EP0940550A2 - Eckverbindungsvorrichtung zum Verbinden einer ersten Zarge mit einer zweiten Zarge sowie damit versehener Zargenrahmen - Google Patents

Eckverbindungsvorrichtung zum Verbinden einer ersten Zarge mit einer zweiten Zarge sowie damit versehener Zargenrahmen Download PDFInfo

- Publication number

- EP0940550A2 EP0940550A2 EP99104285A EP99104285A EP0940550A2 EP 0940550 A2 EP0940550 A2 EP 0940550A2 EP 99104285 A EP99104285 A EP 99104285A EP 99104285 A EP99104285 A EP 99104285A EP 0940550 A2 EP0940550 A2 EP 0940550A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- frame

- corner

- tab

- frames

- connection device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/96—Corner joints or edge joints for windows, doors, or the like frames or wings

- E06B3/9604—Welded or soldered joints

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B1/00—Border constructions of openings in walls, floors, or ceilings; Frames to be rigidly mounted in such openings

- E06B1/04—Frames for doors, windows, or the like to be fixed in openings

- E06B1/52—Frames specially adapted for doors

- E06B1/526—Frames specially adapted for doors for door wings that can be set up to open either left or right, outwards or inwards, e.g. provided with grooves for easily detachable hinges or latch plates

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B1/00—Border constructions of openings in walls, floors, or ceilings; Frames to be rigidly mounted in such openings

- E06B1/56—Fastening frames to the border of openings or to similar contiguous frames

- E06B1/60—Fastening frames to the border of openings or to similar contiguous frames by mechanical means, e.g. anchoring means

- E06B1/6092—Fastening door frames to the floor or ceiling; Jamb feet; Cross members uniting the jamb feet

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/96—Corner joints or edge joints for windows, doors, or the like frames or wings

- E06B3/988—Corner joints or edge joints for windows, doors, or the like frames or wings specially adapted for sheet metal frame members with an open U-shaped cross-section

Definitions

- the invention relates to a corner connecting device for connecting a first Frame with a second frame, in order to create a frame corner especially for To create fire doors suitable frame.

- the Invention a frame frame provided with such corner connections for a door, in particular a fire door, with two side frames and two with the side frames connected horizontally via these corner connections Frames.

- So fire protection doors to protect well from smoke and fire, tight and stable close, fire protection door frame generally have next to the side frames and the top frame also a bottom or bottom frame to be anchored in the floor on.

- This fourth frame stabilizes the frame frame as a whole and is also often provided with a stop bar that the door when the door leaf is in contact overall stabilized and tightly sealed, but depending on the installation situation is often either the stop bar or the entire bottom or bottom frame undesirable.

- corner connections of such known frame frames are so far realizes that the frames forming a frame corner along their abutting End edges are welded together, which - especially with galvanized Materials - is complex and expensive.

- corner connections can be made do not loosen so that the entire frame has to be cut if e.g. the Lower frame is undesirable.

- the invention has for its object a corner connection of the beginning to create the type mentioned, the easy and inexpensive formation of a corner connection of frames allowed, which is preferably easier when needed than before is separable again.

- the at least one tab is preferably made in one piece with the first frame, for example, it is released from the end area of the first frame.

- the tab leaves easy to handle on the one hand because they are easy to create the corner connection required position can be bent and also easily a welding pressure or the like can be exercised on the tab. In addition, no need to be exact positioning weld seam are applied, the tabs are rather spot welded. On the other hand, one can at least one Slightly loosen the corner connection device with the corner connection device, because only the flap and not the entire frame, for example by sawing or Flexen or the like must be cut.

- Particularly preferred for the selective, i.e. in limited local Design held welded connections between the at least one Tab and the second frame are spot welds or weld spots or also short weld seams or the like.

- weld nipples the locations of weld spots to be attached to one on the second frame Define the part of the tab to be created. These weld nipples are preferred made by embossing. Preferably, on each tab, i.e. on the part of the Tab to be attached to the second frame, two weld nipples, one in each diagonally opposite corner areas. In yet When not welded, the tabs are advantageously aligned so that they despite the weld nipples, the frames fit together easily Allow frame corner; e.g.

- first and / or second tabs are provided, wherein the first tab parallel areas and the second tab abutting each other at the corner Connect areas of the frames.

- the first tab is configured in a Z-shape, so that it can also rest against the parallel area of the second frame, if this area is not only parallel but in the same plane to it connecting area of the first frame, from which the first tab extends, should run.

- the second tab extends angled from the corner adjoining area of the first frame.

- the parallel or corner Areas of the two frames can, for example, first and second legs of Be angles or angular ranges that are formed on the frames.

- the at least one tab extends according to a preferred embodiment of the Invention from a horizontal frame to overlap with a Side frame to be spot welded. In such a case, it corresponds to the horizontal frame of the first frame (with the tabs) and the one on it The side frame to be connected forms the second frame. But it is also an embodiment conceivable in which one or more or all of the tabs in particular integrally formed from the side frame to be welded to the Extend horizontal frame.

- the tabs are preferably only on one, preferably an angle first partial element of a horizontal frame consisting of two partial elements provided, in particular on the first sub-element as an additional profile formed second sub-element weldable or otherwise connected is. Then only the angle is welded to the side frames via the tabs. At the installation location, it can then be decided whether the frame is to be arranged horizontally the way it is to be installed, whether the additional strip or the additional profile is to be canceled, then the angle on the side frames over the Tabs remains attached, or whether the angle and thus the entire horizontal frame to be arranged should be removed. In the latter case, the tabs are through Saws or the like severed.

- additional predetermined breaking points at the transitions between the tabs and the frame to be arranged horizontally for example Hole or slot embossing or punching or other perforation or the like may be provided.

- An advantageous embodiment of the frame frame according to the invention which Frame corners formed by corner connecting devices according to the invention has, is characterized by predetermined breaking points in the area of at least one of the frames to be arranged horizontally, which break off at least one for certain installation situations of unwanted frame part from the rest of the Allow frame frames.

- the predetermined breaking points are preferably in the area arranged the frame that is to serve as the lower frame.

- Cancelable Frame parts can be a stop bar, an additional profile or other parts of the frame to be arranged horizontally if this is undesirable in the area of the floor are.

- the frame frame designed according to this embodiment of the invention in large quantities can be produced and by canceling unwanted parts of the Horizontal frame along the predetermined breaking points of the very specific installation situation in be adjusted in a simple manner.

- the stop bar to remove the respective lower frame. This is achieved particularly simply in that at least one of the two is horizontal frames to be arranged, in particular, of course, those that serve as lower frames should be formed from the two sub-elements.

- the first sub-element is by means of Tabs connected to the side frames and thus increases the stability of the frame.

- the second part element in particular the stop bar, is attached to the first sub-element by means of punctiform connections and thus as one breakable frame part formed.

- the connection between the two sub-elements must be firm on the one hand, on the other hand, the second sub-element should, if necessary however, can be easily removed. Therefore, on one of the sub-elements Creation of points of attack for spot welds or weld spots or also for short weld seams or the like or other point connections produced between the sub-elements, for example by an embossing stamp Expressions are provided in the area of an edge in the area of the connection point reduce the material thickness.

- the partial elements partially overlap, the point connections at the adjacent partial element Edge of the overlapping partial area or overlapping area of the second partial element are trained. This creates a connection through the overlap has a particular strength, but on the other hand by breaking into a suitable direction can be easily broken.

- An embodiment is particularly advantageous in which the expressions are directly on the Edge are provided, the material then being embossed over the edge is driven out and so the overlap area, but also the lever to Canceling the second sub-element is enlarged.

- the weld spots or The like can then still outside the other overlap area be arranged in front of the edge of the second partial element.

- it is particularly easy to break off the second partial element by bending it over.

- a particularly advantageous embodiment of the invention is in a frame realized that is suitable for both right and left hinged doors.

- a frame is made with identical top and bottom frames and delivered to the installation site, so that changing the stop side of the doors is easy can be done by turning the frame around.

- the one door to be hung on the right serving as upper frame, horizontally arranged frame serves as a bottom frame for a door to be hinged on the left and vice versa.

- Such a Frame frame that can be used for various installation purposes is according to the advantageous Embodiment of the invention adaptable to different installation situations, if the predetermined breaking points are provided on both horizontally arranged frames along which the second, which is undesirable for certain installation situations Sub-elements can be broken off from the rest of the horizontal frame.

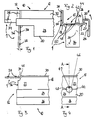

- FIG. 1 shows a frame 10 to be arranged horizontally as a first frame, which both as the top and bottom and bottom frames of a frame frame is suitable for a fire door that can be used on the left and right.

- From the horizontal Frame 10 to be arranged shows only one end region 12, which has a second Frame in the form of a side frame 14 by means of a corner connecting device 1 a frame corner 16 of the frame frame shown in FIG. 5 can be connected.

- horizontally Frame 10 is essentially Z-shaped in cross-section.

- the horizontal Frame 10 to be arranged consists of two sub-elements, namely an angle 18 and an additional profile 20 that overlaps with a wide strip on a first leg 22 of the angle 18 is arranged and thus has an overlap area 24.

- the remaining area of the additional profile 20 has a Z-shaped reinforcing stop profile 26 and an adjoining one, as a stop bar 28 for the Fire protection door shown flange formed on.

- a sealing groove 27 for receiving a door seal (not shown) educated.

- Both the first leg 22 of the bracket 18 and that for fastening on the masonry bordering a door opening or the corresponding Bottom region provided second legs 30 have at the outermost end 32 of the End portion 12 each have a tab 34, 36, the parts of the corner connecting device 1st are.

- both tabs 34, 36 are each in the vicinity of two diagonally opposite Corners welded into the corners 38.

- a first tab 34 is through Notching of the second leg 30 is formed. That is, the first tab 34 is one in the Width of the extension of this second leg 30, which is somewhat less developed first tab 34 is, as FIG. 3 in connection with FIG. 2 shows in more detail, in a Z-shape bent towards the additional profile 20 in such a way that they are approximately, however not quite parallel to the first leg 30.

- the second tab 36 is also by notching the first Leg 22 is formed and is thus an extension made smaller in width this second leg 22. As can be seen from FIG. 1, the second tab 36 bent down but not by a full 90 °. The reason why the first tab 34 not completely parallel to the second leg 30 and the second tab 36 is not runs at a right angle to the first leg 22 is that the tabs 34, 36 on corresponding partial areas of the side frame 14 to form the frame corner 16 should be concerned with what is exactly parallel or right-angled position by the Welding nipples 38 would be difficult.

- the angle 18 and the additional profile 20 are at an edge 44 of the overlap area 24 connected in such a way that predetermined breaking points 42 are created, at which the two parts or partial elements 18, 20 can be broken apart.

- the edge 44 is at some connection points 46 (see FIG. 4) by means of a Embossing stamp has been processed in such a way that embossing points (impressions, characteristics) or expressions 48 are formed.

- embossing points impressions, characteristics

- the material is through the embossing stamp of the additional profile 20 has been pressed so that it is 46 at these junctions is made thinner.

- the embossing also causes the material to go over the edge 44 protrudes. Selective connections are thus pressed out on the edge 44 at these Connection points 46 through two first welding spots 50 as in FIG.

- a first weld spot 50 as shown in FIG. 9, per joint 46 created.

- welding spots 50 one can also selective welding in the form of a short weld seam may be provided.

- a long hump 47 is provided, for example, as described in DIN 8519.

- punctiform connections or welding points 50 are the predetermined breaking points 42 trained. Should a frame frame without stop bar 28 on the horizontal to be arranged frame 10 are provided, the additional profile 20 through Bending in the Z direction relative to the angle 18 broken off from it, whereby the break at the predetermined breaking points 42, i.e. at the first welding spots 50 or the areas of the expressions 48 indicated by hatching in FIG. 2.

- the welding nipples 38 are used to create second welding spots 72 Welding the tabs 34, 36 provided on the side frame 14.

- the side frame 14 is, as shown in Fig. 6, very similar in cross section to that Frame 10 to be arranged horizontally, unlike this, however, from a single piece for example formed by bending, folding or rolling. Accordingly, the Side frame 14 comprises a first leg 56 and a second leg 60 existing angle range 58, with an additional on the first leg 56 Web 62 is arranged.

- a Z-shaped closes Reinforcement profiling or stop profiling 64 with a sealing groove 65 on.

- the stop profile 64 also has the stop profile, by the way 26 a rear stop, which is used to fix the frame is useful on masonry.

- the stop profiling 64 goes to her Angular range 58 opposite end into a stop bar 66.

- the first leg 56 forms the Z-shaped one Stop profiling 64 and the stop bar 66 to form the Frame corner 16 provided end 68 a recess 70 into which the horizontal frame 10 to be arranged can engage with its stop bar 28.

- the stop bar 28 of the frame 10 to be arranged horizontally has such a recess for engaging the corresponding part of the side frame 14.

- the horizontal frame 10 is applied to the side frame 14 as shown, the stop bar 28 in the Recess 70 engages so that there is no gap on the part of the stop bars 66, 28 remains.

- the first tab 34 is attached to the welding nipples 38 Spot welds 72 on the second leg 60 of the side frame 14 connected.

- the second tab 36 is attached to the welding nipples 38 Weld spots 72 are connected to the first leg 56 of the side frame 14.

- the first tab 34 of the corner connecting device 1 thus serves to be parallel to one another to connect to be arranged second legs 30 and 60.

- the second tab 36 of the corner connecting device 1 provides a corner connection the first legs 22, 56 of the frames 10 and 14.

- the final position of the tabs 34, 36 parallel or at right angles to the respective leg 30 or 22 of the angle 18 is only achieved during welding. Before welding, the tabs 34 and 36 on the legs 60 and 56 of the side frame 14 only at the tips of the weld nipples 38 or one of them.

- the corner connection 54 thus created can be separated again by sawing or flexing are, which, if necessary, the entire horizontally arranged frame 10 of the The rest of the frame can be removed.

- a breakable frame part in the form of the additional profile 20th provided on the frame 10 to be arranged horizontally, which at the predetermined breaking points 42 of the remaining remainder of the frame 10 to be arranged horizontally, i.e. the angle 18, can be canceled.

- connections 54 and 46 explained in more detail here is a frame for A fire protection door that can be used on the right and left can be realized, in which all connections can be produced by spot welding. Especially through the Spot welds or first welding spots 50 or by on the long boss 47 executed short welds between the two sub-elements 18, 20 of the frame 10 predetermined breaking points 42 are created, at which frame parts of the so spot-welded frame frames can be broken off if necessary.

- the selective Weldings are also galvanized materials from which the frames 14, 10 preferably consist firmly connectable. With galvanized materials For example, arc welding only leads to unsatisfactory connections. At point expansion of the welds, it is particularly easy to apply high pressures to exercise on the materials to be welded for welding, since comparatively low forces have to be applied.

- a corner connection device (1) in which a first, in particular a Frame (10) to be arranged horizontally is provided with at least one tab (34, 36) which extends from the first frame (10) in such a way that it abuts a second frame, in particular a side frame (14) with this frame (14) for forming the frame corner (16) can be spot welded.

- a first tab (34) is parallel (20, 30) and a second flap (36) corner-abutting areas (22, 56) of the Connect the two frames (10, 14) together.

Landscapes

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Mechanical Engineering (AREA)

- Joining Of Corner Units Of Frames Or Wings (AREA)

- Mirrors, Picture Frames, Photograph Stands, And Related Fastening Devices (AREA)

- Patch Boards (AREA)

- Photovoltaic Devices (AREA)

- Body Structure For Vehicles (AREA)

- Special Wing (AREA)

- Eyeglasses (AREA)

- Adornments (AREA)

Abstract

Description

- Fig. 1

- eine Vorderansicht eines Endbereichs einer horizontal anzuordnenden, wahlweise als Ober- oder Unterzarge zu verwendenden Zarge,

- Fig. 2

- eine linke Seitenansicht der Zarge gemäß Fig. 1,

- Fig. 3

- eine Draufsicht auf den Endbereich der Zarge nach Fig. 1,

- Fig. 4

- eine Draufsicht auf einen mittleren Bereich der Zarge nach Fig. 1,

- Fig. 5

- eine teilweise weggebrochene Vorderansicht auf einen Eckbereich eines Zargenrahmens, in welchem Eckbereich die horizontal anzuordnende Zarge nach Fig. 1 mit einer Seitenzarge verbunden ist,

- Fig. 6

- eine Schnittansicht auf die Seitenzarge von Fig. 5,

- Fig. 7

- eine Rückansicht des in Fig. 5 gezeigten Endabschnitts der Seitenzarge, jedoch in mit der horizontal anzuordnenden Seitenzarge noch nicht verbundenen Zustand,

- Fig. 8

- eine linke Seitenansicht auf die Seitenzarge, wie man sie aus Fig. 7 durch Ansicht von unten und aus Fig. 5 (ohne die horizontal anzuordnende Zarge) durch Ansicht von links erhalten würde, und

- Fig. 9

- eine Querschnittsansicht durch eine horizontal anzuordnende Zarge in einer zweiten Ausführungsform.

- 1

- Eckverbindungsvorrichtung

- 10

- horizontal anzuordnende Zarge (= erste Zarge)

- 12

- Endbereich

- 14

- Seitenzarge (= zweite Zarge)

- 16

- Zargenecke

- 18

- Winkel (= erstes Teilelement)

- 20

- Zusatzprofil (= zweites Teilelement)

- 22

- erster Schenkel

- 24

- Überlappbereich

- 26

- Anschlagsprofilierung

- 27

- Dichtungsnut

- 28

- Anschlagleiste

- 30

- zweiter Schenkel

- 32

- Ende

- 34

- erste Lasche

- 36

- zweite Lasche

- 38

- Schweißwarzen

- 40

- Schulter

- 42

- erste Sollbruchstelle

- 44

- Kante

- 46

- Verbindungsstelle

- 47

- Langbuckel

- 48

- Ausdrückungen

- 50

- Schweißpunkte

- 52

- zweite Sollbruchstelle

- 54

- Eckverbindung

- 56

- erster Schenkel

- 58

- Winkelbereich

- 60

- zweiter Schenkel

- 62

- Steg

- 64

- Z-förmige Verstärkungsprofilierung

- 65

- Dichtungsnut

- 66

- Anschlagleiste

- 68

- Ende

- 70

- Ausnehmung

- 72

- Schweißpunkte

- Z

- Umbiegerichtung

Claims (15)

- Eckverbindungsvorrichtung zum Verbinden einer ersten Zarge (10) mit einer zweiten Zarge (14), um so eine Zargenecke (16) eines insbesondere für Feuerschutztüren geeigneten Zargenrahmens zu schaffen,

gekennzeichnet durch wenigstens eine Lasche (34, 36), die sich von der ersten Zarge (10) aus vorzugsweise einstückig mit dieser ausgebildet so erstreckt, daß sie punktuell an der zweiten Zarge (14) verschweißbar ist. - Eckverbindungsvorrichtung nach Anspruch 1,

dadurch gekennzeichnet,

daß die Stellen, an denen die wenigstens eine Lasche (34, 36) punktuell an die zweite Zarge (14) zu verschweißen ist, durch in noch unverschweißten Zustand an einem an der zweiten Zarge (14) anzulegenden Teil der Lasche (34, 36) angeordnete vorzugsweise durch Prägung hergestellte Schweißwarzen (38) definiert sind. - Eckverbindungsvorrichtung nach Anspruch 2,

dadurch gekennzeichnet,

daß die wenigstens eine Lasche (34, 36) in noch unverschweißtem Zustand so ausgerichtet ist, daß sie trotz der Schweißwarzen (38) eine Zusammenpassung der Zargen (10, 14) zu der zu verschweißenden Zargenecke (16) zuläßt, wobei sie vorzugsweise mit den Schweißwarzen (38) die zweite Zarge (14) berührt. - Eckverbindungsvorrichtung nach einem der Ansprüche 1 bis 3

gekennzeichnet durch eine erste Lasche (34) zum Verbinden paralleler Bereiche der Zagen (10, 14) - insbesondere zum Verbinden parallel zueinander anzuordnender zweiter Schenkel (30, 60) von Winkeln (18) oder Winkelbereichen (58) der Zargen (10, 14) -, wobei sich die erste Lasche (34) von dem parallelen Bereich (30) der ersten Zarge (10) aus Z-förmig so erstreckt, daß sie beim Zusammenpassen der Zargen (10, 14) zu der zu verschweißenden Zargenecke (16) an dem parallelen - vorzugsweise in dergleichen Ebene wie der parallele Bereich (30) der ersten Zarge (10) anzuordnenden - Bereich (60) der zweiten Zarge (14) anliegt. - Eckverbindungsvorrichtung nach einem der Ansprüche 1 bis 4

gekennzeichnet durch eine zweite Lasche (36) zum Verbinden über Eck anstoßender Bereiche der Zagen (10, 14) - insbesondere zum Verbinden über Eck zueinander angeordneter erster Schenkel (22, 56) von Winkeln (18) oder Winkelbereichen (58) der Zargen (10, 14)-, wobei sich die zweite Lasche (34) von dem über Eck anstoßenden Bereich (22) der ersten Zarge (10) aus abgewinkelt so erstreckt, daß sie beim Zusammenpassen der Zargen (10, 14) zu der zu verschweißenden Zargenecke (16) an dem über Eck anstoßenden Bereich (56) der zweiten Zarge (14) anliegt. - Eckverbindungsvorrichtung nach Anspruch 4 und Anspruch 5

dadurch gekennzeichnet,

daß sie sowohl die erste (34) als auch die zweite Lasche (36) aufweist. - Eckverbindungsvorrichtung nach einem der Ansprüche 1 bis 6,

dadurch gekennzeichnet,

daß die wenigstens eine Lasche (34, 36) zwei Schweißwarzen (38) aufweist, die an diagonalen Eckbereichen des an der zweiten Zarge (14) anzulegenden Teils der Lasche (34, 36) angeordnet sind. - Eckverbindungsvorrichtung nach einem der Ansprüche 1 bis 7,

dadurch gekennzeichnet,

daß eine der beiden Zargen, vorzugsweise die erste Zarge, eine horizontal anzuordnenden Zarge (10) und die andere Zarge, vorzugsweise die zweite Zarge, eine Seitenzarge (14) des Zargenrahmens ist. - Eckverbindungsvorrichtung nach Anspruch 8,

dadurch gekennzeichnet,

daß die horizontal anzuordnende Zarge (10) aus zwei Teilelementen (18, 20) zusammengesetzt ist, von denen ein erstes Teilelement (18) mittels der wenigstens einen Lasche (34, 36) mit der Seitenzarge (14) verbindbar ist und ein vorzugsweise eine Anschlagleiste (28) für die Feuerschutztür aufweisendes zweites Teilelement (20) über Sollbruchstellen (42) an dem ersten Teilelement (18) befestigt ist und so als abbrechbares Zargenteil ausgebildet ist. - Eckverbindungsvorrichtung nach Anspruch 9,

dadurch gekennzeichnet,

daß das erste Teilelement ein Winkel (18) mit zwei Schenkeln (22, 30) ist, an dessen erstem Schenkel (22) das zweite Teilelement in Form eines Zusatzprofils (20) mittels der Schweißpunkte (50) abbrechbar geschweißt ist. - Eckverbindungsvorrichtung nach Anspruch 10 und Anspruch 6,

dadurch gekennzeichnet,

daß die erste Lasche (34) einstückig mit dem zweiten Schenkel (30) des Winkels (18) und die zweite Lasche (36) einstückig mit dem ersten Schenkel (22) des Winkels (18) ausgeführt ist. - Zargenrahmen für eine Tür, insbesondere eine Feuerschutztür, mit zwei Seitenzargen (14) und zwei mit den Seitenzargen (14) über Eckverbindungen (54) verbundenen horizontal anzuordnenden Zargen (10),

dadurch gekennzeichnet,

daß die Eckverbindungen (54) jeweils durch eine Eckverbindungsvorrichtung (1) nach einem der Ansprüche 1 bis 11 gebildet sind. - Zargenrahmen nach Anspruch 12,

dadurch gekennzeichnet,

daß er für eine wahlweise rechts oder links anschlag- und/oder verwendbare Feuerschutztür verwendbar ist, wobei beide horizontal anzuordnenden Zargen (10) jeweils aus zwei Teilelementen (18, 20) mit Sollbruchstellen (42) bildenden punktuellen Verbindungen dazwischen zusammengesetzt sind. - Zargenrahmen nach Anspruch 13,

dadurch gekennzeichnet,

daß sich die Teilelemente (18, 20) teilweise überlappen, wobei die punktuellen Verbindungen an der an dem ersten Teilelement (18) anliegenden Kante (44) eines überlappenden Teilbereichs oder Überlappbereichs (24) des zweiten Teilelements (20) ausgebildet sind. - Zargenrahmen nach Anspruch 14,

dadurch gekennzeichnet,

daß die punktuellen Verbindungen zwischen den Teilelementen (18, 20) Schweißverbindungen, insbesondere Schweißpunkte (50), sind, die an - vorzugsweise durch Prägung - an der Kante (44) des zweiten Teilelements (20) hergestellten Ausdrückungen (48) angreifen, und daß jede oder zumindest einige der Ausdrückungen (48) derart ausgebildet ist, daß ausgeprägtes Material über die Kante (44) hinaus ausgewichen ist, wobei das so ausgeprägte Material jeweils als jenseits der Kante (44) angeordnete Basis für eine der punktuellen Verbindungen (50) zwischen den Teilelementen (18, 20) dient.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE29803814U | 1998-03-04 | ||

| DE29803814U DE29803814U1 (de) | 1998-03-04 | 1998-03-04 | Eckverbindungsvorrichtung zum Verbinden einer ersten Zarge mit einer zweiten Zarge sowie damit versehener Zargenrahmen |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0940550A2 true EP0940550A2 (de) | 1999-09-08 |

| EP0940550A3 EP0940550A3 (de) | 2000-10-04 |

| EP0940550B1 EP0940550B1 (de) | 2004-06-16 |

Family

ID=8053585

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99104285A Expired - Lifetime EP0940550B1 (de) | 1998-03-04 | 1999-03-03 | Zargenrahmen und Herstellverfahren hierfür |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0940550B1 (de) |

| AT (1) | ATE269479T1 (de) |

| DE (2) | DE29803814U1 (de) |

| ES (1) | ES2218891T3 (de) |

| PL (1) | PL191991B1 (de) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100414645B1 (ko) * | 2000-04-12 | 2004-01-13 | 김찬근 | 스포트 크린칭으로 결합된 출입용 도어의 문틀결합구조 |

| EP1550786A2 (de) | 2003-12-30 | 2005-07-06 | Hörmann KG Brandis | Zarge, insbesondere für eine Wendetür |

| GB2442733A (en) * | 2006-10-11 | 2008-04-16 | Graham Holmes Astraseal Ltd | Fire resistant frame assembly and fire door |

| DE102004007217B4 (de) * | 2003-12-30 | 2008-10-02 | Hörmann Kg Brandis | Wendezarge für eine Feuerschutztür |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2298063B1 (es) | 2006-10-18 | 2009-07-03 | Antonio Murcia Alonso | Elemento de union angular para carpinteria metalica. |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE7021488U (de) * | 1970-06-09 | 1970-09-03 | Zanker Metallbau Gmbh | Fenster- und tuerzargen aus gekanteten blechen. |

| DE2062796C3 (de) * | 1970-12-19 | 1980-08-21 | Eisenwerk Kuenstler Kg, 8750 Aschaffenburg | Eckverbindung zweier verzinkter Einzelprofile eines Fensterrahmens o.dgl. und Verfahren zur Herstellung |

| DE2539356A1 (de) * | 1975-09-04 | 1977-03-24 | Steinau Kg | Zargenprofil, insbesondere fuer feuerschutztueren |

| DE2654822C3 (de) * | 1976-12-03 | 1981-09-17 | Alois 8411 Winkerling Schmid | Tür, insbesondere Stalltür |

| DE2821235C2 (de) * | 1978-05-16 | 1980-01-24 | Hoermann Kg Amshausen, 4803 Steinhagen | Türzarge |

| DE2947509A1 (de) * | 1979-11-24 | 1981-05-27 | Podszuck Gmbh & Co Kg, 2300 Kiel | Tuer mit einem seitlich und oben ueberfaelzten und unten stumpfen tuerblatt |

| DE29700542U1 (de) * | 1997-01-14 | 1997-02-20 | Novoferm GmbH, 46459 Rees | Feuerschutztür |

-

1998

- 1998-03-04 DE DE29803814U patent/DE29803814U1/de not_active Expired - Lifetime

-

1999

- 1999-03-03 PL PL331728A patent/PL191991B1/pl unknown

- 1999-03-03 ES ES99104285T patent/ES2218891T3/es not_active Expired - Lifetime

- 1999-03-03 AT AT99104285T patent/ATE269479T1/de active

- 1999-03-03 EP EP99104285A patent/EP0940550B1/de not_active Expired - Lifetime

- 1999-03-03 DE DE59909710T patent/DE59909710D1/de not_active Expired - Lifetime

Non-Patent Citations (1)

| Title |

|---|

| None |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR100414645B1 (ko) * | 2000-04-12 | 2004-01-13 | 김찬근 | 스포트 크린칭으로 결합된 출입용 도어의 문틀결합구조 |

| EP1550786A2 (de) | 2003-12-30 | 2005-07-06 | Hörmann KG Brandis | Zarge, insbesondere für eine Wendetür |

| DE102004007217B4 (de) * | 2003-12-30 | 2008-10-02 | Hörmann Kg Brandis | Wendezarge für eine Feuerschutztür |

| GB2442733A (en) * | 2006-10-11 | 2008-04-16 | Graham Holmes Astraseal Ltd | Fire resistant frame assembly and fire door |

Also Published As

| Publication number | Publication date |

|---|---|

| DE59909710D1 (de) | 2004-07-22 |

| ES2218891T3 (es) | 2004-11-16 |

| PL191991B1 (pl) | 2006-07-31 |

| ATE269479T1 (de) | 2004-07-15 |

| EP0940550B1 (de) | 2004-06-16 |

| PL331728A1 (en) | 1999-09-13 |

| EP0940550A3 (de) | 2000-10-04 |

| DE29803814U1 (de) | 1999-07-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3803731A1 (de) | Kunststoffabdeckung fuer eine rohrleitung | |

| EP2783437B1 (de) | Montageschiene für den innenausbau eines schaltschrankgehäuses | |

| EP0875084B1 (de) | Vorrichtung zum elektrisch leitenden verbinden des rahmengestells oder des schrankkorpus eines schaltschrankes mit der türe | |

| EP0940550B1 (de) | Zargenrahmen und Herstellverfahren hierfür | |

| EP0940547B1 (de) | Zargenrahmen für eine Tür, insbesondere eine Feuerschutztür | |

| DE2460402B2 (de) | Ausstellvorrichtung für Drehkippflügel von Fenstern, Türen o.dgl. | |

| EP1076793B1 (de) | Kombination aus einem verbindungselement und zwei länglichen profilteilen | |

| CH664788A5 (de) | Vorrichtung zum verbinden von zwei aneinanderstossenden daemmplatten. | |

| DE4408346A1 (de) | Türflügel für ein Gebäude o. dgl. und Verfahren zum Herstellen eines Türflügels | |

| EP0699815B1 (de) | Klemmvorrichtung zum Befestigen eines Beschlagteils und Verfahren zur Herstellung einer derartigen Klemmvorrichtung | |

| EP0438046B1 (de) | Eckverbinder für Zargen u.dergl. | |

| DE3346624A1 (de) | Tuerfutter aus metall, profilblechstueck und verfahren zu seiner herstellung | |

| DE3500423A1 (de) | Scharnier, insbesondere fuer moebel | |

| DE2431367C2 (de) | Türzarge aus Metall | |

| WO1993011978A1 (de) | Wischarm, insbesondere zur reinigung von scheiben an kraftfahrzeugen | |

| EP0971161B1 (de) | Eckverbindung für die abgekanteten Wandflansche eines im Querschnitt rechwinkeligen Blechkanalschusses | |

| DE19845169C1 (de) | Verfahren zur Fertigung eines Profilschenkels | |

| WO2003000453A1 (de) | Verfahren zur herstellung von lamellenpaketen für verstellbare lenksäulen | |

| DE2821235C2 (de) | Türzarge | |

| EP0426950B1 (de) | Blechkanalformstück | |

| DE2709786C2 (de) | Fensterrahmen, Türrahmen o.dgl. mit einem bezüglich des Wärmedurchgangs isolierenden Verbindungselement und Werkzeug zur Herstellung des Fensterrahmens o.dgl | |

| DE19746821C1 (de) | 3D-Bandtasche | |

| DE202007008202U1 (de) | Rahmengestell für einen Schaltschrank und Eckverbinder | |

| DE19700698C1 (de) | Zusammensetzbare Zarge, insbesondere Türzarge | |

| DE1902044C3 (de) | Stoßverbindung für im wesentlichen horizontal angeordnete und miteinander fluchtende Balken eines Bauwerks |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20001023 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AXX | Extension fees paid |

Free format text: SI PAYMENT 20001023 |

|

| 17Q | First examination report despatched |

Effective date: 20030313 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RTI1 | Title (correction) |

Free format text: FRAME AND METHOD FOR MANUFACTURING A FRAME |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: HOERMANN KG BRANDIS |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Extension state: SI |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040616 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040616 Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040616 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040616 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59909710 Country of ref document: DE Date of ref document: 20040722 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040916 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040916 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20040916 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2218891 Country of ref document: ES Kind code of ref document: T3 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 20040616 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050303 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050303 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050331 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050331 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050331 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20050317 |

|

| BERE | Be: lapsed |

Owner name: *HORMANN K.G. BRANDIS Effective date: 20050331 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| BERE | Be: lapsed |

Owner name: *HORMANN K.G. BRANDIS Effective date: 20050331 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20041116 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080303 |

|

| PGRI | Patent reinstated in contracting state [announced from national office to epo] |

Ref country code: IT Effective date: 20110616 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 59909710 Country of ref document: DE Representative=s name: KASTEL PATENTANWAELTE PARTG MBB, DE Ref country code: DE Ref legal event code: R082 Ref document number: 59909710 Country of ref document: DE Representative=s name: KASTEL PATENTANWAELTE, DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20180326 Year of fee payment: 20 Ref country code: IT Payment date: 20180322 Year of fee payment: 20 Ref country code: AT Payment date: 20180320 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20180423 Year of fee payment: 20 Ref country code: DE Payment date: 20180516 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59909710 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 269479 Country of ref document: AT Kind code of ref document: T Effective date: 20190303 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20200721 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20190304 |