EP0807527A2 - Imprimante - Google Patents

Imprimante Download PDFInfo

- Publication number

- EP0807527A2 EP0807527A2 EP97107924A EP97107924A EP0807527A2 EP 0807527 A2 EP0807527 A2 EP 0807527A2 EP 97107924 A EP97107924 A EP 97107924A EP 97107924 A EP97107924 A EP 97107924A EP 0807527 A2 EP0807527 A2 EP 0807527A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- paper

- rollers

- cut

- insertion opening

- printing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J13/00—Devices or arrangements of selective printing mechanisms, e.g. ink-jet printers or thermal printers, specially adapted for supporting or handling copy material in short lengths, e.g. sheets

- B41J13/26—Registering devices

- B41J13/28—Front lays, stops, or gauges

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J11/00—Devices or arrangements of selective printing mechanisms, e.g. ink-jet printers or thermal printers, for supporting or handling copy material in sheet or web form

- B41J11/48—Apparatus for condensed record, tally strip, or like work using two or more papers, or sets of papers, e.g. devices for switching over from handling of copy material in sheet form to handling of copy material in continuous form and vice versa or point-of-sale printers comprising means for printing on continuous copy material, e.g. journal for tills, and on single sheets, e.g. cheques or receipts

Definitions

- the present invention relates to a printer capable of printing on cut-sheet paper and, more particularly, to a point of sale (POS) printer for printing on cut-sheet paper, such as paper slips, bank checks etc..

- POS point of sale

- Printers that can print on cut-sheet paper, i.e., single sheets of paper, such as a paper voucher, a slip, a bank check or the like, are known.

- a sheet of paper is transferred to a printing area by a first pair of transfer rollers disposed adjacent a paper insertion opening (referred to as insertion rollers hereinafter).

- the sheet of paper is printed at a printing area and then discharged out of the printer by a second pair of transfer rollers disposed adjacent a paper discharge opening (referred to as discharge rollers hereinafter).

- discharge rollers For inserting a sheet of paper, the rollers are separated from each other to facilitate the insertion of the paper.

- slip printing When printing on relatively large sheet of paper, such as a slip (herein after referred to as slip printing), the paper is inserted through the insertion opening, passed through a paper feed path past the printing area, and discharged through the discharge opening.

- validation printing when printing a few lines in a predetermined area on card-like cut-sheet paper such as a bank check for payment validation (herein after referred to as validation printing), the paper is inserted through the discharge opening and printing is performed while the paper is transferred back toward the discharge opening past the printing area.

- slip will be used hereinafter as representative for any kind of cut-sheet paper suitable for slip printing and the term “check” will be used as representative for any kind of cut-sheet paper suitable for validation printing.

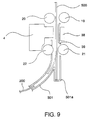

- Fig. 9 shows an explanatory view of a conventional printer that is capable of both slip printing and validation printing.

- Reference numeral 4 denotes a print head for printing on a slip 200 or a check 500 that is transferred to the printing area between print head 4 and a platen 38 by a pair of discharge rollers 19 and 20 and a pair of intermediate rollers 21 and 22, each pair being disposed in a manner that the rollers in each pair can be opened (separated from each other) and closed (brought together).

- Reference numeral 501 denotes a paper feed path for transferring a slip 200.

- a pair of insertion rollers (not shown) for slips is provided next to the insertion opening.

- the discharge rollers 19 and 20 and the intermediate rollers 21 and 22 are both separated from each other as shown in the figure, and the check 500 is inserted through the discharge opening down into a groove section 501a. Then, the discharge rollers 19 and 20 and the intermediate rollers 21 and 22 are both brought into pressure contact to pinch the check 500, and printing by the print head 4 is performed as the check is advanced upwardly back to the discharge opening.

- cut-sheet paper for validation printing may be provided in a variety of types.

- the paper feed path is preferably formed along a straight line.

- a groove section 501a is formed in the prior art for positioning the bottom edge or leading end of the check, in addition to the paper feed path 501 for transferring a slip.

- EP-B-0 428 163 discloses an impact dot matrix POS printer according to the precharacterizing part of claim 1, which differs from the one explained above with reference to Fig. 9 in that only the insertion rollers and the intermediate rollers but not the discharge rollers are provided.

- the platen and one of the intermediate rollers are supported on a first lever and one of the insertion rollers is supported on a second lever.

- the first lever is pivotally supported to close or open the intermediate rollers. When the intermediate rollers are open the printing area is also open, i.e., the platen is retracted from it working position opposite the print head.

- the second lever is also pivotally supported to close or open the insertion rollers.

- a first plunger is used to drive the first lever and a second plunger is used to drive the second lever. Both plungers are controlled in such a way that the insertion rollers and the intermediate rollers are either both open or both closed.

- the present invention is made to solve the above-described problems of the prior art. It is an object of the present invention to provide a printer capable of printing on a variety of types of cut-sheet paper in which a comparatively simple mechanism is used for ensuring that checks are always correctly positioned.

- part of the paper feed path used for slip printing is used as the paper feed path for validation printing.

- the paper feed path for a check used in validation printing has no section, like the groove section in the prior art, which is separate from the paper feed path for a slip used for slip printing.

- the positioning of the check is achieved by stopper means extending into the paper feed path.

- the stopper means is arranged such that it provides a stop for the leading end of a check inserted through the discharge opening but allows a slip a slip to pass in the direction toward the discharge opening. As a consequence, checks are accurately positioned

- the stopper means be provided immediately following transfer roller means used to transfer a slip through paper feed path. This structure shortens the distance between a position where a slip is pinched by transfer rollers and a position where it engages the stopper. As a result, even slip of a very weak sheet of paper can exert the force required to pass the stopper means without being damaged or hindered.

- the paper feed path has a straight section contiguous to the discharge opening and a curved section contiguous to the insertion opening.

- the stopper means is preferably provided adjacent the area where the straight section connects to the curved section. In this case it is even more preferable to arrange the stopper means next to transfer roller means as mentioned above.

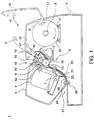

- Figs. 1 and 2 show the overall structure of a printer 1 in accordance with one embodiment of the present invention.

- the printer 1 has a main case 2 made of, for example, resin or the like.

- a roll S of paper is disposed in a rear part inside the main case 2.

- a paper transfer section 3 for transferring paper to be printed is mounted in a front part of the case 2.

- An ink jet printing section 4 for printing on the paper is disposed in front of the paper transfer section 3.

- the printing section 4 is covered by a front cover 5 made of resin or the like.

- the paper roll S, the paper transfer section 3 and the printing section 4 are mounted on a main frame 6 made of metal or the like.

- the printing section 4 is capable of moving between the lateral sides of the main frame 6 along a guide rail 7 fixed to the main frame 6.

- an ink jet head 4a of the printing section 4 is disposed opposite a platen section 8 that is provided in the paper transfer section 3.

- a printing area is defined between the ink jet head 4a and the platen section 8.

- the paper roll S is rotatably supported on a pair of support rollers 10 and 11 disposed in parallel with a roll core 9. The outer end of the paper roll S is drawn from the lower side of the printer toward the upper side.

- a paper path for the roll paper from paper roll S is formed in the paper transfer section 3. In other words, the roll paper is guided and transferred by a paper guide 12 and a roller 13 to the platen section 8. After printing on the roll paper by the printing section 4, the roll paper is further transferred by a roller 14 and discharged through a discharge opening 16 defined in an upper cover 15. When cut-sheet paper (described below) is not inserted, the roll paper can be printed.

- the upper cover 15 is rotatably mounted about a pivot axis 17.

- the platen section 8 is designed to move closer to and farther from the ink jet head 4a in association with the opening or closing of the upper cover 15.

- the platen section 8 and transfer roller 14 are supported on a frame which is rotatable about a shaft of the roller 13. This frame is connected to a lever 46 and is forced by a spring mounted on the lever 46 in a direction in which the platen section 8 and the roller 14 are moved away from the ink jet head 4a.

- the upper cover 15 and the front cover 5 define a discharge opening 18 in the upper central area of the printer for discharging cut-sheet paper (a slip 200 on which slip printing is performed or a check 500 on which validation printing is performed). As described below, the discharge opening 18 also serves as an insertion opening for validation printing.

- a set of discharge rollers 19 and 20 is disposed adjacent the discharge opening 18.

- a set of intermediate rollers 21 and 22 is disposed between the set of insertion rollers and the printing section 4, and a set of insertion rollers 23 and 24 is disposed below the printing section 4.

- These rollers and a pair of guide members 25 and 26 define a paper feed path for transferring a slip 200. As shown in Fig. 2, when slip printing is performed, a slip 200 is inserted into a paper insertion opening 27.

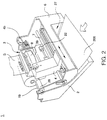

- Figs. 3 and 4 show the paper transfer section 3 in accordance with one embodiment of the present invention.

- each of the above mentioned sets of rollers in this embodiment comprises two pairs of rollers, each pair including a drive roller coupled to a drive source and an associated pinch roller.

- the two drive rollers of a respective set are fixed to the same shaft and the two pinch rollers have the same rotary axis. It is to be noted that the number of pairs of drive and pinch rollers in the respective sets of rollers is not critical to the invention.

- the rollers 13 and 14 for transferring roll paper are mounted on a metal support frame 28 substantially U-shaped in cross-section.

- the support frame 28 is mounted on a metal transfer frame 29 that forms a paper feed path for cut-sheet paper.

- the roller 13 for transferring roll paper is formed from a material that is not slippery, such as rubber or the like, and has a drive shaft 30 coupled to a drive motor (not shown).

- the roller 13 and the roller 14 are rotated in the same direction by a gear train (not shown).

- the support frame 28 is pivotally mounted about the drive shaft 30 of the roller 13.

- insertion rollers 23 for transferring a slip 200 are mounted on a shaft 31 that is rotatably mounted on an open/close lever 37. Also, intermediate rollers 21 are mounted on a shaft 100 that is rotatably mounted on the transfer frame 29.

- the insertion rollers 23 are driven by a drive pulley 32 that is driven by a motor (not shown), a belt 33 and a pulley 34.

- the intermediate rollers 21 are driven by a gear 35 that is driven by the above-described motor via a gear 36 that engages the gear 35.

- the open/close lever 37 is pivotally mounted on the transfer frame 29 about a shaft 32a having the drive pulley 32 mounted on one end thereof and the gear 35 on the other end.

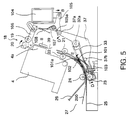

- Figs. 5 and 6 a cut-sheet transfer mechanism and its operation in the case of slip printing will be described. It is noted that the roll paper transfer mechanism shown in Fig. 1 is not shown in Figs. 5 and 6.

- the paper insertion opening 27 is defined by the upper and lower guide members 25 and 26 and guides a slip 200.

- the rollers 23 are separated from the rollers 24 and do not obstruct insertion of the slip 200.

- a tip section 101a of a stopper 101 protrudes from the lower guide member 25 into the paper feed path by the resilient force of a spring 103.

- a paper detector 102 is provided generally at the same location as the tip section 101a of the stopper 101. The paper detector 102 detects insertion of the slip 200.

- the detector 102 also detects the trailing end of the slip 200. Therefore, the detector 102 can be used, for example, to control the bottom margin on a slip (the position of the last printing line) that is pre-set prior to printing. As shown in Fig. 5, when the rollers 23 are separated from the rollers 24, the rollers 20 contact the rollers 19 under pressure. Therefore, a slip 200 cannot be inserted through the discharge opening 18 by mistake.

- a controller section (not shown) activates a plunger 104 so that the armature of the plunger 104 moves in the direction of an arrow A as shown in Fig. 6.

- the rollers 20 are separated from the rollers 19 via levers 105 and 106.

- a spring 107 pushes a pin 37a of the open/close lever 37.

- the open/close lever 37 rotates about the shaft 32a in the direction of an arrow C, and the rollers 23 are brought into pressure contact with the rollers 24 with the slip 200 being pinched therebetween. In other words, the rollers 23 are pushed against the rollers 24 by the resilient force of the spring 107.

- the stopper 101 rotates against the spring force of the spring 103 in association with the motion of the open/close lever 37 in the direction of the arrow C, and thus the tip section 101a of stopper 101 is lowered below the lower guide member 25.

- the rollers 23, 24 are driven to transfer the slip 200 toward the ink jet head 4a.

- the rotation of the drive pulley 32 mounted on the shaft 32a is transferred through the belt 33 to the pulley 34 mounted on the same shaft as the rollers 23 so that the rollers 23 are rotated.

- the tension of the belt 33 is adjustable by finely adjusting the position of an adjusting pulley 37b that is mounted on the open/close lever 37.

- the tension of the belt 33 is factory-adjusted to an appropriate level.

- the slip 200 As the slip 200 is advanced by the rotation of the rollers 23, 24, it is introduced between the intermediate rollers 21 and 22.

- the rollers 21 and 22 are always in pressure contact with each other.

- Rotational force of a drive motor (not shown) is transferred through the drive shaft 32a and the gears 35 and 36 to the rollers 21.

- the slip 200 that is transferred by the rollers 21, 22, 23 and 24, is introduced between the guide member 39 and the ink jet head 4a and printed.

- the ink jet head 4a is moved along the guide rail 7 to print one line of characters.

- the rollers are driven to move the slip 200 by a predetermined amount (for printing the next line), and then printing is performed by the ink jet head 4a again. These operation steps are repeated.

- the slip 200 After passing the printing area between the guide member 39 and the ink jet head 4a, the slip 200 enters an open space between the rollers 19 and 20.

- the distance from the position at which the slip 200 abuts the tip section 101a of the stopper 101 to the position at which the slip 200 reaches the open space between the rollers 19 and 20 is known and a corresponding feeding amount is pre-set in the controller section that controls the motor for driving these transfer rollers.

- the slip 200 reaches the space between the rollers 19 and 20.

- the plunger 104 is activated so that the armature moves in the direction of an arrow B, as shown in Fig. 5, to move the levers 105 and 106.

- the rollers 20 are brought into pressure contact with the rollers 19 and the leading end of the slip 200 is pinched by the rollers 19 and 20. Accordingly, the slip 200 can be transferred by the rollers 19 and 20.

- the pressure force acting between the rollers 19 and 20 is determined by the spring 108.

- the spring 107 is released from the pin 37a of the lever 37, and the resilient force of the spring 107 that acts to bring the rollers 23 in pressure contact with the rollers 24 is removed.

- the open/close lever 37 rotates about the shaft 32a in the direction of an arrow D due to the weight of the rollers 23.

- the slip is transferred by the rollers 23 and 24 immediately after it is inserted.

- the slip is transferred by the two sets of the rollers 23, 24, 21 and 22.

- the slip is transferred by the two sets of rollers 20, 19, 21 and 22.

- the slip is transferred only by the rollers 19 and 20.

- Validation printing by a printer in accordance with the present invention is performed in the following manner. While the rollers 19 and 20 are separated, a check 500 is inserted through the discharge opening 18 down to an area adjacent the rollers 21 and 22. After setting the check in position (described in more detail below), the plunger 104 is activated by a corresponding command or key operation to bring the rollers 19 and 20 in pressure contact with each other. After the rollers 19 and 20 pinch the check, the ink jet head 4a is operated to print on the check, and the rollers 19 are driven as required so that the check is transferred back toward the discharge opening while it is being printed.

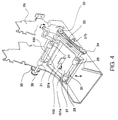

- Figs. 7 and 8 show perspective views of an area adjacent the intermediate rollers 21, 22.

- Fig. 7 shows a state where a check 500 for validation printing is inserted

- Fig. 8 shows a state where a slip 200 for slip printing is inserted.

- a plurality of stoppers 222 are pivotally mounted on the same shaft that mounts the intermediate rollers 22.

- Each of the stoppers 222 is biased by relatively weak spring force of a spring 223 (a torsion spring in this embodiment) into a stopping position in which a protrusion 222b extends through a window 251 that is defined in the paper guide, into the paper feed path (the contact between the lower window edge and the lower face of the protrusion defines the stopping position).

- the stoppers 222 rotate in a direction in which the paper feed path is opened. By this operation, the slip 200 can be transferred further upward.

- the stoppers 222 are provided on the same shaft as the roller 21 or 22.

- the paper feed path for cut-sheet paper between the insertion opening 27 and the discharge opening 18 comprises a first curved section and a second straight or substantially straight section.

- the curved section extends from the insertion opening up to the intermediate rollers 21, 22 and the straight section extends from the intermediate rollers to the discharge opening 18.

- the straight section is used in common for slips 220 and checks 500 and includes the printing area. Therefore, thin and weak paper can be as easily inserted as a check as can thick and strong paper.

- the stoppers 220 which define the lowermost position of the lower (leading) end of a check inserted through the discharge opening 18, extend into the straight section of the paper feed path just above the intermediate rollers 21, 22. Because of this structure a check can be easily positioned and, different from the structure shown in Fig. 9, there is no danger that a check, even if its leading end is curved or bent, unintentionally enters a wrong paper feed path.

- the plunger is a self-holding type plunger that performs pulling or pushing of its armature by an electrical current applied for only a short period of time. As a result, power consumption by the printer is lowered.

- the rollers 23 and 24 are kept open and the rollers 19 and 20 are kept closed.

- the rollers 19 and 20 are closed, and therefore a check for validation printing cannot be inserted to the printing area.

- the tip section 101a of the stopper 101 protrudes in the paper feed path.

- a slip for slip printing can also not be inserted into the printing area.

- the insertion opening 27 and the discharge opening 18 of the paper feed path for cut-sheet paper and the printing area are closed. Therefore, cut-sheet paper cannot be inserted by mistake while printing on roll paper.

- the plunger is operated by a respective command or key operation to separate the rollers 19 and 20 from each other or bring the rollers 19 and 20 into pressure contact with each other.

- the printing area and a part of the paper feed path for slip printing are also used for validation printing in which a check is inserted through the discharge opening that is used for discharging both slips and checks.

- the structure can accommodate a variety of different modes of usage and different types of paper. Also, during a specified print mode, a sheet of paper for a different print mode cannot be inserted by mistake.

- the description is made with reference to a printer that incorporates an ink jet head.

- the present invention is not limited to this particular embodiment, and the present invention is also applicable to a printer having any one of various types of print head, such as a dot impact type print head and the like.

- the present invention is not limited to a printer for printing bills or bank checks, but is also applicable to other types of printers.

- the reference to slips and checks in the foregoing description was only for the purpose of convenience and by no means intended to be restrictive. Both slip and check are representative for any kind of cut-sheet paper to which slip printing or validation printing may be applied.

Landscapes

- Handling Of Cut Paper (AREA)

- Handling Of Sheets (AREA)

- Delivering By Means Of Belts And Rollers (AREA)

- Manual Feeding Of Sheets (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP12066696 | 1996-05-15 | ||

| JP120666/96 | 1996-05-15 | ||

| JP12066696A JP3520384B2 (ja) | 1996-05-15 | 1996-05-15 | プリンタ |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0807527A2 true EP0807527A2 (fr) | 1997-11-19 |

| EP0807527A3 EP0807527A3 (fr) | 1998-09-09 |

| EP0807527B1 EP0807527B1 (fr) | 2001-10-10 |

Family

ID=14791912

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19970107924 Expired - Lifetime EP0807527B1 (fr) | 1996-05-15 | 1997-05-15 | Imprimante |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0807527B1 (fr) |

| JP (1) | JP3520384B2 (fr) |

| DE (1) | DE69707195T2 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2004037543A2 (fr) * | 2002-10-24 | 2004-05-06 | Nur Macroprinters Ltd. | Systeme et procede d'avance pour un appareil d'impression numerique |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5149217A (en) * | 1989-04-10 | 1992-09-22 | Seiko Epson Corporation | Selectively actuatable multiple medium feed mechanism for a micro printer |

| EP0428163B1 (fr) * | 1989-11-14 | 1994-04-20 | Seiko Epson Corporation | Imprimante pour l'impression sur plusieurs genres de papier |

-

1996

- 1996-05-15 JP JP12066696A patent/JP3520384B2/ja not_active Expired - Fee Related

-

1997

- 1997-05-15 DE DE1997607195 patent/DE69707195T2/de not_active Expired - Fee Related

- 1997-05-15 EP EP19970107924 patent/EP0807527B1/fr not_active Expired - Lifetime

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5149217A (en) * | 1989-04-10 | 1992-09-22 | Seiko Epson Corporation | Selectively actuatable multiple medium feed mechanism for a micro printer |

| EP0428163B1 (fr) * | 1989-11-14 | 1994-04-20 | Seiko Epson Corporation | Imprimante pour l'impression sur plusieurs genres de papier |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2004037543A2 (fr) * | 2002-10-24 | 2004-05-06 | Nur Macroprinters Ltd. | Systeme et procede d'avance pour un appareil d'impression numerique |

| WO2004037543A3 (fr) * | 2002-10-24 | 2004-07-22 | Nur Macroprinters Ltd | Systeme et procede d'avance pour un appareil d'impression numerique |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0807527A3 (fr) | 1998-09-09 |

| EP0807527B1 (fr) | 2001-10-10 |

| DE69707195D1 (de) | 2001-11-15 |

| DE69707195T2 (de) | 2002-06-06 |

| JPH09300754A (ja) | 1997-11-25 |

| JP3520384B2 (ja) | 2004-04-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6079887A (en) | Printer with an improved feeding system | |

| US6439454B1 (en) | Transaction printer | |

| US5813782A (en) | Apparatus for moving a paper sheet | |

| US6602008B2 (en) | Print-medium transport unit | |

| WO2013000360A1 (fr) | Mécanisme de support de papier et dispositif d'imprimante ayant le mécanisme de plateau de papier | |

| US5524994A (en) | Paper skew removal apparatus and a printer using the same | |

| EP1219554B1 (fr) | Dispositif d'alimentation de documents pour une imprimante | |

| US20100054837A1 (en) | Thermal printer | |

| EP0807527B1 (fr) | Imprimante | |

| JP4370730B2 (ja) | 印刷用紙の搬送装置、その制御方法及びプログラム | |

| EP0807523B1 (fr) | Imprimante | |

| JP3520383B2 (ja) | プリンタ | |

| US8550734B2 (en) | Transportation guide mechanism and recording device having the same | |

| KR100529813B1 (ko) | 프린터장치,그제어방법및정보기록매체 | |

| JPH09234924A (ja) | プリンタ | |

| EP0868308B1 (fr) | Dispositif pour charger automatiquement un rouleau de papier dans un appareil d'impression et appareil d'impression associe | |

| JPH09300757A (ja) | プリンタ | |

| JPH06183084A (ja) | プリンタの紙送り機構 | |

| JP3791202B2 (ja) | プリンタ装置の制御方法 | |

| JPH042059Y2 (fr) | ||

| JPH092701A (ja) | 用紙クランプ装置 | |

| JPH0844934A (ja) | 通帳印字装置および通帳印字方法 | |

| JPH07267465A (ja) | 用紙排出装置 | |

| JP2002003011A (ja) | プリンタの排紙装置、その制御方法及び情報記録媒体 | |

| JPH09254461A (ja) | プリンタ |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19990302 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 20001110 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT |

|

| REF | Corresponds to: |

Ref document number: 69707195 Country of ref document: DE Date of ref document: 20011115 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20080522 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20080530 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20080521 Year of fee payment: 12 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090515 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090602 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20080514 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090515 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090515 |