EP0657702B1 - Arrangement for producing two air curtains moving in opposing directions - Google Patents

Arrangement for producing two air curtains moving in opposing directions Download PDFInfo

- Publication number

- EP0657702B1 EP0657702B1 EP94119293A EP94119293A EP0657702B1 EP 0657702 B1 EP0657702 B1 EP 0657702B1 EP 94119293 A EP94119293 A EP 94119293A EP 94119293 A EP94119293 A EP 94119293A EP 0657702 B1 EP0657702 B1 EP 0657702B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- air

- arrangement

- fan

- air inlet

- door

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F9/00—Use of air currents for screening, e.g. air curtains

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24F—AIR-CONDITIONING; AIR-HUMIDIFICATION; VENTILATION; USE OF AIR CURRENTS FOR SCREENING

- F24F9/00—Use of air currents for screening, e.g. air curtains

- F24F2009/007—Use of air currents for screening, e.g. air curtains using more than one jet or band in the air curtain

Definitions

- Air curtains are used when on open doors or gates to prevent outside air from entering the room or an escape of room air to the outside should be prevented.

- An order to such Generating gate air curtains is known from DE-PS 30 50 685 known.

- the Ejector nozzle is used to create an induction air jet generate the with another fan from the air outlet blown air over the entire gate height to be able to transport. This so-called primary air is expelled from the air outlet at a lower pressure and wouldn't go far without the induction air jet enough to reach the ground.

- the known device is used in such a way that its air inlet faces the interior of the room, while the air outlet with the ejector nozzles from above is directed downwards parallel to the door opening. Thereby creates an air roller during operation, whose air flow near the floor from the door opening to the Interior is directed, as is also the case in the essay “Energy saving through the use of air curtain systems” in the magazine “Ki air conditioning cooling heating”, 9/1983 is described.

- the known device works satisfactorily as long as than the pressure inside the room the pressure of the Atmosphere outside the room corresponds. However, as soon as in the room more ventilation facilities effective or there is thermal buoyancy a negative pressure and the air curtain is no longer in able to penetrate outside air through the air curtain to prevent through. Rather, it flows near the bed due to the air flow directed there accordingly the air roller of the air curtain outside air one that creates a cold air lake next to the door.

- This type of airflow also creates a Air roller reaching far into the space to be protected.

- the outside air that is constantly sucked in increases compared to the previously explained variant Energy expenditure for tempering the air curtain.

- the Energy consumption is about twice as large as the first Variant if the same interior temperature and one Temperature difference between inside and outside of approx. 10 up to 20 K is assumed.

- Another embodiment known from practice provides for the use of two air curtains, to improve the shielding effect, the one on the inside of the door and the other on the Outside of the door is attached so that both Gate air curtain air rollers with opposite Generate sense of rotation, the descending air flow occurs between the rollers.

- the energy requirement is about the same like like a simple air roller, which is on the ground is directed outside.

- the blower equipment are arranged so that the rising air flow occurs between the rollers.

- This arrangement works the door air curtain directly adjacent to the door like a single gate air curtain according to the state of the art, i.e. the at high speed expelled air flows directly at the door opening down and gets on the ground towards that Inside the room and shortly thereafter redirected upwards.

- This The arrangement is for pressure equalization between the interior of the room and the outside atmosphere already extraordinary effective.

- the internal air roller flows in the opposite direction, though because of the reverse running air roller the door from the inner air roller no air to the outside can penetrate.

- the outer blower device As a result of the operational independence of the two Blower devices need the outer blower device not to be heated without doing so a deterioration in comfort in the interior is coming. On the contrary, it tracks on the inside air flowing down to a less far inside reaching air roller and thus to a lower Air movement near the screened door opening.

- the heating energy requirement is reduced to around 60% with a gate air curtain with simple Air roller, which is directed inwards on the ground.

- the outer unheated air roller shields the inner heated Air roller and thus prevents heat loss to the outside.

- the Blower devices either spaced apart be, for example, in a kind of windscreen, with between the two air curtain systems a considerable one Distance is, or the blower equipment can be accommodated in a common housing.

- the blower equipment can be accommodated in a common housing.

- shared accommodation in one Housing can also combine the two air intakes into one common air inlet.

- first and second blower devices are next to each other optionally several first and second blower devices arranged.

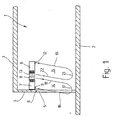

- Fig. 1 shows a in a highly schematic form Room 1 of a building covered by a floor 2, a ceiling 3 and a wall 4 surrounding it on all sides is bounded.

- a wall 4 In the wall 4 is at one point an open door or gate opening 5 from the floor 2 extends to a lintel 6 that extends from the ceiling 3 is spaced.

- 1 is located on the right from the wall 4 the interior of the room, to the left of wall 4 is "outside".

- the first blower device 7 has an air outlet 9, which is next to the lintel 6 is directed down towards the bottom 2.

- the first one points further to the interior of the room Blower device 7 has an air inlet on its underside 11, over which it sucks in air, which then over the aforementioned air outlet 9 is blown out.

- the second blower device 8 has the same structure, but is built in mirror image, i.e. their air outlet 12 is further inside than you Air intake 13.

- blower devices are expediently 7 and 8 designed so that their air inlets 11, 13 or air outlets 9, 12 over the entire width of the door 5 extend. If not for design reasons is possible, there is also the possibility along the Lintel 6 several first blower devices 7 and to provide a plurality of second blower devices 8 next to one another, thus the width of all air outlets 9, 12 and Air inlets 11, 13 together approximately the width of the door 5 corresponds.

- the air roller 15 consists of a blown out of the air outlet 9 onto the floor 2 Airflow 15 that is near the bottom 2 at 17 in Is diverted towards the interior of the room and then as an ascending air flow 18 to the air inlet 11 returned, i.e. the air roller 15 circulates to the illustration in Fig. 1, clockwise while the air roller 14 due to the mirror image Arrangement of the blower device in the counterclockwise direction running.

- Your airflow 19 directed towards the floor 2 is the furthest towards the interior of the room or in other words farthest from door 5 and will at 21 in the direction of the door 5 to then redirected as an upward air flow 22 to the air inlet 13 to get back.

- the second Blower device 8 an air conditioning device contains the flow between the air inlet 13th and the air outlet 12 is arranged, the outside air passes 23 only after temperature and Moisture is set to corresponding values as Air flow 24 the interior of the room. So is also at negative pressure in room 1 through the new arrangement ensures that no outside air immediately without Conditioning reaches the interior of the room.

- the first blower device 7 does not need an air conditioning device, because it is supposed to be the inner air roller shield from the outside. Furthermore, the amount of air per unit of time of the outer air roller less than with the inner one, which is adjacent to the room Air roller.

- 1 and 2 are the two blower devices 7 and 8 arranged directly next to each other. They can also be shared if necessary Housing be housed, the common Air intake between the ends of the case lying air outlets.

- the two blower devices 7 and 8 designed so are that for the outer air roller like that from the first Blower device 7 comes, no heating energy expended unlike the inner air roller. I.e. the two blower devices 7 and 8 are at least with regard to the heating of the air rollers in terms of ventilation essentially independent of each other.

- FIG. 3 shows in addition to the immediately adjacent attachment of the two blower devices 7 and 8 .

- the room contains 1 at a distance from its outer wall 4 with the door opening 5 to Located inside the room is another wall 25 with a own door opening 26, which is on its upper edge by a Lintel 27 is limited.

- the first blower device 7 is, as in the embodiment of FIG. 1, oriented above the lintel 6 towards the interior of the room attached.

- the air outlet 9 is directly the Door opening 5 adjacent.

- the other blower device 8 is at a distance from the first blower device 7 on the wall 25 attached above the lintel 27, on that Side facing the outer wall 4.

- the second blower device 8 on the Partition 25 is attached such that its air outlet 12 creates an air curtain, the door opening 26 immediately is directed adjacent to the floor 2.

- two air rollers 14 and 15 with opposite Sense of rotation, so that the upward air flows directed to the blower devices 7 and 8 18 and 22 of the two air rollers 14 and 15 between these lie.

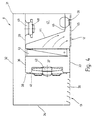

- Fig. 4 shows schematically the structure of the second Blower device 8. It has an all-round closed, rectangular sheet metal housing 31 with a Top 32, a bottom 33 and with a total four side walls 34 parallel to one another in pairs on. In the bottom 33 is next to the left Side wall 34 of the air inlet 13 in the form of a plurality notched longitudinal slots 35 through which the air can penetrate into the interior of the housing 31.

- An inner partition begins next to this air inlet 13 36, a chamber 37 inside the housing 31 departments.

- the partition 36 connects on the one hand to the Floor 33 next to the air inlet 13 and leads at a distance to the top 32 to the right side wall 34.

- the air outlet 12, for example in the form of a Grille cover, is also in the bottom 33 and connects the partitioned chamber 37 to the outside atmosphere. The arrangement is such that the air outlet 12 parallel to the right side wall 34 and runs adjacent to it.

- the partition 36 consists of a on the bottom 33 beginning ascending part 38 which is at a distance from the Top 32 ends and in a horizontal section 39 passes, which leads to the right side wall 34 this is largely airtight. Furthermore these two sections 38 and 39 extend the partition 36 perpendicular to the plane of the drawing between the side walls 34 parallel to the plane of the drawing.

- An intake funnel is located in the partition wall section 38 41, in which a fan 42 is arranged.

- a schematic in the chamber 37 indicated air conditioning device 43 is provided, which in the simplest case is a heat exchanger that the air flows through.

- a further partition 44 is arranged in the chamber 37, starting at the upper partition section 39 thence sloping down towards the right side wall 34 runs and above that in the Air outlet 12 seated grille 45 in a horizontal Section 46 passes over to its free end the right side wall 34 is attached.

- This will in the chamber 37 a further inner chamber 47 in terms of flow divided.

- This further chamber 47 serves as Air duct for generating an induction air jet using a high pressure blower 48 attached to an intake funnel 49 connected in the upper Partition section 39 is formed and into the inner Chamber 47 opens.

- the air from the inner chamber 37 passes through a Ejector nozzle 51, which is designed as a spherical nozzle and thus adjustable in the lower partition section 46 sits.

- blower device The operation of the blower device is like follows:

- air is passed through the air inlet 13 sucked in and under pressure into the chamber 37 promoted.

- the Blower 42 delivers air to the air conditioner 43 and impinges on the partition 44 on which it is deflected downward so that it passes through the grating 45 of the air outlet 12 can flow out.

- Another, air stream entering through the air inlet 13 flows past the blower 42 through the between the top 32 and the upper partition section 39 delimited Channel to the intake funnel 49.

- the high pressure fan 48 which is connected to the suction funnel 49 presses the air drawn in at relatively high pressure and thus a correspondingly high speed over the Ejector nozzle 51 to the outside, which is behind the grille 45 of the Air outlet 12 is arranged.

- the high speed of the induction jet emerging from the ejector 51 also serves as a support beam for stabilization of the air curtain and thus to that from the Air conditioning device 43 coming air with lower Air speed against the effect of the natural Convection to the floor 2 of the room 1 too create.

- Blower device is thus only a part of the intake Air conditioned, while the other part without Conditioning blown out at high speed becomes.

- a second air conditioning device to also provide the air that exits through the ejector nozzle 51 with respect to temperature and / or bring moisture to appropriate values.

- the Blower device 8 Because of the type of representation is shown in the Blower device 8 only one ejector 51 visible. However, it is easy to understand that several according to the width of the blower device 8 such ejector nozzles 51 are arranged side by side can.

- the first blower device 7 can with Except for the air conditioning device 43 as well be constructed like the second blower device 8.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Ventilation (AREA)

- Air Bags (AREA)

- Toys (AREA)

- Duct Arrangements (AREA)

- Particle Accelerators (AREA)

- Curtains And Furnishings For Windows Or Doors (AREA)

- Separation By Low-Temperature Treatments (AREA)

Abstract

Description

Luftschleier werden verwendet, wenn an offenen Türen oder Toren möglichst ein Eindringen von Außenluft in den Raum bzw. ein Entweichen von Raumluft nach außen verhindert werden soll. Eine Anordnung, um einen solchen Torluftschleier zu erzeugen, ist aus der DE-PS 30 50 685 bekannt. In dem Gehäuse befindet sich ein Hochdrucklüfter, dessen Saugseite an einen Lufteinlass und dessen Druckseite an eine Ejektordüse angeschlossen ist. Die Ejektordüse, dient dazu, einen Induktionsluftstrahl zu erzeugen, um die mit einem weiteren Lüfter aus dem Luftauslass ausgeblasene Luft über die gesamte Torhöhe transportieren zu können. Diese sogenannte Primärluft wird mit geringerem Druck aus dem Luftauslass ausgestoßen und würde ohne den Induktionsluftstrahl nicht weit genug bis zum Boden reichen.Air curtains are used when on open doors or gates to prevent outside air from entering the room or an escape of room air to the outside should be prevented. An order to such Generating gate air curtains is known from DE-PS 30 50 685 known. There is a high pressure fan in the housing, its suction side to an air inlet and its Pressure side is connected to an ejector nozzle. The Ejector nozzle is used to create an induction air jet generate the with another fan from the air outlet blown air over the entire gate height to be able to transport. This so-called primary air is expelled from the air outlet at a lower pressure and wouldn't go far without the induction air jet enough to reach the ground.

Außerdem befindet sich in dem Strömungsweg zwischen dem Lufteinlass und dem Luftauslass eine Luftkonditioniereinrichtung, um sowohl die Temperatur als auch gegebenenfalls die Luftfeuchte der ausgeblasenen Luft einstellen zu können.It is also located in the flow path between an air conditioning device for the air inlet and the air outlet, around both the temperature and if necessary, the humidity of the blown air to be able to adjust.

Das bekannte Gerät wird in der Weise eingesetzt, dass sein Lufteinlass dem Rauminneren zugekehrt ist, während der Luftauslass mit den Ejektordüsen von oben nach unten parallel zur Türöffnung gerichtet ist. Dadurch entsteht beim Betrieb eine Luftwalze, deren Luftströmung in der Nähe des Bodens von der Türöffnung zum Rauminneren gerichtet ist, wie dies auch in dem Aufsatz "Energieeinsparung durch Einsatz von Luftschleieranlagen" in der Zeitschrift "Ki Klima-Kälte-Heizung", 9/1983 beschrieben ist.The known device is used in such a way that its air inlet faces the interior of the room, while the air outlet with the ejector nozzles from above is directed downwards parallel to the door opening. Thereby creates an air roller during operation, whose air flow near the floor from the door opening to the Interior is directed, as is also the case in the essay "Energy saving through the use of air curtain systems" in the magazine "Ki air conditioning cooling heating", 9/1983 is described.

Die bekannte Einrichtung arbeitet solange zufriedenstellend, als der Druck im Rauminneren dem Druck der Atmosphäre außerhalb des Raumes entspricht. Sobald jedoch in dem Raum weitere Belüftungseinrichtungen wirksam sind oder thermischer Auftrieb vorhanden ist, entsteht ein Unterdruck und der Luftschleier ist nicht mehr in der Lage, ein Eindringen von Außenluft durch den Luftschleier hindurch zu verhindern. Vielmehr strömt in Bedennähe aufgrund der dort entsprechend gerichteten Luftströmung der Luftwalze des Torluftschleiers Außenluft ein, die neben der Tür einen Kaltluftsee hervorruft. The known device works satisfactorily as long as than the pressure inside the room the pressure of the Atmosphere outside the room corresponds. However, as soon as in the room more ventilation facilities effective or there is thermal buoyancy a negative pressure and the air curtain is no longer in able to penetrate outside air through the air curtain to prevent through. Rather, it flows near the bed due to the air flow directed there accordingly the air roller of the air curtain outside air one that creates a cold air lake next to the door.

Außerdem erzeugt diese Art der Luftführung eine weit in den zu schützenden Raum reichende Luftwalze.This type of airflow also creates a Air roller reaching far into the space to be protected.

Man hat deswegen bereits versucht, wie ebenfalls in dem bereits zitierten Aufsatz "Energieeinsparung durch Einsatz von Luftschleieranlagen" in der Zeitschrift "Ki Klima-Kälte-Heizung", 9/1983 erläutert ist, das bekannte Gerät anders herum zu montieren, so dass die Luftwalze am Boden nicht mehr zum Rauminneren, sondern nach außen gerichtet ist. Diese Anordnung hat bei Druckausgleich zwischen Rauminnerem und Außenatmosphäre aber bereits den Nachteil verhältnismäßig großer Wärmeverluste, weil unterhalb der Türoberkante in den Lufteinlass ständig Außenluft eingesaugt wird, die beim Ausblasen aus dem Torluftschleiergerät zu einer Druckerhöhung im Rauminneren führt, so dass sich im Rauminneren ein Überdruck aufbaut, der den Luftschleier nach außen drückt. Umgekehrt entsteht bei Unterdruck im Rauminneren ein zusätzlicher Abstrom von Außenluft als Zuluft in den Raum selbst.One has therefore already tried, as also in the essay "Energy saving through Use of air curtain systems "in the magazine" Ki Air-conditioning-heating ", 9/1983 is explained, the known Mount device the other way around, so that the air roller on the floor no longer towards the inside of the room, but outside is directed. This arrangement has with pressure equalization between the inside of the room and the outside atmosphere the disadvantage of relatively large heat losses because below the top edge of the door into the air intake constantly Outside air is sucked in, which when blowing out of the Gate air curtain for increasing the pressure inside the room leads, so that there is an overpressure inside the room that pushes the air curtain outwards. Vice versa If there is negative pressure inside, there is an additional one Outflow of outside air as supply air into the room self.

Die ständig unmittelbar eingesaugte Außenluft erhöht im Vergleich zu der zuvor erläuterten Variante den Energieaufwand zur Temperierung des Luftschleiers. Der Energiebedarf ist etwa doppelt so groß wie bei der ersten Variante, wenn gleiche Innenraumtemperatur und eine Temperaturdifferenz zwischen Innen und Außen von ca 10 bis 20 K angenommen wird.The outside air that is constantly sucked in increases compared to the previously explained variant Energy expenditure for tempering the air curtain. The Energy consumption is about twice as large as the first Variant if the same interior temperature and one Temperature difference between inside and outside of approx. 10 up to 20 K is assumed.

Eine weitere aus der Praxis bekannt Ausführungsform sieht die Verwendung von zwei Luftschleiergeräten vor, um die abschirmende Wirkung zu verbessern, wobei das eine an der Innenseite der Tür und das andere an der Außenseite der Tür so angebracht ist, dass beide Torluftschleiergeräte Luftwalzen mit entgegengesetztem Drehsinn erzeugen, wobei die absteigende Luftströmung zwischen den Walzen auftritt. Dies bedeutet, dass das auf der Außenseite befindliche Torluftschleiergerät ständig kalte Außenluft ansaugt und folglich dieses Luftschleiergerät eine große Wärmeleistung erbringen muß, da die abwärtsströmende Luft aus diesem Luftschleiergerät etwa dieselbe Temperatur haben muß wie das mit der Raumluft versorgte Luftschleiergerät. Andernfalls würde bei Unterdruck im Raum die kältere Luft aus dem äußeren Luftschleiergerät als Zugluft in den Raum eingesaugt werden. Diese Zuluftströmung würde unter der Luftwalze des inneren Torluftschleiergerätes am Boden eindringen und wiederum in der Nachbarschaft der Tür einen Kaltluftsee erzeugen.Another embodiment known from practice provides for the use of two air curtains, to improve the shielding effect, the one on the inside of the door and the other on the Outside of the door is attached so that both Gate air curtain air rollers with opposite Generate sense of rotation, the descending air flow occurs between the rollers. This means that Gate air curtain located on the outside constantly sucking in cold outside air and consequently this Air curtain provide a great heat output must, because the downward flowing air from this air curtain must have about the same temperature as that with air curtain supplied to the room air. Otherwise If the room was under vacuum, the colder air would come out of the external air curtain is sucked into the room as drafts become. This supply air flow would be under the air roller of the inner air curtain on the floor and again in the neighborhood of the door Create cold air lake.

Der Energiebedarf ist hierbei etwa genauso groß wie bei einer einfachen Luftwalze, die am Boden nach außen gerichtet ist.The energy requirement is about the same like a simple air roller, which is on the ground is directed outside.

Schließlich ist es aus dem Aufsatz "Kaltluftabriegelung durch Warmluftschleier", in "Sanitäre Technik", Nr. 2/1961 bekannt zwei gegenläufige Luftglocken zu verwenden, wobei die aufwärts gerichtete Strömung zwischen den beiden Luftglocken auftritt. Hierzu wird ein gemeinsames Gebläse sowie eine gemeinsame Heizeinrichtung verwendet, um beide Luftglocken zu erzeugen. Der Energiebedarf zum Heizen der umgewälzten Luft ist deswegen mindestens so groß wie bei der ganz oben als erstes diskutierten Ausführungsform.Finally, it is from the essay "Cold Air Block through warm air curtains ", in" sanitary technology ", No. 2/1961 known two opposing air bells to use, with the upward flow occurs between the two air bells. To do this a common fan and a common heating device used to generate both air bells. The energy required to heat the circulated air is therefore at least as large as the one at the top as first discussed embodiment.

Die in dieser Zeitschrift gezeigt Einrichtung unterscheidet sich funktionsmäßig nicht von der Anordnung nach der EP 0 511 576 A2 oder der Torluftschleieranlage nach der US-A-3 023 688. In beiden Fällen haben beide Luftwalzen dieselbe Lufttemperatur, was zu einem erheblichen Energieverlust führt.The facility shown in this magazine functionally does not differ from the arrangement according to EP 0 511 576 A2 or the air curtain system according to US-A-3 023 688. In both cases both air rollers have the same air temperature, resulting in one leads to significant energy loss.

Ähnlich wie die zuvor erläuterte Kaltluftabriegelung durch Warmluftschleier arbeitet die Einrichtung nach der US-A-3 023 688. Auch bei dieser Einrichtung sind oberhalb des lufttechnisch abzuriegelnden Tores zwei Gebläseeinrichtungen angeordnet, von denen jede für sich einen walzenförmigen Luftschieier erzeugt. Die walzenförmigen Luftschleier haben entgegengesetzten Drehsinn und erzeugen zwischen sich eine nach oben gerichtete Luftströmung. Bei der bekannten Einrichtung sind in beiden Strömungswegen Heizeinrichtungen vorgesehen. Auf diese Weise wird nicht nur der zum Rauminneren gelegene Luftschleier auf Temperatur gehalten sondern auch der außenliegende Luftschleier, was zu einem erheblichen Energiebedarf führt. Da sich diese Anordnung nicht grundsätzlich von der zuvor erläuterten Kaltluftabriegelung durch Warmluftschleier unterscheidet, ist der Energiebedarf entsprechend hoch.Similar to the cold air lock explained earlier the device works through warm air curtains according to US-A-3 023 688. Also with this device are above the airlocked gate two blowers arranged, each for creates a roller-shaped air curtain. The roller-shaped Air curtains have the opposite direction of rotation and create an upward between them Air flow. In the known device are in heaters provided in both flow paths. On this way, not only does it become the interior of the room Air curtain kept at temperature but also the external air curtains, resulting in a significant Energy demand leads. Since this arrangement is not basically from the cold air lock previously explained distinguished by warm air curtains is the energy requirement correspondingly high.

Ausgehend hiervon ist es Aufgabe der Erfindung, eine Anordnung zum Erzeugen eines Tür- oder Torluftschleiers zu schaffen, die auch bei Unterdruck im Rauminneren wirksam ein Eindringen von kalter Außenluft verhindert und einen geringeren Energiebedarf hat.Proceeding from this, it is the object of the invention an arrangement for generating a door or gate air curtain to create that even with negative pressure inside the room effectively prevents cold outside air from entering and has a lower energy requirement.

Diese Aufgabe wird erfindungsgemäß durch die Anordnung mit den Merkmalen des Anspruches 1 gelöst. This object is achieved by the arrangement solved with the features of claim 1.

Infolge der Verwendung der zwei Gebläseeinrichtungen werden zwei Luftwalzen erzeugt, die gegensinnig gerichteten Drehsinn aufweisen. Die Gebläseeinrichtungen sind so angeordnet, dass die aufsteigende Luftströmung zwischen den Walzen auftritt. Bei dieser Anordnung arbeitet das der Tür unmittelbar benachbarte Torluftschleiergerät wie ein einzelnes Torluftschleiergerät nach dem Stand der Technik, d.h. die mit hoher Geschwindigkeit ausgestoßene Luft strömt unmittelbar an der Türöffnung nach unten und wird am Boden in Richtung auf das Rauminnere und kurz danach nach oben umgelenkt. Diese Anordnung ist bei Druckausgleich zwischen Rauminneren und Außenatmosphäre bereits für sich genommen außerordentlich wirkungsvoll. Die innenliegende Luftwalze strömt in der entgegengesetzten Richtung, wobei aber wegen der umgekehrt laufenden Luftwalze unmittelbar an der Tür von der inneren Luftwalze keine Luft nach außen dringen kann.As a result of using the two blower devices two air rollers are generated, the opposite have direction of rotation. The blower equipment are arranged so that the rising air flow occurs between the rollers. This arrangement works the door air curtain directly adjacent to the door like a single gate air curtain according to the state of the art, i.e. the at high speed expelled air flows directly at the door opening down and gets on the ground towards that Inside the room and shortly thereafter redirected upwards. This The arrangement is for pressure equalization between the interior of the room and the outside atmosphere already extraordinary effective. The internal air roller flows in the opposite direction, though because of the reverse running air roller the door from the inner air roller no air to the outside can penetrate.

Zufolge der betriebsmäßigen Unabhängigkeit der beiden Gebläseeinrichtungen braucht die äußere Gebläseeinrichtung nicht beheizt zu werden, ohne dass dadurch eine Verschlechterung des Komforts im Innenraum zustande kommt. Im Gegenteil führt die auf der Innenseite nach unten strömende Luft zu einer weniger weit in den Innenraum reichenden Luftwalze und damit zu einer geringeren Luftbewegung in der Nähe der abgeschirmten Türöffnung. Der Heizenergiebedarf verringert sich auf ca. 60 % verglichen mit einem Torluftschleiergerät mit einfacher Luftwalze, die am Boden nach innen gerichtet ist. Die äußere unbeheizte Luftwalze schirmt die innere beheizte Luftwalze ab und verhindert so Wärmeverluste nach außen. As a result of the operational independence of the two Blower devices need the outer blower device not to be heated without doing so a deterioration in comfort in the interior is coming. On the contrary, it tracks on the inside air flowing down to a less far inside reaching air roller and thus to a lower Air movement near the screened door opening. The heating energy requirement is reduced to around 60% with a gate air curtain with simple Air roller, which is directed inwards on the ground. The outer unheated air roller shields the inner heated Air roller and thus prevents heat loss to the outside.

Im Falle eines Unterdrucks im Raum infolge von dort arbeitenden Entlüftungs- oder Belüftungseinrichtungen erfolgt durch die offene Tür und die Torluftschleier ein ständiger Druckausgleich. Die von außen kommende kalte Luft wird dabei von der äußeren Luftwalze zu den Gebläseeinrichtungen geschafft und teilt sich in einen Anteil auf, der in die äußere Luftwalze eingespeist wird und einen weiteren Anteil, der in die innere Luftwalze gelangt. Da dieser Anteil vor dem Eindringen in das Rauminnere durch die Luftkonditioniereinrichtung der inneren zweiten Gebläseeinrichtung läuft, wird hier die eindringende Außenluft so weit aufgeheizt, dass keine Zugwirkung auftritt.In case of negative pressure in the room as a result of there working ventilation or ventilation equipment takes place through the open door and the air curtains constant pressure equalization. The cold coming from outside Air is thereby from the outer air roller to the Blower devices managed and divided into one Share that is fed into the outer air roller and another portion that goes into the inner air roller reached. Because this portion before entering the Interior of the room by the air conditioning device inner second blower device is running here penetrating outside air heated so far that none Tensile effect occurs.

Je nach räumlichen Verhältnissen können die Gebläseeinrichtungen entweder voneinander beabstandet sein, beispielsweise in einer Art Windfang, wobei zwischen den beiden Torluftschleiereinrichtungen ein erheblicher Abstand ist, oder aber die Gebläseeinrichtungen können in einem gemeinsamen Gehäuse untergebracht werden. Im Falle der gemeinsamen Unterbringung in einem Gehäuse können auch die beiden Lufteinlässe zu einem gemeinsamen Lufteinlass vereinigt sein.Depending on the spatial conditions, the Blower devices either spaced apart be, for example, in a kind of windscreen, with between the two air curtain systems a considerable one Distance is, or the blower equipment can be accommodated in a common housing. In the case of shared accommodation in one Housing can also combine the two air intakes into one common air inlet.

Entsprechend der Breite der Tür sind nebeneinander gegebenenfalls mehrere erste und zweite Gebläseeinrichtungen angeordnet.According to the width of the door are next to each other optionally several first and second blower devices arranged.

In der Zeichnung ist ein Ausführungsbeispiel des

Gegenstandes der Erfindung dargestellt. Es zeigen:

Fig. 1 zeigt in stark schematisierter Form einen

Raum 1 eines Gebäudes, der von einem Boden 2, einer Decke

3 sowie einer ihn allseitig umschließenden Wand 4

umgrenzt ist. In der Wand 4 befindet sich an einer Stelle

eine offene Tür- oder Toröffnung 5, die von dem Boden

2 bis zu einem Türsturz 6 reicht, der von der Decke 3

beabstandet ist. Bezogen auf Fig. 1 befindet sich rechts

von der Wand 4 das Rauminnere, während links der Wand 4

"außen" ist.Fig. 1 shows a in a highly schematic form

Room 1 of a building covered by a

Oberhalb des Torsturzes 6 sind eine erste und eine

zweite Gebläseeinrichtung 7, 8 nebeneinander auf gleicher

Höhe angebracht. Die erste Gebläseeinrichtung 7

weist einen Luftauslass 9 auf, der neben dem Türsturz 6

nach unten in Richtung auf den Boden 2 gerichtet ist.

Weiter zum Rauminneren hin gelegen weist die erste

Gebläseeinrichtung 7 an ihrer Unterseite einen Lufteinlass

11 auf, über den sie Luft einsaugt, die sodann über

den vorerwähnten Luftauslass 9 ausgeblasen wird.Above the

Die zweite Gebläseeinrichtung 8 hat denselben Aufbau,

ist jedoch spiegelbildlich angebaut, d.h. ihr Luftauslass

12 befindet sich weiter im Rauminneren als ihr

Lufteinlass 13.The

Zweckmäßigerweise sind beide Gebläseeinrichtungen 7

und 8 so gestaltet, dass sich ihre Lufteinlässe 11, 13

bzw. Luftauslässe 9, 12 über die gesamte Breite der Tür

5 erstrecken. Falls dies aus konstruktiven Gründen nicht

möglich ist, besteht auch die Möglichkeit, längs des

Türsturzes 6 mehrere erste Gebläseeinrichtungen 7 sowie

mehrere zweite Gebläseeinrichtungen 8 nebeneinander vorzusehen,

damit die Breite aller Luftauslässe 9, 12 und

Lufteinlässe 11, 13 zusammen etwa der Breite der Tür 5

entspricht.Both blower devices are expediently 7

and 8 designed so that their

Wenn die Gebläseeinrichtungen 7, 8 in Gang gesetzt

werden, erzeugen sie zwei nebeneinander liegende

Luftwalzen 14 und 15. Die Luftwalze 15 besteht aus einem

aus dem Luftauslass 9 auf den Boden 2 ausgeblasenen

Luftstrom 15, der in der Nähe des Bodens 2 bei 17 in

Richtung auf das Rauminnere umgelenkt wird und sodann

als aufsteigender Luftstrom 18 zu dem Lufteinlass 11

zurückgelangt, d.h. die Luftwalze 15 zirkuliert, bezogen

auf die Darstellung in Fig. 1, im Uhrzeigersinne, während

die Luftwalze 14 aufgrund der spiegelbildlichen

Anordnung der Gebläseeinrichtung im Gegenuhrzeigersinne

läuft. Ihre zum Boden 2 hin gerichtete Luftströmung 19

liegt am weitesten zum Rauminneren hin oder anders ausgedrückt,

am weitesten von der Tür 5 entfernt und wird

bei 21 in Richtung auf die Tür 5 zu umgelenkt, um sodann

als aufwärts gerichtete Luftströmung 22 zu dem Lufteinlass

13 zurückzugelangen.When the

Bei Druckausgleich zwischen dem Rauminneren und

außen verhindert die Luftwalze 14 an der Tür 5 einen

Luftaustausch zwischen außen und innen. Die Luftwalze 15

dagegen begrenzt die Ausdehnung der Luftwalze 14 zum

Rauminneren hin, weil der absteigende Luftstrom 19 mit

der höheren Geschwindigkeit und damit der größeren Richtungsstabilität

in jedem Falle die Größe der Luftwalze

14 zum Rauminneren beschränkt. Damit ergeben sich bereits

in kürzer Entfernung von der Tür 5 praktisch zugluftfreie

Raumklimabedingungen oder, mit anderen Worten,

die Raumluft ist in geringem Abstand von dieser eine

Torluftschleieranlage bildenden Anordnung aus den beiden

Gebläseeinrichtungen 7 und 8 beruhigt bzw. strömungsarm.With pressure equalization between the interior of the room and

outside the

Falls in dem Raum 1 eine zusätzliche Entlüftungseinrichtung

vorgesehen ist, entsteht in dem Raum 1 gegenüber

außen ein Unterdruck, der bestrebt ist, Außenluft

in den Raum 1 einzusaugen. Damit entsteht eine

Luftströmung, wie sie in Fig. 2 schematisch veranschaulicht

ist. Wegen des Unterdrucks gelangt ein von außen

kommender Luftstrom 23 zwischen der Luftwalze 14 und dem

Boden 2 durch die Türöffnung 5 hindurch. Dieser Luftstrom

23 wird durch die Rotationsrichtung der Luftwalze

14 begünstigt. Da aber die Luftwalze 15 im Uhrzeigersinne

und damit entgegen der Rotationsrichtung der Luftwalze

14 läuft, verhindert die am Boden 2 herrschende

Luftströmung 21 mit ihrer auf die Tür 5 gerichteten Komponente,

dass der Luftstrom 23 weiter ungehindert in den

Raum 1 eindringen kann. Statt dessen wird der Luftstrom

23 zwischen den beiden Luftwalzen 14 und 15 eingefangen

und nach oben zu den beiden Gebläseeinrichtungen 7 und 8

geschafft. Je nach Druckverhältnissen wird dieser von

außen kommende Luftstrom 23 nun überwiegend in die zweite

Gebläseeinrichtung 8 eingesaugt und kann dadurch nur

nach Passieren der Gebläseeinrichtung 8 über den Luftauslass

12 in das Rauminnere vordringen, wie dies durch

Pfeile 24 angedeutet ist.If in room 1 an additional ventilation device

is provided, arises in room 1 opposite

outside a negative pressure that is striving for outside air

suck into room 1. This creates one

Air flow, as illustrated schematically in Fig. 2

is. Because of the negative pressure one gets from the

Da, wie weiter unten noch erläutert wird, die zweite

Gebläseeinrichtung 8 eine Luftkonditioniereinrichtung

enthält, die strömungsmäßig zwischen dem Lufteinlass 13

und dem Luftauslass 12 angeordnet ist, gelangt die Außenluft

23 erst, nachdem sie hinsichtlich Temperatur und

Feuchte auf entsprechende Werte eingestellt ist, als

Luftströmung 24 das Innere des Raumes. Somit ist auch

bei Unterdruck in dem Raum 1 durch die neue Anordnung

sichergestellt, dass keine Außenluft unmittelbar ohne

Konditionierung das Rauminnere erreicht.There, as will be explained below, the

Die erste Gebläseeinrichtung 7 braucht keine Luftkonditioniereinrichtung, denn sie soll die innere Luftwalze nach außen hin abschirmen. Ferner kann die Luftmenge pro Zeiteinheit der äußeren Luftwalze geringer sein als bei der inneren also dem Raum benachbarten Luftwalze.The first blower device 7 does not need an air conditioning device, because it is supposed to be the inner air roller shield from the outside. Furthermore, the amount of air per unit of time of the outer air roller less than with the inner one, which is adjacent to the room Air roller.

Gemäß den Fig. 1 und 2 sind die beiden Gebläseeinrichtungen

7 und 8 unmittelbar nebeneinander angeordnet.

Sie können gegebenenfalls auch in einem gemeinsamen

Gehäuse untergebracht sein, wobei sich dann der gemeinsame

Lufteinlass zwischen den an den Enden des Gehäuses

liegenden Luftauslässen befindet.1 and 2 are the two

Wesentlich ist bei der neuen Ausführungsform, dass

die beiden Gebläseeinrichtungen 7 und 8 so gestaltet

sind, dass für die äußere Luftwalze wie sie von der ersten

Gebläseeinrichtung 7 kommt, keinen Heizenergie aufgewendet

wird, im Gegensatz zu der inneren Luftwalze.

D.h. die beiden Gebläseeinrichtungen 7 und 8 sind zumindest

hinsichtlich der Beheizung der Luftwalzen lufttechnisch

im wesentlichen voneinander unabhängig.It is essential in the new embodiment that

the two

Neben der unmittelbar benachbarten Anbringung der

beiden Gebläseeinrichtungen 7 und 8 ist auch eine räumlich

beabstandete Anbringung möglich, wie dies Fig. 3

zeigt. Bei dieser Anordnung enthält der Raum 1 im Abstand

von seiner Außenwand 4 mit der Türöffnung 5 zum

Rauminneren hin gelegen eine weitere Wand 25 mit einer

eigenen Türöffnung 26, die an ihrer Oberkante durch einen

Türsturz 27 begrenzt ist. Die erste Gebläseeinrichtung

7 ist, wie bei dem Ausführungsbeispiel nach Fig. 1,

oberhalb des Türsturzes 6 zum Rauminneren hin orientiert

befestigt. Der Luftauslass 9 ist dabei unmittelbar der

Türöffnung 5 benachbart.In addition to the immediately adjacent attachment of the

two

Die andere Gebläseeinrichtung 8 dagegen ist im Abstand

von der ersten Gebläseeinrichtung 7 an der Wand 25

oberhalb des Türsturzes 27 angebracht, und zwar auf jener

Seite, die der Außenwand 4 zugekehrt ist. Das eigentliche

Rauminnere, das gemäß Fig. 3 rechts von der

Trennwand 25 liegt, enthält somit keine Gebläseeinrichtungen

mehr. Die zweite Gebläseeinrichtung 8 an der

Trennwand 25 ist derart befestigt, dass ihr Luftauslass

12 einen Luftschleier erzeugt, der Türöffnung 26 unmittelbar

benachbart zum Boden 2 gerichtet ist. Hierdurch

entstehen wiederum zwei Luftwalzen 14 und 15 mit entgegengesetztem

Drehsinn, und zwar so, dass die aufwärts

zu den Gebläseeinrichtungen 7 und 8 gerichteten Luftströme

18 und 22 der beiden Luftwalzen 14 und 15 zwischen

diesen liegen.The

Die Wirkungsweise dieser Anordnung gemäß Fig.3 ist dieselbe, wie dies im Zusammenhang mit den Fig. 1 und 2 beschrieben ist.The operation of this arrangement according to Figure 3 is the same as this in connection with FIGS. 1 and 2 is described.

Fig. 4 zeigt schematisiert den Aufbau der zweiten

Gebläseeinrichtung 8. Sie weist ein allseitig

geschlossenes, quaderförmiges Blechgehäuse 31 mit einer

Oberseite 32, einer Unterseite 33 sowie mit insgesamt

vier paarweise zueinander parallelen Seitenwänden 34

auf. In der Unterseite 33 befindet sich neben der linken

Seitenwand 34 der Lufteinlass 13 in Gestalt einer Vielzahl

ausgeklinkter Längsschlitze 35, durch die hindurch

die Luft in das Innere des Gehäuses 31 eindringen kann.

Neben diesem Lufteinlass 13 beginnt eine innere Trennwand

36, die innerhalb des Gehäuses 31 eine Kammer 37

abteilt. Die Trennwand 36 schließt einerseits an den

Boden 33 neben dem Lufteinlass 13 an und führt im Abstand

zu der Oberseite 32 bis zu der rechten Seitenwand

34. Der Luftauslass 12, beispielsweise in Gestalt einer

Gitterblende, befindet sich ebenfalls in der Unterseite

33 und verbindet die abgeteilte Kammer 37 mit der Außenatmosphäre.

Die Anordnung ist dabei so getroffen, dass

der Luftauslass 12 parallel zu der rechten Seitenwand 34

und an dieser angrenzend verläuft.Fig. 4 shows schematically the structure of the

Die Trennwand 36 besteht aus einem an dem Boden 33

beginnenden aufsteigenden Teil 38, der im Abstand zu der

Oberseite 32 endet und in einen horizontalen Abschnitt

39 übergeht, der zu der rechten Seitenwand 34 führt, an

dieser weitgehend luftdicht angeschlossen ist. Im übrigen

erstrecken sich diese beiden Abschnitte 38 und 39

der Trennwand 36 senkrecht zu der Zeichenebene zwischen

den zu der Zeichenebene parallelen Seitenwänden 34.The

In dem Trennwandabschnitt 38 sitzt ein Ansaugtrichter

41, in dem ein Gebläse 42 angeordnet ist. Im Abstand

zu dem Gebläse 42 ist in der Kammer 37 eine schematisch

angedeutete Luftkonditioniereinrichtung 43 vorgesehen,

die im einfachsten Falle ein Wärmetauscher ist, durch

den die Luft hindurchströmt.An intake funnel is located in the

Neben dem abluftseitigen Ende der Luftkonditioniereinrichtung

43, die sich über die gesamte Tiefe der Kammer

37, d.h. senkrecht zu der Zeichenebene erstreckt,

ist in der Kammer 37 eine weitere Trennwand 44 angeordnet,

die an dem oberen Trennwandabschnitt 39 beginnt,

von dort ausgehend nach unten schräg in Richtung auf die

rechte Seitenwand 34 verläuft und oberhalb des in dem

Luftauslass 12 sitzenden Gitters 45 in einen horizontalen

Abschnitt 46 übergeht, der an seinem freien Ende an

der rechten Seitenwand 34 befestigt ist. Hierdurch wird

in der Kammer 37 eine weitere innere Kammer 47 strömungsmäßig

abgeteilt. Diese weitere Kammer 47 dient als

Luftführung zum Erzeugen eines Induktionsluftstrahles

mit Hilfe eines Hochdruckgebläses 48, das an einen Ansaugtrichter

49 angeschlossen ist, der in dem oberen

Trennwandabschnitt 39 ausgebildet ist und in die innere

Kammer 47 mündet.Next to the exhaust air end of the

Die Luft aus der inneren Kammer 37 tritt über eine

Ejektordüse 51 aus, die als Kugeldüse ausgebildet ist

und somit verstellbar in dem unteren Trennwandabschnitt

46 sitzt.The air from the

Die Betriebsweise der Gebläseeinrichtung ist wie folgt:The operation of the blower device is like follows:

Mit Hilfe des Gebläses 42 wird Luft über den Lufteinlass

13 angesaugt und unter Druck in die Kammer 37

befördert. In der Kammer 37 durchströmt die von dem

Gebläse 42 geförderte Luft die Luftkonditioniereinrichtung

43 und prallt auf die Trennwand 44 auf, an der sie

nach unten abgelenkt wird, damit sie durch das Gitter 45

des Luftauslasses 12 ausströmen kann. Ein weiterer,

durch den Lufteinlass 13 eintretender Luftstrom strömt

an dem Gebläse 42 vorbei durch den zwischen der Oberseite

32 und den oberen Trennwandabschnitt 39 begrenzten

Kanal zu dem Ansaugtrichter 49. Der Hochdrucklüfter 48,

der an den Ansaugtrichter 49 angeschlossen ist, presst

die angesaugte Luft mit verhältnismäßig hohem Druck und

damit einer entsprechend hohen Geschwindigkeit über die

Ejektordüse 51 nach außen, die hinter dem Gitter 45 des

Luftauslasses 12 angeordnet ist. Die hohe Geschwindigkeit

des aus der Ejektordüse 51 austretenden Induktionsstrahles

dient gleichzeitig als Stützstrahl zum Stabilisieren

des Luftschleiers und damit dazu, die aus der

Luftkonditioniereinrichtung 43 kommende Luft mit niedriger

Luftgeschwindigkeit gegen die Wirkung der natürlichen

Konvektion bis zu dem Boden 2 des Raumes 1 zu

schaffen.With the aid of the

Bei der gezeigten Ausführungsform der

Gebläseeinrichtung wird somit nur ein Teil der angesaugten

Luft konditioniert, während der andere Teil ohne

Konditionierung mit hoher Geschwindigkeit ausgeblasen

wird. Es ist jedoch auch möglich, eine zweite Luftkonditioniereinrichtung

vorzusehen, um auch die Luft, die

über die Ejektordüse 51 austritt, hinsichtlich Temperatur

und/oder Feuchte auf entsprechende Werte zu bringen.In the embodiment shown

Blower device is thus only a part of the intake

Air conditioned, while the other part without

Conditioning blown out at high speed

becomes. However, it is also possible to use a second air conditioning device

to also provide the air that

exits through the

Wegen der Darstellungsart ist bei der gezeigten

Gebläseeinrichtung 8 lediglich eine Ejektordüse 51

sichtbar. Es ist jedoch ohne weiteres verständlich, dass

entsprechend der Breite der Gebläseeinrichtung 8 mehrere

derartige Ejektordüsen 51 nebeneinander angeordnet werden

können. Die erste Gebläseeinrichtung 7 kann mit

Ausnahme der Luftkonditioniereinrichtung 43 genauso

aufgebaut sein wie die zweite Gebläseeinrichtung 8. Because of the type of representation is shown in the

Die in den Fig. 1 bis 3 gezeigte Ausbildung der

gegensinnigen Luftschleier läßt sich nicht nur mit der

Torluftschleiereinrichtung nach Fig. 4 erzielen, bei der

ein zusätzlicher Induktionsluftstrahl eingesetzt wird.

Alternativ ist es auch möglich, diese Luftwalzen 14 und

15 mit Luftschleiereinrichtungen zu erzeugen, denen der

Hochdruckteil und folglich der Induktionsluftstrahl fehlen.

Es reicht aus, lediglich die Primärluft zu verwenden,

die mit Hilfe des Gebläses 42 erzeugt wird und aus

dem Luftauslass 12 austritt.The training shown in Figs. 1 to 3

opposing air curtains can not only with the

4 achieve air curtain device according to FIG

an additional induction air jet is used.

Alternatively, it is also possible to use these

Claims (13)

- Arrangement for producing an air curtain on a door or a doorway (5, 26) of a room (1),characterised in that only the second fan arrangement (8) has an air conditioning arrangement (43) which is disposed between its air inlet (13) and its air outlet (12) in terms of the flow and with the aid of which the air flowing from the air inlet (13) to the air outlet (12) can be adjusted with regard to the temperature and/or humidity values.with a first fan arrangement (7) which is disposed above the door or the doorway (5, 26),has at least one air outlet (9) adjacent to the door or the doorway (5, 26),has at least one air inlet (11) positioned nearer to the interior of the room relative to the air outlet (9), andfrom the air outlet (9) of which an air stream (16) emerges which is directed downwards from above, is deflected upwards from the floor (2) to the fan arrangement (7) and at least part of it is drawn into the air inlet (11) in such a way that a first air roll (14) is produced of which the upwardly streaming part (18) is remote from the door or the doorway (5, 26),with a second fan arrangement (8) which has at least one air outlet (12) directed towards the floor (2) and at least one air inlet (13),and which lies further into the interior of the room relative to the first fan arrangement (7), andis oriented in such a way that its air inlet (13) is adjacent to the air inlet (11) of the first fan arrangement (7) in order to produce an air roll (15) which has a direction of rotation opposite to that of the first air roll (14), the rising air flow (18, 22) occurring between the air rolls (14, 15),

- Arrangement as claimed in Claim 1, characterised in that both fan arrangements (7, 8) are accommodated in their own housings (31) which are separate from one another.

- Arrangement as claimed in Claim 1, characterised in that the first and the second fan arrangement (7, 8) are spaced from one another.

- Arrangement as claimed in Claim 1, characterised in that both fan arrangements (7, 8) are accommodated in a common housing.

- Arrangement as claimed in Claim 1, characterised in that the air inlet (11) of the first fan arrangement (7) and the air inlet (13) of the second fan arrangement (8) are combined into one common air inlet.

- Arrangement as claimed in Claim 1, characterised in that a plurality of first and second fan arrangements (7, 8) are disposed adjacent to one another along the width of the door or the doorway (5, 26).

- Arrangement as claimed in Claim 1, characterised in that the first and the second fan arrangement (7, 8) are optionally of identical construction up to an air conditioning arrangement (43).

- Arrangement as claimed in Claim 1, characterised in that the first and/or the second fan arrangement (7, 8) comprises a secondary air fan (48) for producing an induction air jet as well as a primary air fan (42) which produces an air stream with a large volume and a slower speed than the secondary air fan (49).

- Arrangement as claimed in Claim 8, characterised in that the secondary air fan (49) has at least one ejector nozzle (51) which belongs to the air outlet (9, 12).

- Arrangement as claimed in Claim 1, characterised in that the first and/or the second fan arrangement (7, 8) contains its own fan, these fans being optionally adjustable independently of one another.

- Arrangement as claimed in Claim 1, characterised in that the first and/or the second fan arrangement (7, 8) contains its own air guide arrangements which are substantially independent of one another.

- Arrangement as claimed in Claim 1, characterised in that the first and the second fan arrangement (7, 8) are substantially independent of one another in aerodynamic terms.

- Arrangement as claimed in Claim 1, characterised in that the air conditioning arrangement (43) is merely a heating arrangement.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4341784 | 1993-12-08 | ||

| DE4341784A DE4341784C2 (en) | 1993-12-08 | 1993-12-08 | Arrangement for generating two opposing air curtains |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0657702A2 EP0657702A2 (en) | 1995-06-14 |

| EP0657702A3 EP0657702A3 (en) | 1997-02-05 |

| EP0657702B1 true EP0657702B1 (en) | 2000-04-12 |

Family

ID=6504448

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP94119293A Expired - Lifetime EP0657702B1 (en) | 1993-12-08 | 1994-12-07 | Arrangement for producing two air curtains moving in opposing directions |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0657702B1 (en) |

| AT (1) | ATE191783T1 (en) |

| DE (2) | DE4341784C2 (en) |

| DK (1) | DK0657702T3 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102010061007A1 (en) | 2010-04-29 | 2011-11-03 | Teddington Luftschleieranlagen Gmbh | Arrangement for separating entrance regions of building, has air blast generating devices arranged closer to inner and outer doors, where inner door lies opposite to each other at exhaust region of one of air blast generating devices |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19932708A1 (en) * | 1999-07-16 | 2001-01-25 | Lks Luft Und Klimaservice Chri | Arrangement for generating air curtain on door to low temperature room has air inlet to fan in low temperature room, outlet nozzle arranged along boundary of door in low temperature room |

| DE10029543B4 (en) * | 2000-06-15 | 2006-02-09 | Christiani Gmbh | Air curtain |

| DE20200246U1 (en) | 2002-01-09 | 2002-04-18 | LKS Israel GmbH Klimatechnisches Engineering, 09125 Chemnitz | Arrangement for creating an air bulkhead |

| DE10313108A1 (en) * | 2003-03-24 | 2004-10-07 | Lwt Luftwandtechnologie Gmbh | Air wall device for separating of two areas lying on both sides of door opening has first and second air outlet through which first and second compressed airflow as air wall emerges at angle of 0 to 60 degrees to plane of door opening |

| DE10320490A1 (en) * | 2003-03-25 | 2004-10-14 | Kampmann Gmbh | Device for generating an air curtain |

| DE102010007295A1 (en) | 2010-02-08 | 2011-08-11 | Novoferm tormatic GmbH, 44309 | Drive control unit for sectional door, has auxiliary device controlling opening time and/or opening width of closure based on temperature, weather or aperture height of closure and including non-volatile memories storing different programs |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3023688A (en) * | 1958-05-16 | 1962-03-06 | Jr Fred A Kramer | Air barrier |

| DE3050685C2 (en) * | 1980-02-05 | 1985-10-17 | TTL Tür + Torschleier lufttechnische Geräte GmbH, 7065 Winterbach | Device for generating an air curtain |

| DE3004073A1 (en) * | 1980-02-05 | 1981-08-13 | TTL Tür + Torschleier lufttechnische Geräte GmbH, 7065 Winterbach | Ventilation equipment for room - has high-pressure fan supplying room air to secondary air ejector nozzles |

| DE9010016U1 (en) * | 1990-07-02 | 1990-09-06 | Teddington Controls GmbH, 5202 Hennef | Device for generating an air curtain |

| JPH04327736A (en) * | 1991-04-30 | 1992-11-17 | Mitsubishi Heavy Ind Ltd | Fluid suction nozzle and fluid treatment device |

-

1993

- 1993-12-08 DE DE4341784A patent/DE4341784C2/en not_active Expired - Fee Related

-

1994

- 1994-12-07 DK DK94119293T patent/DK0657702T3/en active

- 1994-12-07 DE DE59409287T patent/DE59409287D1/en not_active Expired - Fee Related

- 1994-12-07 AT AT94119293T patent/ATE191783T1/en not_active IP Right Cessation

- 1994-12-07 EP EP94119293A patent/EP0657702B1/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102010061007A1 (en) | 2010-04-29 | 2011-11-03 | Teddington Luftschleieranlagen Gmbh | Arrangement for separating entrance regions of building, has air blast generating devices arranged closer to inner and outer doors, where inner door lies opposite to each other at exhaust region of one of air blast generating devices |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE191783T1 (en) | 2000-04-15 |

| DE4341784C2 (en) | 1995-09-07 |

| DK0657702T3 (en) | 2000-07-31 |

| EP0657702A3 (en) | 1997-02-05 |

| DE59409287D1 (en) | 2000-05-18 |

| DE4341784A1 (en) | 1995-06-14 |

| EP0657702A2 (en) | 1995-06-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1130331B1 (en) | Method and device for the ventilation and the temperature controlling of a room | |

| EP0657702B1 (en) | Arrangement for producing two air curtains moving in opposing directions | |

| DE69912031T2 (en) | Device for ventilating, cooling and / or heating a room | |

| DE1270771B (en) | Air barrier formed from two air curtains | |

| DE69912030T2 (en) | Air cooling arrangement of a room | |

| DE2033195C3 (en) | Air outlet device for air conditioning systems | |

| DE19525945C2 (en) | Method and device for generating comfortable indoor air conditions | |

| DE2328186A1 (en) | EQUIPMENT FOR COOLING AND / OR WARMING ROOMS | |

| DE19758139C2 (en) | Method and device for air conditioning a room | |

| DE20011500U1 (en) | Ventilation equipment, especially for air conditioning large halls | |

| DE69213259T2 (en) | AIR EXCHANGE SYSTEM FOR A VARIETY BUILDING | |

| EP1035385B1 (en) | Method for temperature control of a hall and device for curring out this method | |

| EP1996870A1 (en) | Floor convector | |

| DE102008046361A1 (en) | Decentralized ventilation device and ventilation system with such a device | |

| DE3914242A1 (en) | Room heater and cooler - comprises blower with heat exchanger along with air inlets and outlets with air blown in through adjustable flaps by semi axial rotor | |

| AT408482B (en) | DEVICE FOR PREVENTING THE MIXING OF TWO AIR FLOWS | |

| DE3523937A1 (en) | Door air-curtain installation | |

| EP3837475B1 (en) | Pressure shielding system, differential pressure device and building | |

| DE3025342A1 (en) | Air conditioning system for factory halls - has main and auxiliary air outlets in vertical arrangement, some discharging horizontally and some obliquely | |

| DE4016078C1 (en) | ||

| DE3050685C2 (en) | Device for generating an air curtain | |

| DE20022731U1 (en) | Ventilation equipment, especially for air conditioning large halls | |

| DE2627727B2 (en) | Window with two frames arranged one behind the other at a distance | |

| DE20102312U1 (en) | Ventilation equipment | |

| DE2600478A1 (en) | Room air curtain control - using position, direction and section of discharge or intake apertures which adjusts to ambient conditions and certain length |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK FR GB LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK FR GB LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19970125 |

|

| 17Q | First examination report despatched |

Effective date: 19980806 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK FR GB LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 191783 Country of ref document: AT Date of ref document: 20000415 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: KIRKER & CIE SA Ref country code: CH Ref legal event code: EP |

|

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 59409287 Country of ref document: DE Date of ref document: 20000518 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20000519 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20001123 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20001127 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20001201 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20001204 Year of fee payment: 7 Ref country code: SE Payment date: 20001204 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20001205 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20001207 Year of fee payment: 7 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011207 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011207 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011207 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011208 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011231 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| BERE | Be: lapsed |

Owner name: TUR + TORLUFTSCHLEIER LUFTTECHNISCHE GERATE G.M.B. Effective date: 20011231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020701 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 94119293.2 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20011207 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020830 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20020701 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20081223 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20081216 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20081230 Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091207 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091231 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100701 |