EP0948803B1 - Detecteur de rayonnements a tres haute performance - Google Patents

Detecteur de rayonnements a tres haute performance Download PDFInfo

- Publication number

- EP0948803B1 EP0948803B1 EP98956848A EP98956848A EP0948803B1 EP 0948803 B1 EP0948803 B1 EP 0948803B1 EP 98956848 A EP98956848 A EP 98956848A EP 98956848 A EP98956848 A EP 98956848A EP 0948803 B1 EP0948803 B1 EP 0948803B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- electric field

- bored

- radiation detector

- gas

- holes

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J47/00—Tubes for determining the presence, intensity, density or energy of radiation or particles

- H01J47/02—Ionisation chambers

Definitions

- the present invention relates to an improved technique for embodying a radiation detector of very high performance that can be used for detecting in position ionizing radiations such as charged particles, photons, X-rays and neutrons.

- Radiation detectors exploiting the process of ionization and charge multiplication in gases have: been in use with continued improvements since hundred years. Methods for obtaining large "stable" proportional gains in gaseous detectors are a continuing subject of investigation in the detectors community.

- G.CHARPAK and F.SAULI introduced the multistep chamber, thereafter designated as MSC, as a way to overcome on limitations of gain in parallel plate and multiwire proportional chambers, thereafter designated as MWPC.

- MSC chambers In MSC chambers, two parallel grid electrodes mounted in the drift region of a conventional gas detector and operated as parallel plate multipliers allow to preamplify drifting electrons and transfer them into the main detection element. Operated with a photosensitive gas mixture, the MSC chamber allows to reach gains large enough for single photodetection in ring-imaging CHERENKOV detectors, thereafter designated as RICH.

- RICH ring-imaging CHERENKOV detectors

- G.CHARPAK and Y.GIOMATARIS have developed an improved radiation detector device thereafter designated as MICROMEGAS which is a high gain gas detector using as multiplying element a narrow gap parallel plate avalanche chamber.

- such a detector In a general point of view, such a detector consists of a gap in the range 50 to 100 ⁇ m which is realized by stretching a thin metal micromesh electrode parallel to a read-out plane.

- G.CHARPAK and Y.GIOMATARIS have demonstrated very high gain and rate capabilities which are understood to result from the special properties of electrode avalanches in very high electric fields.

- Y.GIOMATARIS, P.REBOUGEARD, J.P.ROBERT and G.CHARPAK in Nuclear Instruments Methods, A376, 1996, 29.

- This detector device thereafter designated as CAT, for Compteur à trous, substantially consists of a matrix of holes which are drilled through a cathode foil. The insertion of an insulating sheet between cathode and buried anodes allows thus to guaranty a good gap uniformity and to obtain high gains.

- a proportional wire chamber embodied as a large aperture X-ray imaging chamber equipped with a spherical drift space has been also disclosed by G.CHARPAK, C.DEMIERRE, R.KAHN, J-C.STANDIARD and F.SAULI at the CERN in Geneva. See NUCLEAR INSTRUMENTS AND METHODS 141 (1977) 449-455, North-Holland Publishing Co.

- a spherical drift space is disclosed as to embodying entrance and exit electrodes of spherical shape with an angular acceptance for X-rays to 90°.

- Coupling of spherical drift space and readout proportional chamber is disclosed to consist of a transfer space T, the lateral wall of which comprises a resistive divider adapted to generate spherical equipotential surfaces of increasing radius up to the first cathode electrode of the readout proportional chamber.

- entrance window of the readout chamber is further provided with a particular conductive pattern adapted to introduce progressive bending of the equipotential surfaces, electric field lines crossing thus this equipotential surfaces at right angle, whichever the impinging direction of X-rays emanating from the focal point, so as to correct and reduce any parallax error.

- the above mentioned X-ray imagers may prove satisfactory to the extent that the parallax error is now reduced to a few percent.

- Embodying the entrance window of the readout chamber with conductive pattern adapted to provide full correction of parallax error is quite difficult to implement, since actual pattern and corresponding voltage which is to be applied to these conductive patterns are such that the electric field is approximately radial only close to the ring patterned entrance window, while it becomes substantially parallel in approaching the equipotential second electrode which defines the conversion volume.

- parallax error is thus increasing with penetration of the converting X-rays.

- a gas electron multiplier is also disclosed by:

- two elementary cathodes of complementary shape surrounding the anode wire are necessary to generate a signal which is a function of the solid angle and thus of the surface of the elementary cathode.

- Such a detector cannot be used to embody a multiposition avalanche phenomenon detector, since the provided elementary cathodes are adapted to integrate each of the avalanche events as their gravity center.

- An object of the present invention is therefore to provide a radiation detector of very high performance that overcomes the above-mentioned drawbacks of the radiation detectors of the prior art.

- Another object of the present invention is furthermore to provide a radiation detector of very high performance that appears to hold both the simplicity of the MSC chamber and the high field advantages of the MICROMEGAS and CAT radiation detectors however mechanically much simpler to implement and more versatile in use.

- Another object of the present invention is therefore to provide a radiation detector of very high performance in which a very high degree of accuracy and resolution is obtained thanks to an electric charges transfer coefficient which substantially equals unity.

- Another object of the present invention is therefore to provide a radiation detector with substantially constant amplifying factor for counting rates up to 10 5 Hz/mm 2 .

- a radiation detector in which primary electrons are released into a gas by ionizing radiations and drift to a collecting electrode by means of an electric field.

- the radiation detector of the invention includes a gas electron multiplier comprising at least one matrix of electric field condensing areas with these electric field condensing areas being distributed within a solid surface which is substantially perpendicular to the electric field.

- Each of the electric field condensing areas is adapted to produce a local electric field amplitude enhancement proper to generate in the gas an electron avalanche from each one of the primary electrons.

- the gas electron multiplier operates thus as an amplifier of given gain for the primary electrons.

- the radiation detector according to the invention is now disclosed as a non-limitative example in the present specification. Particularly, it should be kept in mind that the radiation detector in accordance with the invention can be used with the same advantages in many types of applications such as radiography, imaging medicine, and in a more general sense any kind of radiation which comes to effect to release primary electrons in a gas.

- the radiation detector in accordance to the invention is a detector of the type in which primary electrons are released into a gas by ionizing radiations with these primary electrons being drifted to a collecting electrode by means of an electric field.

- vector E ⁇ designates the electric field

- CE designates the collecting electrode.

- the radiation detector of the invention may comprise a vessel referred to as V containing the gas in which the primary electrons are released by an incident ionizing radiation.

- the ionizing radiation is designated as X-rays or gamma-rays which are generated from a source referred to as S.

- the X-rays or gamma-rays generated by the source S enter thus the radiation detector of the invention through an inlet window referred to as IW and generate primary electrons which are released into the gas contained within the vessel V.

- the inlet window IW has a metal clad inner surface generally consisting of a thin metal film which, in operation, is put at a drift potential thereafter designated as VD.

- the collecting electrode CE, and the inlet window IW and drift electrode DE may well form the vessel V so as to contain the gas in which the primary electrons are thus released on inpingement of the ionizing radiation.

- Light frames referred to as F 1 , F 2 may be used to build up the vessel V.

- the vessel V is further provided with a gas inlet thereafter designated as GI, and a gas outlet designated as GO, both consisting of a threaded tiny tube allowing the filling of the vessel V with a particular gas mixture or dedicated gas as it will be disclosed in more details later in the description.

- Gas inlet GI and gas outlet GO may well be located onto opposite sides of the vessel V so as to insure proper gas filling and circulation.

- the radiation detector in accordance with the invention further includes a gas electron multiplier, thereafter designated as GEM and bearing reference sign 1, this gas electron multiplier 1 comprising at least one matrix of electric field condensing areas with these electric field condensing areas being each designated as 1 i .

- the electric field condensing areas are distributed within a solid surface which is substantially perpendicular to the electric field vector E ⁇ .

- Each of the electric field condensing areas 1 i is adapted to produce a local electric field amplitude enhancement which is proper to generate in the gas an electron avalanche from each one of the primary electrons.

- the gas electron multiplier 1 operates thus as an amplifier of given gain for these primary electrons while the collecting electrode CE allows a detection of the electron avalanche to be performed, as it is disclosed later in the specification.

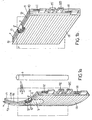

- the solid surface forming the matrix of electric field condensing areas may well have different shapes with the shape of the vessel V containing the gas being adapted accordingly as shown in the above-mentioned figures.

- the solid surface embodying the gas electron multiplier is cylindrical in shape with both the inlet window IW and associated drift electrode DE together with collecting electrode CE being of same cylindrical shape so as to develop a radial electric field vector E ⁇ which is substantially perpendicular to this cylindrical solid surface forming the gas electron multiplier 1.

- the gas electron multiplier is formed by a solid surface which is planar in shape with the inlet window IW and its associated drift electrode DE together with collecting electrode CE being parallel to one another so as to form a planar structure.

- the electric field vector, vector E ⁇ which is developed between collecting electrode CE and inlet window and drift electrode DE, is substantially perpendicular to the planar solid surface embodying the gas electron multiplier 1.

- the solid surface embodying the gas electron multiplier 1 is spherical in shape with this solid surface being delimited by planar intersections of this solid surface.

- collecting electrode CE and inlet window IW and its associated drift electrode DE are spherical in shape so as to develop an electric field vector E ⁇ which is substantially perpendicular to corresponding spherical solid surface embodying the gas electron multiplier 1.

- each electric field condensing area 1 i is represented for better comprehension as to consist of a hole in which the local electric field amplitude enhancement generated thereto is substantially symmetrical in relation to an axis of symmetry of this condensing local area.

- This local electric field amplitude enhancement is thus substantially at a maximum at the center of symmetry of each condensing local area 1 i .

- the electric field condensing areas 1 i are substantially identical in shape and regularly distributed within the solid surface whichever its shape as shown at figure 1a to 1c so as to form the gas electron multiplier 1.

- Figure 2a represents a cross-section view of the radiation detector in accordance with the invention as shown at figure 1a or figure 1b with this cross-section view being taken along intersecting plane P which is shown in phantom line at figures 1a and 1b while figure 2b is a cross-section view along corresponding intersecting plane P shown in phantom line at figure 1c.

- Figures 2a and 2b differ only in the extent that the same elements of figure 2b are bent owing to the spherical shape of the solid surface embodying the gas electron multiplier 1 and the collecting electrode CE, the inlet window IW and its associated drift electrode DE.

- collecting electrode CE is deemed to consist as an example of metal pads or strips which are laid onto a printed circuit board so as to allow detection of the electrode avalanches as previously mentioned in the specification.

- the matrix of electric field condensing areas 1 i may comprise a foil metal clad insulator, referred to as 10, on each of its faces so as to form a first and second metal-cladding, referred to as 11 and 12 respectively, with these metal-cladding sandwiching the insulator foil 10 to form a regular sandwich structure.

- the matrix of electric field condensing areas further comprises a plurality of bored-through holes, referred to as 1 i , traversing the regular sandwich structure as shown at figures 2a and 2b so as to form these electric field condensing areas.

- biasing means are adapted to develop a bias voltage potential which is applied to the first and second metal cladding 11, 12, so as to generate at the level of each of the bored-through holes one electric field condensing area 1 i .

- the biasing means are referred 2 and adapted to develop a difference potential denoted VGEM.

- the first metal-cladding 11 forms thus an input face for the drift electrons while the second metal-cladding 12 forms an output face for any electron avalanche which is generated at the level of each bored-through hole forming one of the electric field condensing areas 1 i .

- each of the local electric field condensing area 1 i i.e. each bored-through hole, behaves as a dipole which in fact super-imposes a further electric field vector E ⁇ ′ with this further electric field being substantially directed along a symmetry axis of each bored-through hole.

- the electric field lines are thus distorted as shown at figure 3a or 3b at the level of each of the local electric field condensing areas 1 i .

- any virtual solid surface thereafter designated as FT which is delimited by the outermost electric field lines reaching one given local electric field condensing area, as shown at figure 3a for example, delineates an electric field tube FT in which the electric field flux presents a preservative character.

- any virtual solid surface formed by the outermost electric field lines reaching a corresponding local electric field condensing area 1 i is substantially transferred as a symmetrical virtual solid surface formed by the electric field line leaving the same local electric field condensing area in the detection region, as shown at figure 3a with respect to the same electric field tube FT.

- the electric field E ⁇ within the drift region and the electric field E ⁇ ′′ within the detection region are substantially parallel, they may well have amplitude of different value.

- the detection region electric field amplitude E ⁇ ′′ may be set up at a larger value than the drift region electric field amplitude E ⁇ so as to increase the transfer velocity to the collecting electrode to get thus faster signals.

- the general form of the electric field lines being modified only by the spherical shape of the sandwich structure and more particularly its circular shape as represented at figure 3b.

- the gas electron multiplier 1 may consist of a thin insulator foil referred to as 10 which is metal clad on each of its faces, the metal cladding being thus referred to as 11 and 12 with reference to figures 2a and 2b, the sandwich structure thus formed being further traversed by a regular matrix of tiny holes referred to as 1 i .

- Typical values are 25 to 500 ⁇ m of thickness for the foil with the centre of the tiny holes being separated at a distance comprised between 50 and 300 ⁇ m.

- the tiny holes may well have a diameter which is comprised between 20 and 100 ⁇ m.

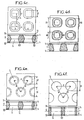

- the matrix of tiny holes 1 i is generally formed in the central area of an insulator foil of regular shape as shown at figure 4a.

- the insulator foil 10 is thus provided with electrodes on each of its faces which are referred to as 120 and 110, these electrodes being thus adapted so as to apply a potential difference between the two metal sides of the mesh embodying the matrix of tiny holes.

- the composite mesh can thus be manufactured with conventional technologies which will be described later in the description, is simple to install rugged and resistant to accidental discharges.

- the mesh as shown at figure 4a can be realized by conventional printed circuit technology.

- two identical films or masks are imprinted with the desired pattern of holes and overlaid on each side of the metal clad insulator foil 10 which is previously coated with a light sensitive resin.

- the insulator foil 10 may consist of a polymer such as KAPTON or the like, KAPTON being a registered trade-mark to DUPONT DE NEMOURS. Exposure to ultra-violet light and development of the resin exposes thus the metal to acid etching only in the regions to be removed, i.e. the tiny holes. The foils are then immersed into an adequate solvent for the polymer used and holes dig within the foils from the two sides by chemical etching.

- the whole processing uses common and well-known industrial procedures as though a precise control of the etching parameter are essential to obtain a reproducible mesh.

- the above-mentioned method is proper to allow the manufacturing of mesh from an insulator foil of thickness comprised between 20 to 100 ⁇ m for example.

- insulator foils of greater thickness i.e. of a thickness comprised between about 100 to 500 ⁇ m

- alternative standard methods of manufacturing like plasma etching or laser drilling can also be used and provide similar results.

- One method of particular interest appears to be laser drilling since the process of drilling holes can be computed and controlled accordingly so as to obtain matrices of tiny holes of adapted shape with respect to corresponding application.

- FIG 4b A detail of the mesh thus obtained is represented at figure 4b.

- the tiny holes shown at figure 4b are circular in shape, they may well be of different shape as it will be thus disclosed with reference to figures 4c, 4d and 4e.

- each tiny hole is deemed to be included within an opening aperture diameter which is comprised between 20 and 100 ⁇ m. While the tiny holes as shown at figure 4b are circular in shape with the outermost dimension of the holes fully corresponding to its aperture diameter, to the contrary, the tiny holes which are shown at figures 4c and 4d fully correspond to square holes with rounded angles with the rounded angles corresponding to the opening aperture diameter of the hole.

- the rounded angles allow to reduce the erratic electric discharges phenomenon.

- each bored-through hole 1 i consists of a bored-through hole which is formed by a first and a second frusto-conical bored hole.

- the first frusto-conical bored hole extends from the first metal-cladding 11 to an intermediate surface of the regular sandwich structure which is referred to as plane Q at figure 3a, 3b and 4c, 4e.

- the second frusto-conical bored hole extends from the second metal-cladding 12 to the same intermediate surface referred to as plane Q, both frusto-conical bored-holes having a first circular opening of a diameter of a given value as previously mentioned in the description at the level of the corresponding metal-cladding 11 or 12.

- Both of the frusto-conical bored holes join together at the level of the intermediate surface Q of the regular sandwich structure forming thus the corresponding bored-through hole 1 i as shown at figures 4c and 4e.

- the bored-through holes 1 i which are identical in shape and regularly distributed over all the metal clad faces of the insulator foil 10 form thus the matrix of tiny holes embodying the matrix of local electric field condensing areas in operation.

- each of the bored-through holes 1 i has a cross-section along a longitudinal plane of symmetry of this bored-through hole which is conical in shape.

- Each of the bored-through holes 1 i as shown at figure 4d comprises thus a first and a second circular opening or substantially circular opening for given values which are different from each other and thus form a first and a second opening aperture diameter of different value at the level of the first 11 and the second cladding 12.

- Figure 4f refers to another particular embodiment in which each of the bored-through holes is fully circular in shape, all the way through.

- the dimensions given at figure 4f may thus well correspond to those given at table III, with d being thus equal to D.

- Such a matrix as shown at figure 4f can be obtained by laser drilling.

- the electric field enhancement as shown at figures 3a or 5a, 5b is large enough to induce an avalanche multiplication from any primary electron entering one of the field tube FT of the drift region as shown at figures 3a, 3b or 5a.

- Figure 5b represents the distribution of the electric field lines and the potential lines at the level of one electric field condensing area of the gas electron multiplier 1 embodying a radiation detector in accordance with the object of the invention, with the electric field lines being represented in solid lines and the potential lines in phantom lines. It is particularly emphasized that provided a given potential difference VGEM is applied to the first 11 and second 12 metal-cladding of the gas electron multiplier 1 embodying a radiation detector in accordance with the present invention, no electric field lines do reach either the first and second metal-cladding 11 and 12 or the insulator foil 10 as it is clearly shown at figure 5b.

- any local electric field condensing area 1 i provides thus a full transmission of any drift electron as an electron avalanche, the gas electron multiplier 1 embodying the radiation detection of the invention providing thus a full electrical charges transmission and, as a consequence, an electrical transparency that substantially equals 1.

- This electrical transparency should be distinguished over the optical transparency of the mesh embodying the gas electron multiplier 1 since this electrical transparency substantially equal to 1 is obtained for an optical transparency of the mesh which is defined as the ratio between the total surface of all the tiny holes embodying the local electric field condensing areas over the total surface of the metal clad insulator foil and thus is comprised between 10% and 50%. It is further emphasized that the high density of channels, i.e. of tiny holes, reduces thus the image distorsions to values which are comparable to the intrinsic spread due to diffusion.

- the gain or the amplifying factor of the radiation is in a direct relationship to the amplifying factor yield by the gas electron multiplier as disclosed in the description.

- This amplifying factor is in a direct relationship to the electric field enhancement and more particularly to the electric field amplitude value along the symmetrical axis of symmetry X'X of each tiny hole embodying one electric field condensing area together with the path length of the electron avalanche within one of the local electric field condensing area, and as a consequence, the thickness of the metal clad insulator foil 10.

- the amplifying factor which is defined as a ratio of the number of electrons of the electron avalanche entering the detection region to one primary electron yields those values to above 1000.

- the collecting electrode CE is adapted to operate at unity gain in ionization mode for example.

- this electrode may consist of a plurality of elementary anodes as shown for example at figures 1a to 1c, each elementary anode consisting for example of one strip or one pad of conductive material which allows an electronic detection of each electron avalanche.

- Each elementary anode as shown for example at figures 2a and 2b is put at a reference potential such as a ground potential and is connected thanks to a capacitor CA to an amplifier A adapted to deliver a detection signal to a detection device which is not shown in the above-mentioned figures.

- the detection device is not disclosed for it is well-known per se to any person of ordinary skill in the corresponding art.

- the radiation detector of the invention may well be adapted to perform either monodimensional or bidimensional position detection.

- the collecting electrode CE may be provided with elementary anodes ST i which are laid onto the face of an insulator foil or printed circuit board facing the gas electron multiplier 1, in case of monodimensional detection, with these elementary anodes each consisting of one electric conductive strip, these strips being thus parallel and extending along a first direction.

- elementary anodes ST j may be provided on the other side of the insulator foil, and separated from the first ones, so as to form parallel electric conductive strips extending along a second direction transverse to the first one.

- the conductive strips ST i facing the gas electron multiplier 1 are preferably regularly spaced apart from each other so as to cover 50% only of the total surface of the collecting electrode CE, so as to allow any electron avalanche generated in front of any elementary anode ST i facing the gas electron multiplier 1 to also induce a corresponding detection signal onto corresponding elementary anodes ST j which are partially masked by the latters.

- the gain of detection amplifiers A embodying each detection circuit with capacitor CA and resistor RA may well be set up to different adapted values for each set of elementary electrodes, so as to introduce a good balance of the induced detection signal onto each set of elementary electrodes.

- a plurality of successive matrices of electric field condensing areas can be used, these matrices being in a cascade relationship over the primary electron stream, two matrices referred to as GEM 1 and GEM 2 being shown only for the sake of better comprehension at figure 6a.

- GEM 1 and GEM 2 two matrices referred to as GEM 1 and GEM 2 being shown only for the sake of better comprehension at figure 6a.

- These successive matrices are put parallel to one another, i.e. in the absence of intersection, to define homothetic matrices over a common centre C forming the radiation detector as shown at figure 6a.

- the drift electrode DE, the first matrix or gas electron multiplier GEM 1 , the second matrix or second gas electron multiplier GEM 2 and successive matrices together with the collecting electrode CE define therebetween successive electric fields which are referred to as vector E ⁇ 1 D , vector E ⁇ 21 , vector E ⁇ 02 and the like, each successive electric field allowing any primary electron or electron of one electron avalanche to drift as a primary electron along the separating distance thanks to its corresponding electric field.

- the gas electron multiplier formed by successive matrices as shown at figures 6a and 6b cooperates thus as an amplifier, the gain of which is the product of the gain yield for each successive matrix.

- Figure 6b actually represents a planar embodiment of the radiation detector shown at figure 6a. It is further recalled that for planar embodiments as shown at figure 6b, the common center C actually lies at an infinite distance.

- the radiation detector of the invention as it has been disclosed up to now with reference to figures 1a to 6b fully operates as an amplifier, the collecting electrode CE of which operates at unity gain and can thus be made of a simple and very cheap stripped printed circuit for which the total gain or amplifying factor is obtained from the gas electron multiplier only, either single or multiple gas electron multiplier as shown at figures 6a and 6b.

- the gas electron multiplier 1 is inserted into a host detector which has its proper gain with reference to figures 7a and 7b.

- the host detector in a general way, may consist as a non-limitative example, as a well-known micro-strip gas chamber, thereafter designated as MSGC, or a multiwire proportional chamber.

- MSGC micro-strip gas chamber

- the collecting electrode CE consists now of successive anode electrodes designated as AN and cathode electrodes, referred to as CO, which are interleaved and distributed over a dielectric support so as to form the collecting electrode CE.

- Each of the anode electrodes AN is connected to the reference potential referred to as the ground potential through resistor RA and to an amplifier A so as to allow detection while each of the cathode electrodes CO is connected to a bias potential generator VC, the MSGC chamber having thus its own gain depending on the gain which is yield through amplification between each of the cathode electrodes and anode electrodes.

- one gas electron multiplier 1 is further inserted between the drift electrode DE and the collecting electrode CE so as to define a first drift region, drift 1 , and a second drift region, drift 2 , which are separated from each other by the gas electron multiplier 1.

- the microstrip gas chamber which is made with its thin and fragile metal strips appears particularly exposed to discharge damages.

- the sophisticated electronic circuits connected to the strips such as amplifier A as shown at figure 7a, can also be irreversibly damaged by these discharges.

- the gas electron multiplier 1 of the invention operates thus as a preamplifier of given gain for the primary electrons upstream the collecting electrode CE of the radiation detector.

- bias potentials which are put to the drift electrode DE and the collecting electrode CE, particularly to the cathode electrode CO and the first and second metal-cladding 11 and 12 of the gas electron multiplier 1 as shown at figure 7a are independent, such a configuration allows independent operation of the gas electron multiplier 1 and the microstrip gas chamber or multiwire proportional chamber as well as a controlled injection of ionization electrons into the preamplifying gas electron multiplier 1.

- Such mode of operation is called preamplification mode and can be used to largely increase the electric charges to be detected. Combined with a multiwire or a microstrip gas chamber, it makes much easier and safer to detect small amounts of electric charges. While the combination of a gas electron multiplier 1 adapted to a multiwire proportional chamber or a microstrip gas chamber of corresponding shape can be performed with these shapes corresponding to spherical or cylindrical ones, the preamplification mode of operation of the gas electron module 1 of the invention appears of highest interest in case of multiwire proportional chamber or microstrip gas chamber of planar structure, the gas electron multiplier 1 in such a case corresponding also to a planar structure as shown at figure 7a.

- the voltage potentials can be set up at the following values:

- the distances separating the gas electron multiplier from the drift electrode, or the successive electrode CE were set up to 3 mm.

- a multistage detector in accordance with the invention operating in either amplification or preamplification mode is thus functionnaly equivalent to a multidynode photomultiplier except it operates in a gaseous environment while each matrix element of local electric field condensing areas has a much larger gain.

- the gas electron multiplier which is the object of the invention is fully self-supporting since the multiplying gap and therefore the gain are kept substantially constant by the fixed thickness of the insulating foil regardless of the precise location of the gas electron multiplier within the detector or the host detector. Furthermore, heavy support frames are not necessary, this greatly simplifying construction and increasing reliability while reducing costs.

- Figure 8a gives some examples of the gas electron multiplier amplification factor which is plotted in relation to the potential difference which is applied to the first and second metal-cladding 11 and 12 embodying one gas electron multiplier 1 in accordance with the invention. Experimental results as shown in figure 8a are given for a first mixture of:

- Preceding ratios are given as volume ratios.

- the voltage difference which was applied to the first 11 and second metal-cladding 12 was comprised between 200 and about 600 volts, thereafter designated as V GEM .

- a fundamental property of the gas electron multiplier embodying one radiation detector in accordance with the invention appears to be the wide range of electric fields strengths that can be applied above the mesh forming the matrix of local electric field condensing areas without affecting the gain actually yield. Such a property appears of highest importance because it makes the gas electron multiplier of the invention almost insensitive to large mechanical variations in the surrounding electrodes. As a consequence, such a property allows the choice of the drift field for optimal physical requirements as the value of the electrons drift velocity, diffusion and collection time.

- a concern of high-rate applications is the behavior of the gas electron multiplier embodying the radiation detector in accordance with the present invention under condition of large detected currents. While most of the electric charges, electrons and positive ions, smoothly drift in the open gas channel without affecting the operation, some stray charges may collect on the surface of the insulator with these stray charges distorting the field and therefore the gain thus obtained. It has been however demonstrated that a very small surface conductivity in the channel which is obtained very simply by the addition to the gas of a small amount not exceeding 1% of water vapor completely stabilizes the operation up to detected X-ray fluxes of 10 7 Hz cm -2 or more.

- each tiny hole or bored-through hole 1 i is provided with an internal lateral surface which is delimited by the insulator foil 10.

- this lateral surface comprises preferably one local zone with intrinsic resistivity between 10 12 and 10 13 ⁇ x cm.

- this local zone is deemed to cover the extremal portion of the frusto-conical bored-through hole in which electric charges such as positive ions have been introduced through ion implantation for example.

- gas electron multiplier embodying the radiation detector of the invention is its high-rate capability while the gain or the relative pulse height of the radiation detector is substantially maintained at a constant value over its full rate range.

- the gain of the gas electron multiplier in accordance with the present invention has been defined as the ratio of the electrons number in the electron avalanche leaving the output face to the number of electrons of the primary electrons or the electrons entering the input face at the level of each local condensing area of the matrix embodying the gas electron multiplier

- one mode of operation to evaluate such a gain may consist as an example to measure the preamplification factor or the amplification factor which is defined as a ratio of the most probable pulse height between transferred and direct spectra for the 5.9 keV line radiated by an external 55 Fe source.

- the relative pulse height PH is plotted with respect to the rate expressed in Hz/mm 2 in three modes of operation of a gas electron multiplier inserted within a host detector which consists of a micro-strip gas chamber in the following situations:

- Figure 8c shows the variation of the pulse amplifying factor of one gas electron multiplier 1 in accordance of the object of the present invention, with this amplifying factor being plotted over the time during which the gas electron multiplier 1 is actually on, the time being expressed in minutes.

- Corresponding curve I is given for a gas electron multiplier operated with a potential difference applied to the first 11 and second 12 metal-cladding of the sandwich structure which was put to 420 volts with the radiation detector being filled with a gas mixture of argon and carbon dioxide to a ratio 72% / 28%.

- the charging up phenomenon comes up to effect to increase the pulse amplifying factor for an initial value that equals 40 to a value greater than or substantially equal to 52 after 20 minutes the radiation detector is on.

- Corresponding curve II is given for the same radiation detector as it was used to get curve 1 except that the gas mixture is further provided with water vapor to 0.35% in addition.

- Curve II clearly shows the full constant character of the pulse amplifying factor which substantially equals 40 all over the time the radiation detector of the invention is on, that is from the very beginning to the end of the experiment 50 minutes later.

- the inter-electrode resistivity of the gas electron multiplier mesh decreases gradually by a factor of 10, from 100 to 10 G ⁇ , and then remains constant. Taking into account the total area of the channels and particularly of the tiny holes embodying the latters, this clearly indicates that a surface resistivity around 10 16 ⁇ /square is sufficient to eliminate the charging up phenomenon as the highest rates.

- the original value of resistivity as well as the final one after introduction of water depend on the total area and the number of tiny holes. Preceding values refer to a 10 x 10 cm 2 gas electron multiplier 1 provided with about 5 x 10 5 tiny holes.

- each of the above-mentioned embodiments is well adapted to operate either on amplification or preamplification mode as previously disclosed in the description. It is furthermore emphasized that the amplification mode may well be preferred for applications in which ionizing radiations of very high energy level are to be investigated.

- figure 9a shows the radiation detector of the invention in which the sandwich structure forming a gas electron multiplier 1 is provided which is spherical in shape.

- This radiation detector may well correspond to that which is shown at figure 1c with the external form of the detector being circular in shape as shown at the front view of figure 9a.

- This radiation detector is adapted to crystallography trials in which X rays are directed to a crystal, the radiation detector of the invention being thus adapted to allow a full detection of the diffraction pattern generated by the impingement of the X-rays onto the crystal.

- the bored-through holes forming the electric field condensing areas are regularly distributed over a part only of the metal-clad faces of the insulator foil so as to form at least one blind detection zone which is referred to as BZ for the radiation detector.

- the blind detection zone is thus substantially spherical in shape and located at the center part of the sandwich structure with the bored-through holes being distributed all around this blind detection zone so as to allow detection of the diffraction pattern out of this blind detection zone only.

- the radiation detector of the invention as shown at figure 9a is used in amplification mode, that is in the absence of micro-strip or multiwire chamber as final amplifier, it allows to adapt the collecting electrode CE shape to the needs with this electrode for example consisting of strips, pads or rings, the rings being particularly adapted in case of crystal diffraction measurements.

- the rings forming the collecting electrode CE are shown in phantom line for better comprehension and clarity of the drawings.

- Figures 9b and 9c are concerned with radiation detectors in accordance with the present invention which are more particularly adapted and suited for colliding beams accelerators or very high energy particles colliding ring accelerators like that which is in operation at the CERN (Centre Eurocheren de mecanic Nucléaire) in Geneva, Switzerland.

- the colliding ring accelerator owing to its very high curvature radius, is represented as a straight portion.

- the gas electron multiplier embodying the radiation detector in accordance with the invention consists of a solid surface made of adjacent elementary solid surfaces, each elementary solid surface forming one elementary gas electron multiplier which comprises at least one matrix of electric field condensing area so as to form elementary detectors which are referred to as RD 1 to RD 9 .

- the elementary detectors are joined to one another so as to form a three-dimensional radiation detector which surrounds the colliding ring accelerator as shown at figures 9b and 9c.

- the three-dimensional detector shown at figure 9b is spherical in shape and formed from elementary radiation detectors which are each spherical in shape and fully correspond to the radiation detector in accordance with the present invention which is shown at figure 1c with elementary detectors RD 1 , RD 2 , RD 3 and RD 4 being designed so as to form a skullcap while the other elementary detectors are design as a part of a corresponding volume spherical in shape.

- Elementary detectors RD 2 and RD 3 may well be provided with a central blind detection zone, as already shown at figure 9a, this blind detection zone being further drilled so as to allow the colliding ring accelerator to pass through.

- Each elementary radiation detector may be manufactured as the radiation detector shown at figure 1c by thermo-forming all its constituting parts such as the input window and drift electrode, the sandwich structure and the collecting electrode CE together with the intermediate frames which are necessary to build up any radiation detector or elementary radiation detector in accordance of the present invention.

- the gas inlet and gas outlet GI and GO may be removed and replaced by bored-through holes with the bored-through holes forming the gas inlet and gas outlet of two neighbouring adjacent elementary radiation detectors, such as RD 2 and RD 5 at figure 9b, these bored-through holes being put to face each other and to be sealed thanks to O rings.

- the electrodes terminals which are adapted to apply the difference potential to the input and output face formed by the first and second metal-cladding 11 and 12 as shown at figures 1a and 1c, are reduced and adapted to further allow the interconnecting of the first and second metal-cladding respectively of two successive adjacent elementary radiation detectors, the same difference potential voltage being thus applied to each gas electron multiplier embodying each elementary radiation detector which as a consequence yield the same gain.

- one general gas inlet GI and gas outlet GO only are provided which are preferably located close the blind zone in the vicinity of the colliding ring accelerator.

- Figure 9c is directed to a three-dimensional radiation detector which is substantially cylindrical in shape at the extremities of which two elementary half-spherical radiation detectors are abutted.

- the elementary half-spherical radiations detectors may well consist of one or several elementary radiation detectors thereafter designated as RD 1 , RD 2 , RD 8 , RD 9 with elementary radiation detectors RD 1 and RD 9 playing the same role as the elementary detectors as RD 2 and RD 3 at figure 9b.

- the length of the cylindrical part as shown at figure 9c may extend along the colliding ring accelerator for several meters with this cylindrical part consisting of several adjacent elementary radiation detectors thereafter designated as RD 3 to RD 7 .

- the inner part of these detectors as shown at figures 9b and 9c may well be filled outside the inlet window of each elementary radiation detector with a foam which is substantially transparent to the X or gamma rays of very high energy.

- a radiation detector of very high efficiency in accordance with the present invention, has thus been disclosed in which a gas electron multiplier may be used in the field of elementary particle experiments.

- HELLAZ Another detector, thereafter designated as HELLAZ, is proposed for large cosmic rays experiment in the Italian Laboratory under the GRAN SASSO with the aim of achieving large enough gains to detect single electrons.

- a further particular use of the gas electron multiplier of the invention may also consist to prevent transmission of electrons and/or ions through the control of external voltages.

- the biasing source 2 may well consist of two detening voltage generators of opposite polarity that can be switched through a common switch K. Operating the switch K allows the difference voltage potential VGEM to be reversed so as to allow to prevent transmission of electrons and/or ions, the sandwich structure operating thus as an active gate, the enhanced electric field being thus strong enough to repell given electric charges ions or electrons.

- This embodiment is more particularly directed to a radiation detector for photons which are emitted by an external source.

- the operating principle of the gas electron multiplier 1 which is the object of the present invention operating as a photon detector relies on the following specific properties of its structure:

- An inlet window IW is further provided which is associated with a transparent electrode denoted as C, this inlet window and transparent electrode being adapted to transmit the photons within the gas contained by the vessel.

- the inlet window IW and transparent electrode C are made of a material which is substantially transparent to the photons wavelength. Well-known technology may be used so as to put the inlet window IW and the transparent electrode C together, the transparent electrode for this reason being represented with phantom line only at figure 10.

- a photocathode layer faces the transparent electrode C with this photocathode layer being adapted to generate one photo-electron as a primary electron under impingement of each one of the photons onto this photocathode layer.

- a gas electron multiplier 1 is further provided so as to include at least, as previously mentioned in the description, one matrix of electric field condensing areas which is formed from the foil metal clad insulator 10 provided with metal cladding 11 and 12 onto its faces, with metal cladding 11 facing the transparent electrode C.

- the photocathode layer PhC, the metal claddings 11 and 12 together with the insulator foil 10 form thus a regular sandwich structure as previously mentioned in the description.

- a plurality of bored-through holes denoted 1 i traverse thus the regular sandwich structure with each of the bored-through holes being adapted to allow a free flowing therethrough for the gas and any electrically charged particle generated within the latter.

- a metal clad insulator provided with metal claddings 11 and 12 onto one of the faces of which a layer of photosensitive material is deposited so as to build up the photocathode layer PhC.

- the bored-through holes may thus be drilled according to anyone of the technologies which are actually disclosed in the description.

- inlet window IW and transparent electrode C are spaced apart to form a convey region which operates in a similar way as the drift region of figure 3a, as it will be disclosed in more details later in the description.

- the detector of the invention further includes a detection unit adapted to perform a position detection of any electron avalanche generated within the detection region which is formed between the gas electron multiplier 1 and the detection unit as shown at figure 10.

- the detection unit is represented as a collecting electrode CE as previously mentioned with reference to figures 2a or 3a.

- the detection unit may well include another gas electron multiplier so as to form a multistage gas electron multiplier as previously mentioned in the description or a microstrip chamber or even a multiwire chamber for example.

- the top electrode of the collecting electrode CE is provided with elementary anodes, each of which is denoted ST i , whith these elementary anodes consisting for example as parallel electric conductive strips which are laid onto an insulator foil denoted CEF.

- Electronic circuits consisting of resistor RA, capacitor CA and amplificator A, are further provided as previously mentioned in the description.

- a biasing circuit referred to as B 1 is provided and adapted so as to maintain the transparent electrode C and the first metal cladding 11 substantially to the same voltage potential value with respect to the reference potential value so as to allow extraction of any photo-electron which is generated by the photocathode layer PhC under impingement onto the latter of each one of the emitted photons.

- Biasing circuit B 1 is represented thus as a short-circuit conductor.

- a further biasing circuit referred to as B 2 , is provided so as to develop a bias voltage potential referred to as VGEM which is applied between the metal claddings 11 and 12 so as to form at the level of each of the bored-through holes one of the electric field condensing areas 1 i as previously mentioned in the description. Applying such a voltage allows thus to generate a condensed electric field denoted as vector E ⁇ ′ within each of the electric field condensing area.

- VGEM bias voltage potential

- Another biasing circuit referred to as B 3 , is further provided so as to develop a bias voltage potential which is actually applied between metal-cladding 12 and collecting electrode CE and more particularly elementary anodes referred to as ST i at figure 10 so as to allow the detection of the electron avalanche as it will be explained thereafter.

- each elementary anode ST i forming part of the collecting electrode CE is substantially set up as a reference potential thanks to resistor RA which is a resistor of very high value connecting each corresponding elementary anode to the reference potential.

- each condensed electric field vector E ⁇ ′ generated within each electric field condensing area which is thus an electric field of very high amplitude value, operates thus within the region delimited between the transparent electrode C and the metal-cladding 11 and photocathode layer PhC as to convey each of the photo-electron to one given electric field condensing area which is the closest of the impingement region of this photon within the fill tube FT which is actually generated between metal-cladding 11 and collecting electrode CE, as shown at figure 10.

- Cancelling the electric field vector E ⁇ with its amplitude being quite set up to zero value in the vicinity of transparent electrode C as shown at figure 10 comes thus to the effect of substituting a convey region to the drift region which is represented at figure 3a.

- the field tube FT is thus folded back to the metal-cladding 11 with any photo-electron being thus conveyed to within a corresponding electric field condensing area 1 i .

- the condensed electric field vector E ⁇ ′ operates thus to generate from this photo-electron regarded as a primary electron one electron avalanche within corresponding bored-through hole with this electron avalanche being thus passed through this bored-through hole to the detection region, as shown at figure 10.

- the electron avalanche is thus submitted to detection thanks to electric field vector E ⁇ ′′ and elementary anodes ST i of the collecting electrode CE.

- corresponding voltage potential values may well be set up to similar values.

- potential value VGEM may well be set up to 500 volts while potential value applied between metal-cladding 12 and elementary anodes ST i may be set up to 1000 volts, with this values being thus given as an example.

- position detection of any avalanche which is passed through any electric field condensing area 1 i may preferably be performed as a bidimensional detection.

- the inner face of the collecting electrode CE is provided with a first set of elementary anodes ST i

- the outer face of same collecting electrode CE is thus provided with another set of elementary anodes referred to as ST j consisting also of parallel electric conductive strips, with each of the sets of elementary anodes ST i and ST j extending along distinct transverse directions so as to allow bidimensional detection in corresponding directions.

- a fundamental property of the radiation detector for photons either as single stage or multistage version, which cannot be obtained with any other known gas detector, is that secondary photons produced during the electron avalanche process, both primary in the bored-through holes forming each electric field condensing area of the gas electron multiplier and secondary in the second stage element, cannot heat the photocathode layer PhC thereby preventing to induce secondary emission.

- the high dipole field which is created within the bored-through holes allow thus to obtain a collection efficiency, i.e. electrical transparency close to unity with an optical transparency close to zero.

- the large ratio of the total area to the holes area implies also that most of the surface of the metal-cladding 11 can thus be coated by photosensitive material with a geometrical quantum efficiency close to 1.

- the field configuration which is obtained with a large difference of potential between metal-cladding 12 and elementary anodes ST i is such that only a small fraction of the positive ions which are produced at the final amplification stage can thus actually reach the photocathode layer PhC reducing thus the damage effects.

- the radiation detector for photons in accordance with the object of the present invention permits thus to obtain simultaneously :

- the total combined gain of the two amplification elements in case of a multistage gas electron multiplier may thus be set up to a value sufficient enough for the detection and localization of single photo-electrons opening thus the way to numerous scientific, technical or industrial applications like CHERENKOV ring imaging, image intensifiers, fluorescence analysis in the visible and near ultraviolet range, or any applications requiring detection and localization of photons over extended areas.

- gas electron multiplier detectors in accordance with the object of the present invention, either in preamplification or amplification mode, makes them interesting for applications in many fields where low and high rate detection and localization of radiation can be exploited for industrial or medical diagnosis.

- One further possibility of the radiation detector of the invention also concerns the possibility for the gas electron multiplier to be tailored to applications or specific needs and particularly its shape with special cut outs as for approaching vacuum beam tubes in accelerators or the like.

Landscapes

- Measurement Of Radiation (AREA)

- Electron Tubes For Measurement (AREA)

- Light Receiving Elements (AREA)

Claims (18)

- Détecteur de rayonnement dans lequel des électrons primaires sont libérés dans un gaz par des rayonnements ionisants et entraînés vers une électrode collectrice (CE) au moyen d'un champ électrique (E̅), ledit détecteur de rayonnement comprenant un multiplicateur d'électrons (1) du gaz comprenant au moins une matrice de zones de condensation (1i) de champ électrique, lesdites zones de condensation (1i) de champ électrique étant réparties dans une surface pleine qui est sensiblement perpendiculaire audit champ électrique (E̅), chacune des zones de condensation (1i) de champ électrique étant adaptée pour produire une augmentation locale de l'amplitude du champ électrique convenant pour générer dans ledit gaz une avalanche électronique à partir de l'un desdits électrons primaires, ledit multiplicateur d'électrons (1) du gaz agissant alors comme un amplificateur d'un gain donné desdits électrons primaires, ladite surface pleine étant de forme plane, sphérique ou cylindrique, ladite électrode collectrice étant adaptée pour fonctionner à un gain unité, en mode d'ionisation, ladite électrode collectrice (CE) se composant au moins d'une pluralité d'anodes élémentaires (STi) permettant une détection électronique de chaque avalanche électronique.

- Détecteur de rayonnement selon la revendication 1, dans lequel ladite augmentation locale (E̅ ') de l'amplitude du champ électrique (E̅) générée par chacune desdites zones de condensation locales (1i) est sensiblement symétrique par rapport à un axe de symétrie de ladite zone de condensation locale (1i), ladite augmentation locale (E̅') de l'amplitude du champ électrique étant alors à un maximum au centre de symétrie de ladite zone de condensation locale (1i).

- Détecteur de rayonnement selon la revendication 1, dans lequel lesdites zones de condensation (1i) de champ électrique ont une forme sensiblement identique et sont réparties régulièrement dans ladite surface pleine afin de former ladite matrice.

- Détecteur de rayonnement selon la revendication 1, dans lequel ladite matrice de zones de condensation de champ électrique comprend :- un isolant en feuille métallisé (10) sur chacune de ses faces afin de former un premier (11) et un deuxième (12) placages métalliques prenant en sandwich ledit isolant (10), afin de former une structure sandwich régulière ;- une pluralité de trous alésés jusqu'au passage à travers traversant ladite structure sandwich régulière ;- un moyen de polarisation (2) adapté pour créer une tension électrique de polarisation qui est appliquée auxdits premier (11) et un deuxième (12) placages métalliques afin de générer au niveau de chacun desdits trous alésés jusqu'au passage à travers l'une desdites zones de condensation (1i) de champ électrique.

- Détecteur de rayonnement selon la revendication 4, dans lequel ladite structure sandwich régulière étant mise en oeuvre sensiblement perpendiculairement audit champ électrique (E̅), ledit premier placage métallique (11) forme une face d'entrée pour lesdits électrons entraînés et ledit deuxième placage métallique (12) forme une face de sortie pour une avalanche électronique générée au niveau de chaque trou alésé jusqu'au passage à travers formant l'une desdites zones de condensation de champ électrique.

- Détecteur de rayonnement selon la revendication 5, dans lequel lesdits trous alésés jusqu'au passage à travers ont une forme sensiblement identique et pratiquement circulaire vue le long d'une direction sensiblement perpendiculaire à ladite structure sandwich standard.

- Détecteur de rayonnement selon la revendication 5, dans lequel chacun desdits trous alésés jusqu'au passage à travers est formé par un premier et un deuxième trous alésés tronconiques, ledit premier trou alésé tronconique s'étendant sensiblement depuis ledit premier placage métallique (11) vers une surface intermédiaire (Q) de ladite structure sandwich régulière et ledit deuxième trou alésé tronconique s'étendant sensiblement depuis ledit deuxième placage métallique (12) vers ladite surface intermédiaire (Q) de ladite structure sandwich, lesdits premier et un deuxième trous alésés tronconiques comprenant chacun une première ouverture circulaire ayant un diamètre d'une première valeur donnée au niveau respectivement de ladite face (11) d'entrée et de ladite face (12) de sortie et une deuxième ouverture circulaire ayant un diamètre d'une deuxième valeur donnée, plus petite que la première, lesdites deuxièmes ouvertures desdits premier et un deuxième trous alésés tronconiques se rejoignant au niveau de ladite surface intermédiaire (Q) de ladite structure sandwich régulière pour former ledit trou alésé jusqu'au passage à travers.

- Détecteur de rayonnement selon la revendication 4, dans lequel lesdits trous alésés jusqu'au passage à travers ont une forme sensiblement identique et sont répartis régulièrement sur toutes les faces des placages métalliques (11, 12) de ladite feuille isolante.

- Détecteur de rayonnement selon la revendication 4, dans lequel lesdits trous alésés jusqu'au passage à travers ont une forme sensiblement identique et sont répartis régulièrement sur une partie des faces des placages métalliques (11, 12) de ladite feuille isolante (10) afin de former au moins une zone aveugle de détection pour ledit détecteur de rayonnement.

- Détecteur de rayonnement selon la revendication 1, dans lequel ladite surface pleine consiste en surfaces pleines élémentaires adjacentes, chacune desdites surfaces pleines élémentaires formant ainsi un multiplicateur élémentaire d'électrons (1) du gaz comprenant au moins une matrice de zones de condensation de champ électrique.

- Détecteur de rayonnement selon la revendication 1, comprenant une pluralité de matrices (GEM1, GEM2) successives de zones de condensation de champ électrique, lesdites matrices (GEM1, GEM2) successives étant placées parallèlement les unes aux autres pour définir des matrices homothétiques par rapport à un centre commun (C) formant ledit multiplicateur d'électrons du gaz et deux matrices (GEM1, GEM2) successives parmi lesdites matrices successives étant espacées l'une de l'autre d'une valeur donnée de distance de séparation dans une direction parallèle audit champ électrique formant un premier champ électrique afin de définir entre les deux des champs électriques (E̅10, E̅21, E̅22) successifs et permettre à un quelconque électron d'une avalanche électronique d'être entraîné en tant qu'électron primaire sur ladite distance de séparation au moyen de son champ électrique correspondant, ledit multiplicateur d'électrons du gaz agissant alors comme un amplificateur dont le gain est le produit du rendement de gain de chaque matrice successive.

- Détecteur de rayonnement selon l'un quelconque des revendications précédentes, dans lequel ladite matrice de zones de condensation de champ électrique comprend :- un isolant en feuille métallisé (10) sur chacune de ses faces afin de former un premier (11) et un deuxième (12) placages métalliques prenant en sandwich ledit isolant, afin de former une structure sandwich régulière ;- une pluralité de trous alésés jusqu'au passage à travers traversant ladite structure sandwich régulière, chacun desdits trous alésés jusqu'au passage à travers ayant un diamètre d'ouverture compris entre 20 µm et 100 µm.

- Détecteur de rayonnement selon la revendication 12, dans lequel ladite feuille isolante est constituée d'un polymère ayant une épaisseur comprise entre 25 µm et 500 µm, lesdits trous alésés jusqu'au passage à travers étant espacés les uns des autres d'une distance comprise entre 50 µm et 300 µm.

- Détecteur de rayonnement selon la revendication 12, dans lequel chaque trou alésé jusqu'au passage à travers de ladite pluralité de trous alésés jusqu'au passage à travers est muni d'une surface latérale intérieure délimitée par ledit isolant, ladite surface latérale comprenant au moins une zone locale dans laquelle des charges électriques permanentes (q+) sont implantées, lesdites charges électriques permanentes étant réparties dans ledit isolant et dans sa zone locale afin d'augmenter davantage et de stabiliser ledit champ électrique au niveau de chaque zone correspondante de condensation (1i) de champ électrique.

- Détecteur de rayonnement selon la revendication 12, dans lequel chaque trou alésé jusqu'au passage à travers de ladite pluralité de trous alésés jusqu'au passage à travers est muni d'une surface latérale intérieure délimitée par ledit isolant, ladite surface latérale comprenant au moins une zone locale ayant une conductivité électrique comprise entre 1015 et 1016 Ω/carré.

- Détecteur de rayonnement selon la revendication 12, dans lequel chacun des trous alésés jusqu'au passage à travers de ladite pluralité de trous alésés jusqu'au passage à travers a une section transversale le long d'un plan longitudinal de symétrie dudit trou alésé jusqu'au passage à travers qui est de forme conique, chacun des trous alésés jusqu'au passage à travers comprenant une première et une deuxième ouvertures circulaires de valeurs données différentes l'une de l'autre formant ainsi un premier et un deuxième diamètres d'ouverture de valeur différente, ledit détecteur de rayonnement comprenant en outre des moyens de polarisation directe et inverse pouvant être commandés adaptés pour créer respectivement une tension de polarisation directe et une tension de polarisation inverse qui sont appliquées auxdits premier (11) et un deuxième (12) placages métalliques afin de générer au niveau de chacun desdits trous alésés jusqu'au passage à travers l'une desdites zones de condensation de champ électrique qui est alors inversée d'un point de vue fonctionnel.

- Détecteur de rayonnement pour des photons émis par une source externe, ledit détecteur de rayonnement comprenant au moins, dans un récipient contenant un gaz adapté pour générer une avalanche électronique à partir d'un électron primaire par l'intermédiaire d'un champ électrique :- une fenêtre d'entrée (IW) et une électrode transparente (C) posée sur la face intérieure de ladite fenêtre d'entrée (IW), ladite fenêtre d'entrée et ladite électrode transparente (C) étant adaptées pour transmettre lesdits photons dans ledit gaz ;- une couche de photocathode (Phc) faisant face à ladite électrode transparente (C), ladite couche de photocathode (Phc) étant adaptée pour générer un photoélectron en tant qu'électron primaire sous l'impact de chacun desdits photons ;- un multiplicateur d'électrons (1) du gaz comprenant au moins une matrice de zones de condensation (1i) de champ électrique, ladite matrice de zones de condensation (1i) de champ électrique comprenant :- un isolant en feuille métallisé (10) sur chacune de ses faces afin de former un premier (11) et un deuxième (12) placages métalliques sur ledit isolant en feuille (10), ladite couche de photocathode (Phc) étant posée sur ledit premier placage métallique (11) de façon à faire face à ladite électrode transparente (C), ladite couche de photocathode (Phc), le premier placage métallique (11) et le deuxième placage métallique (12) formant ainsi une structure sandwich régulière avec ladite feuille isolante (10),- une pluralité de trous alésés jusqu'au passage à travers traversant ladite structure sandwich régulière, chacun desdits trous alésés jusqu'au passage à travers permettant ainsi un écoulement libre du gaz et de toute particule chargée électriquement générée dans le gaz ;- un premier moyen de polarisation (B1) adapté pour maintenir ladite électrode transparente (C) et le premier placage métallique (11) sensiblement à la même valeur de tension électrique, afin de permettre l'extraction de tout photoélectron généré par ladite couche de photocathode (Phc) sous l'impact de chacun desdits photons ;- un deuxième moyen de polarisation (B2) adapté pour créer une tension électrique de polarisation qui est appliquée entre lesdits premier (11) et deuxième (12) placages métalliques afin de former au niveau de chacun desdits trous alésés jusqu'au passage à travers l'une desdites zones de condensation (1i) de champ électrique, dans laquelle un champ électrique condensé (E̅') est généré, ledit champ électrique condensé fonctionnant de manière à transporter chacun desdits photoélectrons vers une zone donnée de condensation (1i) de champ électrique et à générer à partir dudit photoélectron considéré comme un électron primaire une avalanche électronique qui passe par ledit trou alésé jusqu'au passage à travers formant ladite zone de condensation (1i) de champ électrique ;- une électrode collectrice (FCE) se composant d'au moins une pluralité d'anodes élémentaires (STi), ladite électrode collectrice faisant face audit deuxième placage métallique (12) et étant distante de celui-ci, pour définir une région de détection dans ledit récipient ;- un troisième moyen de polarisation (B3) adapté pour créer une tension électrique de polarisation qui est appliquée à ladite électrode collectrice (FCE) pour permettre la détection de ladite avalanche électronique.

- Détecteur de rayonnement selon la revendication 17, dans lequel ladite électrode collectrice (FCE) comprend sur feuille isolante :- un premier ensemble d'anodes élémentaires (STi) posé sur une première face de ladite feuille isolante, ladite première face de ladite feuille isolante et ledit premier ensemble d'anodes élémentaires (STi) faisant face à un multiplicateur d'électrons (1) du gaz, ledit premier ensemble d'anodes élémentaires (STi) se composant d'au moins une pluralité de bandes parallèles conductrices de l'électricité s'étendant le long d'une première direction donnée ;- un deuxième ensemble d'anodes élémentaires (STi) posé sur une deuxième face de ladite feuille isolante, lesdits premier (STi) et deuxième (STi) ensembles d'anodes élémentaires étant ainsi séparés par ladite feuille isolante, ledit deuxième ensemble (STj) d'anodes élémentaires se composant d'au moins une pluralité de bandes parallèles conductrices de l'électricité s'étendant le long d'une première direction donnée, transversale à la première,lesdits premier (STi) et deuxième (STj) ensembles d'anodes élémentaires permettant ainsi une détection de ladite avalanche électronique le long respectivement desdites deuxième et première directions afin de former un détecteur de rayonnement bidirectionnel.

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US956128 | 1992-10-02 | ||

| US08/956,128 US6011265A (en) | 1997-10-22 | 1997-10-22 | Radiation detector of very high performance |

| US150046 | 1998-09-09 | ||

| US09/150,046 US6198798B1 (en) | 1998-09-09 | 1998-09-09 | Planispherical parallax-free X-ray imager based on the gas electron multiplier |

| PCT/EP1998/006569 WO1999021211A1 (fr) | 1997-10-22 | 1998-10-16 | Detecteur de rayonnements a tres haute performance et imageur a rayons x planispherique sans parallaxe |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0948803A1 EP0948803A1 (fr) | 1999-10-13 |

| EP0948803B1 true EP0948803B1 (fr) | 2006-11-08 |

Family

ID=26847280

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP98956848A Expired - Lifetime EP0948803B1 (fr) | 1997-10-22 | 1998-10-16 | Detecteur de rayonnements a tres haute performance |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP0948803B1 (fr) |

| JP (1) | JP4264984B2 (fr) |

| AT (1) | ATE344974T1 (fr) |

| CA (1) | CA2275159C (fr) |

| DE (1) | DE69836373T2 (fr) |

| ES (1) | ES2277395T3 (fr) |

| WO (1) | WO1999021211A1 (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102011051472A1 (de) | 2011-06-30 | 2013-01-03 | Gsi Helmholtzzentrum Für Schwerionenforschung Gmbh | Elektronenvervielfältigende Detektorfolie |

| WO2013157975A1 (fr) | 2012-04-18 | 2013-10-24 | Siemens Aktiengesellschaft | Détecteur de rayonnement |

Families Citing this family (41)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3479230B2 (ja) * | 1999-01-19 | 2003-12-15 | 科学技術振興事業団 | 導電型キャピラリープレートによるガス放射線検出器 |

| JP3535045B2 (ja) * | 1999-07-01 | 2004-06-07 | 独立行政法人 科学技術振興機構 | MSGCによる反跳電子の軌跡映像からのγ線入射方向決定装置 |

| SE530172C2 (sv) * | 2000-03-31 | 2008-03-18 | Xcounter Ab | Spektralt upplöst detektering av joniserande strålning |

| US6847042B2 (en) * | 2003-06-19 | 2005-01-25 | Ge Medical Systems Global Technology Co., Llc | Centroid apparatus and method for sub-pixel X-ray image resolution |

| US7332726B2 (en) * | 2004-06-19 | 2008-02-19 | Integrated Sensors, Llc | Plasma panel based ionizing radiation detector |

| JP2006302844A (ja) * | 2005-04-25 | 2006-11-02 | Univ Of Tokyo | ガス電子増幅器、その製造方法及びガス電子増幅器を使用した放射線検出器 |

| US7476867B2 (en) * | 2005-05-27 | 2009-01-13 | Iba | Device and method for quality assurance and online verification of radiation therapy |

| EP1891464A4 (fr) * | 2005-06-16 | 2013-02-13 | Integrated Sensors Llc | Detecteur de rayonnements photoniques ionisants base sur un ecran a plasma |

| US7432510B2 (en) * | 2005-09-13 | 2008-10-07 | In Hwan Yeo | Dosimeter based on a gas electron multiplier for dose measurements of therapeutic radiation |

| KR100784196B1 (ko) | 2005-12-16 | 2007-12-10 | 한창희 | 일차원 기체전자증폭 디지털 영상화 방사선 검출장치 및 그제어방법 |

| FR2912837B1 (fr) * | 2007-02-20 | 2009-05-22 | Ensmse | Dispositif de multiplication des electrons et systeme de detection de rayonnements ionisants |

| JP4613319B2 (ja) * | 2007-03-28 | 2011-01-19 | 大学共同利用機関法人 高エネルギー加速器研究機構 | ガス放射線検出器 |

| GB0723487D0 (en) * | 2007-11-30 | 2008-01-09 | Micromass Ltd | Mass spectrometer |

| JP5335893B2 (ja) * | 2008-04-14 | 2013-11-06 | ヨーロピアン オーガナイゼーション フォー ニュークリア リサーチ | ガス電子増倍管の製造方法 |

| EP2110845B1 (fr) * | 2008-04-16 | 2011-10-05 | Casimir Bamberger | Méthode d'imagerie de spectrométrie de masse et son application dans un dispositif |

| US8853643B2 (en) * | 2009-02-12 | 2014-10-07 | CERN—European Organization for Nuclear Research | Protected readout electrode assembly |

| EP2317538B1 (fr) * | 2009-10-28 | 2017-03-22 | CERN - European Organization For Nuclear Research | Procédé de fabrication d'un espace d'amplification d'un détecteur de particules en avalanche |

| DE102010032215A1 (de) * | 2010-07-26 | 2012-01-26 | Siemens Aktiengesellschaft | Teilchendetektor |

| JP5853370B2 (ja) * | 2011-01-25 | 2016-02-09 | 大日本印刷株式会社 | ガス増幅を用いた放射線検出器 |

| JP5951203B2 (ja) * | 2011-08-26 | 2016-07-13 | 浜松ホトニクス株式会社 | 検出器 |

| JP5912732B2 (ja) * | 2012-03-23 | 2016-04-27 | 国立大学法人 東京大学 | 電子増幅用基板および検出器 |

| US8798234B2 (en) | 2012-03-30 | 2014-08-05 | Elekta Ab (Publ) | Imaging during radiotherapy |

| US9594171B2 (en) | 2012-06-08 | 2017-03-14 | Siemens Aktiengesellschaft | Detector for radiation, particularly high energy electromagnetic radiation |

| JP6206948B2 (ja) | 2012-06-26 | 2017-10-04 | 大学共同利用機関法人 高エネルギー加速器研究機構 | 二次元tofパルス中性子検出器 |

| JP2014170642A (ja) * | 2013-03-01 | 2014-09-18 | Hoya Corp | 電子増幅用基板および電子増幅用基板の製造方法 |

| JP5638664B2 (ja) * | 2013-06-10 | 2014-12-10 | セルン − ヨーロピアン オーガナイゼーション フォー ニュークリア リサーチCERN − European Organization for Nuclear Research | 保護された読み出し電極アセンブリ及びアバランシェ粒子検出器 |

| ES2545685B1 (es) * | 2014-02-11 | 2016-06-30 | Consejo Superior De Investigaciones Cientificas (Csic) | Dispositivo multiplicador de electrones micromecanizado y para detección de partículas ionizantes,sistema de detección de partículas ionizantes y método de fabricación del dispositivo |

| US9739892B2 (en) | 2014-04-09 | 2017-08-22 | Phenix Medical Llc | Fast, high-rate, position-sensitive absolute dosimeter for ion beam therapy |

| JP5973513B2 (ja) * | 2014-09-17 | 2016-08-23 | 株式会社フジクラ | イオンフィルターの製造方法 |

| JP6027584B2 (ja) * | 2014-09-17 | 2016-11-16 | 株式会社フジクラ | ガス電子増幅器用イオンフィルター |

| JP6027583B2 (ja) * | 2014-09-17 | 2016-11-16 | 株式会社フジクラ | イオンフィルター及びその製造方法 |

| US10453661B2 (en) | 2015-12-02 | 2019-10-22 | Fujikura Ltd. | Ion filter and method of manufacturing ion filter |

| US10825939B2 (en) | 2016-01-07 | 2020-11-03 | The Research Foundation For The State University Of New York | Selenium photomultiplier and method for fabrication thereof |

| GB2550578A (en) * | 2016-05-23 | 2017-11-29 | Univ Warwick | Charge carrier multiplier structure |

| FR3062926B1 (fr) | 2017-02-15 | 2019-04-12 | Universite Claude Bernard Lyon 1 | Detecteur gazeux de particules elementaires |

| KR102166734B1 (ko) * | 2019-02-19 | 2020-10-16 | 주식회사 메카로 | Gem 검출기 및 그 배경 노이즈 제거 방법 |

| CN111239792B (zh) * | 2020-01-15 | 2023-05-05 | 广西大学 | 一种侧窗式穿越辐射气体探测器 |

| US11201041B2 (en) * | 2020-02-03 | 2021-12-14 | Baker Hughes Holdings Llc | Gas electron multiplier board photomultiplier |

| CN113539780A (zh) * | 2020-04-10 | 2021-10-22 | 群创光电股份有限公司 | 气体电子倍增器复合膜及包含其的气体电子倍增器和检测装置 |

| GB202019563D0 (en) | 2020-12-11 | 2021-01-27 | Univ Liverpool | Appratus and method |

| JPWO2023095576A1 (fr) * | 2021-11-25 | 2023-06-01 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IL93969A (en) * | 1990-04-01 | 1997-04-15 | Yeda Res & Dev | Ultrafast x-ray imaging detector |

| DE4423338A1 (de) * | 1994-06-20 | 1995-12-21 | Betaray Kubisiak Gmbh | Detektor für eine Meßvorrichtung |

| FR2727525B1 (fr) * | 1994-11-25 | 1997-01-10 | Centre Nat Rech Scient | Detecteur de rayonnements ionisants a microcompteurs proportionnels |

| FR2739941B1 (fr) * | 1995-10-11 | 1997-11-14 | Commissariat Energie Atomique | Detecteur de position, a haute resolution, de hauts flux de particules ionisantes |

| CA2245862A1 (fr) * | 1996-02-12 | 1997-08-14 | George C. Giakos | Detecteurs multimedias pour imagerie medicale |

-

1998

- 1998-10-16 JP JP52315999A patent/JP4264984B2/ja not_active Expired - Lifetime

- 1998-10-16 ES ES98956848T patent/ES2277395T3/es not_active Expired - Lifetime