EP0901839B1 - Dispositif pour l'application de fluides sur un substrat - Google Patents

Dispositif pour l'application de fluides sur un substrat Download PDFInfo

- Publication number

- EP0901839B1 EP0901839B1 EP98250323A EP98250323A EP0901839B1 EP 0901839 B1 EP0901839 B1 EP 0901839B1 EP 98250323 A EP98250323 A EP 98250323A EP 98250323 A EP98250323 A EP 98250323A EP 0901839 B1 EP0901839 B1 EP 0901839B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- roller

- substrate

- application roller

- shaped body

- application

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C1/00—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating

- B05C1/04—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length

- B05C1/08—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line

- B05C1/0813—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line characterised by means for supplying liquid or other fluent material to the roller

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C1/00—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating

- B05C1/04—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length

- B05C1/08—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line

- B05C1/0821—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line characterised by driving means for rollers or work

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C—APPARATUS FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05C1/00—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating

- B05C1/04—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length

- B05C1/08—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line

- B05C1/0826—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line the work being a web or sheets

- B05C1/083—Apparatus in which liquid or other fluent material is applied to the surface of the work by contact with a member carrying the liquid or other fluent material, e.g. a porous member loaded with a liquid to be applied as a coating for applying liquid or other fluent material to work of indefinite length using a roller or other rotating member which contacts the work along a generating line the work being a web or sheets being passed between the coating roller and one or more backing rollers

Definitions

- the invention relates to a device for applying determinable amounts in particular also viscous liquids on a moving substrate, including one in device length a long-running application roller, an application roller with fluid supplying feeder, one the application roller against the substrate pressing pressing device, which when pressed between the application roller and the Substrate in the running direction of the application roller narrowing feeder gusset forms, and at least one on the substrate, the width of the applied liquid (application width) defines bounding, cooperating with the application role limiting element.

- a device with sealing blocks which is a liquid Limit the (substance) retaining trough space at the front and in the device longitudinal direction slidably arranged to adjust the application width.

- the blocks exist made of a sealing material such as felt. Use this sealing material to touch the blocks a dosing roller forming an applicator roller and a counter-roller.

- the sealing contact system must be such that in particular at Device standstill the liquid to be applied leak-free in the substance trough is held.

- At the counter-roller a substance film is formed, which in the apex area the counter-roller is applied to a train.

- From DE 40 16 662 A is a liquid transfer device with a device known, which prevents liquid from a triangular space between two rollers to the end faces axially propagates. Narrow edges of substance-limiting elements forming sealing plates are in completely sealed Pressure and impact contact with the rollers around the triangular fluid space complete at the front.

- the object of the invention is to improve the quality of application by that each application edge extending in the direction of substrate movement is free from thickening and is formed clean with precise marginal boundary, in particular for the Making coatings, e.g. the painting of webs.

- This cross flow is, preferably in coordination with the structure surface the application roller (metering roller) so small that the application limit on the substrate a narrow, thickening-free outlet edge receives, with in essential straight line is limited.

- the cross flow section can be especially on each longitudinal side of a web, a defined and clearly defined, produce coating-free edge of the track, which can also be very narrow because due to the bead-free outlet edge even with relatively thick coatings edge contamination reliably avoided.

- the limiting shaped body according to the invention can be easily arranged on the application roller, taking special measures that are conventional for the sealing contact of a sealing block on the application roller, a Substrate and / or a counter system are provided, omitted.

- the invention achieved dosing, bead-free application of substance can directly to a web respectively. Instead, the bead-free substance application can also be applied to a transfer roller be provided.

- the surface elements to which Substance is applied referred to as substrates.

- the rimmed from the molding section of the application roller free only in the area of the roller installation on the substrate. It encompasses the Shaped body the application roller suitably about 2/3 to 4/5 of its circumference.

- a particularly advantageous embodiment of the invention is the application roller to arrange in a feed trough forming the feeder and the shaped body together with the application roller in the direction transverse to the substrate surface movable on the Store the dipping trough.

- a particularly preferred design is that the inventive device a magnetic pressing device, wherein the substrate is a magnetic bar is assigned and the application roller is magnetizable to them magnetically to press against the substrate, and that the shaped body captive on the application roller is plugged.

- the magnetic contact pressure can be the Arrange moldings particularly easy. He expediently consists of a non-magnetizable Material such as brass or the like., So that he himself not to contact instead of only being taken on by the applicator role particularly simple and effective way the defined tearing cross flow to the Generating the exact outlet edge is brought about.

- the molded body advantageously by means of a sliding bearing in the Anpreßcardi the application roller parallel direction be slidably mounted.

- a further advantageous embodiment of the invention is that the shaped body at least slightly pivotable about the axis of the application roller by means of the latter is stored.

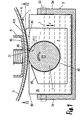

- Fig. 1 and 2 is a device according to the invention with its essential components in Partial views shown.

- the device comprises an application roller in the form of a Dosing roller 1, a long extending in the device longitudinal direction with this device Gegenstromwalze 2, a completely below the roller 2 arranged immersion trough 3, wherein the dosing roll 1 partially immersed in held in the dip tank 3 substance 7, at the two front ends attached to the dosing roll 1, partially immersed in the substance 7 Boundary shaped body 4 and arranged within the roller 2, with this long-extending magnetic bar 5, with the magnetizable dosing 1 magnetically against the roller 2 and thus against a between the dosing roll. 1 and the roller 2 passed through track 6 can be pressed.

- the roller 2 is stationary and rotatable on a machine frame, not shown stored, with their journals are held in machine-stationary pivot bearings. By means of a rotary drive, not shown, the roller 2 in the direction L in Be rotated.

- the end wall 30 is in the device longitudinal direction arranged displaceably, as shown by the double arrow S in Fig. 2 is. In its position, it is arranged by means of a dipping trough 3, shown in phantom Fixing device 33, e.g. by means of the longitudinal walls 34 attacking Screw clamp connection, fixable.

- Each molded part 4 is fitted so far on the end of the metering roller 1, that the roller end wall 12 abuts in a sliding surface on a web surface 42 through the bottom surface of the Plug recess 40 of the molded body 4 is formed.

- the moldings 4 are made of non-magnetizable material, e.g. Brass.

- the Plug recess 40 of the molded body 4 summarizes the end of the metering roll 1 along the end side roller longitudinal section A over the greater part of the roll circumference form and a cross-section same, wherein the fit is provided so that the metering roller 1 with Circumferential sliding system in the plug-in recess 40 remains easily rotatable.

- the cross section of the plug-in receptacle 40 is dimensioned so that the metering roller 1 over about 4/5 of its scope is bordered. Accordingly, the plug recess 40 is at about 1/5 the roll circumference open at the top. Through this opening 48 is the rimmed roller section A up, i. free to counter roll 2 out. The length of the longitudinal opening 48 corresponds to the length A of the enclosed roller longitudinal section.

- Fig. 1 which shows the partial sectional view according to I-I in Fig. 2, the device is in Operating state with magnetically pressed, i. by means of the magnetic bar 5 against the stationary contact roller 2 drawn metering roller 1 can be seen.

- the driven roller 2 runs in the direction of L.

- the drive-less metering roller 1 running in the exemplary embodiment in the opposite direction in direction D

- a liquid (coating substance) 7 to be coated Substrate, namely the web 6, lies in the region of the dipping trough 3 on the roller 2 and is in the direction L by the pressure zone between the roller 2 and the Dosing roller 1 moves.

- the metering roller 1 dives with its lower lateral surface in the Diving trough 3 held substance 7, whereby on the rotating dosing roll. 1 between the filling level and the roller apex a metering layer in the direction of roller rotation D is promoted upwards.

- L and D arises before the contact line of the Roller vertex a substance entrainment gusset 21

- the metering roller 1 facing end face of the molding 4 is flat and is perpendicular to the dosing roll axis 10.

- the molded body end wall is provided with a, in Running direction L and D viewed, located in front of the vertex location wall section provided, which forms a front boundary wall 41, which has a nose portion 411, which in Profile cross section is substantially identical in shape with the feeder gusset 21. It is the Top of the front boundary wall 41, viewed in profile cross-section of Fig. 1, concave curved, in such a way that between the application surface (track 6) and the concave surface remains a slight gap 410. Although this can be very low, e.g. with a gap width of about 0.5 mm between the web 6 and the front boundary wall 41.

- the gap width in the outlet region, that is in the apex area of the roller 1 is greater than in the area in front of it.

- the gap width of the outlet area is particularly expedient 0.5 to 3 mm.

- Nose 411 of the front boundary wall 41 is provided with a chamfered edge or chamfer 49.

- the molded body 4 is only translationally movable in the sliding direction V, while it is not rotatable about its longitudinal axis, so far as it is arranged rotatably.

- the molded body 4 also captively connected to the dosing roll 1. Based on these Measures is achieved that the moldings 4 at the roll ends in the magnetic Tightening the metering roller 1 taken along and only translationally upwards be moved. This results in the pressing and operating state of the device of defined gap 410 between the web 6 and the gap surface 46.

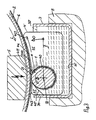

- two moldings 4 'are modified Storage provided. Otherwise, the device corresponds to the embodiment according to Fig. 1 and 2, wherein like reference numerals for corresponding parts and Arrangements are used.

- the dipping trough 3 is in a corresponding bearing recess a support bearing 8 of the device stored.

- the shaped body 4 ' also extends considerably longer in length e, e.g. about the 3.5 times as a formed with a molding wall 41 'gap behind the metering roll 1, viewed in the direction L of the web 6.

- the plug-in receptacle 40 of the molded body 4 ' arranged off-center.

- the installation position according to FIG. 3 is obtained during the working operation of the device, that is, when the metering roller 1 is compressed and the counter-roller 2 is rotating in the direction L. and accordingly in direction D rotating metering roller 1.

- Starting position are the moldings 4 'on the bottom 35 of the dipping trough 3.

- the magnetizable dosing roller 1 against the web. 6 pressed, with the two hanging on the dosing roller 1 molded body 4 'of non-magnetizable Material to be lifted together with the former.

- Each shaped body 4 ' is, as in the embodiment of FIG. 1 and 2, equipped with a longitudinal surface 45 ', which is provided in the area behind the dosing roll 1 and directed against the roller rotation direction D, to optionally from the metering roller 1 to cause a drain of excess substance 7.

- the tilting position shown in Fig. 4 is determined by the fact that the metering roller 1, although magnetic pressed against the web 6 and the counter-roller 2 by means of the magnetic bar 5 is, but the counter roll 2 and the metering roll 1 are at a standstill.

- This Position pivots before the metering roll 1 extending part of the molding 4 'in Direction U down, due to gravity on the front of the metering roller 1 extending part of the molding 4 '.

- In this pivoting movement is the magnetically attracted metering roller 1 in the magnetic field slightly against the direction of rotation L. added.

- the molded body 4 'comes with a flat, an investment element forming Section 462 at the gap edge behind the metering roller 1 for engagement with the web 6, and / or he comes in the lower part of his rear, an investment element forming Vertical edge 463 to the tilting system against the longitudinal wall 34 of the dipping trough 3. This is limits the tilting position, wherein the pivoting movement in the region of the front contact section 461 on, for example relative to the extension length e relative small dimension m remains limited.

- each shaped body 4 'in the device longitudinal direction be arranged displaceable.

- Sliding bearing can then a the bearing part 43 in FIG. 2 corresponding part of Shaped body 4 'with three degrees of freedom in a recess not shown a associated end transverse wall 30 'be held.

Landscapes

- Coating Apparatus (AREA)

- Non-Metallic Protective Coatings For Printed Circuits (AREA)

- Encapsulation Of And Coatings For Semiconductor Or Solid State Devices (AREA)

- Exposure Of Semiconductors, Excluding Electron Or Ion Beam Exposure (AREA)

Claims (17)

- Dispositif d'application de quantités déterminées de matières, en particulier également de liquides visqueux (7), sur un substrat déplacé (6), ledit dispositif comportant un rouleau d'application (1) s'étendant dans la direction longitudinale du dispositif, un dispositif d'amenée alimentant le rouleau d'application (1) en liquide (7), un dispositif de pressage pressant le rouleau d'application (1) contre le substrat (6) et formant lors du pressage entre le rouleau d'application (1) et le substrat (6) un espace d'introduction (21) s'amincissant dans le sens de défilement (D) du rouleau d'application (1), et au moins un élément de limitation limitant de façon définie la largeurs du liquide appliqué (largeur d'application) sur le substrat (6) et coopérant avec le rouleau d'application (1), caractérisé en ce que l'élément de limitation est formé par un corps profilé (4, 4') qui borde, avec une forme et une section identique, le rouleau d'application (1) le long d'une portion longitudinale de rouleau (A) sur une partie de sa périphérie tout conservant la capacité de rotation dudit rouleau d'application de telle sorte que la portion longitudinale de rouleau (A) forme partiellement une portion qui est dirigée transversalement à la direction de déplacement du substrat (6), qui provoque dans cette direction transversale une introduction de liquide, et qui permet de générer un bord (R) limitant la largeur d'apptication.

- Dispositif selon la revendication 1, caractérisé en ce que le corps profilé (4, 4') comporte une paroi limite frontale (41) qui, lorsque l'on regarde en coupe transversale de profil, pénètre dans la région de l'espace d'introduction (21) qui est formée entre le rouleau d'application (1) et le substrat (6).

- Dispositif selon la revendication 1 ou 2, caractérisé en ce que le rouleau d'application (1) est un rouleau de dosage qui comporte une surface structurée de dosage (11) et qui fait saillie sur une longueur prédéterminée (B) dans la direction longitudinale du rouleau dans le corps profilé (4, 4').

- Dispositif selon l'une des revendications 1 à 3, caractérisé en ce que la portion de rouleau (A), bordée par le corps profilé (4, 4'), du rouleau d'application (1) n'est découverte que dans la région d'application du rouleau sur le substrat (6).

- Dispositif selon l'une des revendications 1 à 4, caractérisé en ce que le corps profilé (4, 4') présente une surface longitudinale (45), orientée dans la direction de rotation (D) du rouleau (1) et saillant dans la région de la périphérie de rouleau (1), dans la région qui est en arrière de l'application du rouleau d'application (1) sur le substrat (6) par référence au sens de rotation (D) du rouleau d'application (1).

- Dispositif selon l'une des revendications 1 à 5, caractérisé en ce que le rouleau d'application (1) est un rouleau de dosage qui est doté d'une structure filetée et/ou d'une structure enroulée.

- Dispositif selon l'une des revendications 1 à 6, caractérisé en ce que le corps profilé (4, 4') est placé de façon être mobile dans la direction longitudinale du dispositif afin de régler la largeur d'application.

- Dispositif selon l'une des revendications 1 à 7, caractérisé en ce que le dispositif comporte deux corps profilés (4, 4') entre lesquels est définie la largeur d'application.

- Dispositif selon l'une des revendications 1 à 8, caractérisé en ce que le corps profilé (4') est doté, dans la région qui est en avant du rouleau d'application (1) par référence au sens de déplacement (L) du substrat (6), d'une face fendue (46) dans la longueur d'extension (e) transversalement à l'axe (10) du rouleau d'application (1) est sensiblement supérieure au rayon du rouleau d'application (1).

- Dispositif selon l'une des revendications 1 à 9, caractérisé en ce que le corps profilé (4, 4') est placé sur le rouleau d'application (1) et est maintenu de façon être mobile transversalement à la surface du substrat (6).

- Dispositif selon l'une des revendications 1 à 10, caractérisé en ce que le corps profilé (4) est monté de façon être mobile dans une direction (V), correspondant à la direction de pressage du rouleau d'application (1), au moyen d'un palier coulissant (32, 43).

- Dispositif selon l'une des revendications 1 à 11, caractérisé en ce que le corps profilé (4') est monté au milieu du rouleau d'application (1) de façon à pouvoir pivoter au moins légèrement autour de l'axe (10) dudit rouleau d'application et à venir en appui contre le substrat (6) au moyen d'un élément d'appui avant (461) situé à distance du rouleau d'application (1), par référence au sens de déplacement (L) du substrat (6).

- Dispositif selon la revendication 12, caractérisé en ce que le corps profilé (4') est doté dans la région qui est en arrière du rouleau d'application (1), par référence au sens de déplacement (L) du substrat (6), d'une portion d'appui (462, 463) avec laquelle le rouleau (1) vient en appui contre un élément de butée (6, 34) destiné à limiter sa position de pivotement lorsque le rouleau d'application (1) ne tourne pas et pressé contre le substrat (6).

- Dispositif selon l'une des revendications 1 à 13, caractérisé en ce qu'une fente d'entrée (410) est ménagée en avant du rouleau d'application (1) entre le corps profilé (4') et le substrat (6) et s'étend davantage, par référence à la direction de défilement (L) du substrat (6), qu'une fente de sortie ménagée entre le corps profilé (4') et le substrat (6) en arrière du rouleau d'application (1).

- Dispositif selon l'une des revendications 1 à 14, caractérisé en ce qu'il comporte un dispositif de pressage magnétique, un dispositif magnétique (5) étant associé au substrat (6) et le rouleau d'application (1) pouvant être aimanté de façon à être pressé magnétiquement contre le substrat (6).

- Dispositif selon l'une des revendications 1 à 15, caractérisé en ce que le rouleau d'application (1) est placé dans un bac d'immersion (3) qui forme le dispositif d'amenée et qui est placé de façon appropriée au-dessous du substrat (6) par référence à une dimension verticale du dispositif.

- Dispositif selon l'une des revendications 1 à 16, caractérisé en ce qu'il comporte des rouleaux d'appui formant un contre-appui (2).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE29716541U DE29716541U1 (de) | 1997-09-11 | 1997-09-11 | Vorrichtung zum Auftragen von Flüssigkeiten auf ein Substrat |

| DE29716541U | 1997-09-11 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0901839A2 EP0901839A2 (fr) | 1999-03-17 |

| EP0901839A3 EP0901839A3 (fr) | 2002-01-02 |

| EP0901839B1 true EP0901839B1 (fr) | 2005-12-07 |

Family

ID=8046006

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP98250323A Expired - Lifetime EP0901839B1 (fr) | 1997-09-11 | 1998-09-11 | Dispositif pour l'application de fluides sur un substrat |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US6197113B1 (fr) |

| EP (1) | EP0901839B1 (fr) |

| AT (1) | ATE311946T1 (fr) |

| DE (2) | DE29716541U1 (fr) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE20010388U1 (de) | 2000-06-09 | 2001-10-11 | Timatec Maschinen Und Anlagenbau Gmbh, Velden | Vorrichtung zum Auftragen von Substanzen auf bahnförmiges Material |

| US7913703B1 (en) * | 2003-06-27 | 2011-03-29 | Lam Research Corporation | Method and apparatus for uniformly applying a multi-phase cleaning solution to a substrate |

| EP1500438B1 (fr) * | 2003-07-25 | 2006-09-13 | Hauni Maschinenbau AG | Appareil pour appliquer une masse sur une nappe de tissus |

| ES2394833B1 (es) * | 2010-03-16 | 2013-10-09 | Jesus Francisco Barberan Latorre | Sistema para aplicacion de recubrimiento de alto brillo |

| US9539605B2 (en) * | 2012-02-28 | 2017-01-10 | Toray Plastics (America), Inc. | Gravure roll edge masking system for in-line film coating |

| JP5730825B2 (ja) * | 2012-07-13 | 2015-06-10 | 富士フイルム株式会社 | 塗布装置およびインクジェット記録装置 |

| US10195638B2 (en) * | 2013-10-30 | 2019-02-05 | Samsung Sdi Co., Ltd. | Apparatus for coating a separator having collection chamber and method for coating the separator |

| JP2015205261A (ja) * | 2014-04-23 | 2015-11-19 | Bellmatic株式会社 | 塗布システム |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4073263A (en) * | 1976-05-10 | 1978-02-14 | Melton Baxter Wayne | Liquid adhesive coating machine |

| US4165688A (en) | 1977-04-14 | 1979-08-28 | Magna-Graphics Corporation | Ink dam for printing press |

| US4091129A (en) * | 1977-05-16 | 1978-05-23 | Paper Converting Machine Company | Method and apparatus for coating using an open-ended ink chamber having restrictions for partially limit ink flow |

| EP0155293B1 (fr) | 1983-09-12 | 1988-07-06 | Johannes Zimmer | Dispositif pour appliquer un materiau sur un support |

| WO1989003257A1 (fr) * | 1987-10-10 | 1989-04-20 | Johannes Zimmer | Raclette |

| JP2813719B2 (ja) | 1989-05-27 | 1998-10-22 | 株式会社イソワ | 液体転移装置 |

| AT401480B (de) * | 1989-07-06 | 1996-09-25 | Zimmer Johannes | Rakelgerät zum auftragen bzw. auftragen und abrakeln bzw. zum dosierten auftragen fliessfähiger oder streichfähiger substanzen |

| EP0465898B1 (fr) * | 1990-07-10 | 1996-09-25 | Johannes Zimmer | Appareil pour l'application de substances coulantes et pour d'autre traitement par pressage de surfaces et procédé pour l'utilisation de l'appareil |

| AT403299B (de) * | 1991-09-23 | 1997-12-29 | Johannes Zimmer | Arbeitsvorrichtung mit mehreren wahlweise oder kombinierbar einzusetzenden bearbeitungseinheiten für bahnmaterial |

| DE29517095U1 (de) | 1994-12-27 | 1996-04-25 | Zimmer, Johannes, Klagenfurt | Vorrichtung zum Auftragen bestimmbarer Flüssigkeitsmengen |

| US5997645A (en) | 1995-05-24 | 1999-12-07 | 3M Innovative Properties Company | Inserts for stripe coating |

-

1997

- 1997-09-11 DE DE29716541U patent/DE29716541U1/de not_active Expired - Lifetime

-

1998

- 1998-09-10 US US09/150,930 patent/US6197113B1/en not_active Expired - Fee Related

- 1998-09-11 AT AT98250323T patent/ATE311946T1/de not_active IP Right Cessation

- 1998-09-11 EP EP98250323A patent/EP0901839B1/fr not_active Expired - Lifetime

- 1998-09-11 DE DE59813256T patent/DE59813256D1/de not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| DE29716541U1 (de) | 1999-01-14 |

| US6197113B1 (en) | 2001-03-06 |

| ATE311946T1 (de) | 2005-12-15 |

| DE59813256D1 (de) | 2006-01-12 |

| EP0901839A2 (fr) | 1999-03-17 |

| EP0901839A3 (fr) | 2002-01-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE19803617C1 (de) | Vorrichtung zum Dekorieren von Objekten | |

| DE3347735C2 (de) | Streicheinrichtung zur Beschichtung laufender Warenbahnen | |

| DE2832172A1 (de) | Farbwerk zum drucken mit fetter farbe | |

| AT396436B (de) | Einrichtung und verfahren zur beschichtung laufender warenbahnen | |

| EP0901839B1 (fr) | Dispositif pour l'application de fluides sur un substrat | |

| EP0235204B1 (fr) | Dispositif d'application et de dosage d'agents fluides sur une bande ou sur un cylindre | |

| DE3408183C1 (de) | Farbkasten fuer Druckmaschinen | |

| DE69321433T2 (de) | Beschichtungsvorrichtung mit gegenläufigen rollen | |

| EP0264396B1 (fr) | Dispositif pour appliquer de faibles ou tres faibles quantites de substances coulantes | |

| DE3438041C2 (de) | Luftmesser-Beschichter | |

| DE3139739A1 (de) | "bahnbeschichtungsvorrichtung" | |

| DE2611625C3 (fr) | ||

| EP0028608A1 (fr) | Dispositif utilisant une force de pression a effet magnetique. | |

| DE3530352C2 (fr) | ||

| EP1125740B1 (fr) | Procédé et dispositif pour le nettoyage de rouleaux-guides dans une machine rotative à bobine | |

| EP0002006A1 (fr) | Dispositif pour l'application en continu d'un apprêt, d'un liant ou analogues sur des fils en mouvement d'une matière minérale, en particulier de verre | |

| DE3027564A1 (de) | Klebstoffbeschichtungsgeraet zur beschichtung von flaechigem material | |

| DE19929843A1 (de) | Oberflächen-Behandlungsvorrichtung | |

| DE2163786B2 (de) | Vorrichtung zum Entwickeln eines elektrostatischen latenten Bildes | |

| EP0480285B1 (fr) | Dispositif à rouleaux pour revêtement de bandes ou de feuilles | |

| WO2006069626A1 (fr) | Dispositif d'application de colle sur des parties de segments tubulaires ou en forme de bande | |

| CH570267A5 (en) | Printing unit for electrically insulated wire - printing wheel supplied with ink by powered pump | |

| DE69422473T2 (de) | Konfiguration einer Schlitzauftragsdüse | |

| DE1411118C (de) | Befeuchtungseinrichtung fur die Druckplatte einer Offset Druckmaschine | |

| DE3233330A1 (de) | Vorrichtung zum aufbringen von sand auf wenigstens eine oberflaeche eines tonstranges oder dergleichen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE Kind code of ref document: A2 Designated state(s): AT DE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| RIC1 | Information provided on ipc code assigned before grant |

Free format text: 7B 05C 1/08 A, 7B 05C 11/02 B |

|

| 17P | Request for examination filed |

Effective date: 20020628 |

|

| AKX | Designation fees paid |

Free format text: AT DE |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: JOHANNES ZIMMER BETEILIGUNGS- UND VERWALTUNGS GMBH |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: ZIMMER, JOHANNES |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT DE |

|

| REF | Corresponds to: |

Ref document number: 59813256 Country of ref document: DE Date of ref document: 20060112 Kind code of ref document: P |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20060908 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20090921 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20090926 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59813256 Country of ref document: DE Effective date: 20110401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100911 |