EP0769439B2 - Switch drive with adjustable stroke - Google Patents

Switch drive with adjustable stroke Download PDFInfo

- Publication number

- EP0769439B2 EP0769439B2 EP96440086A EP96440086A EP0769439B2 EP 0769439 B2 EP0769439 B2 EP 0769439B2 EP 96440086 A EP96440086 A EP 96440086A EP 96440086 A EP96440086 A EP 96440086A EP 0769439 B2 EP0769439 B2 EP 0769439B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- crank

- adjusting

- disc

- movement

- adjusting bar

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B61—RAILWAYS

- B61L—GUIDING RAILWAY TRAFFIC; ENSURING THE SAFETY OF RAILWAY TRAFFIC

- B61L5/00—Local operating mechanisms for points or track-mounted scotch-blocks; Visible or audible signals; Local operating mechanisms for visible or audible signals

- B61L5/06—Electric devices for operating points or scotch-blocks, e.g. using electromotive driving means

Definitions

- the invention relates to a device for actuation a railway switch according to the preamble of claim 1

- Such a device is z. B. from a Company publication of the standard Elektrik Lorenz AG with the title “Turnout Drive L700M”, which appeared in 1972 is and said point drive in construction and mode of action describes, as well as from the DE-OS 1530 403 known.

- An electro-hydraulically driven point control device is known from DE-OS 1952 824.

- the crank is designed here as an angle lever, on the required for the changeover of the switch Torque due to two hydraulic power cylinders is exercised.

- the act Locking means here, however, not directly on the Crank.

- the known devices are for one predetermined stroke, each designed for a certain type of turnout or other adjustable Track element with which the respective device cooperates, is coordinated and not changed can be replaced without replacing important parts or correspondingly expensive and expensive adjustment and provide closure mechanisms.

- z. B. with switches with large radii several drives with act on a switch in different setting strokes, as this z. B. in DE-PS 19 52 823 is provided is, so must the individual drive devices in may be set differently in their setting strokes But they do not differ from one another in their positioning times.

- the invention is therefore based on the object a device of o. g. To specify the species whose Stellhub can be easily changed without getting the operating time of the operated switch changed and without that settings for closing this switch changed Need to become.

- crank connects here in an ideal way the requirement for a variable travel with unchanged Positioning time with the advantage, the point lock for all travel variants in the same place to be able to leave. Since the lock is immediately on the crank is done, the entire drive can do so so compact that he is in a caste Takes place.

- Embodiments of the device according to the invention are given in the subclaims. So relates to claim 2 a particularly space-saving design the crank as a two-armed lever whose the drive torque receiving arm disc-like is widened and both driving surfaces for receiving the drive torque from a parallel guided unlocking disc as well as stop surfaces for limiting the angle of rotation and for the intervention having locking elements.

- Claims 3 and 4 relate to embodiments one for power transmission between crank and slide arranged coupling member, the one easier, in a parallel slide arranged on the slide sliding pin or one instead the pin arranged roll, which can be a rolling motion in the slightly wider than the roll diameter performs measured leadership.

- Claim 5 relates to a development in which instead of a pin engaging in a guide an articulated lever the power transmission from the crank on the lock valve übemimmt.

- Claims 6 and 7 relate to possibilities for changing the distance between the coupling member and axis of rotation of the crank. This distance, which is the Length of the control stroke determined, can either, according to Claim 6, by changing the length of the espagnolette driving lever arm of the crank or, according to claim 7, by changing the position the coupling member changed on this lever arm who the.

- Claim 8 relates to the possibility of the Weichenverstellvorraum to be made mobile.

- Claim 9 relates to an embodiment of a space-saving crank lock.

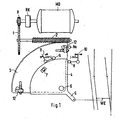

- Fig. 1 is schematically a crank drive for a turnout WE reproduced.

- An engine M0 drives via a slip clutch RK, a pinion R and a Gear 1 a screw 2.

- the worm is with a helical gear sector 3 in engagement, which is rotatable about a shaft 6.

- the Actual crank handle also forms around the shaft 6 rotatable double lever, on one arm 5 of the Slider of the switch is hinged and the other Arm 4 sector-shaped widened, parallel to Schrägstirnradsektor runs and with this over a Driver 7 and a z. B. as a slot in azimuthal Direction trained recess into which the driver protruding, connected.

- the excavated lever which at his End can play a role, slides or rolls up now the arcuate edge surface of the sector-shaped Part of the crank until after reaching the other End position of the switch for locking the crank in this end position provided locking lever 9 behinddie Limitation of the sector-shaped part 4 of the crank incident. About one connected to the locking lever 9 Contact 11 will be the new turnout location at the Signal box signaled. The return of the switch is done in an analogous way.

- Fig. 2 the principle of the device according to reproduced the invention.

- a housing G are connected as with a switch to be operated Elements a lock slider ST and two educaerschieber PS stored. While the adjusting slide to the Umstellen the switch required force on the switch blades exercised, the strigerschieber transfer the Positions of the switch blades inside the housing G. There are then z.

- B. educaferriegel PR provided in the existing in the fürerschiebem recesses einfalls while a not shown electrical Press contact once the checker pushers have reached a position that is an end position of corresponding to each switch blade corresponds to ..

- the drive of the lock slider ST via a crank K is rotatable.

- This crank is as a double lever educated.

- a first lever arm that the Actuator ST drives, has a slot L, in the a pin Z is arranged adjustable and in an am Locking slide, perpendicular to its direction of movement arranged parallel guide F engages.

- the second lever arm the crank K is close to a circular sector with radially oriented edges K1, K2 widened, the approximately in the middle of its arcuate boundary a bent down here driver MT1 carries.

- This driver comes with drivers MT2, MT3 of a parallel to the crank, also around the shaft W rotatable unlocking disk E engaged as soon as the release disk against the Stellkurbel under the action of a torque M is rotated by a small forward angle.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Railway Tracks (AREA)

- Vehicle Body Suspensions (AREA)

- Braking Arrangements (AREA)

- Bending Of Plates, Rods, And Pipes (AREA)

- Transmission Devices (AREA)

- Forklifts And Lifting Vehicles (AREA)

Abstract

Description

Die Erfindung betrifft eine Vorrichtung zur Betätigung einer Eisenbahnweiche gemäß dem Oberbegriff des Patentanspruchs 1.The invention relates to a device for actuation a railway switch according to the preamble of claim 1

Eine derartige Vorrichtung ist z. B. aus einer Firmendruckschrift der Standard Elektrik Lorenz AG mit dem Titel "Weichenantrieb L700M", die 1972 erschienen ist und den genannten Weichenantrieb in Aufbau und Wirkungsweise beschreibt, sowie aus der DE-OS 1530 403 bekannt.Such a device is z. B. from a Company publication of the standard Elektrik Lorenz AG with the title "Turnout Drive L700M", which appeared in 1972 is and said point drive in construction and mode of action describes, as well as from the DE-OS 1530 403 known.

Eine elektrohydraulisch angetriebene Weichenstellvorrichtung ist aus der DE-OS 1952 824 bekannt. Die Stellkurbel ist hier als Winkelhebel ausgebildet, auf den das zum Umstellen der Weiche erforderliche Drehmoment durch zwei hydraulische Arbeitszylinder ausgeübt wird. Anders als bei der in der zuerst genannten Schrift beschriebenen-Verrichtung wirken die Verriegelungsmittel hier jedoch nicht unmittelbar auf die Stellkurbel ein.An electro-hydraulically driven point control device is known from DE-OS 1952 824. The crank is designed here as an angle lever, on the required for the changeover of the switch Torque due to two hydraulic power cylinders is exercised. Unlike the one in the first mentioned Scripture-described action the act Locking means here, however, not directly on the Crank.

Die bekannten Vorrichtungen sind für einen vorgegebenen Stellhub ausgelegt, der jeweils auf einen bestimmten Typ einer Weiche oder eines anderen verstellbaren Gleiselementes, mit dem die jeweilige Vorrichtung zusammenwirkt, abgestimmt ist und nicht verändert werden kann, ohne wichtige Teile auszuwechseln oder entsprechend aufwendige und teure Verstell- und Verschlußmechanismen vorzusehen. Sollen z. B. bei Weichen mit großen Radien mehrere Antriebe mit unterschiedlichen Stellhüben auf eine Weiche einwirken, wie dies z. B. in der DE-PS 19 52 823 vorgesehen ist, so müssen die einzelnen Antriebsvorrichtungen in ihren Stellhüben unterschiedlich eingestellt sein, dürfen sich aber in ihren Stellzeiten nicht voneinander unterscheiden. Dazu müssen bei mechanischen Antrieben die Getriebeübersetzungen, bei hydraulischen Antrieben die Fördervolumina der Pumpen verändert werden oder es müssen in den elektrischen Zuleitungen der Antriebe teure Frequenzumrichter vorgesehen werden.The known devices are for one predetermined stroke, each designed for a certain type of turnout or other adjustable Track element with which the respective device cooperates, is coordinated and not changed can be replaced without replacing important parts or correspondingly expensive and expensive adjustment and provide closure mechanisms. Should z. B. with switches with large radii several drives with act on a switch in different setting strokes, as this z. B. in DE-PS 19 52 823 is provided is, so must the individual drive devices in may be set differently in their setting strokes But they do not differ from one another in their positioning times. For mechanical drives the gear ratios, with hydraulic drives the delivery volumes of the pumps are changed or it must be in the electrical supply lines of the drives expensive frequency converters are provided.

Der Erfindung liegt deshalb die Aufgabe zugrunde, eine Vorrichtung der o. g. Art anzugeben, deren Stellhub einfach verändert werden kann, ohne daß sich die Stellzeit der betätigten Weiche verändert und ohne daß Einstellungen zum Verschluß dieser Weiche geändert werden müssen.The invention is therefore based on the object a device of o. g. To specify the species whose Stellhub can be easily changed without getting the operating time of the operated switch changed and without that settings for closing this switch changed Need to become.

Diese Aufgabe wird durch die im Patentanspruch 1 angegebenen Merkmale gelöst.This object is achieved by the in the claim 1 specified characteristics solved.

Die Stellkurbel verbindet hier in idealer Weise die Forderung nach einem variablen Stellweg bei unveränderter Stellzeit mit dem Vorteil, den Weichenverschluß für alle Stellwegvarianten an derselben Stelle belassen zu können. Da die Verriegelung unmittelbar an der Stellkurbel erfolgt, läßt sich der gesamte Antrieb dazuhin so kompakt aufbauen, daß er in einer Kastenschwelle Platz findet.The crank connects here in an ideal way the requirement for a variable travel with unchanged Positioning time with the advantage, the point lock for all travel variants in the same place to be able to leave. Since the lock is immediately on the crank is done, the entire drive can do so so compact that he is in a caste Takes place.

Ausgestaltungen der Vorrichtung nach der Erfindung sind in den Unteransprüchen angegeben. So betrifft Anspruch 2 eine besonders platzsparende Ausführung der Stellkurbel als zweiarmiger Hebel, dessen das Antriebsdrehmoment aufnehmender Arm scheibenartig verbreitert ist und sowohl Mitnehmerflächen zur Aufnahme des Antriebsdrehmoments von einer parallel geführten Entsperrscheibe wie auch Anschlagflächen zur Begrenzung des Drehwinkels und für den Eingriff von Verriegelungselementen aufweist.Embodiments of the device according to the invention are given in the subclaims. So relates to claim 2 a particularly space-saving design the crank as a two-armed lever whose the drive torque receiving arm disc-like is widened and both driving surfaces for receiving the drive torque from a parallel guided unlocking disc as well as stop surfaces for limiting the angle of rotation and for the intervention having locking elements.

Die Ansprüche 3 und 4 betreffen Ausgestaltungen eines zur Kraftübertragung zwischen Stellkurbel und Stellschieber angeordneten Koppelgliedes, das ein einfacher, in einer am Stellschieber angeordneten Parallelführung gleitender Zapfen oder aber eine anstelle des Zapfens angeordnete Rolle sein kann, die eine Rollbewegung in der geringfügig weiter als der Rollendurchmesser bemessenen Führung ausführt.Claims 3 and 4 relate to embodiments one for power transmission between crank and slide arranged coupling member, the one easier, in a parallel slide arranged on the slide sliding pin or one instead the pin arranged roll, which can be a rolling motion in the slightly wider than the roll diameter performs measured leadership.

Anspruch 5 betrifft eine Weiterbildung, bei der anstelle eines in eine Führung eingreifenden Zapfens ein Gelenkhebel die Kraftübertragung von der Stellkurbel auf den Stellschieber übemimmt.Claim 5 relates to a development in which instead of a pin engaging in a guide an articulated lever the power transmission from the crank on the lock valve übemimmt.

Die Ansprüche 6 und 7 betreffen Möglichkeiten

zur Veränderung des Abstandes zwischen Koppelglied

und Drehachse der Stellkurbel. Dieser Abstand, der die

Länge des Stellhubes bestimmt, kann entweder, gemäß

Anspruch 6, durch Verändern der Länge des den Steilschieber

antreibenden Hebelarmes der Stellkurbel

oder, gemäß Anspruch 7, durch Verändern der Position

des Koppelgliedes auf diesem Hebelarm verändert wer

den.

Anspruch 8 betrifft die Möglichkeit, die Weichenverstellvorrichtung auffahrbar zu gestalten.Claim 8 relates to the possibility of the Weichenverstellvorrichtung to be made mobile.

Anspruch 9 betrifft ein Ausführungsbeispiel für

eine platzsparende Stellkurbelverriegelung.

Anhand von 2 Figuren soll nun ein Ausführungsbeispiel der Vorrichtung nach der Erfindung eingehend beschrieben und seine Funktion erklärt werden.

- Fig. 1

- zeigt schematisch das Prinzip eines Stellkurbel-Weichenantriebs nach dem Stand der Technik.

- Fig. 2

- zeigt das Prinzip der Vorrichtung nach der Erfindung.

- Fig. 1

- schematically shows the principle of a crank handle turnout drive according to the prior art.

- Fig. 2

- shows the principle of the device according to the invention.

In Fig. 1 ist schematisch ein Stellkurbelantrieb

für eine Weiche WE wiedergegeben. Ein Motor M0 treibt

über eine Rutschkupplung RK, ein Ritzel R und ein

Zahnrad 1 eine Schnecke 2 an.In Fig. 1 is schematically a crank drive

for a turnout WE reproduced. An engine M0 drives

via a slip clutch RK, a pinion R and a

Gear 1 a

Die Schnecke ist mit einem Schrägstirnradsektor

3 im Eingriff, der um eine Welle 6 drehbar ist. Die

eigentliche Stellkurbel bildet ein ebenfalls um die Welle

6 drehbarer Doppelhebel, an dessen einem Arm 5 der

Stellschieber der Weiche angelenkt ist und dessen anderer

Arm 4 sektorförmig verbreitert, parallel zum

Schrägstirnradsektor verläuft und mit diesem über einen

Mitnehmer 7 und eine z. B. als Langloch in azimutaler

Richtung ausgebildete Ausnehmung, in die der Mitnehmer

hineinragt, verbunden ist.The worm is with a helical gear sector

3 in engagement, which is rotatable about a

Beim Stellvorgang wird, ausgehend von einer

Endlage der Weiche, in der Schrägstirnradsektor 3 und

Stellkurbel 4 an einem Anschlag anliegen und in der die

Stellkurbel gegen eine vom Anschlag weg gerichtete

Bewegung durch einen Sperrhebel 8 verriegelt ist, der

Schrägstirnradsektor über die Schnecke 2 angetrieben.

Noch bevor der Mitnehmer 7 Kraft auf die Stellkurbel

ausübt, hebt der Schrägstirnradsektor über eine Schräge

12 den Sperrhebel 8, 8a gegen eine ihn in einer die

Drehbewegung der Stellkurbel blockierenden Ruhelage

haltende Federkraft aus und gibt damit die Stellkurbel

frei. Mit dem Ausheben des Sperrhebels 8 wird außerdem

ein Kontakt 10 geschlossen, der den beginnenden

Weichenumlauf z. B. an ein Stellwerk meldet.During the setting process, starting from a

End position of the switch, in the helical gear sector 3 and

Stellkurbel 4 abut a stop and in the

Crank against a directed away from the stop

Movement is locked by a locking lever 8, the

Schrägstirnradsektor driven via the

Der ausgehobene Stellhebel, der an seinem

Ende eine Rolle tragen kann, gleitet oder rollt nun auf

der kreisbogenförmigen Randfläche des sektorförmigen

Teils der Stellkurbel bis nach Erreichen der anderen

Endlage der Weiche der für die Verriegelung der Stellkurbel

in dieser Endlage vorgesehene Sperrhebel 9 hinterdie

Begrenzung des sektorförmigen Teils 4 der Stellkurbel

einfällt. Über einen mit dem Sperrhebel 9 Verbundenen

Kontakt 11 wird die neue Weichenlage an das

Stellwerk gemeldet. Die Rückstellung der Weiche erfolgt

in analoger Weise.The excavated lever, which at his

End can play a role, slides or rolls up now

the arcuate edge surface of the sector-shaped

Part of the crank until after reaching the other

End position of the switch for locking the crank

in this end position provided

Anstelle eines über ein Getriebe an die Stellkurbel angekoppelten Motors, können selbstverständlich auch hydraulische Arbelszylinder zur Ausübung eines Drehmomentes auf die Stellkurbel zum Einsatz kommen, wie dies bei elektrohydraulischen Weichenantrieben der Fall ist.Instead of a gearbox to the crank coupled engine, of course also hydraulic Arbelszylinder for the exercise of a Torque on the crank for use come, as with electrohydraulic turnout drives the case is.

In Fig. 2 ist das Prinzip der Vorrichtung nach der Erfindung wiedergegeben. In einem Gehäuse G sind als mit einer zu betätigenden Weiche verbundene Elemente ein Stellschieber ST und zwei Prüferschieber PS gelagert. Während der Stellschieber die zum Umstellen der Weiche erforderliche Stellkraft auf die Weichenzungen ausübt, übertragen die Prüferschieber die Positionen der Weichenzungen ins Innere des Gehäuses G. Dort sind dann z. B. Prüferriegel PR vorgesehen, die in in den Prüferschiebem vorhandene Ausnehmungen einfallen und dabei einen nicht dargestellten elektrischen Kontakt betätigen, sobald die Prüferschieber eine Position erreicht haben, die einer Endposition der jeweils mit ihnen verbundenen Weichenzunge entspricht..In Fig. 2, the principle of the device according to reproduced the invention. In a housing G are connected as with a switch to be operated Elements a lock slider ST and two Prüferschieber PS stored. While the adjusting slide to the Umstellen the switch required force on the switch blades exercised, the Prüferschieber transfer the Positions of the switch blades inside the housing G. There are then z. B. Prüfferriegel PR provided in the existing in the Prüferschiebem recesses einfalls while a not shown electrical Press contact once the checker pushers have reached a position that is an end position of corresponding to each switch blade corresponds to ..

Der Antrieb des Stellschiebers ST erfolgt über eine Stellkurbel K, die um eine im Gehäuseboden gelagerte Welle W drehbar ist. Diese Stellkurbel ist als Doppelhebel ausgebildet. Ein erster Hebelarm, der den Stellschieber ST antreibt, besitzt ein Langloch L, in dem ein Zapfen Z verstellbar angeordnet ist und in eine am Stellschieber, senkrecht zu dessen Bewegungsrichtung angeordnete Parallelführung F eingreift. Der zweite Hebelarm der Stellkurbel K ist zu einem Kreissektor mit nahezu radial ausgerichteten Kanten K1, K2 verbreitert, der etwa in der Mitte seiner kreisbogenförmigen Begrenzung einen hier nach unten abgekröpften Mitnehmer MT1 trägt. Dieser Mitnehmer kommt mit Mitnehmern MT2, MT3 einer parallel zur Stellkurbel geführten, ebenfalls um die Welle W drehbaren Entsperrscheibe E in Eingriff, sobald die Entsperrscheibe gegenüber der Stellkurbel unter der Wirkung eines Drehmomentes M um einen kleinen Vorlaufwinkel gedreht wird.The drive of the lock slider ST via a crank K, which is mounted around a housing in the bottom Shaft W is rotatable. This crank is as a double lever educated. A first lever arm that the Actuator ST drives, has a slot L, in the a pin Z is arranged adjustable and in an am Locking slide, perpendicular to its direction of movement arranged parallel guide F engages. The second lever arm the crank K is close to a circular sector with radially oriented edges K1, K2 widened, the approximately in the middle of its arcuate boundary a bent down here driver MT1 carries. This driver comes with drivers MT2, MT3 of a parallel to the crank, also around the shaft W rotatable unlocking disk E engaged as soon as the release disk against the Stellkurbel under the action of a torque M is rotated by a small forward angle.

In den Endlagen der Weiche ist die Stellkurbel jeweils einerseits durch eine Rolle R1 oder R2, die an einem federkraftbeaufschlagten Hebel H 1 bzw. H2 befestigt ist, und andererseits einen Anschlag A1 bzw. A2 in ihrer Lage verriegelt. Allein die Entsperrscheibe E ist in der Lage, wenn sie von einem nicht dargestellten Motor oder einem hydraulischen Arbeitszylinder mit dem Drehmoment M beaufschlagt wird, mit einer Schräge E1 die Rolle R1 gegen die Federkraft des Hebels H1 aus der in Fig. 2 dargestellten, die Bewegung der Stellkurbel sperrenden Lage zu drücken und mit der Vorderfläche V1 ihres Mitnehmers MT2, die nach Drehung um den Vorlaufwinkel gegen die zum Mitnehmer MT2 hin gerichtete Seitenfläche V2 des Mitnehmers MT1 der Stellkurbel läuft, die Stellkurbel mitzuführen, bis die Stellkurbelkante K1 den Anschlag A2 erreicht hat und die am Hebel H2 befestigte Rolle R2 hinter der anderen Kante K2 der Stellkurbel, die ausgangs der Bewegung am Anschlag A1 angelegen hat, eingefallen ist.In the end positions of the switch is the crank on the one hand by a roller R1 or R2, the on attached to a spring-loaded lever H 1 or H2 is, and on the other hand, a stop A1 and A2 locked in their position. Only the release disk E is capable of being driven by a motor, not shown or a hydraulic cylinder with the Torque M is applied, with a slope E1 the role R1 against the spring force of the lever H1 the illustrated in Fig. 2, the movement of the crank locking position to press and with the front surface V1 of their driver MT2, which after turning around the Lead angle against the driver MT2 directed towards Side surface V2 of the driver MT1 of the crank running, carry the crank up to the crank edge K1 has reached the stop A2 and the am Lever H2 fixed roller R2 behind the other edge K2 the crank, the exit of movement at the stop A1 has come to mind.

Während des Drehvorgangs der Stellkurbel wurde der Stellschieber ST um einen Stellhub S1 nach links bewegt. Soll dieser Stellhub kleiner sein, z. B. weil der Stellschieber nicht in der Nähe der Spitze der Weichenzungen; sondern z. B., in einem von mehreren Antrieben einer Langweiche angeordnet, in der Mitte der Weichenzungen angreift, so kann der Stellhub hier auf einfache Weise verstellt werden, indem der Zapfen Z im Langloch L in eine andere Position Z' verschoben wird, in der er von der Mittelachse der Welle W nicht einen Abstand L1 sondern einen kleineren Abstand L2 hat. Wie aus der Figur ersichtlich, verkürzt sich dadurch der Stellhub auf einen Weg S2. Die Stellzeit bleibt dabei unverändert und auch die Einstellungen der Hebel H1, H2 brauchen nicht verändert zu werden. Beim Weichenrücklauf kehrt die Vorrichtung aus der zuletzt eingenommenen Endlage in die in Fig. 2 dargestellte Ausgangslage zurück. Dabei laufen die einzelnen Bewegungsvorgänge, Ausheben der Rolle R2 durch die entsprechende Schräge der Entsperrscheibe E während des Vorlaufes, Kraftschluß zwischen Mitnehmer MT3 und Mitnehmer MT1 und Mitdrehen der Stellkurbel bis in die dargestellte Endlage völlig analog zur vorstehend beschriebenen Stellbewegung ab.During the turning process of the crank the adjusting slide ST was followed by a setting stroke S1 moved left. If this stroke should be smaller, z. Because the lock slider is not near the tip of the switch blades; but z. B., in one of several drives arranged a long cross, in the middle of the Switch points attack, so the stroke can here on be easily adjusted by the pin Z in Slot L is moved to a different position Z ', in which he from the central axis of the wave W not one Distance L1 but a smaller distance L2 has. As can be seen from the figure, thereby shortening the Stellhub on a way S2. The positioning time remains unchanged and also the settings of the levers H1, H2 do not need to be changed. At the switchback returns the device from the last occupied End position in the starting position shown in Fig. 2 back. The individual movement processes, Lifting the role of R2 by the corresponding Slope of the release disk E during the pre-run, Frictional connection between driver MT3 and driver MT1 and turning the crank to the illustrated End position completely analogous to the one described above Adjusting movement.

Für den Fall, daß die Eisenbahnweiche aus der falschen Richtung befahren wird (Auffahren der Welche) wird dem Stellschieber ST eine Kupplung zugeordnet, die dann den Stellschieber ST von den die Endlagen bestimmenden Verriegelungsetementen trennt.In the event that the railway turn off the wrong direction is driven (Auffahren the Which) the control valve ST is assigned a clutch, then the lock valve ST of the End position determining locking elements separates.

Claims (6)

- Device for actuating railway points (WE) with a drive element (MO), an adjusting bar (ST), actuated by this via an adjusting crank (K), constructed as a double lever, with a first and a second lever arm and rotatable about an axis, and acting on the tongues of the points, and with locking means (R1, R2, H1, H2), which fix the adjusting crank in its respective end position after an adjusting movement has been completed, wherein the adjusting crank (K) is connected to the adjusting bar (ST) via a coupling member (Z), characterised in that the first lever arm has an elongated hole (L) into which the coupling member (Z) is mounted as adjustable in its distance from the rotational axis (W).

- Device according to claim 1, characterised in that the first or second lever arm of the double lever, which is not connected to the adjusting bar, is constructed as a segment of a circle, through the centre point of which the rotational axis runs, in that an unblocking disc (E), arranged substantially parallel to the segment of a circle and preferably constructed as the size of the segment of a circle, is arranged as rotatable about the rotational axis, which unlocking disc receives a torque (M) to be transmitted from the drive element to the adjusting crank and the adjusting crank, via carriers (MT1, MT2, MT3), attached to adjusting crank and unblocking disc, coming from a position corresponding to an end position of the adjusting bar into engagement with one another after a short forward movement, simultaneously rotates until it is in an end position corresponding to the other end position of the adjusting bar and which has oblique faces (E1, E2) on both sides, which during the forward movement press a locking element (R1, R2) previously preventing the rotation of the adjusting crank and standing in engagement with a buffer face (K1, K2) of the adjusting crank, out of the locking position against a restoring force.

- Device according to claim 1 or 2, characterised in that the coupling member (Z), adjustable in its distance from the rotational axis, is a tenon, perpendicular to the longitudinal extension of the lever arm, which engages in a guiding device (F), arranged on the adjusting bar, preferably perpendicular to its direction of movement, and is movable within this.

- Device according to claim 3, characterised in that the tenon is the bearing for a roller.

- Device according to one of claims 1 to 4, characterised in that the adjusting bar (ST) is connected to a clutch in such a way that if the railway points (WE) are passed trailing from the wrong direction (forcing open the points) the adjusting bar is separated from the locking elements.

- Device according to one of claims 2 to 5, characterised in that rollers (R1, R2) are provided as locking elements, which are fixed to levers (H1, H2), held in a resting position in the end positions of the adjusting bar by biased springs, and in cooperation with in each case one buffer face (K1, K2) of the lever arm of the adjusting crank receiving the drive torque prevent its movement, in that the rollers are wide enough to project into the track of the unblocking disc (E) and in that the oblique faces (E1, E2) are provided in the areas of the edge of the unblocking disc which first come into contact with a roller during the rotational movement of the unblocking disc.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19538966A DE19538966A1 (en) | 1995-10-19 | 1995-10-19 | Point machine with adjustable stroke |

| DE19538966 | 1995-10-19 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0769439A1 EP0769439A1 (en) | 1997-04-23 |

| EP0769439B1 EP0769439B1 (en) | 2002-07-03 |

| EP0769439B2 true EP0769439B2 (en) | 2005-08-10 |

Family

ID=7775280

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96440086A Expired - Lifetime EP0769439B2 (en) | 1995-10-19 | 1996-10-14 | Switch drive with adjustable stroke |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0769439B2 (en) |

| AT (1) | ATE220020T1 (en) |

| DE (2) | DE19538966A1 (en) |

| HU (1) | HUP9602869A3 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1459954B1 (en) * | 2003-03-21 | 2006-06-14 | Alcatel | Railway points actuating system |

| FR2905922B1 (en) * | 2006-09-14 | 2008-12-05 | Vossloh Cogifer Sa | MECHANISM FOR MANEUVERING NEEDLES |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE948164C (en) * | 1953-07-03 | 1956-08-30 | Lorenz C Ag | Tongue checking device for electrical point machines |

| DE1055578B (en) * | 1956-08-08 | 1959-04-23 | Standard Elektrik Lorenz Ag | Coupling device on electrical point machines in railway safety systems |

| DE1116713B (en) * | 1957-03-06 | 1961-11-09 | Standard Elektrik Lorenz Ag | Coupling device on electrical point machines in railway safety systems |

| DE1124538B (en) * | 1958-01-27 | 1962-03-01 | Licentia Gmbh | Electromotive point actuator |

| FR1382106A (en) * | 1963-06-27 | 1964-12-18 | Westinghouse Freins & Signaux | Method for controlling heel-capable needles and a motor for implementing said method |

| DE1530403A1 (en) * | 1965-05-18 | 1969-10-02 | Standard Elek K Lorenz Ag | Coupling device on electrical point machines for railway safety systems |

| DE1530404A1 (en) * | 1965-06-14 | 1969-10-02 | Standard Elek K Lorenz Ag | Coupling device on electrical point machines for railway safety systems |

| NL6901277A (en) * | 1969-01-24 | 1970-07-28 | ||

| FR2510059B1 (en) * | 1981-07-23 | 1987-12-04 | Dietrich & Cie De | MECHANISM FOR HANDLING DRAWINGS OF RAILWAYS OF THE "HOLD TYPE" |

| SE506183C2 (en) * | 1993-05-27 | 1997-11-17 | Abb Daimler Benz Transp | Device at railroad tracks for the change of track gear |

-

1995

- 1995-10-19 DE DE19538966A patent/DE19538966A1/en active Pending

-

1996

- 1996-10-14 AT AT96440086T patent/ATE220020T1/en active

- 1996-10-14 EP EP96440086A patent/EP0769439B2/en not_active Expired - Lifetime

- 1996-10-14 DE DE59609398T patent/DE59609398D1/en not_active Expired - Lifetime

- 1996-10-17 HU HU9602869A patent/HUP9602869A3/en unknown

Also Published As

| Publication number | Publication date |

|---|---|

| EP0769439B1 (en) | 2002-07-03 |

| EP0769439A1 (en) | 1997-04-23 |

| DE19538966A1 (en) | 1997-04-24 |

| HUP9602869A2 (en) | 1998-05-28 |

| HUP9602869A3 (en) | 2001-04-28 |

| HU9602869D0 (en) | 1996-12-30 |

| ATE220020T1 (en) | 2002-07-15 |

| DE59609398D1 (en) | 2002-08-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2467548B1 (en) | Guide rail for a sliding wall and method for operating a switch point in a guide rail | |

| DE102020108906A1 (en) | Air flap arrangement with asynchronously movable air flap fields | |

| EP1365177A2 (en) | Selector device for the gearbox of a motor vehicle | |

| EP0191907B1 (en) | Device for partially cutting a paper strip at will | |

| DE69312560T2 (en) | Automatic locking device for the electronic motor drive of doors, shutters, shutters and the like | |

| EP0769439B2 (en) | Switch drive with adjustable stroke | |

| DE19535578B4 (en) | Point machine with inner lock | |

| DE3134515C2 (en) | ||

| DE10226355B3 (en) | actuator | |

| EP1117950A1 (en) | Selector device for a vehicle with an automatic gear system | |

| DE3718513C2 (en) | Turning device for a venetian blind | |

| DE3714705A1 (en) | SWITCHING DEVICE ON A MAGNETIC TAPE DEVICE FOR AUTOREVERSE OPERATION | |

| DE3322292C2 (en) | Safety switch with false locking device | |

| DE19605711A1 (en) | Drive system for medium voltage switch gear | |

| DE19626178C2 (en) | Actuator for actuating an actuator | |

| EP2297015B1 (en) | Driving device for switching mechanical elements | |

| DE69815034T2 (en) | Device and method for obtaining an actuating torque | |

| EP0157011B1 (en) | Lamellar blind closure | |

| DE2025582C3 (en) | Program switches, in particular for washing machines | |

| DE2254192C2 (en) | Switching device of a transmission for differently driving one, possibly several control elements | |

| DE2363714C2 (en) | Cam-controlled, two-stage window adjustment device | |

| DE750335C (en) | Identifier with changeable identifier | |

| DE3234193A1 (en) | Reverse drive of an audio tape apparatus | |

| DE2922319A1 (en) | Shedding mechanism operated by axially-sliding clutch - connecting drive wheel with coaxial eccentric operating lift levers | |

| DE649867C (en) | Contactor box control |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT CH DE ES FR GB IT LI SE |

|

| 17P | Request for examination filed |

Effective date: 19970823 |

|

| RAP3 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ALCATEL |

|

| RAP3 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ALCATEL |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 20010903 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE ES FR GB IT LI SE |

|

| REF | Corresponds to: |

Ref document number: 220020 Country of ref document: AT Date of ref document: 20020715 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20020703 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: CABINET ROLAND NITHARDT CONSEILS EN PROPRIETE INDU |

|

| REF | Corresponds to: |

Ref document number: 59609398 Country of ref document: DE Date of ref document: 20020808 |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20030130 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| 26 | Opposition filed |

Opponent name: SIEMENS AG Effective date: 20030401 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20050810 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT CH DE ES FR GB IT LI SE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AEN Free format text: AUFRECHTERHALTUNG DES PATENTES IN GEAENDERTER FORM |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20021015 |

|

| GBTA | Gb: translation of amended ep patent filed (gb section 77(6)(b)/1977) | ||

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: RPEO |

|

| ET3 | Fr: translation filed ** decision concerning opposition | ||

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20151006 Year of fee payment: 20 Ref country code: CH Payment date: 20151012 Year of fee payment: 20 Ref country code: GB Payment date: 20151014 Year of fee payment: 20 Ref country code: IT Payment date: 20151026 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20151008 Year of fee payment: 20 Ref country code: SE Payment date: 20151013 Year of fee payment: 20 Ref country code: AT Payment date: 20151012 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59609398 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20161013 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 220020 Country of ref document: AT Kind code of ref document: T Effective date: 20161014 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20161013 |