EP0802018A1 - Apparatus for grinding an end-face, specially a ring-face, on the edge of a workpiece bore - Google Patents

Apparatus for grinding an end-face, specially a ring-face, on the edge of a workpiece bore Download PDFInfo

- Publication number

- EP0802018A1 EP0802018A1 EP97106045A EP97106045A EP0802018A1 EP 0802018 A1 EP0802018 A1 EP 0802018A1 EP 97106045 A EP97106045 A EP 97106045A EP 97106045 A EP97106045 A EP 97106045A EP 0802018 A1 EP0802018 A1 EP 0802018A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- shaft

- grinding tool

- grinding

- guide pin

- workpiece

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000004575 stone Substances 0.000 claims description 12

- 239000011248 coating agent Substances 0.000 claims description 10

- 238000000576 coating method Methods 0.000 claims description 10

- 230000006835 compression Effects 0.000 claims description 4

- 238000007906 compression Methods 0.000 claims description 4

- 230000037431 insertion Effects 0.000 claims 1

- 238000003780 insertion Methods 0.000 claims 1

- 230000000737 periodic effect Effects 0.000 abstract description 4

- 238000006073 displacement reaction Methods 0.000 description 7

- 238000003754 machining Methods 0.000 description 7

- 238000004519 manufacturing process Methods 0.000 description 3

- 230000001419 dependent effect Effects 0.000 description 2

- 238000002485 combustion reaction Methods 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000003973 paint Substances 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B33/00—Honing machines or devices; Accessories therefor

- B24B33/055—Honing machines or devices; Accessories therefor designed for working plane surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B15/00—Machines or devices designed for grinding seat surfaces; Accessories therefor

- B24B15/02—Machines or devices designed for grinding seat surfaces; Accessories therefor in valve housings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B33/00—Honing machines or devices; Accessories therefor

- B24B33/02—Honing machines or devices; Accessories therefor designed for working internal surfaces of revolution, e.g. of cylindrical or conical shapes

- B24B33/025—Internal surface of conical shape

Definitions

- the invention relates to a grinding device according to the preamble of claim 1.

- a known device of this type (DE 44 41 623 A1) is used for the fine machining of a bevel which is ground on the edge of the workpiece bore and which serves as a sealing seat for a valve needle.

- Such valve bores are provided, for example, in injection pumps for internal combustion engines. They have a very small diameter of only a few millimeters and have to be machined with high precision.

- the end face of the workpiece forming the edge of the bore or surrounding it must also be machined precisely; When sanding or when machining a chamfer, it must also be ensured that the frustoconical surface is exactly concentric to the axis of the hole.

- the known device For the surface processing of the chamfer, the known device has a conical grinding surface on the grinding tool, which is driven to rotate about the bore axis.

- the shape of the chamfer is directly dependent on the shape of the grinding surface of the grinding surface, which often has to be dressed in series production. Since grinding surfaces are generally inhomogeneous, the shape accuracy and the surface quality the chamfer in series production is inadequate for very high requirements.

- Plan honing devices are also known in which the honing tool with its abrasive coating is displaced on the surface to be machined. However, because of their relatively large dimensions, these devices cannot be used in confined spaces.

- the object of the invention is to implement the device with the smallest possible space requirement so that even small end faces, in particular ring faces at the edge of a bore, can be produced or machined with very high accuracy.

- the periodic shifting of the grinding tool transversely to the axis of the guide pin enables the surface of the end face of the workpiece and also the creation of a chamfer on the edge of the hole with a flat grinding surface, the shape of which is not changed by wear and dressing, so that a very high level in series production Accuracy and quality of the finished surface can be achieved.

- the displacement movement can be realized in a very small space, which results in a small size of the entire device.

- the grinding tool is expediently driven in rotation via a drive shaft, for example at 2000 to 6000 rpm, the periodic displacement being able to be generated by means of an eccentric, which is preferably part of a driven one Hollow shaft with an eccentric bore.

- the hollow shaft is preferably driven in the opposite direction to the drive shaft at a speed of 500 to 2000 rpm.

- the path of the transverse displacement is dimensioned such that the grinding surface completely sweeps over the end face to be machined, the distance when machining the surrounding area of very thin bores being, for example, 0.5 to 3 mm.

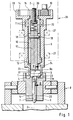

- the device according to FIGS. 1 to 3 has a grinding tool 1, which is designed as a honing stone 3 with a grinding coating 23 and is fastened to a holder 22.

- the holder 22 is a cylindrical slide, in which the honing stone 3 is inserted parallel to its axis, and which is arranged displaceably in a through opening 21 of a shaft 17.

- the shaft 17 is in one piece with a guide pin 7 executed, which dips into the finished honed bore 5 of a workpiece 6.

- the workpiece 6 is arranged in a known manner in a holding device 8 with a cardanic suspension of the workpiece clamping device, so that it is aligned precisely with its axis 2 by means of the guide pin 7, which axis coincides with the axis of the shaft 17.

- the shaft 17 forms the inner member of a telescopic drive shaft, the outer tube 10 of which is supported in a hollow shaft 9 by means of bearings 11 and 12.

- the shaft 17 is positively connected to the outer tube 10 in the direction of rotation of the drive shaft 10, 17 via a transverse bolt 19 which passes through the shaft 17 and has its ends in a longitudinal slot 18 of the outer tube 10.

- a compression spring 20 located within the outer tube loads the shaft 17 in the direction of the workpiece 6; its pretension is adjustable by means of an adjusting screw 30 which is inserted into the upper end of the outer tube 10.

- the shaft 17 is axially displaceable in the outer tube 10 when the compression spring 20 is loaded, the displacement path being limited by the length of the longitudinal slot 18.

- the drive shaft 10, 17 and the hollow shaft 9 are driven in opposite directions.

- the outer tube 10 of the drive shaft has an external toothing 15 at the upper end, and this upper end lies within a cup-shaped section 13 of the hollow shaft 9, which has an internal toothing 14 there.

- a drive pinion 16 engages in both toothings 14 and 15.

- the hollow shaft 9 has a bore 24 eccentric to the common axis 2 of the shafts and the guide pin within its lower section 9a, which thus forms an eccentric.

- the cylindrical slide 22 is in the through hole 21 of the shaft 17 arranged so that it rests with its two convex end faces 25 flat against the wall 26 of the eccentric bore 24 and is thus supported there in a sliding manner.

- the through-opening 21 is keyhole-shaped through a slot 21a extending into the guide pin 7, the slide 22 slidingly abutting the cylindrical wall of the through-opening 21, while the honing stone 3 lies within the slot 21a (FIG. 2).

- the honing stone 3 with the abrasive coating 23 projects outwards at both ends of the slot 21a (FIG. 1).

- the abrasive coating 23 can therefore completely paint over the end face 4 of the workpiece 6 to be machined with its abrasive surface 23a.

- the hollow shaft 9 is supported by means of bearings 27 in a device carrier 28 indicated by dash-dotted lines, which can be advanced axially in the direction of the workpiece 6 on guides (not shown).

- the carrier 28 and the holding device 8 are aligned with one another in such a way that the guide pin 7 is coaxial with the workpiece bore 5.

- the carrier 28 is then advanced in the direction of the workpiece 6, the guide pin 7 being immersed in the workpiece bore 5 which has been pre-machined or finished by honing.

- the gimbal-mounted workpiece 6 is aligned precisely with the axis 2, which then coincides with the axis of the bore.

- the guide pin 7 can be coated with a wear-resistant coating or also have guide strips 29 which are made of wear-resistant material, for example hard metal.

- the infeed can be controlled in a known manner depending on the route and also in a force-dependent manner, one gradual or continuous delivery is possible.

- the abrasive coating 23 of the honing stone 3 comes into contact with the annular surface 4 of the workpiece, the counter-rotating movements of the drive shaft 10, 17 and the hollow shaft 9 are initiated via the drive pinion 16.

- the delivery movement can be slowed down or briefly interrupted.

- the grinding surface 23a of the abrasive coating 23 bears against the workpiece surface 4, which is then machined by rotating movement and at the same time approximately radial, periodic displacement movements of the tool 1.

- the compression spring 20 is increasingly tensioned due to the further, continuous or step-by-step infeed.

- the feed movement is stopped as soon as the abrasive coating 23 of the honing stone 3 bears against the workpiece surface 4 under the pressure of the spring 20 with a predetermined machining force.

- the machining force to be specified can be set by specifying the infeed path, or - in the case of continuous infeed - by adjusting the spring force by means of the adjusting screw 30.

- Known path and / or force measuring devices can be provided to switch off the infeed when the predetermined final dimension is reached.

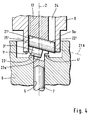

- Fig. 4 shows the device in the region of the machining zone in an enlarged partial axial section.

- a grinding tool 1 ' is provided with which a chamfer in the form of a conical ring surface 4' is ground at the edge of the workpiece bore 5.

- the chamfer 4 ' can be produced by means of the grinding tool 1' by removing the edge of the bore; However, the surface of an existing, previously created chamfer can also be finished to an exact dimension and exactly concentric to axis 2.

- the grinding tool 1 ' consists of a honing stone 3' provided with a grinding coating 23 ', which is inserted into a slide 22' as shown in FIG. 2.

- a through opening 21 'of the shaft 17 also extends into the guide pin 7, but extends with its central axis 21A of the upper region obliquely to the axis 2 of the guide pin 7.

- the cylindrical slide 22' is accordingly arranged obliquely in the shaft 17, so that its convex end faces 25 'are correspondingly beveled in axial section.

- the central axis of the slider 22 ' coincides with the axis 21A of the through opening, and the grinding surface 23a' of the grinding pad 23 'lies parallel to this axis 21A.

- the angle between the grinding surface 23a 'and the axis 2 corresponds to the target angle of the chamfer 4'.

- the honing stone 3 ' is dimensioned and arranged on the slide 22' in such a way that it extends partly into the workpiece bore 5 and completely covers the conical ring surface or chamfer 4 'during the turning and sliding movements of the tool 1'.

- the rotary and sliding movements are generated as described by means of the drive shaft and the outer hollow shaft 9.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Geometry (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

- Grinding And Polishing Of Tertiary Curved Surfaces And Surfaces With Complex Shapes (AREA)

Abstract

Description

Die Erfindung betrifft eine Schleifvorrichtung nach dem Oberbegriff des Anspruches 1.The invention relates to a grinding device according to the preamble of

Eine bekannte Vorrichtung dieser Art (DE 44 41 623 A1) dient zur Feinbearbeitung einer am Rand der Werkstück-Bohrung angeschliffenen Fase, die als Dichtsitz für eine Ventilnadel dient. Solche Ventilbohrungen sind beispielsweise in Einspritzpumpen für Brennkraftmaschinen vorgesehen. Sie haben einen sehr kleinen Durchmesser von nur einigen Millimetern und müssen hochgenau bearbeitet sein. Die den Rand der Bohrung bildende oder ihn umgebende Stirnfläche des Werkstückes muß ebenfalls genau bearbeitet sein; beim Anschleifen oder bei der Oberflächenbearbeitung einer Fase ist außerdem darauf zu achten, daß die kegelstumpfförmige Flache genau konzentrisch zur Bohrungsachse liegt. Die bekannte Vorrichtung hat zur Oberflächenbearbeitung der Fase eine konische Schleiffläche an dem um die Bohrungsachse rotierend angetriebenen Schleifwerkzeug. Dabei ist die Form der Fase unmittelbar von der Form der Schleiffläche des Schleifbelages abhängig, der in der Serienfertigung häufig abgerichtet werden muß. Da Schleifbeläge allgemein inhomogen sind, ist die Formgenauigkeit und die Oberflächenqualität der Fase in der Serienfertigung bei sehr hohen Anforderungen unzureichend.A known device of this type (DE 44 41 623 A1) is used for the fine machining of a bevel which is ground on the edge of the workpiece bore and which serves as a sealing seat for a valve needle. Such valve bores are provided, for example, in injection pumps for internal combustion engines. They have a very small diameter of only a few millimeters and have to be machined with high precision. The end face of the workpiece forming the edge of the bore or surrounding it must also be machined precisely; When sanding or when machining a chamfer, it must also be ensured that the frustoconical surface is exactly concentric to the axis of the hole. For the surface processing of the chamfer, the known device has a conical grinding surface on the grinding tool, which is driven to rotate about the bore axis. The shape of the chamfer is directly dependent on the shape of the grinding surface of the grinding surface, which often has to be dressed in series production. Since grinding surfaces are generally inhomogeneous, the shape accuracy and the surface quality the chamfer in series production is inadequate for very high requirements.

Es sind auch Planhonvorrichtungen bekannt, bei denen das Honwerkzeug mit seinem Schleifbelag auf der zu bearbeitenden Oberfläche verschoben wird. Diese Vorrichtungen sind aber wegen ihrer relativ großen Abmessungen bei beengten Platzverhältnissen nicht einsetzbar.Plan honing devices are also known in which the honing tool with its abrasive coating is displaced on the surface to be machined. However, because of their relatively large dimensions, these devices cannot be used in confined spaces.

Der Erfindung liegt die Aufgabe zugrunde, die Vorrichtung mit möglichst geringem Platzbedarf so auszuführen, daß auch kleine Stirnflächen, insbesondere Ringflächen am Rand einer Bohrung mit sehr hoher Genauigkeit erzeugt oder bearbeitet werden können.The object of the invention is to implement the device with the smallest possible space requirement so that even small end faces, in particular ring faces at the edge of a bore, can be produced or machined with very high accuracy.

Die Aufgabe wird gemäß der Erfindung mit den Merkmalen des Anspruches 1 gelöst.The object is achieved according to the invention with the features of

Das periodische Verschieben des Schleifwerkzeuges quer zur Achse des Führungszapfens ermöglicht die Oberflächenbearbeitung der Stirnfläche des Werkstückes und auch die Erzeugung einer Fase an der Bohrungskante mit einer planen Schleiffläche, deren Form also durch Abnutzung und Abrichten nicht verändert wird, so daß in der Serienfertigung eine sehr hohe Genauigkeit und Güte der fertigen Oberfläche erreicht werden. Die Verschiebebewegung kann auf engstem Raum realisiert werden, womit sich eine geringe Baugröße der gesamten Vorrichtung ergibt.The periodic shifting of the grinding tool transversely to the axis of the guide pin enables the surface of the end face of the workpiece and also the creation of a chamfer on the edge of the hole with a flat grinding surface, the shape of which is not changed by wear and dressing, so that a very high level in series production Accuracy and quality of the finished surface can be achieved. The displacement movement can be realized in a very small space, which results in a small size of the entire device.

Während der Verschiebebewegung wird das Schleifwerkzeug zweckmäßig über eine Antriebswelle rotierend angetrieben, beispielsweise mit 2000 bis 6000 U/min, wobei die periodische Verschiebung mittels eines Exzenters erzeugt werden kann, der vorzugsweise Bestandteil einer angetriebenen Hohlwelle mit Exzenterbohrung ist. Vorzugsweise wird die Hohlwelle gegensinnig zu der Antriebswelle mit einer Drehzahl von 500 bis 2000 U/min angetrieben. Dar Weg der Querverschiebung ist so bemessen, daß die Schleiffläche die zu bearbeitende Stirnfläche vollständig überstreicht, wobei die Wegstrecke bei der Bearbeitung des Umgebungsbereichs sehr dünner Bohrungen beispielsweise 0,5 bis 3 mm beträgt.During the displacement movement, the grinding tool is expediently driven in rotation via a drive shaft, for example at 2000 to 6000 rpm, the periodic displacement being able to be generated by means of an eccentric, which is preferably part of a driven one Hollow shaft with an eccentric bore. The hollow shaft is preferably driven in the opposite direction to the drive shaft at a speed of 500 to 2000 rpm. The path of the transverse displacement is dimensioned such that the grinding surface completely sweeps over the end face to be machined, the distance when machining the surrounding area of very thin bores being, for example, 0.5 to 3 mm.

Weitere Merkmale der Erfindung ergeben sich aus den Unteransprüchen.Further features of the invention emerge from the subclaims.

Zwei Ausführungsformen der erfindungsgemäßen Schleifvorrichtung werden im folgenden anhand der Zeichnungen näher erläutert. Es zeigen

- Fig. 1

- die Schleifvorrichtung mit einer zugehörigen Haltevorrichtung für das Werkstück im Axialschnitt,

- Fig. 2

- einen Schnitt nach II-II in Fig. 1,

- Fig. 3

- einen Schnitt nach III-III in Fig. 2,

- Fig. 4

- einen ausschnittsweisen Axialschnitt durch die Vorrichtung und ein zu bearbeitendes Werkstück mit einer anderen Ausbildung und Lagerung des Werkzeuges in schematischer Darstellung.

- Fig. 1

- the grinding device with an associated holding device for the workpiece in axial section,

- Fig. 2

- 2 shows a section according to II-II in FIG. 1,

- Fig. 3

- 2 shows a section according to III-III in FIG. 2,

- Fig. 4

- a partial axial section through the device and a workpiece to be machined with a different design and storage of the tool in a schematic representation.

Die Vorrichtung nach den Fig. 1 bis 3 hat ein Schleifwerkzeug 1, das als Honleiste 3 mit einem Schleifbelag 23 ausgeführt und an einer Halterung 22 befestigt ist. Die Halterung 22 ist ein zylindrischer Schieber, in den parallel zu seiner Achse die Honleiste 3 eingesetzt ist, und der in einer Durchgangsöffnung 21 eines Schaftes 17 verschieblich angeordnet ist. Der Schaft 17 ist einstückig mit einem Führungszapfen 7 ausgeführt, der in die fertig gehonte Bohrung 5 eines Werkstückes 6 eintaucht. Das Werkstück 6 ist in bekannter Weise in einer Haltevorrichtung 8 mit kardanischer Aufhängung der Werkstück-Spannvorrichtung angeordnet, so daß es mittels des Führungszapfens 7 genau auf dessen Achse 2 ausgerichtet wird, die mit der Achse des Schaftes 17 zusammenfällt. Der Schaft 17 bildet das Innenglied einer Teleskop-Antriebswelle, deren Außenrohr 10 in einer Hohlwelle 9 mittels Lagern 11 und 12 abgestützt ist. Der Schaft 17 ist mit dem Außenrohr 10 in Drehrichtung der Antriebswelle 10, 17 formschlüssig über einen Querbolzen 19 verbunden, der den Schaft 17 durchsetzt und mit seinen Enden in einem Längsschlitz 18 des Außenrohres 10 liegt. Eine innerhalb des Außenrohres befindliche Druckfeder 20 belastet den Schaft 17 in Richtung auf das Werkstück 6; ihre Vorspannung ist mittels einer Stellschraube 30 einstellbar, die in das obere Ende des Außenrohres 10 eingesetzt ist. Der Schaft 17 ist in dem Außenrohr 10 unter Belastung der Druckfeder 20 axial verschieblich, wobei der Verschiebeweg durch die Länge des Längsschlitzes 18 begrenzt ist.The device according to FIGS. 1 to 3 has a

Die Antriebswelle 10, 17 und die Hohlwelle 9 werden gegensinnig angetrieben. Das Außenrohr 10 der Antriebswelle hat zu diesem Zweck am oberen Ende eine Außenverzahnung 15, und dieses obere Ende liegt innerhalb eines napfförmigen Abschnittes 13 der Hohlwelle 9, die dort eine Innenverzahnung 14 aufweist. In beide Verzahnungen 14 und 15 greift ein Antriebsritzel 16 ein.The

Die Hohlwelle 9 hat eine zu der gemeinsamen Achse 2 der Wellen und des Führungszapfens exzentrische Bohrung 24 innerhalb ihres unteren Abschnittes 9a, der damit einen Exzenter bildet. Wie die Fig. 2 und 3 zeigen, ist der zylindrische Schieber 22 in der Durchgangsöffnung 21 des Schaftes 17 so angeordnet, daß er mit seinen beiden konvexen Stirnflächen 25 flächig an der Wandung 26 der Exzenterbohrung 24 anliegt und damit dort gleitend abgestützt ist. Die Durchgangsöffnung 21 ist durch einen bis in den Führungszapfen 7 reichenden Schlitz 21a schlüssellochförmig gestaltet, wobei der Schieber 22 an der zylindrischen Wandung der Durchlaßöffnung 21 gleitend anliegt, während die Honleiste 3 innerhalb des Schlitzes 21a liegt (Fig. 2). Im Bereich des Führungszapfens 7 ragt die Honleiste 3 mit dem Schleifbelag 23 an beiden Enden des Schlitzes 21a nach außen (Fig. 1). Der Schleifbelag 23 kann darum mit seiner Schleiffläche 23a die zu bearbeitende Stirnfläche 4 des Werkstückes 6 vollständig überstreichen.The

Die Hohlwelle 9 ist mittels Lagern 27 in einem strichpunktiert angedeuteten Vorrichtungsträger 28 gelagert, der an - nicht dargestellten - Führungen axial in Richtung auf das Werkstück 6 zustellbar ist.The

Vor Beginn der Bearbeitung werden der Träger 28 und die Haltevorrichtung 8 so zueinander ausgerichtet, daß der Führungszapfen 7 koaxial zu der Werkstückbohrung 5 steht. Der Träger 28 wird dann in Richtung auf das Werkstück 6 zugestellt, wobei der Führungszapfen 7 in die Werkstückbohrung 5 eintaucht, die durch Honen vorbearbeitet oder fertigbearbeitet ist. Dabei richtet sich das kardanisch gehalterte Werkstück 6 genau auf die Achse 2 aus, die dann mit der Bohrungsachse zusammenfällt. Der Führungszapfen 7 kann mit einem verschleißfesten Belag beschichtet sein oder auch Führungsleisten 29 aufweisen, die aus verschleißfestem Werkstoff, beispielsweise Hartmetall bestehen.Before starting the machining, the

Die Zustellung kann in bekannter Weise wegeabhängig und auch zusätzlich kraftabhängig gesteuert werden, wobei eine stufenweise oder stetige Zustellung möglich ist. Kurz bevor der Schleifbelag 23 der Honleiste 3 mit der Ringfläche 4 des Werkstückes in Berührung kommt, werden die gegenläufigen Drehbewegungen der Antriebswelle 10, 17 und der Hohlwelle 9 über das Antriebsritzel 16 eingeleitet. Hierfür kann die Zustellbewegung verlangsamt oder kurzzeitig unterbrochen werden. Bei weiterer Zustellung legt sich die Schleiffläche 23a des Schleifbelages 23 an die Werkstückfläche 4 an, die dann durch rotierende Bewegung und zugleich etwa radiale, periodische Verschiebebewegungen des Werkzeuges 1 bearbeitet wird. Die Rotation wird von der Antriebswelle 10, 17 erzeugt und die Verschiebebewegung von dem Exzenter 9a der Hohlwelle 9, wobei der Schieber 22 mit seinen Stirnflächen 25 an der Wandung 26 der Exzenterbohrung 24 gleitet und zusammen mit der Honleiste 3 in der Durchgangsöffnung 21, 21a radial zur Achse 2 periodisch gegenläufig verschoben wird. Mit dieser kombinierten Bewegung überstreicht die Schleiffläche 23a die gesamte Werkstück-Ringfläche 4.The infeed can be controlled in a known manner depending on the route and also in a force-dependent manner, one gradual or continuous delivery is possible. Shortly before the

Während der Bearbeitung wird infolge der weiteren, stetigen oder schrittweisen Zustellung die Druckfeder 20 zunehmend gespannt. Die Zustellbewegung wird gestoppt, sobald der Schleifbelag 23 der Honleiste 3 unter dem Druck der Feder 20 mit einer vorgegebenen Bearbeitungskraft an der Werkstückfläche 4 anliegt. Die vorzugebende Bearbeitungskraft ist durch Vorgabe des Zustellweges einstellbar, oder - bei kontinuierlicher Zustellung - durch Einstellung der Federkraft mittels der Stellschraube 30. Zum Abschalten der Zustellung bei Erreichen des vorgegebenen Endmaßes können bekannte Wege- und/oder Kraft-Meßeinrichtungen vorgesehen sein.During processing, the

Fig. 4 zeigt die Vorrichtung im Bereich der Bearbeitungszone in einem vergrößerten Teil-Axialschnitt. Bei dieser Ausführung ist ein Schleifwerkzeug 1' vorgesehen, mit dem an der Kante der Werkstückbohrung 5 eine Fase in Form einer konischen Ringfläche 4' geschliffen wird. Die Fase 4' kann mittels des Schleifwerkzeuges 1' durch Abtragen der Bohrungskante erzeugt werden; es kann aber auch die Oberfläche einer bereits vorhandenen, vorher erzeugten Fase auf genaues Maß und genau konzentrisch zur Achse 2 fertigbearbeitet werden.Fig. 4 shows the device in the region of the machining zone in an enlarged partial axial section. In this embodiment, a grinding tool 1 'is provided with which a chamfer in the form of a conical ring surface 4' is ground at the edge of the workpiece bore 5. The chamfer 4 'can be produced by means of the grinding tool 1' by removing the edge of the bore; However, the surface of an existing, previously created chamfer can also be finished to an exact dimension and exactly concentric to

Das Schleifwerkzeug 1' besteht aus einer mit einem Schleifbelag 23' versehenen Honleiste 3', die entsprechend der Darstellung in Fig. 2 in einen Schieber 22' eingesetzt ist. Eine Durchgangsöffnung 21' des Schaftes 17 erstreckt sich ebenfalls bis in den Führungszapfen 7, verläuft aber mit ihrer Mittelachse 21A des oberen Bereiches schräg zur Achse 2 des Führungszapfens 7. Der zylindrische Schieber 22' ist dementsprechend schräg in dem Schaft 17 angeordnet, so daß seine konvexen Stirnflächen 25' im Axialschnitt entsprechend abgeschrägt sind. Die Mittelachse des Schiebers 22' fällt mit der Achse 21A der Durchgangsöffnung zusammen, und die Schleiffläche 23a' des Schleifbelages 23' liegt parallel zu dieser Achse 21A. Der Winkel zwischen der Schleiffläche 23a' und der Achse 2 entspricht dem Sollwinkel der Fase 4'. Die Honleiste 3' ist derart dimensioniert und am Schieber 22' angeordnet, daß sie sich zum Teil bis in die Werkstückbohrung 5 erstreckt und während der Dreh- und Schiebebewegungen des Werkzeuges 1' die konische Ringfläche bzw. Fase 4' vollständig überstreicht. Die Dreh- und Schiebebewegungen werden wie beschrieben mittels der Antriebswelle und der äußeren Hohlwelle 9 erzeugt.The grinding tool 1 'consists of a honing stone 3' provided with a grinding coating 23 ', which is inserted into a slide 22' as shown in FIG. 2. A through opening 21 'of the

Claims (17)

dadurch gekennzeichnet, daß das Schleifwerkzeug (1) quer zur Achse (2) des Führungszapfens (7) periodisch verschiebbar ist.Device for grinding an end face, in particular an annular surface, on the edge of a workpiece bore, with a driven grinding tool (1), the grinding surface of which is oriented at an angle to the axis (2) of a guide pin (7), which is used, for example, for a precise insertion into the machined part honed hole is dimensioned and connected to the grinding tool (1),

characterized in that the grinding tool (1) is periodically displaceable transversely to the axis (2) of the guide pin (7).

dadurch gekennzeichnet, daß der Führungszapfen (7) fluchtend zu einer Antriebswelle (10, 17) angeordnet ist, über die das Schleifwerkzeug (1) rotierend angetrieben ist.Device according to claim 1,

characterized in that the guide pin (7) is aligned with a drive shaft (10, 17) via which the grinding tool (1) is driven in rotation.

dadurch gekennzeichnet, daß zum periodischen Verschieben des Schleifwerkzeuges (1) ein Exzenter (9a) vorgesehen ist.Device according to claim 1 or 2,

characterized in that an eccentric (9a) is provided for periodically shifting the grinding tool (1).

dadurch gekennzeichnet, daß der Exzenter (9a) Bestandteil einer angetriebenen Hohlwelle (9) mit Exzenterbohrung (24) ist, in der eine Halterung (22) des Schleifwerkzeuges (1) quer zur Achse der Hohlwelle (9) verschieblich gelagert ist.Device according to claim 3,

characterized in that the eccentric (9a) is part of a driven hollow shaft (9) with an eccentric bore (24) in which a holder (22) of the grinding tool (1) is slidably mounted transversely to the axis of the hollow shaft (9).

dadurch gekennzeichnet, daß das Schleifwerkzeug (1) in einer quer zur Achse (2) des Führungszapfens (7) liegenden Durchgangsöffnung (21) eines Schaftes (17) verschieblich geführt ist, an dem der Führungszapfen (7) angeordnet ist.Device according to one of claims 1 to 4,

characterized in that the grinding tool (1) is displaceably guided in a through opening (21) of a shaft (17) lying transversely to the axis (2) of the guide pin (7), on which the guide pin (7) is arranged.

dadurch gekennzeichnet, daß der Schaft (17) das Innenglied der als Teleskopwelle ausgeführten Antriebswelle (10, 17) ist, deren Außenrohr (10) angetrieben ist, wobei der Schaft (17) in dem Außenrohr (10) der Antriebswelle (10, 17) begrenzt axial verschieblich ist.Device according to claim 5 and one of claims 2 to 4,

characterized in that the shaft (17) is the inner member of the drive shaft (10, 17) designed as a telescopic shaft, the outer tube (10) of which is driven, the shaft (17) in the outer tube (10) of the drive shaft (10, 17) is axially displaceable to a limited extent.

dadurch gekennzeichnet, daß der Schaft (17) in einem Längsschlitz (18) des Außenrohres (10) der Antriebswelle (10, 17) mittels eines Querbolzens (19) geführt ist, der den Schaft (17) durchsetzt und die Formschlußverbindung zwischen Schaft (17) und Außenrohr (10) in Drehrichtung der Antriebswelle (10, 17) herstellt.Apparatus according to claim 6,

characterized in that the shaft (17) is guided in a longitudinal slot (18) of the outer tube (10) of the drive shaft (10, 17) by means of a transverse bolt (19) which passes through the shaft (17) and the positive connection between the shaft (17 ) and outer tube (10) in the direction of rotation of the drive shaft (10, 17).

dadurch gekennzeichnet, daß das Schleifwerkzeug (1) in Richtung auf das Werkstück (6) zustellbar ist.Device according to one of claims 1 to 7,

characterized in that the grinding tool (1) can be advanced in the direction of the workpiece (6).

dadurch gekennzeichnet, daß der Schaft (17) in Richtung auf das Werkstück (6) federbelastet ist, vorzugsweise über eine Druckfeder (20), deren Vorspannung mittels einer Stellschraube (30) einstellbar ist.Device according to one of claims 5 to 8,

characterized in that the shaft (17) is spring-loaded in the direction of the workpiece (6), preferably via a compression spring (20), the pretension of which can be adjusted by means of an adjusting screw (30).

dadurch gekennzeichnet, daß der Schaft (10) und der Führungszapfen (7) einstückig ausgeführt sind.Device according to one of claims 5 to 9,

characterized in that the shaft (10) and the guide pin (7) are made in one piece.

dadurch gekennzeichnet, daß die Halterung (22) des Schleifwerkzeuges (1) ein vorzugsweise zylindrischer Schieber ist, dessen Stirnflächen (25) konvex ausgebildet und an der Wandung (26) der Exzenterbohrung (24) gleitend abgestützt sind.Device according to one of claims 4 to 10,

characterized in that the holder (22) of the grinding tool (1) is a preferably cylindrical slide, the end faces (25) of which are convex and are slidably supported on the wall (26) of the eccentric bore (24).

dadurch gekennzeichnet, daß das Schleifwerkzeug (1) ein Planhonwerkzeug ist, wobei vorzugsweise das Schleifwerkzeug (1) mindestens eine Honleiste (3) mit einem die Schleiffläche (23a) bildenden Schleifbelag (23) aufweist.Device according to one of claims 1 to 11,

characterized in that the grinding tool (1) is a plan honing tool, the grinding tool (1) preferably having at least one honing stone (3) with a grinding surface (23) forming the grinding surface (23a).

dadurch gekennzeichnet, daß die Durchgangsöffnung (21) des Schaftes (17) zur Aufnahme der Honleiste (3) und deren Halterung (22) etwa schlüssellochförmig mit einem Schlitz (21a) ausgebildet ist, der sich bis in den Führungszapfen (7) erstreckt, und aus dem die Honleiste (3) mit ihrem Schleifbelag (23) an mindestens einem seitlichen Schlitzende übersteht.Device according to one of claims 4, 5 and 12,

characterized in that the through opening (21) of the shaft (17) for receiving the honing stone (3) and its holder (22) is approximately keyhole-shaped with a slot (21a) which extends into the guide pin (7), and from which the honing stone (3) with its abrasive coating (23) protrudes at at least one side slot end.

dadurch gekennzeichnet, daß die Antriebswelle (10, 17) in der die Exzenterbohrung (24) aufweisenden Hohlwelle (9) gelagert und gegensinnig zu ihr angetrieben ist, wobei vorzugsweise die Antriebswelle (10, 17) einen Abschnitt mit Außenverzahnung (15) aufweist, der innerhalb eines Abschnittes (13) der Hohlwelle (9) mit Innenverzahnung (14) liegt, und daß in beide Verzahnungen (14 und 15) ein Antriebsritzel (16) eingreift.Device according to one of claims 2 and 4 to 12,

characterized in that the drive shaft (10, 17) is mounted in the hollow shaft (9) having the eccentric bore (24) and is driven in opposite directions to it, the drive shaft (10, 17) preferably having a section with external teeth (15) which lies within a section (13) of the hollow shaft (9) with internal toothing (14), and that a drive pinion (16) engages in both toothings (14 and 15).

dadurch gekennzeichnet, daß der Schleifvorrichtung eine Haltevorrichtung (8) mit kardanisch aufgehängter Spannvorrichtung für das Werkstück (6) zugeordnet ist.Device according to one of claims 1 to 14,

characterized in that the grinding device is assigned a holding device (8) with a gimbal-mounted clamping device for the workpiece (6).

dadurch gekennzeichnet, daß der Führungszapfen (7) mindestens eine Führungsleiste (29) zur Abstützung an der Wandung der Werkstück-Bohrung aufweist.Device according to one of claims 1 to 15,

characterized in that the guide pin (7) has at least one guide bar (29) for support on the wall of the workpiece bore.

dadurch gekennzeichnet, daß das Schleifwerkzeug (1) mit seiner planen Schleiffläche (23a) senkrecht zur Achse (2) des Führungszapfens (7) verschiebbar ist oder das Schleifwerkzeug (1) mit seiner planen Schleiffläche (23a) zur Achse (2) des Führungszapfens (7) in einem Winkel verschiebbar ist, der dem Sollwinkel einer Fase an der Kante der Werkstück-Bohrung entspricht.Device according to one of claims 1 to 16,

characterized in that the grinding tool (1) with its flat grinding surface (23a) can be displaced perpendicular to the axis (2) of the guide pin (7) or the grinding tool (1) with its flat grinding surface (23a) to the axis (2) of the guide pin ( 7) can be displaced at an angle which corresponds to the desired angle of a chamfer at the edge of the workpiece bore.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE29607203U | 1996-04-20 | ||

| DE29607203U DE29607203U1 (en) | 1996-04-20 | 1996-04-20 | Device for grinding an end face, in particular an annular surface, on the edge of a workpiece bore |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0802018A1 true EP0802018A1 (en) | 1997-10-22 |

| EP0802018B1 EP0802018B1 (en) | 2000-07-19 |

Family

ID=8022876

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97106045A Expired - Lifetime EP0802018B1 (en) | 1996-04-20 | 1997-04-12 | Apparatus for grinding an end-face, specially a ring-face, on the edge of a workpiece bore |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US6267653B1 (en) |

| EP (1) | EP0802018B1 (en) |

| JP (1) | JP3749777B2 (en) |

| DE (2) | DE29607203U1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2000002705A1 (en) * | 1998-07-10 | 2000-01-20 | Lidköping Machine Tools AB | Abrasive machine |

| WO2001008847A1 (en) * | 1999-07-29 | 2001-02-08 | Prochniewicz Zbigniew | Toolhead designed particularly to machining of valve seats incorporated in combustion engines |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE20311716U1 (en) | 2003-07-30 | 2003-10-30 | Hans Joachim Sauer (GmbH & Co), 22339 Hamburg | Grinding or milling tool, for machining flat sealing surface at bottom of cylindrical bore, has knob at top and fits inside sleeve with knob at top and has guide rod extending through central through bore |

| DE102006012516A1 (en) * | 2006-03-18 | 2007-09-20 | Bayerische Motoren Werke Ag | Tight chamfer processing tool for use in automobile industry, has cutting head axially movable relative to housing against spring force of elastic unit that absorbs force developed during processing of tight chamfer in axial direction |

| JP4990643B2 (en) * | 2007-02-13 | 2012-08-01 | トーヨーエイテック株式会社 | Honing machine |

| US7861738B2 (en) * | 2008-03-04 | 2011-01-04 | Caterpillar Inc. | Remanufactured machine component and remanufacturing process |

| ES2332568B1 (en) * | 2008-07-23 | 2011-04-18 | Airbus Operations, S.L. | POST-SHAVED ORBITAL REACHING SYSTEM OF RIVETS. |

| JP5078971B2 (en) * | 2009-11-13 | 2012-11-21 | 株式会社フジエ | Surface processing work tool unit |

| CN102601730B (en) * | 2012-03-28 | 2016-08-17 | 常州博瑞油泵油嘴有限公司 | High pressure common rail injector needle-valve body precise positioning clamping device |

| CN102601729B (en) * | 2012-03-28 | 2016-08-17 | 常州博瑞油泵油嘴有限公司 | Needle-valve body class part axial elasticity precise positioning clamping device |

| CN115256211A (en) * | 2022-08-17 | 2022-11-01 | 江苏威马悦达智能装备有限公司 | Honing cutter special for valve body parts and assembling method thereof |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS59182055A (en) * | 1983-03-31 | 1984-10-16 | Japan Electronic Control Syst Co Ltd | Method of grinding valve-seat surface |

| DE3627541A1 (en) * | 1986-08-13 | 1988-02-18 | Gehring Gmbh Maschf | Grinding device |

| EP0399088A2 (en) * | 1989-05-24 | 1990-11-28 | Alfredo Suarez Menendez | Lapping machine |

| DE4441623A1 (en) * | 1993-12-15 | 1995-06-22 | Kopp Kadia Maschinenbau | Process for precision grinding bezel in inlet of bore to produce fuel injection pumps |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2226207A (en) * | 1938-07-22 | 1940-12-24 | Nomar Louis Nolan | Magazine rifle |

| US2443489A (en) * | 1946-05-06 | 1948-06-15 | Weynand Paul | Grinding tool |

| US2525119A (en) * | 1947-04-09 | 1950-10-10 | S & D Engineering Company | Valve-seat grinding means |

| US2754642A (en) * | 1952-05-14 | 1956-07-17 | Soulet Armand | Carrier for grindwheels for the truing of valve seats |

| US2809482A (en) * | 1953-04-10 | 1957-10-15 | Soulet Armand | Valve seat grinder |

| US2769287A (en) * | 1955-08-31 | 1956-11-06 | Tobin Arp Mfg Company | Valve seat grinder |

| US4467566A (en) * | 1982-01-29 | 1984-08-28 | Sunnen Products Company | Valve seat grinding device and tool for using same |

-

1996

- 1996-04-20 DE DE29607203U patent/DE29607203U1/en not_active Expired - Lifetime

-

1997

- 1997-04-12 DE DE59702039T patent/DE59702039D1/en not_active Expired - Lifetime

- 1997-04-12 EP EP97106045A patent/EP0802018B1/en not_active Expired - Lifetime

- 1997-04-18 US US08/844,706 patent/US6267653B1/en not_active Expired - Fee Related

- 1997-04-18 JP JP10198597A patent/JP3749777B2/en not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS59182055A (en) * | 1983-03-31 | 1984-10-16 | Japan Electronic Control Syst Co Ltd | Method of grinding valve-seat surface |

| DE3627541A1 (en) * | 1986-08-13 | 1988-02-18 | Gehring Gmbh Maschf | Grinding device |

| EP0399088A2 (en) * | 1989-05-24 | 1990-11-28 | Alfredo Suarez Menendez | Lapping machine |

| DE4441623A1 (en) * | 1993-12-15 | 1995-06-22 | Kopp Kadia Maschinenbau | Process for precision grinding bezel in inlet of bore to produce fuel injection pumps |

Non-Patent Citations (1)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN vol. 009, no. 042 (M - 359) 22 February 1985 (1985-02-22) * |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2000002705A1 (en) * | 1998-07-10 | 2000-01-20 | Lidköping Machine Tools AB | Abrasive machine |

| US6350187B2 (en) | 1998-07-10 | 2002-02-26 | Lidkoping Machine Tools Ab | Abrasive machine |

| CN1129505C (en) * | 1998-07-10 | 2003-12-03 | 利德雪平机器工具公司 | Abrasive machine |

| WO2001008847A1 (en) * | 1999-07-29 | 2001-02-08 | Prochniewicz Zbigniew | Toolhead designed particularly to machining of valve seats incorporated in combustion engines |

Also Published As

| Publication number | Publication date |

|---|---|

| JP3749777B2 (en) | 2006-03-01 |

| DE59702039D1 (en) | 2000-08-24 |

| US6267653B1 (en) | 2001-07-31 |

| EP0802018B1 (en) | 2000-07-19 |

| DE29607203U1 (en) | 1997-08-14 |

| JPH1044010A (en) | 1998-02-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE10234707A1 (en) | Method and device for grinding a rotationally symmetrical machine component | |

| DE2460997A1 (en) | MACHINING TOOLS AND METHODS FOR HOLES | |

| DE3227924C2 (en) | ||

| EP3921118B1 (en) | Honing tool and fine machining method using the honing tool | |

| EP0802018B1 (en) | Apparatus for grinding an end-face, specially a ring-face, on the edge of a workpiece bore | |

| DE69506474T2 (en) | Device for planning or polishing stony materials | |

| EP0237790B1 (en) | Honing device | |

| DE4423422A1 (en) | Process for fine external machining, in particular rotationally symmetrical bodies | |

| DE3208536C2 (en) | Grinding machine | |

| DE29608877U1 (en) | Holder for optical lenses | |

| DE102010036470A1 (en) | Device for honing e.g. conical running surfaces, of roller bearing ring of large bearing, has eccentric cam drive for creation of oscillating movements of tool base support, where tool base support includes adjustable tool connector | |

| AT517140B1 (en) | grinding tool | |

| EP0841116A2 (en) | Working method for rotational symmetric workpiece surfaces and tool therefor | |

| DE2731554A1 (en) | Internal grinder for fine machining of cylinder bores - has roller shaped grinding tool supported on carrier on movable support | |

| DE20120294U1 (en) | Tool | |

| DE2462847C2 (en) | Method and honing machine for honing bores | |

| EP0144786A1 (en) | Separation device | |

| DE1279500B (en) | Internal grinding device for long holes | |

| DE2912814A1 (en) | Finishing grinder for conical fuel injector seat - has tail sleeve holding and guiding workpiece in its bore, with grinding tool spindle extending through sleeve | |

| DE102004047520A1 (en) | Tool for honing holes with different diameter sections (stepped holes) | |

| DE3837172A1 (en) | Tool arrangement for machining internal workpiece surfaces | |

| WO2024022756A1 (en) | Honing method, cleaning unit, cleaning device and honing machine | |

| DE102020007920A1 (en) | METHOD AND DEVICE FOR FINISHING AXICONS, SUITABLE FINISHING MACHINE FOR THIS AND THEIR USE | |

| WO2020234346A1 (en) | Combined grinding and brushing device | |

| DE19738500A1 (en) | Honing tool for finishing bores |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19970911 |

|

| 17Q | First examination report despatched |

Effective date: 19990326 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT |

|

| REF | Corresponds to: |

Ref document number: 59702039 Country of ref document: DE Date of ref document: 20000824 |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20000928 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20080426 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20080418 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20080423 Year of fee payment: 12 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090412 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20091231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090412 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091222 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090412 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20110628 Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59702039 Country of ref document: DE Effective date: 20121101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121101 |