた建築構造物 |

| USD863953S1 (en) * | 2016-02-29 | 2019-10-22 | Focke & Co. (Gmbh & Co. Kg) | Cigarette pack |

| JP6941027B2 (ja) * | 2017-10-31 | 2021-09-29 | 株式会社トーモク | 蓋付き箱体及びその組立て方法 |

| CA3110719A1 (en) * | 2020-02-28 | 2021-08-28 | Hub Folding Box Company, Inc. | Packaging for personal care product |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2951626A (en) * | 1956-02-08 | 1960-09-06 | Weiss Adolph | Box construction |

| US3910487A (en) * | 1974-06-19 | 1975-10-07 | Hoerner Waldorf Corp | Reclosable carton |

| US4216898A (en) * | 1976-08-06 | 1980-08-12 | Molins Limited | Cigarette packets |

| DE2813390A1 (de) * | 1978-03-28 | 1979-10-11 | Ocke & Co | Klappschachtel, insbesondere fuer zigaretten |

| WO1979000034A1 (en) * | 1977-06-28 | 1979-01-25 | Focke & Co | Box with a folding cap,especially for cigarettes |

| DE2833494C2 (de) * | 1978-07-31 | 1984-06-20 | Focke & Co, 2810 Verden | Klappschachtel, insbesondere für Zigaretten |

| DE2844444C2 (de) * | 1978-10-12 | 1984-09-20 | Focke & Co, 2810 Verden | Verpackung, insbesondere quaderförmige Zigarettenpackung, und Verfahren zur Herstellung von Zuschnitten für diese Verpackung |

| DE3713612C2 (de) * | 1987-04-23 | 1996-07-11 | Focke & Co | Klappschachtel |

| US4948038A (en) * | 1989-04-11 | 1990-08-14 | Philip Morris Incorporated | Freshness-preserving container |

| DE3916756A1 (de) * | 1989-05-23 | 1990-11-29 | Focke & Co | Materialbahn aus miteinander verbundenen (verpackungs-)zuschnitten |

| US5143282A (en) * | 1990-08-28 | 1992-09-01 | Philip Morris Incorporated | Apparatus and method for maintaining closed hinged lid boxes |

| DK170417B1 (da) * | 1991-07-10 | 1995-08-28 | Schur Eng As | Kartonæske af klaplågstypen og med midler til snaplåsning af klaplåget |

| IT1274806B (it) * | 1994-06-30 | 1997-07-25 | Gd Spa | Pacchetto rigido con coperchio incernierato per elementi allungati, inparticolare sigarette |

| DE19506844B4 (de) * | 1995-02-28 | 2007-05-03 | Focke & Co.(Gmbh & Co. Kg) | Klappschachtel für Zigaretten sowie Verfahren zum Einführen von Coupons in Klappschachteln |

| BR9608907A (pt) | 1995-05-23 | 1999-12-14 | Easycarton Ltd | Recipiente suscetìvel de ser aberto de extremidade em empresa, processo de abertura do mesmo, preforma plana e processo de fabricação da mesma e patilha de puxar para abrir |

| DE19519437A1 (de) * | 1995-05-26 | 1996-11-28 | Henkel Kgaa | Wiederverschließbare Faltschachtel mit Öffnungssicherung |

| IT1285635B1 (it) * | 1996-03-22 | 1998-06-18 | Gd Spa | Pacchetto rigido con coperchio incernierato per il confezionamento stabile di gruppi di elementi allungati ad ingombro variabile |

| DE19644759A1 (de) * | 1996-10-29 | 1998-04-30 | Focke & Co | Klappschachtel für Zigaretten |

-

1997

- 1997-05-05 DE DE19718821A patent/DE19718821A1/de not_active Withdrawn

-

1998

- 1998-04-25 JP JP54768598A patent/JP2001523199A/ja active Pending

- 1998-04-25 ES ES98924221T patent/ES2166164T3/es not_active Expired - Lifetime

- 1998-04-25 EP EP98924221A patent/EP1007446B1/de not_active Expired - Lifetime

- 1998-04-25 BR BR9809229-4A patent/BR9809229A/pt not_active Application Discontinuation

- 1998-04-25 CN CN98803690A patent/CN1097001C/zh not_active Expired - Fee Related

- 1998-04-25 AU AU76497/98A patent/AU7649798A/en not_active Abandoned

- 1998-04-25 DE DE59802755T patent/DE59802755D1/de not_active Expired - Lifetime

- 1998-04-25 WO PCT/EP1998/002477 patent/WO1998050287A1/de active IP Right Grant

- 1998-04-25 US US09/423,240 patent/US6302322B1/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2001523199A (ja) | 2001-11-20 |

| DE59802755D1 (de) | 2002-02-21 |

| CN1251076A (zh) | 2000-04-19 |

| CN1097001C (zh) | 2002-12-25 |

| DE19718821A1 (de) | 1998-11-12 |

| BR9809229A (pt) | 2000-06-27 |

| ES2166164T3 (es) | 2002-04-01 |

| AU7649798A (en) | 1998-11-27 |

| EP1007446A1 (de) | 2000-06-14 |

| WO1998050287A1 (de) | 1998-11-12 |

| US6302322B1 (en) | 2001-10-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1007446B1 (de) | Klappschachtel für zigaretten | |

| EP0625469B1 (de) | Verpackung, nämlich Klappschachtel | |

| EP1615830B2 (de) | Klappschachtel für zigaretten | |

| DE69904052T2 (de) | Verpackung für rauchartikel | |

| EP0778212B1 (de) | Klappschachtel für Zigaretten oder dergleichen | |

| EP1449791B1 (de) | Packung und Zuschnitt | |

| EP0082388B1 (de) | Zuschnitt für eine für Zigaretten oder Zigarillos bestimmte Schachtel | |

| EP0675056B1 (de) | Klappschachtel für Zigaretten oder dergleichen | |

| DE10219464A1 (de) | Zigarettenpackung | |

| EP0745541A1 (de) | Klappschachtel für Zigaretten | |

| EP1747153A1 (de) | Zigarettenpackung | |

| EP0007410B1 (de) | Klappschachtel, insbesondere für Zigaretten | |

| DE2844444C2 (de) | Verpackung, insbesondere quaderförmige Zigarettenpackung, und Verfahren zur Herstellung von Zuschnitten für diese Verpackung | |

| WO1999015436A1 (de) | Klappschachtel für zigaretten | |

| DE3509232C2 (de) | Zuschnitt zur Herstellung einer Klappschachtel für rauchbare Artikel sowie daraus hergestellte Klappschachtel | |

| CH620165A5 (zh) | ||

| DE19809865C1 (de) | Klappdeckel-Packung für Zigaretten | |

| EP0618150A2 (de) | Verpackung aus dünnem Verpackungsmaterial sowie Verfahren zum Herstellen derselben | |

| EP0960832A1 (de) | Klappschachtel für Zigaretten und Zuschnitt zum Herstellen derselben | |

| EP0519257A2 (de) | Verpackung für eine Mehrzahl von Packungen | |

| DE2710163C2 (zh) | ||

| EP0703160B1 (de) | Klappschachtel für Zigaretten oder dergleichen | |

| DE19814255A1 (de) | Packung aus Karton für Zigaretten | |

| EP1121297B1 (de) | Packung für zigaretten | |

| EP2064134B1 (de) | Klappschachtel für zigaretten sowie zuschnitt für klappschachteln |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19990916 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE ES FR GB IT LI NL |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 20010425 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: FOCKE & CO. (GMBH & CO.) |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE ES FR GB IT LI NL |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: DIPL.-ING. ETH H. R. WERFFELI PATENTANWALT Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20011122 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| REF | Corresponds to: |

Ref document number: 59802755 Country of ref document: DE Date of ref document: 20020221 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2166164 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20060403 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20070427 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20070521 Year of fee payment: 10 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20071101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20071101 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20070411 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080430 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080430 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20081231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080430 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20080426 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080426 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20090423 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20090422 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20100423 Year of fee payment: 13 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20100425 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100425 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100425 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59802755 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59802755 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111031 |