EP0852634B1 - Procede de fabrication d'un cable d'acier - Google Patents

Procede de fabrication d'un cable d'acier Download PDFInfo

- Publication number

- EP0852634B1 EP0852634B1 EP96931018A EP96931018A EP0852634B1 EP 0852634 B1 EP0852634 B1 EP 0852634B1 EP 96931018 A EP96931018 A EP 96931018A EP 96931018 A EP96931018 A EP 96931018A EP 0852634 B1 EP0852634 B1 EP 0852634B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- steel cord

- filaments

- wire

- core

- set forth

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 229910000831 Steel Inorganic materials 0.000 title claims abstract description 75

- 239000010959 steel Substances 0.000 title claims abstract description 75

- 238000000034 method Methods 0.000 title claims description 23

- 241001589086 Bellapiscis medius Species 0.000 claims abstract description 10

- 230000005012 migration Effects 0.000 abstract description 2

- 238000013508 migration Methods 0.000 abstract description 2

- 238000007493 shaping process Methods 0.000 abstract 2

- 239000002131 composite material Substances 0.000 abstract 1

- 238000004519 manufacturing process Methods 0.000 description 17

- 239000011248 coating agent Substances 0.000 description 4

- 238000000576 coating method Methods 0.000 description 4

- 229910001369 Brass Inorganic materials 0.000 description 3

- 239000010951 brass Substances 0.000 description 3

- 230000006735 deficit Effects 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 2

- 238000010073 coating (rubber) Methods 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 150000001875 compounds Chemical class 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 239000000314 lubricant Substances 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B1/00—Constructional features of ropes or cables

- D07B1/06—Ropes or cables built-up from metal wires, e.g. of section wires around a hemp core

- D07B1/0606—Reinforcing cords for rubber or plastic articles

- D07B1/0646—Reinforcing cords for rubber or plastic articles comprising longitudinally preformed wires

- D07B1/0653—Reinforcing cords for rubber or plastic articles comprising longitudinally preformed wires in the core

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B1/00—Constructional features of ropes or cables

- D07B1/06—Ropes or cables built-up from metal wires, e.g. of section wires around a hemp core

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B1/00—Constructional features of ropes or cables

- D07B1/06—Ropes or cables built-up from metal wires, e.g. of section wires around a hemp core

- D07B1/0606—Reinforcing cords for rubber or plastic articles

- D07B1/0646—Reinforcing cords for rubber or plastic articles comprising longitudinally preformed wires

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B3/00—General-purpose machines or apparatus for producing twisted ropes or cables from component strands of the same or different material

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B7/00—Details of, or auxiliary devices incorporated in, rope- or cable-making machines; Auxiliary apparatus associated with such machines

- D07B7/02—Machine details; Auxiliary devices

- D07B7/025—Preforming the wires or strands prior to closing

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2201/00—Ropes or cables

- D07B2201/20—Rope or cable components

- D07B2201/2001—Wires or filaments

- D07B2201/2007—Wires or filaments characterised by their longitudinal shape

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2201/00—Ropes or cables

- D07B2201/20—Rope or cable components

- D07B2201/2001—Wires or filaments

- D07B2201/2007—Wires or filaments characterised by their longitudinal shape

- D07B2201/2008—Wires or filaments characterised by their longitudinal shape wavy or undulated

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2201/00—Ropes or cables

- D07B2201/20—Rope or cable components

- D07B2201/2015—Strands

- D07B2201/2016—Strands characterised by their cross-sectional shape

- D07B2201/2018—Strands characterised by their cross-sectional shape oval

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2201/00—Ropes or cables

- D07B2201/20—Rope or cable components

- D07B2201/2015—Strands

- D07B2201/2019—Strands pressed to shape

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2201/00—Ropes or cables

- D07B2201/20—Rope or cable components

- D07B2201/2015—Strands

- D07B2201/2022—Strands coreless

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2201/00—Ropes or cables

- D07B2201/20—Rope or cable components

- D07B2201/2015—Strands

- D07B2201/2023—Strands with core

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2201/00—Ropes or cables

- D07B2201/20—Rope or cable components

- D07B2201/2015—Strands

- D07B2201/2024—Strands twisted

- D07B2201/2029—Open winding

- D07B2201/2031—Different twist pitch

- D07B2201/2032—Different twist pitch compared with the core

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2201/00—Ropes or cables

- D07B2201/20—Rope or cable components

- D07B2201/2015—Strands

- D07B2201/2035—Strands false twisted

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2201/00—Ropes or cables

- D07B2201/20—Rope or cable components

- D07B2201/2015—Strands

- D07B2201/2038—Strands characterised by the number of wires or filaments

- D07B2201/2039—Strands characterised by the number of wires or filaments three to eight wires or filaments respectively forming a single layer

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2201/00—Ropes or cables

- D07B2201/20—Rope or cable components

- D07B2201/2047—Cores

- D07B2201/2052—Cores characterised by their structure

- D07B2201/2059—Cores characterised by their structure comprising wires

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2201/00—Ropes or cables

- D07B2201/20—Rope or cable components

- D07B2201/2095—Auxiliary components, e.g. electric conductors or light guides

- D07B2201/2097—Binding wires

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2207/00—Rope or cable making machines

- D07B2207/40—Machine components

- D07B2207/4004—Unwinding devices

- D07B2207/4009—Unwinding devices over the head

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2207/00—Rope or cable making machines

- D07B2207/40—Machine components

- D07B2207/4004—Unwinding devices

- D07B2207/4013—Unwinding devices comprising flyer

-

- D—TEXTILES; PAPER

- D07—ROPES; CABLES OTHER THAN ELECTRIC

- D07B—ROPES OR CABLES IN GENERAL

- D07B2501/00—Application field

- D07B2501/20—Application field related to ropes or cables

- D07B2501/2046—Tire cords

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S57/00—Textiles: spinning, twisting, and twining

- Y10S57/902—Reinforcing or tire cords

Definitions

- the invention relates to a method for producing a steel cord and a steel cord made by this method.

- Steel cords as inserts in pneumatic tires for motor vehicles for improvement their driving characteristics, dynamics, stability and extension their lifespan are known and are usually made of strands constructed, one strand a bundle of at least two, usually however, there is several individual wires that are laid around and / or are twisted around each other. The production takes place by means of a Bunching machine and is quite complex.

- Steel cords are also known, their soul from a central, folded wire bundle, which is no longer in a separate Stranding process is produced, but immediately during stranding can be formed.

- DE-A 26 19 086 describes a method for producing a Steel cords are known in which several serve as soul filaments Wire filaments are pulled off the spools.

- the soul filaments are combined into a strand and on the edges of a Guide eyes sharply bent and deformed helically.

- a sheathed wire is pulled off a coil is also helical on the edges of another Guide eyes sharply bent and also helical deformed.

- the soul filaments bent together are on Rope formation point wrapped in the preformed sheathed wires.

- the the resulting rope runs over a pair of rollers to a false twist device, which plastically deformed the steel cord obtained and the existing ones Residual torsional stresses reduced.

- EP 0 492 682 describes a manufacturing method for a steel cord known in which serving as soul filaments Coils are withdrawn and twisted around their longitudinal axis become. The soul filaments are then in a single plane merged in parallel and with a sheathed wire envelops.

- One or more of the core filaments arranged in one plane or the plane of the core filaments as a whole exhibits elastic Residual torsional stresses.

- the elastic residual torsional stresses are chosen such that the wire bundle in its entire length remains essentially flat as long as no external forces attack it.

- the size and direction of the residual torsional stresses are so chosen that the elastic residual torsional stresses of the core filaments with the restoring forces of the sheath filaments.

- the production such a flat wire bundle is difficult and technical expensive because the parallel single filaments are kept on one level Need to become.

- the invention has for its object a method for manufacturing to propose a steel cord where no interference wire coating or local pressure marks.

- step B two, three or four soul filaments twisted together and that two or more strands with two, three or four twisted soul filaments combined in an additional step C to form a soul become.

- the steel cord is pressed so that it gets an oval shape.

- the deformation is expediently carried out by a Pair of roles.

- a steel cord produced by the method according to the invention has in its simplest form three wire filaments, one of which two soul filaments are spirally shaped and one too spiral-shaped sheathed wire are surrounded.

- the soul filaments in a suitable manner using a false twister the desired speed twisted around to get after the false twister again parallel to each other, but with spiral preforming to be brought together.

- To make this bundle more parallel Soul filament becomes another filament with the same pitch and Direction of thread to the spiral shape of the preforming of the individual filaments.

- This inventive formation of a wire bundle the individual filaments are neither damaged nor deformed locally, so that a steel cord of this type for a tire, in particular when subjected to compression, has very good fatigue properties.

- one or several layers of sheathed wires are provided which cover the at least two Soul filaments surround.

- the wire bundle according to the invention can be produced very inexpensively because the bundle of souls does not need its own work process, but be produced in line with the entire production can.

- a steel cord according to claim 16 proposed with a wire bundle, with at least two Wire filaments as a soul-forming bundle of soul filaments running parallel to each other and elastic residual torsional stresses have in connection with the restoring forces Pick up at least one sheath wire surrounding the core filaments.

- the wire bundle according to the invention can be easily produced because the wire filaments of the soul are not parallel in parallel one level, which is technically with some effort is connected, but can be summarized in the form of a bundle.

- easy processing with rubber coating is achieved because the wire bundle according to the invention lie flat in the rubber coating remains.

- the steel cord has a flattened, essentially oval shape.

- This invention oval shape has significant for use in tires Advantages, especially due to the different stiffness of the Steel cords in radial and lateral directions.

- the flattened, essentially oval shape can, for example, by squeezing of the steel cord can be reached with a pair of rollers.

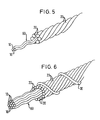

- Figures 3 to 6 show different embodiments of the invention Steel cords with different numbers of the soul of the wire filament forming the steel cord.

- Figure 3 is one first embodiment of a steel cord according to the invention shown with a wire bundle with two core filaments 10 as core 60, the are spirally shaped and run parallel to each other.

- the two soul filaments 10 are of another filament than Surrounding sheath wire 20, namely the sheath wire 20 is the same Pitch height and direction to the spiral shape of the soul filaments 10 placed.

- the soul filaments are 10 left-handed spiral shaped, and the sheath wire 20 is also left-handed wound around the two soul filaments 10.

- the aisle is typically about 14 mm in such a steel cord, the diameter of the core filaments 10 and the sheath wire 20 is about 0.28 mm.

- Figure 4 shows another embodiment of an inventive Steel cords according to FIG. 3, in which the core 60 consists of six spirally shaped and parallel to each other Soul filaments 10 is formed, the left-hand spiral shaped are and wrapped by a seventh filament as a sheath 20 left-handed are.

- the pitch can be, for example 18 mm and the diameter of the used Filaments 0.35 mm.

- Figure 5 shows a further embodiment of an inventive Steel cords in a schematic perspective view.

- the Core 60 of the steel cord is made from three spirally preformed core filaments 10 formed, which run parallel to each other. This are made from a layer of six closely spaced sheathed wires 20 surround, which have the same direction as that Soul filaments 10. For reasons of clarity the soul filaments 10 shown longer than the sheathed wires 20. Die Direction of the soul filaments 10 can also be in opposite directions the thread direction of the sheathed wires 20.

- Such a tight covering of the core 60 with a layer of sheathed wires 20 has the advantage that the soul filaments 10 of the bundle of souls even when used as a steel belt, not from the rope assembly can migrate.

- manufacture of such a steel cord very inexpensive since the bundle of souls 60, as below will not be described, but needed can be produced in line with the steel cord production.

- the Soul filaments 10 advantageously over a diameter of 0.2 mm, the sheathed wires 20 over a diameter of 0.35 mm.

- FIG. 6 shows an embodiment of the invention which is similar to the exemplary embodiment in FIG Steel cord shown over a soul 60 out of twelve has left-hand spiral preformed core filaments 10, the again from a left-handed position from fifteen sheathed wires 20 are surrounded.

- all wires advantageously have same diameter of 0.175 mm.

- the one in FIG. 6 Steel cord shown is additionally with a spiral wire 30 wrapped right-handed.

- the diameter of the spiral wire 30 is 0.15 mm, for example.

- the direction of the soul filaments 10 can of course also work in opposite directions in this exemplary embodiment to the thread direction of the sheathed wires.

- FIG. 1 illustrates a schematic representation of an inventive Process for producing an inventive device shown in FIG Steel cords.

- a first Step A the core filaments 10 drawn from six spools 11.

- a further step B three of the six Core filaments 10 are combined into a strand 50 by means of deflection rollers 15, to then in a third step C of two false twists 40 each clockwise with one set Pitch (here: 18 mm) to be preformed spirally.

- the two bundles with each three core filaments in a further work step D using pulleys 15 assembled into a wire bundle from six wire filaments, that forms the core 60 of the steel cord to be produced.

- the soul 60 from six soul filaments 10, the right-hand spiral are formed in the same operation with a sheath wire 20 surrounded, which is withdrawn from a coil 21 in step E. and right-handed in step F with a predetermined pitch (for example 18 mm) is wound around the core 60.

- a predetermined pitch for example 18 mm

- the result this manufacturing process is a steel cord according to the invention, such as he is shown in Figure 4, wherein the steel cord shown in Figure 4 just like the steel cord shown in Figure 3 on left-handed Soul filaments 10 and sheathed wires 20 has.

- the wire filaments used as core filaments in this manufacturing process are advantageously made of wire rod with a steel quality of 0.6 to 0.9% C, 0.4 to 0.8% Mn and 0.1 to 0.3% Si and a maximum of 0.03% S, P and other usual accompanying elements.

- the wire rod is in advance rolled in several steps from 5.5 mm to thinner diameters, drawn, heat-treated and before the subsequent, final stage, mostly a wet drawing step, brassed.

- the brass is called "Lubricant" used when pulling, but primarily serves as liability of the steel cord with the rubber compound of the tire.

- the production the steel cords are made by twisting and stranding the Wire filaments in a suitable number and shape, with the choice of Machine parameters a suitable combination of coil size and Engine speed must be found because of a high speed with small insert coils and accordingly a low one Speed is connected with large insert coils.

- the method according to the invention for producing a Steel cords are suitable for the production of steel cords with bundles of souls from two to thirty wire filaments, including cord constructions same type imaginable with more than thirty wire filaments are.

- Figure 2 illustrates a method for producing an inventive Steel cords as shown in Figure 3.

- a first Step A becomes two core filaments 10 from two spools 11 deducted and merged in a second step B.

- the two soul filaments 10 are in a further step C in a false twister 40 right-handed with a set pitch (e.g. 14 mm) right-hand spiral shaped.

- This two spirally twisted soul filaments 10 form the 60 core of the steel cord to be produced.

- a wire filament is drawn off a spool 21, which as a sheath wire 20 in a last step F around the soul 60 right-handed with a pitch of 14 mm, for example becomes.

- the proposed steel cord according to the invention is simple and inexpensive producible and is characterized by excellent properties, especially in the case of compressive stress. He lets himself rubberize slightly, as the residual torsional stresses are released to the outside are and thus lie flat during the gumming process remains. The migration ability of the wire filaments used is also great from the rope assembly when used as a belt very low.

- a variety of configurations proposed according to the invention are numerous of steel cord constructions that can be used in a wide range of applications cover, starting with steel cords for car tires from light truck tires to truck and bus tires.

Landscapes

- Ropes Or Cables (AREA)

- Tires In General (AREA)

- Heat Treatment Of Steel (AREA)

- Heat Treatment Of Strip Materials And Filament Materials (AREA)

Claims (18)

- Procédé de fabrication d'un câblé d'acier, caractérisé par les étapes suivantes :a) au moins deux filaments de fil servant de filaments d'âme (10) sont tirés depuis des bobines (11),b) les filaments d'âme (10) tirés sont réunis en un brin (50) au moyen d'un dispositif à fausse-torsion (40) et d'abord torsadés les uns autour des autres, afin d'être préformés en spirale,c) les filaments d'âme (10) préformés en spirale et juxtaposés parallèlement sous la forme d'une âme (60) sont entourés, après le dispositif à fausse-torsion (40), par au moins un filament de fil servant de fil enveloppe qui est tiré depuis une bobine (21).

- Procédé selon la revendication 1, caractérisé en ce que dans l'étape b, deux, trois ou quatre filaments d'âme (10) sont torsadés conjointement les uns autour des autres, et en ce que deux brins (50) ou plus sont réunis en une âme (60) dans une étape c supplémentaire avec deux, trois ou quatre filaments d'âme (10) torsadés les uns autour des autres.

- Procédé selon l'une ou l'autre des revendications 1 et 2, caractérisé en ce que lesdits au moins deux filaments d'âme (10) sont torsadés les uns autour des autres avec pas à gauche ou pas à droite, et en ce que ledit au moins un fil enveloppe (20) est enroulé également avec pas à gauche ou pas à droite autour des filaments d'âme préformés (10).

- Procédé de fabrication d'un câblé d'acier, caractérisé en ce qu'un câblé d'acier réalisé selon l'une quelconque des revendications 1 à 3 est comprimé de manière à prendre une forme ovale.

- Procédé selon la revendication 4, caractérisé en ce que le câblé d'acier est comprimé en une forme ovale par une paire de galets.

- Câblé d'acier, réalisé par un procédé selon l'une quelconque des revendications 1 à 5.

- Câblé d'acier selon la revendication 6, caractérisé en ce que lesdits au moins deux filaments d'âme (10) sont formés en spirale avec pas à droite ou pas à gauche, et ledit au moins un fil enveloppe (20) entoure lesdits au moins deux filaments d'âme (10) également avec pas à droite ou pas à gauche.

- Câblé d'acier selon l'une ou l'autre des revendications 6 et 7, caractérisé en ce que la hauteur de pas du préformage spiralé des filaments d'âme (10) correspond à la hauteur de pas du fil enveloppe (20) qui entoure ceux-ci.

- Câblé d'acier selon l'une quelconque des revendications 6 à 8, caractérisé en ce que la hauteur de pas du préformage et la hauteur de pas du fil enveloppe entourant (20) sont comprises entre 6 mm et 30 mm.

- Câblé d'acier selon l'une quelconque des revendications 6 à 9, caractérisé en ce que le diamètre extérieur de la spirale de chaque filament d'âme (10) préformé est compris entre 0,1 et 0,5 mm.

- Câblé d'acier selon l'une quelconque des revendications 6 à 10, caractérisé en ce que le diamètre des filaments d'âme (10) est compris entre 0,12 et 0,5 mm.

- Câblé d'acier selon l'une quelconque des revendications 6 à 11, caractérisé en ce qu'une ou plusieurs couches de fils enveloppes (20) sont prévues qui entourent lesdits au moins deux filaments d'âme (10).

- Câblé d'acier selon l'une quelconque des revendications 6 à 12, caractérisé en ce que les filaments d'âme (10) et les fils enveloppes (20) présentent le même diamètre.

- Câblé d'acier selon l'une quelconque des revendications 6 à 12, caractérisé en ce que les filaments d'âme (10) et les fils enveloppes (20) présentent des diamètres différents.

- Câblé d'acier selon l'une quelconque des revendications 6 à 14, caractérisé en ce qu'il est prévu un fil hélicoïdal (30) entourant les fils enveloppes (20).

- Câblé d'acier selon l'une quelconque des revendications 6 à 15, caractérisé en ce qu'au moins deux filaments de fil s'étendent, en tant que filaments d'âme (10) formant une âme (60), parallèlement les uns aux autres en étant juxtaposés les uns contre les autres en forme de faisceau, et présentent des contraintes de torsion élastiques résiduelles qui s'annulent en association avec les forces de rappel de l'un au moins des fils enveloppes (20) entourant les filaments d'âme (10).

- Câblé d'acier selon l'une quelconque des revendications 6 à 16, caractérisé en ce qu'il présente une forme aplatie sensiblement ovale.

- Câblé d'acier selon la revendication 11, caractérisé en ce que le rapport entre la largeur et la hauteur du câblé d'acier aplati est compris entre 1,15 et 1,50.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19535598A DE19535598A1 (de) | 1995-09-25 | 1995-09-25 | Verfahren zur Herstellung eines Stahlcords |

| DE19535598 | 1995-09-25 | ||

| PCT/EP1996/003884 WO1997012091A1 (fr) | 1995-09-25 | 1996-09-04 | Procede de fabrication d'un cable d'acier |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0852634A1 EP0852634A1 (fr) | 1998-07-15 |

| EP0852634B1 true EP0852634B1 (fr) | 1999-12-08 |

Family

ID=7773114

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96931018A Expired - Lifetime EP0852634B1 (fr) | 1995-09-25 | 1996-09-04 | Procede de fabrication d'un cable d'acier |

Country Status (15)

| Country | Link |

|---|---|

| US (1) | US6076344A (fr) |

| EP (1) | EP0852634B1 (fr) |

| JP (1) | JPH11512787A (fr) |

| KR (1) | KR100434750B1 (fr) |

| CN (1) | CN1079864C (fr) |

| AT (1) | ATE187512T1 (fr) |

| BR (1) | BR9610722A (fr) |

| CA (1) | CA2232549A1 (fr) |

| CZ (1) | CZ294724B6 (fr) |

| DE (2) | DE19535598A1 (fr) |

| ES (1) | ES2142610T3 (fr) |

| RU (1) | RU2151227C1 (fr) |

| SK (1) | SK284783B6 (fr) |

| TR (1) | TR199800542T2 (fr) |

| WO (1) | WO1997012091A1 (fr) |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19912192C2 (de) * | 1999-03-18 | 2001-03-08 | Drahtcord Saar Gmbh & Co Kg | Falschdraller und Verfahren insbesondere zum Herstellen von spiralförmigen Filamenten |

| EP1167620A1 (fr) * | 2000-06-19 | 2002-01-02 | DRAHTCORD SAAR GMBH & Co.KG | Câble d'acier |

| JP2002294573A (ja) * | 2001-03-30 | 2002-10-09 | Tokusen Kogyo Co Ltd | タイヤ補強用スチールコード及びタイヤ |

| PL206484B1 (pl) * | 2001-04-26 | 2010-08-31 | Bekaert Sa Nv | Kord stalowy |

| US20050034443A1 (en) * | 2003-08-14 | 2005-02-17 | Cook Thomas Christopher | Optical fibers twinning apparatus and process |

| US7901870B1 (en) | 2004-05-12 | 2011-03-08 | Cirrex Systems Llc | Adjusting optical properties of optical thin films |

| US7565084B1 (en) | 2004-09-15 | 2009-07-21 | Wach Michael L | Robustly stabilizing laser systems |

| JP5319219B2 (ja) * | 2008-09-16 | 2013-10-16 | 株式会社ブリヂストン | コード製造装置及びコード製造方法 |

| WO2012141710A1 (fr) * | 2011-04-14 | 2012-10-18 | Otis Elevator Company | Filin ou courroie revêtu destiné à des systèmes d'ascenseur |

| JP5825234B2 (ja) * | 2012-09-11 | 2015-12-02 | 横浜ゴム株式会社 | ゴム補強用スチールコードおよびコンベヤベルト |

| FR3028872B1 (fr) * | 2014-11-25 | 2017-05-19 | Michelin & Cie | Procede de fractionnement |

| FR3028873B1 (fr) * | 2014-11-25 | 2016-12-23 | Michelin & Cie | Installation de fractionnement |

| CN104631167B (zh) * | 2015-02-11 | 2017-03-01 | 辽宁通达建材实业有限公司 | 低消耗预应力钢绞线生产工艺 |

| CN107044060B (zh) * | 2017-05-31 | 2022-10-14 | 东华大学 | 连续态超细金属长丝的加捻合股方法与设备 |

| CN109338766A (zh) * | 2018-11-10 | 2019-02-15 | 江苏兴达钢帘线股份有限公司 | 一种1×n×d系列子午线轮胎钢帘线的生产方法 |

| CN110373922B (zh) * | 2019-05-22 | 2022-07-29 | 东台磊达钢帘线有限公司 | 一种钢帘线的生产设备及生产方法 |

| FR3099191A1 (fr) | 2019-07-25 | 2021-01-29 | Compagnie Generale Des Etablissements Michelin | Câble ouvert renforçant à haute compressibilité |

| FR3099192A1 (fr) * | 2019-07-25 | 2021-01-29 | Compagnie Generale Des Etablissements Michelin | Procédé de fractionnement et de réassemblage d’un assemblage à deux couches |

| US11598027B2 (en) * | 2019-12-18 | 2023-03-07 | Patrick Yarn Mills, Inc. | Methods and systems for forming a composite yarn |

| CN113403870A (zh) * | 2021-06-25 | 2021-09-17 | 山东大业股份有限公司 | 一种超高强度高渗胶性能钢帘线及捻制方法及捻制设备 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2260660B1 (fr) * | 1974-02-12 | 1976-11-26 | Michelin & Cie | |

| IT1059752B (it) * | 1975-05-12 | 1982-06-21 | Akzo Nv | Cavo di rinforzo per a ticoli elastomerici e relativo metodo ed apparecchio di fabbricazione |

| GB1582647A (en) * | 1977-07-07 | 1981-01-14 | Bekaert Sa Nv | Metal cord |

| US4545190A (en) * | 1983-09-26 | 1985-10-08 | The Goodyear Tire & Rubber Company | Metallic cable and method and apparatus for making same |

| DE3561164D1 (en) * | 1984-07-09 | 1988-01-21 | Bekaert Sa Nv | Steel cord twisting structure |

| GB8424086D0 (en) * | 1984-09-24 | 1984-10-31 | Bekaert Sa Nv | Steel cord |

| DE3635298A1 (de) * | 1986-10-16 | 1988-04-21 | Akzo Gmbh | Luftreifen mit flachcorden bzw. flachcord |

| AT391292B (de) * | 1987-12-18 | 1990-09-10 | Miller Martin Ag | Verfahren zur herstellung eines ein- oder zweiseitigen stanzmessers fuer nichtmetallische werkstoffe |

| JPH02104783A (ja) * | 1988-10-11 | 1990-04-17 | Kanai Hiroyuki | スチールコードおよびタイヤ |

| JP2936112B2 (ja) * | 1988-11-11 | 1999-08-23 | 株式会社ブリヂストン | 補強用スチールコード |

| US5323596A (en) * | 1990-11-05 | 1994-06-28 | The Goodyear Tire & Rubber Company | Open metallic cord for penetration by elastomer |

| US5198307A (en) * | 1990-12-21 | 1993-03-30 | N. V. Bekaert S.A. | Steel strip and method of making |

| US5581990A (en) * | 1994-04-07 | 1996-12-10 | N.V. Bekaert S.A. | Twisting steel cord with wavy filament |

| IT1277689B1 (it) * | 1995-12-21 | 1997-11-11 | Pirelli | Cordicella metallica di rinforzo da impiegarsi particolarmente in manufatti compositi a matrice elastomerica procedimento ed apparato |

-

1995

- 1995-09-25 DE DE19535598A patent/DE19535598A1/de not_active Withdrawn

-

1996

- 1996-09-04 AT AT96931018T patent/ATE187512T1/de not_active IP Right Cessation

- 1996-09-04 CA CA002232549A patent/CA2232549A1/fr not_active Abandoned

- 1996-09-04 US US09/043,500 patent/US6076344A/en not_active Expired - Lifetime

- 1996-09-04 CN CN96198549A patent/CN1079864C/zh not_active Expired - Fee Related

- 1996-09-04 RU RU98107841/02A patent/RU2151227C1/ru not_active IP Right Cessation

- 1996-09-04 ES ES96931018T patent/ES2142610T3/es not_active Expired - Lifetime

- 1996-09-04 TR TR1998/00542T patent/TR199800542T2/xx unknown

- 1996-09-04 DE DE59603883T patent/DE59603883D1/de not_active Expired - Lifetime

- 1996-09-04 KR KR10-1998-0702170A patent/KR100434750B1/ko not_active IP Right Cessation

- 1996-09-04 WO PCT/EP1996/003884 patent/WO1997012091A1/fr active IP Right Grant

- 1996-09-04 SK SK369-98A patent/SK284783B6/sk not_active IP Right Cessation

- 1996-09-04 CZ CZ1998892A patent/CZ294724B6/cs not_active IP Right Cessation

- 1996-09-04 EP EP96931018A patent/EP0852634B1/fr not_active Expired - Lifetime

- 1996-09-04 JP JP9513103A patent/JPH11512787A/ja active Pending

- 1996-09-04 BR BR9610722A patent/BR9610722A/pt not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| KR100434750B1 (ko) | 2004-09-04 |

| CN1202942A (zh) | 1998-12-23 |

| JPH11512787A (ja) | 1999-11-02 |

| CA2232549A1 (fr) | 1997-04-03 |

| DE59603883D1 (de) | 2000-01-13 |

| WO1997012091A1 (fr) | 1997-04-03 |

| CZ294724B6 (cs) | 2005-03-16 |

| ATE187512T1 (de) | 1999-12-15 |

| US6076344A (en) | 2000-06-20 |

| SK284783B6 (sk) | 2005-11-03 |

| SK36998A3 (en) | 2000-02-14 |

| CN1079864C (zh) | 2002-02-27 |

| EP0852634A1 (fr) | 1998-07-15 |

| ES2142610T3 (es) | 2000-04-16 |

| BR9610722A (pt) | 1999-07-13 |

| RU2151227C1 (ru) | 2000-06-20 |

| TR199800542T2 (xx) | 1998-07-21 |

| CZ89298A3 (cs) | 1998-07-15 |

| DE19535598A1 (de) | 1997-03-27 |

| KR19990063703A (ko) | 1999-07-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0852634B1 (fr) | Procede de fabrication d'un cable d'acier | |

| DE69811271T2 (de) | Stahlseil mit gewellten elementen | |

| DE68905155T2 (de) | Stahlkabel zum verstaerken von kautschuk. | |

| DE2619086C2 (de) | Verstärkungsseil für Elastomererzeugnisse, Verfahren und Vorrichtung zur Herstellung | |

| DE3317712C2 (de) | Verstärkungscord zur Verstärkung von elastomeren Erzeugnissen | |

| DE69228831T2 (de) | Betätigungsseil | |

| EP2289072B1 (fr) | Procédé de fabrication d'un toron et toron composé de plusieurs brins | |

| DE3047365A1 (de) | Durch stahlcordfaeden verstaerkter luftreifen in radialbauart | |

| DE3215638A1 (de) | Stahlseil zur verstaerkung von elastomermaterial | |

| DE60121671T2 (de) | Drahtseil für Kraftwagenfensterheber | |

| DE7936995U1 (de) | Verbundstrang aus gummi oder gummiartigem werkstoff oder kunststoff mit zugbewehrung | |

| DE69726052T2 (de) | Stahlseil mit mehreren Litzen | |

| DE3516220C2 (de) | Luftreifen in Radialbauart | |

| DE69503676T2 (de) | Verstärkung für Fahrzeugreifen | |

| EP0852635B1 (fr) | Filament metallique s'utilisant notamment pour renforcer des articles en caoutchouc ou en plastique, procede permettant de le produire et dispositif de mise en uvre dudit procede | |

| DE2044665A1 (fr) | ||

| CH688915A5 (de) | Stahldrahtseil. | |

| DE60212367T2 (de) | Stahlseil zur verstärkung von gummiartikeln | |

| DE69024384T2 (de) | Stahlkabel zur Verstärkung von Gummi | |

| DE69414912T2 (de) | Kompaktes Stahlseil ohne Umhüllungselement | |

| DE69611149T2 (de) | Strahlseil mit mehreren Litzen | |

| DE69406849T2 (de) | Behandlung eines Stahlseils | |

| EP0164065B1 (fr) | Procédé pour la fabrication d'un câblé de renforcement compact à un seul toron à plusieurs couches pour articles élastomères et câblé de renforcement fabriqué selon ce procédé | |

| DE69708611T2 (de) | Aus zwei gruppen von filamenten (m+n) bestehendes stahlseil | |

| DE112018007311T5 (de) | Aufzugseil |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19980424 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE DE ES FR GB IT LU |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 19990114 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE DE ES FR GB IT LU |

|

| REF | Corresponds to: |

Ref document number: 187512 Country of ref document: AT Date of ref document: 19991215 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 59603883 Country of ref document: DE Date of ref document: 20000113 |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20000222 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2142610 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20010814 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20010921 Year of fee payment: 6 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020904 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020904 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20020904 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20050927 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20060922 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20060927 Year of fee payment: 11 |

|

| BERE | Be: lapsed |

Owner name: *DRAHTCORD SAAR G.M.B.H. & CO. K.G. Effective date: 20070930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070930 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20070905 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070905 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070904 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20120926 Year of fee payment: 17 Ref country code: DE Payment date: 20120928 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20121008 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59603883 Country of ref document: DE Effective date: 20140401 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20140530 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140401 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130930 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130904 |