EP0835701B1 - Durchsetzfügematrize - Google Patents

Durchsetzfügematrize Download PDFInfo

- Publication number

- EP0835701B1 EP0835701B1 EP97115887A EP97115887A EP0835701B1 EP 0835701 B1 EP0835701 B1 EP 0835701B1 EP 97115887 A EP97115887 A EP 97115887A EP 97115887 A EP97115887 A EP 97115887A EP 0835701 B1 EP0835701 B1 EP 0835701B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- press

- die according

- component

- joining die

- parts

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21J—FORGING; HAMMERING; PRESSING METAL; RIVETING; FORGE FURNACES

- B21J13/00—Details of machines for forging, pressing, or hammering

- B21J13/02—Dies or mountings therefor

- B21J13/03—Die mountings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D28/00—Shaping by press-cutting; Perforating

- B21D28/24—Perforating, i.e. punching holes

- B21D28/34—Perforating tools; Die holders

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D37/00—Tools as parts of machines covered by this subclass

- B21D37/04—Movable or exchangeable mountings for tools

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D39/00—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders

- B21D39/03—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders of sheet metal otherwise than by folding

- B21D39/031—Joining superposed plates by locally deforming without slitting or piercing

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/34—Means for forming clench-tongue [eg, for tieband]

Definitions

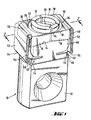

- FIG. 2 it is a clinching die very similar to that shown in Figure 1 of the above-mentioned US-A-4,972,565 is. It comprises an anvil 10 with a base 12 and roof-like beveled support surfaces 14 on which (in the exemplary embodiment: two) expanding parts 16 are supported.

- the expansion parts 16 are with upright, approximately crescent-shaped extensions 18 in plan view Mistake.

- stamp material in enforced the space enclosed by the extensions 18 and between the stamp and the working surface 20 of the anvil 'compressed and thus spread , the expansion parts move sideways and give space free for the lateral flow of the material.

- the evasive movement of the Spreading parts 16 also has a downward component due to the inclination of the support surfaces 14.

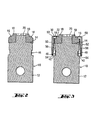

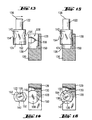

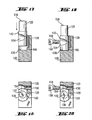

- the straight edge regions 34 lie in a line with fold lines 38 .mu.m the tab portions 40 are angled so that they are in the finished Component run perpendicular to the central section.

- “bend” is not to be understood here as the formation of a sharp edge, but a bending radius is intentionally provided; because the component is preferred made of spring steel would cause brittle fracture without a bending radius consist. This applies mutatis mutandis to others to be described Deformation of the blank.

- the arrows indicate the direction in which the individual parts are facing relocated to carry out the installation of the tool.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Mounting, Exchange, And Manufacturing Of Dies (AREA)

- Orthopedics, Nursing, And Contraception (AREA)

- Automatic Assembly (AREA)

- Insertion Pins And Rivets (AREA)

- Perforating, Stamping-Out Or Severing By Means Other Than Cutting (AREA)

- Shaping Metal By Deep-Drawing, Or The Like (AREA)

- Stereophonic System (AREA)

- Measurement Of Resistance Or Impedance (AREA)

Description

- Halten der Spreizteile 16 auf dem Amboß 10,

- Führen der Spreizteile 16 parallel zu ihrer Ausweichbewegung,

- Begrenzen des Ausweichhubes,

- elastisches Rückstellen der Spreizteile in ihre Ruheposition,

- unlösbares Verbinden aller die Matrize bildenden Elemente.

Claims (13)

- Durchsetzfügematrize mit einem Amboß (10), auf dem beweglich mindestens zwei Spreizteile (16) mittels federelastischer Rüdcstellelemente (56) gehalten sind, dadurch gekennzeichnet, daß alle Spreizteile (16) von einem nichtelastomeren Bauteil gehalten sind, das nur unter Zerstörung der Matrize lösbar ist, wozu das Bauteil die Spreizteile (16) übergreift.

- Durchsetzfügematrize nach Anspruch 1, dadurch gekennzeichnet, daß das Bauteil die Rückstellelemente (56) sowie eine Wegbegrenzung (36) für die Spreizteile (16) aufweist

- Durchsetzfügematrize nach Anspruch 1 oder 2, dadurch gekennzeichnet, daß das Bauteil einen Durchbruch (32) aufweist, dessen Ränder (34, 36) auf den Spreizteilen (16) aufliegen.

- Durchsetzfügematrize nach Anspruch 3, dadurch gekennzeichnet, daß die Spreizteile (16) den Durchbruch (32) durchsetzende Anschlagfortsätze (18) aufweisen und Teile (36) des Durchbruchrandes Gegenanschläge bilden.

- Durchsetzfügematrize nach einem der Ansprüche 1 bis 4, dadurch gekennzeichnet, daß das Bauteil Laschen (40) aufweist, längs denen die Spreizteile (16) geführt sind.

- Durchsetzfügematrize nach einem der Ansprüche 1 bis 5, dadurch gekennzeichnet, daß das Bauteil am Amboß (10) befestigt ist.

- Durchsetzfügematrize nach Anspruch 6, dadurch gekennzeichnet, daß das Bauteil einen in eine Umfangsnut (46) des Amboß' (10) greifenden Reif (42, 44) aufweist.

- Durchsetzfügematrize nach Anspruch 7, dadurch gekennzeichnet, daß zunächst offene Enden des Reifs miteinander form- und/oder stoffschlüssig verbunden sind.

- Durchsetzfügematrize nach Anspruch 8, dadurch gekennzeichnet, daß die Reifenden punktverschweißt sind.

- Durchsetzfügematrize nach einem der Ansprüche 8 oder 9, dadurch gekennzeichnet, daß längere Teile (42) des Reifs als Fortsätze einer der Laschen nach Anspruch 6 und kürzere Teile (44) des Reifs als Fortsätze der anderen Lasche nach Anspruch 6 ausgebildet sind, derart, daß die Verbindungsstellen der Reifenden zugänglich sind.

- Durchsetzfügematrize nach einem der vorangehenden Ansprüche, dadurch gekennzeichnet, daß das Bauteil ein Stanz- und Biegeteil vorzugsweise aus Federstahl ist.

- Durchsetzfügernatrize nach Anspruch 2 oder einem auf diesen rückbezogenen Anspruch, dadurch gekennzeichnet, daß die Rückstellelemente (56) als Federzungen ausgebildet sind.

- Zuschnitt für die Herstellung des Bauteils der Durchsetzfügematrize nach einem der Ansprüche 1 bis 12, der umfasst:einen Zentralabschnitt (30), versehen mit einem Durchbruch (32),mit dem Zentralabschnitt verbundene, von diesem rechtwinklig abwinkelbare Laschenabschnitte (40),mit mindestens einem der Laschenabschnitte verbundene Reifabschnitte (42, 44),mit dem Zentralabschnitt (30) verbundene, von diesem rechtwinklig abwinkelbare Zwischenabschnitte (52),mit je einem Zwischenabschnitt verbundene, von diesem um mehr als 90° abwinkelbare Rückstellelementabschnitte (56).

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE29617574U DE29617574U1 (de) | 1996-10-09 | 1996-10-09 | Werkzeugschaft und Sockel für seine Aufnahme |

| DE29617574U | 1996-10-09 | ||

| DE29618060U DE29618060U1 (de) | 1996-10-18 | 1996-10-18 | Durchsetzfügematrize |

| DE29618060U | 1996-10-18 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0835701A2 EP0835701A2 (de) | 1998-04-15 |

| EP0835701A3 EP0835701A3 (de) | 1999-11-10 |

| EP0835701B1 true EP0835701B1 (de) | 2003-11-19 |

Family

ID=26059505

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97115887A Expired - Lifetime EP0835701B1 (de) | 1996-10-09 | 1997-09-12 | Durchsetzfügematrize |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US5992206A (de) |

| EP (1) | EP0835701B1 (de) |

| JP (2) | JPH10180374A (de) |

| AT (1) | ATE254516T1 (de) |

| DE (1) | DE59711026D1 (de) |

| ES (1) | ES2212024T3 (de) |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE9904167D0 (sv) * | 1999-11-16 | 1999-11-16 | Attexor Equip | Atool for joining two or several overlaying sheet formed members |

| DE10006789C2 (de) * | 2000-02-15 | 2002-05-16 | Eckold Vorrichtung | Vorrichtung zum mechanischen Fügen, Scheren, Schneiden, Bördeln oder schlagenden Umformen von Blech-, Rohr- oder Profilteilen |

| US6430794B1 (en) | 2000-05-17 | 2002-08-13 | Mckee James E. | Female crimping die and system for crimping metal sheets |

| JP4694011B2 (ja) * | 2001-03-01 | 2011-06-01 | 三洋機工株式会社 | 金属薄板の結合装置 |

| US7150086B2 (en) * | 2001-04-04 | 2006-12-19 | Eugen Rapp | Tool that connects pieces through a process of riveting |

| ITTO20010659A1 (it) * | 2001-07-06 | 2003-01-06 | Comau Spa | Dispositivo integrato di bloccaggio e clinciatura, particolarmente per l'unione di pannelli di lamiera metallica e simili. |

| US20060096075A1 (en) * | 2004-11-08 | 2006-05-11 | Victor Robinson | Clinching tool, die and method for use thereof |

| DE102006024112A1 (de) * | 2006-05-19 | 2007-11-22 | Eckold Gmbh & Co Kg | Matrize zum mechanischen Fügen |

| US20130042450A1 (en) * | 2011-08-15 | 2013-02-21 | Hans R. Bergkvist | Apparatus for joining two or more overlapping material members and method for manufacturing of the apparatus |

| DE102012101894A1 (de) * | 2012-03-06 | 2013-09-12 | Tkr Spezialwerkzeuge Gmbh | Werkzeugverbindung |

| WO2015063333A1 (en) * | 2013-11-04 | 2015-05-07 | Attexor Clinch Systems S.A. | Tool for making joints of clinch type |

| CN103586384B (zh) * | 2013-11-05 | 2015-08-05 | 燕山大学 | 一种组合预紧凹模快速卸载胀模力的装置 |

| DE102013021056B4 (de) | 2013-12-18 | 2024-07-18 | Newfrey Llc | Wechselmatrize, Fügewerkzeug und Fügeverfahren |

| CN106583625A (zh) * | 2016-12-26 | 2017-04-26 | 苏州沃森优金电子科技有限公司 | 一种组装式模具夹具 |

| PL3769859T3 (pl) * | 2019-07-24 | 2021-12-13 | Btm Company Llc | Urządzenie do łączenia blach zawierające zespół matrycowy i sposób jego montażu |

| US11446726B2 (en) * | 2020-05-14 | 2022-09-20 | BTM Company, LLC | Metal fastening die assembly |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2619855A (en) * | 1947-05-20 | 1952-12-02 | Ivan A Williams | Material uniting punch and die |

| US2626687A (en) * | 1949-05-23 | 1953-01-27 | Ivan A Williams | Cleft fastener for uniting materials and method of forming the same |

| US5072518A (en) * | 1980-02-02 | 1991-12-17 | Multifastener Corporation | Installation head for attaching female fasteners |

| JPS56114536A (en) * | 1980-02-13 | 1981-09-09 | Toshiba Corp | Joining device of sheet material |

| US4757609A (en) * | 1980-09-08 | 1988-07-19 | Btm Corporation | Apparatus for joining sheet material |

| US5177861A (en) * | 1980-09-08 | 1993-01-12 | Btm Corporation | Apparatus for joining sheet material |

| FR2661341B2 (fr) * | 1988-09-13 | 1994-09-09 | Pignon Guy | Dispositif pour fixer des elements d'outils de presse dans leur support. |

| DE3836937A1 (de) * | 1988-10-29 | 1990-05-03 | Eckold Vorrichtung | Durchsetzfuegevorrichtung |

| US5315743A (en) * | 1990-05-18 | 1994-05-31 | Tech-Line Engineering Co. | Apparatus for forming a clinch joint |

| DE69215591T2 (de) * | 1991-07-05 | 1997-05-15 | Nippon Steel Welding Prod Eng | Steckersystem mit faseroptischem Kabel mit einem Metallrohrmantel |

| US5860315A (en) * | 1994-07-29 | 1999-01-19 | Etm Corporation | Device for securing tools |

-

1997

- 1997-09-12 AT AT97115887T patent/ATE254516T1/de active

- 1997-09-12 EP EP97115887A patent/EP0835701B1/de not_active Expired - Lifetime

- 1997-09-12 DE DE59711026T patent/DE59711026D1/de not_active Expired - Lifetime

- 1997-09-12 ES ES97115887T patent/ES2212024T3/es not_active Expired - Lifetime

- 1997-10-08 US US08/946,890 patent/US5992206A/en not_active Expired - Lifetime

- 1997-10-09 JP JP9277444A patent/JPH10180374A/ja not_active Withdrawn

-

2004

- 2004-08-13 JP JP2004235946A patent/JP2005046912A/ja active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| US5992206A (en) | 1999-11-30 |

| JP2005046912A (ja) | 2005-02-24 |

| EP0835701A2 (de) | 1998-04-15 |

| ES2212024T3 (es) | 2004-07-16 |

| JPH10180374A (ja) | 1998-07-07 |

| ATE254516T1 (de) | 2003-12-15 |

| EP0835701A3 (de) | 1999-11-10 |

| DE59711026D1 (de) | 2003-12-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0835701B1 (de) | Durchsetzfügematrize | |

| DE69116354T2 (de) | Scherungskraft übertragende Befestigungsvorrichtung | |

| DE69003662T2 (de) | System für den koaxialen Zusammenbau zweier rotierender Teile. | |

| DE4420073C2 (de) | Nutenstein | |

| DE69803632T2 (de) | Einpressmutter | |

| DE2217490B2 (de) | Halterung einer schwimmend gelagerten mutter an einem werkstueck | |

| DE4329824A1 (de) | Adapter für ein optisches Verbindungsglied und Schaltplattenanschlußstück für denselben | |

| EP0175856B1 (de) | Spannmuffe mit einer Spannschraube | |

| DE69408080T2 (de) | Verbesserungen an werkzeugen zur erzeugung von befestigungspunkten an blechen durch kaltformung | |

| DE2525178A1 (de) | Riemenverbindervorrichtung | |

| EP0782898A1 (de) | Verfahren zum Befestigen eines Spannaufsatzes auf einem Werkstück und Vorrichtung zu seiner Durchführung | |

| DE60113449T2 (de) | Matrizenkäfiganordnung mit gelenk | |

| DE2163763C3 (de) | Verbindung zweier Tafeln aus Blech unter Verwendung eines Verbindungsglieds | |

| DE102008028972A1 (de) | Radschützer für ein Fahrrad | |

| EP3420238A1 (de) | Vorrichtung zum ausgleichen von toleranzen | |

| DE3409392A1 (de) | Einrichtung zum zentrieren und fixieren eines werkzeuges in einem traggestell | |

| EP2110566A2 (de) | Verbindungsgruppe zur Befestigung eines Anbauelements auf einem Trägerelement | |

| DE19720412A1 (de) | Zweischneidiger, mit einer einzelnen Schneidplatte versehener Fräser erhöhter Festigkeit und Genauigkeit | |

| EP1377397B1 (de) | Werkzeug zum nietartigen verbinden | |

| EP1896219B1 (de) | Verbindungsstelle | |

| WO2006131538A2 (de) | Kennzeichnungsstempel mit einschraubbarem zentraleinsatz | |

| EP1857197A1 (de) | Matrize zum mechanischen Fügen | |

| EP1103482A2 (de) | Verkaufsverpackung für ein Bohrwerkzeug | |

| WO1991011630A1 (de) | Selbstbohrendes befestigungselement | |

| DE3802798A1 (de) | Verfahren und vorrichtung zum verbinden von bauelementen insbesondere von pfetten und wandriegeln |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE ES FR GB IT LI NL SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 19991214 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH DE DK ES FI FR GB LI |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT CH DE ES FR GB IT LI NL SE |

|

| 17Q | First examination report despatched |

Effective date: 20020612 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE ES FR GB IT LI NL SE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59711026 Country of ref document: DE Date of ref document: 20031224 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: DR. BRUNO HAMMER |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040126 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2212024 Country of ref document: ES Kind code of ref document: T3 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20040820 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20160920 Year of fee payment: 20 Ref country code: CH Payment date: 20160920 Year of fee payment: 20 Ref country code: NL Payment date: 20160920 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20160921 Year of fee payment: 20 Ref country code: SE Payment date: 20160920 Year of fee payment: 20 Ref country code: AT Payment date: 20160921 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20160916 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20161128 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20160922 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59711026 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MK Effective date: 20170911 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20170911 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 254516 Country of ref document: AT Kind code of ref document: T Effective date: 20170912 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20170911 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20180507 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20170913 |