EP0769439B2 - Weichenantrieb mit einstellbarem Hub - Google Patents

Weichenantrieb mit einstellbarem Hub Download PDFInfo

- Publication number

- EP0769439B2 EP0769439B2 EP96440086A EP96440086A EP0769439B2 EP 0769439 B2 EP0769439 B2 EP 0769439B2 EP 96440086 A EP96440086 A EP 96440086A EP 96440086 A EP96440086 A EP 96440086A EP 0769439 B2 EP0769439 B2 EP 0769439B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- crank

- adjusting

- disc

- movement

- adjusting bar

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000033001 locomotion Effects 0.000 claims abstract description 15

- 230000008878 coupling Effects 0.000 claims abstract description 7

- 238000010168 coupling process Methods 0.000 claims abstract description 7

- 238000005859 coupling reaction Methods 0.000 claims abstract description 7

- 239000000969 carrier Substances 0.000 claims 1

- 230000000284 resting effect Effects 0.000 claims 1

- 210000002105 tongue Anatomy 0.000 claims 1

- 230000009471 action Effects 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 230000005540 biological transmission Effects 0.000 description 2

- 230000008901 benefit Effects 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 238000004904 shortening Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B61—RAILWAYS

- B61L—GUIDING RAILWAY TRAFFIC; ENSURING THE SAFETY OF RAILWAY TRAFFIC

- B61L5/00—Local operating mechanisms for points or track-mounted scotch-blocks; Visible or audible signals; Local operating mechanisms for visible or audible signals

- B61L5/06—Electric devices for operating points or scotch-blocks, e.g. using electromotive driving means

Definitions

- the invention relates to a device for actuation a railway switch according to the preamble of claim 1

- Such a device is z. B. from a Company publication of the standard Elektrik Lorenz AG with the title “Turnout Drive L700M”, which appeared in 1972 is and said point drive in construction and mode of action describes, as well as from the DE-OS 1530 403 known.

- An electro-hydraulically driven point control device is known from DE-OS 1952 824.

- the crank is designed here as an angle lever, on the required for the changeover of the switch Torque due to two hydraulic power cylinders is exercised.

- the act Locking means here, however, not directly on the Crank.

- the known devices are for one predetermined stroke, each designed for a certain type of turnout or other adjustable Track element with which the respective device cooperates, is coordinated and not changed can be replaced without replacing important parts or correspondingly expensive and expensive adjustment and provide closure mechanisms.

- z. B. with switches with large radii several drives with act on a switch in different setting strokes, as this z. B. in DE-PS 19 52 823 is provided is, so must the individual drive devices in may be set differently in their setting strokes But they do not differ from one another in their positioning times.

- the invention is therefore based on the object a device of o. g. To specify the species whose Stellhub can be easily changed without getting the operating time of the operated switch changed and without that settings for closing this switch changed Need to become.

- crank connects here in an ideal way the requirement for a variable travel with unchanged Positioning time with the advantage, the point lock for all travel variants in the same place to be able to leave. Since the lock is immediately on the crank is done, the entire drive can do so so compact that he is in a caste Takes place.

- Embodiments of the device according to the invention are given in the subclaims. So relates to claim 2 a particularly space-saving design the crank as a two-armed lever whose the drive torque receiving arm disc-like is widened and both driving surfaces for receiving the drive torque from a parallel guided unlocking disc as well as stop surfaces for limiting the angle of rotation and for the intervention having locking elements.

- Claims 3 and 4 relate to embodiments one for power transmission between crank and slide arranged coupling member, the one easier, in a parallel slide arranged on the slide sliding pin or one instead the pin arranged roll, which can be a rolling motion in the slightly wider than the roll diameter performs measured leadership.

- Claim 5 relates to a development in which instead of a pin engaging in a guide an articulated lever the power transmission from the crank on the lock valve übemimmt.

- Claims 6 and 7 relate to possibilities for changing the distance between the coupling member and axis of rotation of the crank. This distance, which is the Length of the control stroke determined, can either, according to Claim 6, by changing the length of the espagnolette driving lever arm of the crank or, according to claim 7, by changing the position the coupling member changed on this lever arm who the.

- Claim 8 relates to the possibility of the Weichenverstellvorraum to be made mobile.

- Claim 9 relates to an embodiment of a space-saving crank lock.

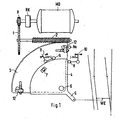

- Fig. 1 is schematically a crank drive for a turnout WE reproduced.

- An engine M0 drives via a slip clutch RK, a pinion R and a Gear 1 a screw 2.

- the worm is with a helical gear sector 3 in engagement, which is rotatable about a shaft 6.

- the Actual crank handle also forms around the shaft 6 rotatable double lever, on one arm 5 of the Slider of the switch is hinged and the other Arm 4 sector-shaped widened, parallel to Schrägstirnradsektor runs and with this over a Driver 7 and a z. B. as a slot in azimuthal Direction trained recess into which the driver protruding, connected.

- the excavated lever which at his End can play a role, slides or rolls up now the arcuate edge surface of the sector-shaped Part of the crank until after reaching the other End position of the switch for locking the crank in this end position provided locking lever 9 behinddie Limitation of the sector-shaped part 4 of the crank incident. About one connected to the locking lever 9 Contact 11 will be the new turnout location at the Signal box signaled. The return of the switch is done in an analogous way.

- Fig. 2 the principle of the device according to reproduced the invention.

- a housing G are connected as with a switch to be operated Elements a lock slider ST and two educaerschieber PS stored. While the adjusting slide to the Umstellen the switch required force on the switch blades exercised, the strigerschieber transfer the Positions of the switch blades inside the housing G. There are then z.

- B. educaferriegel PR provided in the existing in the fürerschiebem recesses einfalls while a not shown electrical Press contact once the checker pushers have reached a position that is an end position of corresponding to each switch blade corresponds to ..

- the drive of the lock slider ST via a crank K is rotatable.

- This crank is as a double lever educated.

- a first lever arm that the Actuator ST drives, has a slot L, in the a pin Z is arranged adjustable and in an am Locking slide, perpendicular to its direction of movement arranged parallel guide F engages.

- the second lever arm the crank K is close to a circular sector with radially oriented edges K1, K2 widened, the approximately in the middle of its arcuate boundary a bent down here driver MT1 carries.

- This driver comes with drivers MT2, MT3 of a parallel to the crank, also around the shaft W rotatable unlocking disk E engaged as soon as the release disk against the Stellkurbel under the action of a torque M is rotated by a small forward angle.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Railway Tracks (AREA)

- Vehicle Body Suspensions (AREA)

- Transmission Devices (AREA)

- Bending Of Plates, Rods, And Pipes (AREA)

- Braking Arrangements (AREA)

- Forklifts And Lifting Vehicles (AREA)

Description

- Fig. 1

- zeigt schematisch das Prinzip eines Stellkurbel-Weichenantriebs nach dem Stand der Technik.

- Fig. 2

- zeigt das Prinzip der Vorrichtung nach der Erfindung.

Claims (6)

- Vorrichtung zur Betätigung einer Eisenbahnweiche (WE) mit einem Antriebselement (MO), einem von diesem über eine als um eine Achse drehbarer Doppelhebel mit einem ersten und zweiten Hebelarm ausgebildete Stellkurbel (K) betätigten, auf die Weichenzungen einwirkenden Stellschieber (ST) und mit Verriegelungsmitteln (R1, R2, H1, H2), die die Stellkurbel nach Beendigung einer Stellbewegung in ihrer jeweiligen Endlage festhalten, wobei die Stellkurbel (K) über ein Koppelglied (Z) mit dem Stellschieber (ST) kraftschlüssig verbunden ist

dadurch gekennzeichnet, daß

der erste Hebelarm ein Langloch (L) besitzt, in das das Koppelglied (Z) versbellbar in seinem Abstand von der Drehachse (W) angeordnet ist. - Vorrichtung nach Anspruch 1,

dadurch gekennzeichnet, daß der erste oder zweite

nicht mit dem Stellschieber verbundene Hebelarm des Doppelhebels als Sektor eines Kreises ausgebildet ist, durch dessen Mittelpunkt die Drehachse verläuft, daß eine im wesentlichen parallel zu dem Kreissektor angeordnete, vorzugsweise in der Größe des Kreissektors ausgebildete Entsperrscheibe (E) um die Drehachse drehbar angeordnet ist, welche ein vom Antriebselement auf die Stellkurbel zu übertragendes Drehmoment (M) aufnimmt und die Stellkurbel über an Stellkurbel und Entsperrscheibe angebrachte, aus einer einer Endlage des Stellschiebers entsprechenden Lage heraus nach kurzem Vorlauf miteinander in Eingriff kommende Mitnehmer (MT1, MT2, MT3) bis in eine der anderen Endlage des Stellschiebers entsprechende Endposition mitdreht und welche beiderseits Schrägflächen (E1, E2) aufweist, die während des Vorlaufs ein die Drehung der Stellkurbel zuvor verhinderndes, mit einer Anschlagsfläche (K1, K2) der Stellkurbel in Eingriff stehendes Verriegelungselement (R1, R2) gegen eine Rückstellkraft aus der Verriegelungsstellung drücken. - Vorrichtung nach Anspruch 1 oder 2,

dadurch gekennzeichnet, daß das in seinem Abstand von der Drehachse verstellbare Koppelglied (Z) ein zur Längsausdehnung des Hebelarmes senkrechter Zapfen ist, der in eine am Stellschieber, vorzugsweise senkrecht zu dessen Bewegungsrichtung angeordnete Führung (F) eingreift und in dieser beweglich ist. - Vorrichtung nach Anspruch 3,

dadurch gekennzeichnet, daß der Zapfen Lager für eine Rolle ist. - Vorrichtung nach einem der Ansprüche 1 bis 4,

dadurch gekennzeichnet, daß der Stellschieber (ST) mit einer Kupplung derart verbunden ist, daß beim stumpf Befahren der Eisenbahnweiche (WE) aus der falschen Richtung (Auffahren der Weiche) der Stellschieber von den Verriegelüngselementen getrennt wird. - Vorrichtung nach einem der Ansprüche 2 bis 5,

dadurch gekennzeichnet, daß als Verriegelungselemente Rollen (R1, R2) vorgesehen sind, die an in den Endlagen des Stellschiebers durch vorgespannte Federn in einer Ruhelage gehaltenen Hebeln (H1, H2) befestigt sind und im Zusammenwirken mit je einer Anschlagsfläche (K1, K2) des das Antriebsdrehmoment aufnehmenden Hebelarms der Stellkurbel deren Bewegung verhindern, daß die Rollen so breit sind, daß sie in die Bahn der Entsperrscheibe (E) ragen und daß die Schrägflächen (E1, E2) in den Bereichen des Randes der Entsperrscheibe vorgesehen sind, die während der Drehbewegung der Entsperrscheibe zuerst mit einer Rolle in Kontakt kommen.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19538966A DE19538966A1 (de) | 1995-10-19 | 1995-10-19 | Weichenantrieb mit einstellbarem Hub |

| DE19538966 | 1995-10-19 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0769439A1 EP0769439A1 (de) | 1997-04-23 |

| EP0769439B1 EP0769439B1 (de) | 2002-07-03 |

| EP0769439B2 true EP0769439B2 (de) | 2005-08-10 |

Family

ID=7775280

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96440086A Expired - Lifetime EP0769439B2 (de) | 1995-10-19 | 1996-10-14 | Weichenantrieb mit einstellbarem Hub |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0769439B2 (de) |

| AT (1) | ATE220020T1 (de) |

| DE (2) | DE19538966A1 (de) |

| HU (1) | HUP9602869A3 (de) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE60306102T2 (de) * | 2003-03-21 | 2007-04-19 | Alcatel | Weichenantriebssystem |

| FR2905922B1 (fr) * | 2006-09-14 | 2008-12-05 | Vossloh Cogifer Sa | Mecanisme de manoeuvre d'aiguilles |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE948164C (de) * | 1953-07-03 | 1956-08-30 | Lorenz C Ag | Zungenpruefvorrichtung fuer elektrische Weichenantriebe |

| DE1055578B (de) * | 1956-08-08 | 1959-04-23 | Standard Elektrik Lorenz Ag | Kupplungseinrichtung an elektrischen Weichenantrieben im Eisenbahnsicherungswesen |

| DE1116713B (de) * | 1957-03-06 | 1961-11-09 | Standard Elektrik Lorenz Ag | Kupplungseinrichtung an elektrischen Weichenantrieben im Eisenbahnsicherungswesen |

| DE1124538B (de) * | 1958-01-27 | 1962-03-01 | Licentia Gmbh | Elektromotorischer Weichenstellantrieb |

| FR1382106A (fr) * | 1963-06-27 | 1964-12-18 | Westinghouse Freins & Signaux | Procédé de commande d'aiguilles talonnables et moteur pour la mise en oeuvre dudit procédé |

| DE1530403A1 (de) * | 1965-05-18 | 1969-10-02 | Standard Elek K Lorenz Ag | Kupplungsvorrichtung an elektrischen Weichenantrieben fuer Eisenbahnsicherungsanlagen |

| DE1530404A1 (de) * | 1965-06-14 | 1969-10-02 | Standard Elek K Lorenz Ag | Kupplungsvorrichtung an elektrischen Weichenantrieben fuer Eisenbahnsicherungsanlagen |

| NL6901277A (de) * | 1969-01-24 | 1970-07-28 | ||

| FR2510059B1 (fr) * | 1981-07-23 | 1987-12-04 | Dietrich & Cie De | Mecanisme de manoeuvre d'aiguillages de voies ferrees du " type cale " |

| SE506183C2 (sv) * | 1993-05-27 | 1997-11-17 | Abb Daimler Benz Transp | Anordning vid järnvägsspår för omläggning av spårväxel |

-

1995

- 1995-10-19 DE DE19538966A patent/DE19538966A1/de active Pending

-

1996

- 1996-10-14 DE DE59609398T patent/DE59609398D1/de not_active Expired - Lifetime

- 1996-10-14 AT AT96440086T patent/ATE220020T1/de active

- 1996-10-14 EP EP96440086A patent/EP0769439B2/de not_active Expired - Lifetime

- 1996-10-17 HU HU9602869A patent/HUP9602869A3/hu unknown

Also Published As

| Publication number | Publication date |

|---|---|

| DE59609398D1 (de) | 2002-08-08 |

| EP0769439A1 (de) | 1997-04-23 |

| DE19538966A1 (de) | 1997-04-24 |

| ATE220020T1 (de) | 2002-07-15 |

| HUP9602869A3 (en) | 2001-04-28 |

| HU9602869D0 (en) | 1996-12-30 |

| EP0769439B1 (de) | 2002-07-03 |

| HUP9602869A2 (hu) | 1998-05-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2467548B1 (de) | Laufschiene für eine schiebewand und verfahren zur betätigung einer weiche in einer laufschiene | |

| DE102020108906A1 (de) | Luftklappenanordnung mit asynchron beweglichen Luftklappenfeldern | |

| EP1365177A2 (de) | Schaltvorrichtung eines Kraftfahrzeuggetriebes | |

| EP0191907B1 (de) | Einrichtung zum wahlweisen Anschneiden oder Abschneiden eines Papierstreifens | |

| DE69312560T2 (de) | Automatische Arretiervorrichtung für den elektronischen Motorantrieb von Türen, Fensterläden, Rolläden und dergleichen | |

| DE19535578B4 (de) | Weichenantrieb mit Innenverschluß | |

| EP0769439B2 (de) | Weichenantrieb mit einstellbarem Hub | |

| DE3134515C2 (de) | ||

| DE10226355B3 (de) | Betätigungsvorrichtung | |

| EP1117950A1 (de) | Schaltvorrichtung eines automatischen kraftfahrzeuggetriebes | |

| DE3718513C2 (de) | Wendevorrichtung für eine raffbare Lamellenjalousie | |

| DE3714705A1 (de) | Schaltvorrichtung an einem magnetbandgeraet fuer autoreversebetrieb | |

| DE3322292C2 (de) | Sicherheitsschalter mit Fehlschließsicherung | |

| DE19605711A1 (de) | Antriebseinrichtung für ein Schaltgerät | |

| DE19626178C2 (de) | Stelleinrichtung zur Betätigung eines Stellorgans | |

| EP2297015B1 (de) | Antriebsvorrichtung zum umschalten mechanischer elemente | |

| DE1212809B (de) | Schrittschaltwerk | |

| DE69815034T2 (de) | Vorrichtung und Verfahren zur Erlangung eines Betätigungsmomentes | |

| EP0157011B1 (de) | Jalousieverschluss | |

| DE2025582C3 (de) | Programmschalter, insbesondere für Waschmaschinen | |

| DE2254192C2 (de) | Umschalteinrichtung eines Getriebes zum unterschiedlichen Antrieb eines, gegebenenfalls mehrerer Steuerelemente | |

| DE2363714C2 (de) | Nockengesteuerte, zweistufige Fensterverstellvorrichtung | |

| DE750335C (de) | Kennungsgeber mit veraenderlicher Kennung | |

| DE3234193A1 (de) | Umkehrlaufwerk eines tonbandgeraetes | |

| DE2922319A1 (de) | Schaftmaschine fuer webmaschinen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT CH DE ES FR GB IT LI SE |

|

| 17P | Request for examination filed |

Effective date: 19970823 |

|

| RAP3 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ALCATEL |

|

| RAP3 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ALCATEL |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 20010903 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE ES FR GB IT LI SE |

|

| REF | Corresponds to: |

Ref document number: 220020 Country of ref document: AT Date of ref document: 20020715 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20020703 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: CABINET ROLAND NITHARDT CONSEILS EN PROPRIETE INDU |

|

| REF | Corresponds to: |

Ref document number: 59609398 Country of ref document: DE Date of ref document: 20020808 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030130 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| 26 | Opposition filed |

Opponent name: SIEMENS AG Effective date: 20030401 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20050810 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT CH DE ES FR GB IT LI SE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AEN Free format text: AUFRECHTERHALTUNG DES PATENTES IN GEAENDERTER FORM |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20021015 |

|

| GBTA | Gb: translation of amended ep patent filed (gb section 77(6)(b)/1977) | ||

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: RPEO |

|

| ET3 | Fr: translation filed ** decision concerning opposition | ||

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20151006 Year of fee payment: 20 Ref country code: CH Payment date: 20151012 Year of fee payment: 20 Ref country code: GB Payment date: 20151014 Year of fee payment: 20 Ref country code: IT Payment date: 20151026 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20151008 Year of fee payment: 20 Ref country code: SE Payment date: 20151013 Year of fee payment: 20 Ref country code: AT Payment date: 20151012 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59609398 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20161013 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 220020 Country of ref document: AT Kind code of ref document: T Effective date: 20161014 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20161013 |