EP0842011B1 - Ponceuse vibrante - Google Patents

Ponceuse vibrante Download PDFInfo

- Publication number

- EP0842011B1 EP0842011B1 EP97907017A EP97907017A EP0842011B1 EP 0842011 B1 EP0842011 B1 EP 0842011B1 EP 97907017 A EP97907017 A EP 97907017A EP 97907017 A EP97907017 A EP 97907017A EP 0842011 B1 EP0842011 B1 EP 0842011B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- sanding plate

- orbital sander

- tool holder

- sanding

- sander according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B23/00—Portable grinding machines, e.g. hand-guided; Accessories therefor

- B24B23/04—Portable grinding machines, e.g. hand-guided; Accessories therefor with oscillating grinding tools; Accessories therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B23/00—Portable grinding machines, e.g. hand-guided; Accessories therefor

- B24B23/02—Portable grinding machines, e.g. hand-guided; Accessories therefor with rotating grinding tools; Accessories therefor

- B24B23/03—Portable grinding machines, e.g. hand-guided; Accessories therefor with rotating grinding tools; Accessories therefor the tool being driven in a combined movement

Definitions

- the invention relates to an orbital sander according to the preamble of claim 1.

- This orbital sander is specially designed for fine grinding smaller ones Surfaces, especially designed in corners and on the edges of workpieces and has only a small eccentric stroke with relative low removal rate.

- This triangle grinder is therefore not for coarse sanding of larger areas, for example wooden floors suitable.

- EP 623 422 is a triangular grinder with a manual transmission known, in the first switching stage of the rotary-swivel movement of the grinding plate, i.e. the orbital sander operation, and in its second switching stage the circular-rotating movement of the grinding plate, i.e. eccentric sander operation, adjustable is.

- This triangular grinder combines the properties of an orbital sander with those of an eccentric grinder, so that smaller ones This means that surfaces can be finely sanded efficiently and larger areas can be rough-ground are, but it is due to the required manual transmission heavier and more expensive than conventional orbital sanders.

- the orbital sander according to the invention with the features of claim 1 has the advantage that, with little manufacturing effort and without changing the basic construction of the orbital sander, both the previously known orbital fine-tuning, particularly in corners, and the known eccentric coarse grinding with a round plate are possible ,

- the drive shaft can be coupled with an axial extension of its eccentric pin via a first roller bearing with a first type of sanding pad, and in that this is a type of sanding pad, in particular a circular sanding pad that can be freely rotated with respect to the drive spindle and which can be coupled to one that rotates with the tool holder , in particular triangular, grinding disc is exchangeable, a particularly easy to manufacture, only the outer area of the orbital sander construction is created, with which, depending on the coupled type of grinding disc, it is possible to carry out orbital grinding in the fine machining stage or eccentric grinding in the rough machining stage.

- a type of sanding pad in particular a circular sanding pad that can be freely rotated with respect to the drive spindle and which can be coupled to one that rotates with the tool holder , in particular triangular, grinding disc is exchangeable, a particularly easy to manufacture, only the outer area of the orbital sander construction is created, with which, depending on the coupled type

- the lowest arranged on the drive shaft Rolling bearing is encompassed by a retaining ring in which a central one Area of one type of grinding plate can be snapped, in particular in that the retaining ring is injection molded onto the first roller bearing is, the axial extension of the eccentric pin is designed as a central stepped pin whose diameter is smaller than that of the eccentric pin, one is inexpensive Manufactured clutch created with which the two types of sanding pads particularly easily interchangeable to different Kind can be coupled drivably.

- the orbital sander with the previous features is thereby structurally particularly simplified that the square sanding disc except for direct engagement with the drive shaft or centric stepped pin or the retaining ring stands and alone holds onto the tool holder.

- the sanding plate Since the sanding plate is a wearing part, it is quick Reposition the corner areas in relation to the tool holder in orbital sander mode or its easy interchangeability of considerable advantage for the random orbit sander mode. This Advantage arises from the interaction of the locking means Grinding plate with those of the tool holder or the drive shaft. This is also the sanding plate an important component or spare part.

- the sanding disc for the eccentric sanding mode has the advantage that he with the eccentric pin on a delayed turning can be rotatably coupled with at least one roller bearing is arranged between the drive shaft and the grinding plate and that it is opposite the at least one vibrating element is freely rotatable.

- the sanding disc for the orbital sander mode has the advantage that when coupled to the tool holder except for immediate Intervention to the drive shaft or to the central stepped journal and the retaining ring comes on the tool holder in a rotationally fixed manner holds and in indirect engagement with the vibrating elements stands, centrically coupled with the drive shaft is, with a plug and a driving pin for Coupling with the drive shaft carries.

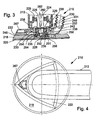

- Fig. 1 in side view and partially Electric hand grinder shown in section is as Orbital sander 9 with a triangular, symmetrical Abrasive plate trained grinding tool 10 designed.

- the Bottom of the sanding plate is made of plastic and is with a Velcro covering 11 for receiving sanding sheets, not shown Mistake.

- the orbital sander 9 has a two-shell machine housing, which is composed of two housing shells 121, 121 ', those running along a parallel to the longitudinal axis of the housing Butt joint 119.

- a Electric motor 13 added, of which only that on the output shaft 14 seated fan 15 can be seen.

- One on the top of the machine housing 12 arranged on / off switch 16 is used for switching the electric motor on and off 13.

- the output shaft 14 drives a drive shaft 18 via an angular gear 17, the ball bearings 19a and 19b arranged in a housing-fixed manner is rotatably mounted and on the lower end of the machine housing 12 with an eccentric pin 20 from the machine housing 12 projects.

- the eccentric pin 20 sits axially centrically in a stepped pin 20'fort, which is a molded Ball bearing 21 'carries, the function of Figure 3 explained in more detail is.

- eccentric pin 20 Radially outside on the eccentric pin 20 is axially immovable the inner ring of another ball bearing 21, which with its Outer ring held in a bowl-shaped tool holder 22, in particular, is injected.

- the one made of plastic Tool holder 22 is over a corrugated membrane-like vibrating body 23 attached to the machine housing 12 so that it rotates of the eccentric pin 20 is prevented from rotating and thus only executes a circular oscillating movement.

- the grinding tool 10 is attached to the tool holder 22 by means of a corresponding one Positive locking elements on the tool holder side or fixed on the tool side and by means of a quick lock 24, which can be operated manually via an operating button 25, being held.

- the grinding tool 10 lies on one Support surface 37 of the bowl-shaped tool holder 22, the is clearly highlighted by a forward line, and includes a dust extraction chamber 26 with the tool holder 22, on the one hand via suction holes 27 in the grinding tool 10 and corresponding, corresponding holes in the sanding sheets to the side to be machined of a workpiece, not shown is open and on the other hand via a bellows 28 with a dust extraction duct running in the machine housing 12 29 is connected, the end of an external suction fan is to be connected.

- Tool-side locking elements 40 are in one piece the grinding tool 10 formed hooks 42 formed on a circular line offset from each other by the same angle of rotation are and of the bearing surface 37 on the tool holder 22 protrude facing the top of the grinding tool 10.

- the Hooks 42 are on the outside for the sake of simplicity Molded sleeve 38, the inner jacket of the polygon profile 39th wearing.

- the interacting holder-side locking elements 41 are formed by an annularly bent spring wire 43 educated.

- a symmetrical Polygon profile 36 formed, the three by 120 ° each there are offset, identical circular arc sections 361, which are offset by 120 ° from each other, same circular arc sections 362 are connected, the arc radius is larger than that of the circular arc sections 361.

- the spring wire 43 has one of the number of hooks 42 on the sleeve 38 corresponding number, here three, pointing radially inwards Indentations 431, which in turn correspond to the hook 42 are offset from one another by the same angle of rotation.

- the spring wire 43 is rotatable in the outer slots 51 by webs 44 or slidably received on the tool holder 22, the on an axis 33 of the pin 32 or of the ball bearing 21 Coaxial pitch circle are arranged and in one piece with the tool holder 22 protrude down from this.

- the webs 44 are arranged in pairs so that in the locked position of the spring wire 43, as shown in Fig. 2, each a pair of webs lies on both sides of an indentation 431.

- the web pairs are in turn offset by the same circumferential angle.

- the annularly curved spring wire 43 runs in approximately two radially striving, mutually parallel legs 432 and 433 out.

- One leg 432 is bent at right angles at the end and lies in front of the straight end of leg 433.

- On the free The ends of the legs 432, 433 are the operating button 25 of the quick lock 24 can be clipped on, for which the control button 25 on your Corresponding not shown grooves and locking lugs on the underside having.

- the leg 432 of the spring wire 43 is in this groove is pushed in, with its bent end in a transverse groove comes to rest, while the other leg 433 in one further, not shown groove is clipped captive.

- the control button 25 can now be used in the transverse slots 51 of the webs 44 guided spring wire 43 in the spring wire plane be pivoted, which in the locked position the hook 42 slip behind recesses 431 away from hook 42, so that the radially outer parts of the Move spring wire 43 to the place of indentations 431 and so that the hook 42 release. Then the grinding tool 10 manually withdrawn from the tool holder 22 in the direction of the axis 33 become. In this position the quick lock 24 can the grinding tool 10 changed and - in the aforementioned training of the grinding tool 10 as a triangular, symmetrical Sanding plate - rotated 120 ° with one corner forward can be inserted again into the tool holder 22.

- Figure 3 shows an embodiment of the invention Orbital sander 210 in sections in longitudinal section, the Housing 212 inside a motor and not shown not shown upper area an electrical input and Switch 216 carries. From the rear of the housing 212 an electrical connection line (not shown) emerges.

- the housing 212 carries at its lower end a tool holder 222 on which a grinding plate 218 is rotatable which supports a sanding sheet 220 with a Velcro connection wearing.

- the drive shaft 224 carries an eccentric pin at its free end 226, towards its free end in a central Step pin 228 merges.

- the drive shaft 224 is above with its central region of the eccentric pin 226 via an upper roller bearing 225 in the housing 212 rotatably mounted.

- the eccentric pin 226 is in a middle one Rolling bearing 230 is rotatably mounted in the tool holder 222.

- the roller bearing 230 engages around the eccentric pin with its inner ring 229 226 and is with its outer ring 231 in the tool holder 222 pressed.

- the stepped pin 228 has a smaller diameter than the eccentric pin 226 and engages in an inner ring 233 of a lower one Rolling bearing 232, the outer ring 235 on the grinding plate 218 can be releasably connected in a rotationally fixed manner by means of a snap connection 236 is.

- the tool holder 222 holds up over the usual columnar vibrating elements 38, 39, 40 elastic on the housing 212 fixed, so that it can be rotated to a limited extent and laterally deflected opposite the housing 212.

- the rear swing elements 239, 240 are arranged side by side in pairs. Therefore only the front vibrating element 239 is visible in FIGS. 1 and 3, covering the vibrating element 240, which is therefore covered with a is provided in parentheses.

- the grinding plate 218 is applied concentrically to the blind bore 252 the back of a circular ring groove 256. This forms an annular collar between the annular groove 256 and the blind bore 252 254. This reaches from below into a centric one that is open at the bottom Counter ring groove 251 of the retaining ring 250 and holds in it releasably non-positive, also positive locking by means of locking or a snap connection is possible.

- an axial spacing joint 248 can be seen, which in the axial Pressure on the grinding plate 218 when grinding with the Orbital sander 210 is smaller or almost closed, so that the grinding plate 218 on the tool holder 222 is slightly rubbing and thus comes to the system slightly braked.

- the tool holder 222 serves here as a high-speed brake for the Sanding disc 218 so that it is idling, i.e. if there is no working braking torque between the grinding plate 218 and a workpiece works, not beyond its optimal working speed is accelerated and thereby damage to the workpiece can be prevented by excessive material removal.

- the grinding plate 218 is of axial lines drawn with dashed lines Exhaust openings 258 pass through on a concentric Are arranged in a circle and through the grinding dust over the bellows 246 into the dust removal duct and via its duct outlet can go to the outside for disposal.

- the round grinding disc 218 is with its ring collar 254 from the Counter ring groove 251 detachably removable axially downward latching.

- the round grinding disc 218 rotates because it is due to the bearing friction taken in the rolling bearing 232 by the drive shaft 224 becomes.

- the grinding plate 218 rotates about an eccentric axis 260, with a circular motion with the eccentricity e is superimposed.

- the eccentricity e corresponds to the distance between the eccentric axis 260 and the central axis 262 according to the solution according to EP 610 810.

- Figure 4 as a top view of Figure 3 shows the circular Contour of the grinding plate 218, that of the triangular tool holder 222 is worn.

- the operation button is 225 clearly recognizable who is in the locking position and the can be moved to the release position by swiveling clockwise is.

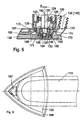

- FIG. 5 shows the orbital sander 110 with one against the round one Sanding disc 218 replaced according to FIG. 3, triangular Sanding disc 168.

- the sanding disc 168 holds over one Snap connection 166 via an operating button 167 of the tool holder 122 is detachable, with a collar 170 directly on the tool holder 122 and not on the retaining ring 150, so that the orbital sander 110 also as a fine-removing triangular sander can be used.

- the triangular sanding plate 168 is not immediate Engagement with the drive shaft 224 and engages with its collar 70 an annular region 123 encompassing the central roller bearing 130 of the tool holder 122.

- the collar 170 goes into a short radial forehead collar 171 with an outer inclined surface 173.

- When attaching the triangular grinding plate 168 to the tool holder 122 enters the forehead collar 171 through a pivotable partially waisted ring spring 174 and keeps up Inclined surfaces 173 like a snap hook on this axially immovable firmly.

- the ring spring 174 can be pivoted, so that the grinding plate 168 axially without further can be removed.

- FIG. 6 shows a top view of the orbital sander 110 according to Figure 5, wherein the triangular contour of both the tool holder 122 and the grinding plate 168.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

Claims (8)

- Ponceuse vibrante (9, 119, 210) comprenant un boítier (12, 112, 212) logeant un moteur (14) et un arbre d'entraínement (18, 124, 224) rotatif, couplé à celui-ci, cet arbre communiquant par l'intermédiaire d'un téton excentré (20), un mouvement orbital à un porte-outil (22, 122, 22) fixé élastiquement au boítier (12, 112, 212) par au moins un élément oscillant (23, 138, 139, 140, 238, 239, 240), et la face inférieure du porte-outil (22, 122, 222) est munie d'un plateau de ponçage anguleux (10, 168) fixé de manière amovible notamment par un clipsage,

caractérisée en ce qu'

à la place du plateau de ponçage anguleux (10, 168) on peut coupler de manière amovible un plateau de ponçage (218) non anguleux, de préférence circulaire, à l'arbre d'entraínement (18, 124, 224), l'arbre d'entraínement (18, 124, 224) pénétrant avec son téton excentré (20, 126, 226) notamment avec son prolongement axial (20', 128, 228) dans la bague intérieure (133, 233) d'un premier palier de roulement (21', 134, 234) dont la bague extérieure (135, 235) est couplée solidairement en rotation au plateau de ponçage (218) non anguleux, le plateau de ponçage (218) étant découplé au moins d'un élément oscillant (23, 138, 139, 142, 138, 239, 240) et pouvant tourner par rapport au porte-outil (22, 122, 222). - Ponceuse vibrante selon la revendication 1,

caractérisée en ce que

la bague extérieure (135, 235) du palier à roulement (134, 234) est entourée par un anneau de fixation (150, 250) qui s'accroche dans la zone centrale du plateau de ponçage (218) et sert d'organe d'entraínement pour le plateau de ponçage (218). - Ponceuse vibrante selon l'une quelconque des revendications 1 ou 2,

caractérisée en ce que

l'anneau de fixation (250) est injecté sur la bague extérieure (235) du palier de roulement (232). - Ponceuse vibrante selon l'une quelconque des revendications précédentes,

caractérisée en ce que

le prolongement axial (128, 228) du tourillon excentré (126, 226) est un tourillon dont le diamètre est inférieur à celui du tourillon excentré. - Ponceuse vibrante selon l'une quelconque des revendications précédentes,

caractérisée en ce que

le plateau de ponçage (218) est circulaire et il peut tourner librement par rapport au pignon d'entraínement (224). - Ponceuse vibrante selon l'une quelconque des revendications précédentes,

caractérisée en ce que

le porte-outil (122) servant à l'entraínement du plateau anguleux (168) touche le plateau de ponçage (218) non anguleux et sert de frein contre l'emballement. - Ponceuse vibrante selon la revendication 6,

caractérisée en ce que

le côté du porte-outil (22) tourné vers le plateau (168) non anguleux est muni d'une couche d'une matière particulièrement résistante à l'usure qui est une partie d'une paire d'éléments de friction et la face supérieure du plateau de ponçage (128) tournée vers le porte-outil (122) est munie d'une partie de la matière résistant à l'usure qui est l'autre partie de la paire d'éléments de friction. - Ponceuse vibrante selon l'une quelconque des revendications précédentes,

caractérisée en ce que

le moteur (14) fonctionnant, l'arbre d'entraínement (224) entraíne de manière indépendante le porte-outil (222) et le plateau de ponçage (218).

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19617475A DE19617475A1 (de) | 1996-05-02 | 1996-05-02 | Schwingschleifer |

| DE19617475 | 1996-05-02 | ||

| PCT/DE1997/000137 WO1997041999A1 (fr) | 1996-05-02 | 1997-01-28 | Ponceuse vibrante |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0842011A1 EP0842011A1 (fr) | 1998-05-20 |

| EP0842011B1 true EP0842011B1 (fr) | 2002-04-17 |

Family

ID=7793013

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97907017A Expired - Lifetime EP0842011B1 (fr) | 1996-05-02 | 1997-01-28 | Ponceuse vibrante |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0842011B1 (fr) |

| CN (1) | CN1077826C (fr) |

| DE (2) | DE19617475A1 (fr) |

| WO (1) | WO1997041999A1 (fr) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10247899B4 (de) * | 2002-10-14 | 2011-08-11 | Robert Bosch GmbH, 70469 | Verfahren zur Herstellung einer Schleifplatte |

| CN101163570B (zh) | 2005-11-18 | 2012-06-27 | 创科电动工具科技有限公司 | 用于打磨机的打磨垫锁定件 |

| DE102012210893A1 (de) * | 2012-06-26 | 2014-01-02 | Robert Bosch Gmbh | Handschleifmaschine mit einer Schwingplatte |

| US20200338686A1 (en) * | 2017-08-04 | 2020-10-29 | Positec Power Tools (Suzhou) Co., Ltd. | Grinding tool, and main component and grinding component thereof |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US544145A (en) * | 1895-08-06 | wirrington | ||

| DE4304059A1 (de) * | 1993-02-11 | 1994-08-18 | Diehl Gmbh & Co | Spiegeleinrichtung mit einem deformierbaren Spiegelelement |

| DE4314799C2 (de) * | 1993-05-05 | 1995-04-13 | Fein C & E | Elektrowerkzeug |

-

1996

- 1996-05-02 DE DE19617475A patent/DE19617475A1/de not_active Withdrawn

-

1997

- 1997-01-28 DE DE59707032T patent/DE59707032D1/de not_active Expired - Fee Related

- 1997-01-28 WO PCT/DE1997/000137 patent/WO1997041999A1/fr active IP Right Grant

- 1997-01-28 CN CN97190409A patent/CN1077826C/zh not_active Expired - Fee Related

- 1997-01-28 EP EP97907017A patent/EP0842011B1/fr not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| WO1997041999A1 (fr) | 1997-11-13 |

| CN1077826C (zh) | 2002-01-16 |

| DE19617475A1 (de) | 1997-11-06 |

| CN1189795A (zh) | 1998-08-05 |

| DE59707032D1 (de) | 2002-05-23 |

| EP0842011A1 (fr) | 1998-05-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0836544B1 (fr) | Meuleuse portative electrique | |

| EP0916456B1 (fr) | Outil à main électrique | |

| EP1116551B1 (fr) | Ponçeuse à guidage manuel | |

| DE69729396T2 (de) | Schleifscheibenanordnung zum Einsatz bei einer Präzisions-Spiralbohrerschleifvorrichtung | |

| DE4236964A1 (de) | Scheibenförmiges Werkzeug für Winkelschleifer | |

| EP0868264B1 (fr) | Outil a main electrique | |

| DE19952108B4 (de) | Exzentertellerschleifmaschine | |

| DE202010008240U1 (de) | Multifunktions-Kraftwerkzeug | |

| DE102012217532A1 (de) | Mittels einer Feder vorgespannte Basis mit versetztem Drehpunkt | |

| EP0336930A1 (fr) | Dispositif de serrage pour la fixation amovible d'un outil, notamment d'un disque abrasif. | |

| EP2366494B1 (fr) | Machine-outil manuelle dotée d'un engrenage excentrique à rotation forcée | |

| DE102004006888A1 (de) | Absaugvorrichtung | |

| DE102012217550A1 (de) | Kreissägen-schutzsystem | |

| EP0842012B1 (fr) | Ponceuse vibrante | |

| EP0842011B1 (fr) | Ponceuse vibrante | |

| WO1998006539A1 (fr) | Ponceuse vibrante | |

| EP0790697A1 (fr) | Machine-outil électrique avec dispositif de commutation pour marche à droite et à gauche | |

| DE9016415U1 (de) | Handgeführte Elektrowerkzeugmaschine mit einer Einrichtung zum Einstellen des Drehmoments | |

| WO1996003900A1 (fr) | Brosse entrainee par un moteur | |

| EP2366495B1 (fr) | Machine-outil manuelle dotée d'un engrenage excentrique et d'un verrou | |

| DE4238245A1 (en) | Hand-held power driven polishing or grinding tool - has attached duct which can be connected to suction source to remove dust generated by tool | |

| WO2005095058A1 (fr) | Tete de meulage pour dispositif de meulage | |

| DE19704110A1 (de) | Handbandschleifer | |

| EP0730931B1 (fr) | Outil mécanisé pour meuler, râper, limer ou polir | |

| DE8711311U1 (de) | Schleifmaschine mit rotierendem Schleifteller |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE GB IT LI |

|

| 17P | Request for examination filed |

Effective date: 19980513 |

|

| 17Q | First examination report despatched |

Effective date: 20000328 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE GB IT LI |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: SCINTILLA AG, DIREKTION Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59707032 Country of ref document: DE Date of ref document: 20020523 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20020709 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20030113 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20030124 Year of fee payment: 7 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030120 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040128 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040131 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040131 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20040128 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050128 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20090327 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100803 |