EP0589907B1 - Zupfkopf für epiliergeräte - Google Patents

Zupfkopf für epiliergeräte Download PDFInfo

- Publication number

- EP0589907B1 EP0589907B1 EP92910145A EP92910145A EP0589907B1 EP 0589907 B1 EP0589907 B1 EP 0589907B1 EP 92910145 A EP92910145 A EP 92910145A EP 92910145 A EP92910145 A EP 92910145A EP 0589907 B1 EP0589907 B1 EP 0589907B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- plucking

- cam

- tube

- pawls

- ratchet wheel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000035617 depilation Effects 0.000 title 1

- 208000002271 trichotillomania Diseases 0.000 title 1

- 230000007246 mechanism Effects 0.000 claims abstract description 13

- 230000009471 action Effects 0.000 claims description 4

- 230000007704 transition Effects 0.000 description 5

- 238000009412 basement excavation Methods 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 230000007480 spreading Effects 0.000 description 3

- 238000003892 spreading Methods 0.000 description 3

- 230000008901 benefit Effects 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 241001136792 Alle Species 0.000 description 1

- 206010034016 Paronychia Diseases 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000011078 in-house production Methods 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45D—HAIRDRESSING OR SHAVING EQUIPMENT; EQUIPMENT FOR COSMETICS OR COSMETIC TREATMENTS, e.g. FOR MANICURING OR PEDICURING

- A45D26/00—Hair-singeing apparatus; Apparatus for removing superfluous hair, e.g. tweezers

- A45D26/0023—Hair-singeing apparatus; Apparatus for removing superfluous hair, e.g. tweezers with rotating clamping elements

-

- A—HUMAN NECESSITIES

- A45—HAND OR TRAVELLING ARTICLES

- A45D—HAIRDRESSING OR SHAVING EQUIPMENT; EQUIPMENT FOR COSMETICS OR COSMETIC TREATMENTS, e.g. FOR MANICURING OR PEDICURING

- A45D26/00—Hair-singeing apparatus; Apparatus for removing superfluous hair, e.g. tweezers

- A45D2026/008—Details of apparatus for removing superfluous hair

- A45D2026/0085—Details of apparatus for removing superfluous hair with means for reducing noise

Definitions

- the invention relates to a plucking head for epilators with a rotatably mounted in the device housing, partially enclosed by this, provided with clamping jaws, motor-driven plucking pipe and a coaxially aligned, rotatably arranged cam that is operatively connected to the clamping jaws.

- the object of the invention is to design the plucking head for an epilator of the type mentioned at the outset in such a way that the energy expenditure for generating the clamping force is reduced.

- the solution according to the invention eliminates the special gear arrangement for driving the camshaft, which in the Epilator according to the cited prior art is provided in addition to the gear for driving the plucking tube.

- the energy requirement which plays an important role in particular in battery-operated, small electrical devices, is significantly reduced by the fact that the clamping force does not have to be applied by the drive during the entire rotation period but only by the drive in the stepping phase.

- the technically relatively complex, flying bearing of the camshaft with all its other disadvantages in terms of construction costs and the space required in the housing of the epilator, is eliminated.

- Step switch mechanisms can be designed in different ways.

- the step-by-step mechanism is designed as a ratchet step-by-step mechanism consisting of a ratchet wheel and at least two pivotal ratchet pawls that cooperate with it and are spring-loaded into the engagement position with the ratchet wheel.

- a major advantage of this measure according to the invention is that by means of such a pawl stepping mechanism the cam adjustment takes place in the load-free state of the cam, as a result of which less drive energy is required or consumed to operate the plucking head and the wear on interacting parts is considerably reduced.

- such a step-by-step mechanism is not very complex in construction, requires little space and can therefore be easily accommodated in the drive path from the motor to the cam.

- a preferred embodiment of the invention provides that the plucking head has a system axis fixed coaxially to its geometric axis in the device housing, on which the cam is rotatably mounted and the ratchet wheel is fastened adjacent thereto, and that the pawls are pivotably mounted on the foot part of the cam body.

- This staggered arrangement of the cam and ratchet wheel on the system axis advantageously contributes to further reducing the dimensions of the plucking head.

- an inner curve is provided and the pawls are each provided with a back profile which projects into the path of the inner curve rotating with the plucking tube.

- the pawls are lifted out of engagement with the ratchet wheel with each rotation of the plucking tube and are adjusted by entrainment together with the cam by an angle of rotation determined by the pitch of the ratchet wheel.

- This measure also contributes significantly to the reduction of the manufacturing costs as an advantage of the invention, furthermore the possibility of in-house production of all parts with the usual manufacturing and assembly work in large series with low overall costs, which ensures high functional reliability, reliability and predictability of the manual adjustment and that a minimal additional energy requirement for driving the plucking head.

- the epilator shown in Fig. 1 consists essentially of a housing 1 designed as a handle for guiding the device, from whose upper ends the crown 2 of the plucking head 3 protrudes, which is thus partially enclosed by the housing 1.

- a motor 4 is also accommodated in the manner described below (FIG. 2), which can be a spring mechanism or an electric motor fed by primary secondary cells or directly from the mains, as by the cable 5 led out at the opposite end of the housing 1 is indicated.

- a switch 6 is used to switch the epilator on and off.

- a mounting plate 7 is fastened in the housing 1, which on the one hand supports the motor 4 and on the other hand is provided with an angular arm 8 on which a system axis 11 is fastened in the extension of the motor shaft 9 and the geometric axis 10 of the plucking head 3.

- a plucking tube 15 is rotatably mounted on the system axis 11 as part of the plucking head 3 by means of a bearing bush 16; the plucking tube 15 can be formed in one piece, or, as can be seen in FIG. 2, can be composed of three parts for easier manufacture and assembly, namely a partially bell-shaped lower part 17, a cylindrical middle part 18 and an upper part in the form of the aforementioned crown 2, which can be designed differently for different applications and is therefore expediently attachable and interchangeable.

- the lower part 17 of the plucking tube 15 is provided with a bearing bush 16 and carries on the inner surface of the bell-shaped area 19 an internal toothing 20 into which the gear 13 meshing with the motor pinion 12 engages, as a result of which the drive connection between the motor shaft 9 and the plucking tube 15 is closed.

- the central part 18 of the plucking tube 15, which overlaps the lower part 17 at the height (FIG. 2) of the bearing bush 16, carries at its free end two clamping jaws 23 and 24 which can be pivoted about axes 21 and 22 and which are known and therefore not explained in more detail cooperate with the inner edge of the crown 2 and are pressed into the closed position by a compression spring 25 inserted between the two jaws 23 and 24, as can be seen from FIG. 2.

- ratchet wheel 26 On the system axis 11, a specially toothed wheel, hereinafter referred to as ratchet wheel 26, is rigidly attached by pressing. Above (FIG. 2) this ratchet wheel 26, a cam 27 as a further part of the plucking head 3 is rotatably mounted on the system axis 11 and secured against axial displacement by means of a clamping sleeve 28. The jaws are beyond their pivot axes 21 and 22 with downward (Fig. 2) lever arms 29 and 30, which under the action of the spring 25 in the lever arms via balls 31 and 32, which serve to reduce friction, partially on the cam 27 apply (Fig. 4).

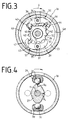

- a widened base part 33 of the cam 27 two diametrically opposite axes 34 and 35 are inserted on both sides and parallel to the system axis 11, on which - as can be seen in Fig. 3 - two pawls 36 and 37 are pivotally mounted, which have the shape of a have two-armed lever.

- a tooth 40 or 41 is provided, which interacts with the toothing 42 of the ratchet wheel 26.

- a two pawls 36 and 37 common spreading spring 43 engages with their free ends 44 and 45 on the other lever arms 46 and 47 of the pawls 36 and 37 and urges them into the engagement position with the toothing 42 of the ratchet wheel 26.

- an inner curve 49 is attached, which with adapted, ie in their web 53 protruding back profiles 50 and 51 on the lever arms 46 and 47 of the pawls 36 and 37 cooperate, in the sense of lifting the pawls 36 and 37 from the toothing 42 of the ratchet wheel 26 against the action of the spreading spring 43.

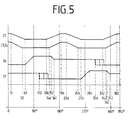

- the ratchet wheel 26 and the two pivotable pawls 36 and 37 together form a ratchet step mechanism which, controlled by the inner curve 49, translates the continuously rotating rotary movements of the plucking tube 15 of the plucking head 3 into an intermittent rotary movement of the cam 27, in the manner described below (cf. Fig. 3 to 5, the latter with associated explanation):

- the plucking tube 15 rotates driven by the motor 4 via the pinion 12 and the gear 13 in the direction of arrow A.

- the upper Pawl 36 engages with its tooth 40 in the toothing 42 of the ratchet wheel 26 and blocks a movement of the cam 27 in both directions of rotation. Due to the constructive design and arrangement of the pawls 36 and 37 shown in FIG.

- the holding function therefore requires minimal force of the spreading spring 43 and practically no friction due to the self-locking between the pawls and the ratchet wheel.

- the lower pawl 37 rests with its tooth 41 on the head 52 of the respectively assigned tooth of the ratchet toothing 42 and is thus in the pre-locking position.

- the cam 27 has the position shown in FIG. 4 and the balls 30, 31 of the clamping jaws 23, 24 rest against the outer radius R a , so that the clamping jaws 23, 24 are forced into the open position.

- the drawing Fig. 3 is based, for example, a ratchet wheel division of 11 divisions. However, a different division can also be selected.

- the adjustment of the cam-pawl system during the mutual latching process of the pawls is in each case half a division step, i.e. 32.73 °.

- the plucking system moves from this plucking process to the next by this angle.

Landscapes

- Transmission Devices (AREA)

- Hydraulic Motors (AREA)

- Paper (AREA)

- Liquid Crystal Substances (AREA)

- Supporting Of Heads In Record-Carrier Devices (AREA)

- Harvesting Machines For Specific Crops (AREA)

- Bending Of Plates, Rods, And Pipes (AREA)

- Sampling And Sample Adjustment (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4120014A DE4120014C1 (ja) | 1991-06-18 | 1991-06-18 | |

| DE4120014 | 1991-06-18 | ||

| PCT/EP1992/001056 WO1992022227A1 (de) | 1991-06-18 | 1992-05-14 | Zupfkopf für epiliergeräte |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0589907A1 EP0589907A1 (de) | 1994-04-06 |

| EP0589907B1 true EP0589907B1 (de) | 1996-03-20 |

Family

ID=6434174

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP92910145A Expired - Lifetime EP0589907B1 (de) | 1991-06-18 | 1992-05-14 | Zupfkopf für epiliergeräte |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US5458607A (ja) |

| EP (1) | EP0589907B1 (ja) |

| JP (1) | JPH06508771A (ja) |

| AT (1) | ATE135539T1 (ja) |

| DE (2) | DE4120014C1 (ja) |

| ES (1) | ES2085013T3 (ja) |

| WO (1) | WO1992022227A1 (ja) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5470332A (en) * | 1989-12-21 | 1995-11-28 | Thomas L. Mehl, Sr. | System for permanent removal of multiple hairs |

| WO1995020340A1 (de) * | 1994-01-27 | 1995-08-03 | Payer Elektroprodukte Gesellschaft M.B.H. | Enthaarungsgerät |

| FR2776858B1 (fr) * | 1998-03-27 | 2003-07-04 | Genus Technologies | Dispositif de maintien, de positionnement, ou de serrage, a actionnement electrique |

| JP3873550B2 (ja) * | 1999-11-25 | 2007-01-24 | 松下電工株式会社 | 脱毛装置 |

| US20040167481A1 (en) * | 2003-01-16 | 2004-08-26 | Conair Corporation | Hand-held buffing device |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3922949C1 (ja) * | 1989-07-12 | 1990-09-27 | Braun Ag, 6000 Frankfurt, De | |

| FR2658050B1 (fr) * | 1990-02-14 | 1993-12-03 | Moulinex | Appareil epilatoire. |

| DE4023252A1 (de) * | 1990-07-21 | 1992-01-23 | Braun Ag | Zupfkopf fuer motorisch betriebene epiliergeraete |

| US5234441A (en) * | 1992-01-06 | 1993-08-10 | Braun Aktiengesellschaft | Epilating appliance |

-

1991

- 1991-06-18 DE DE4120014A patent/DE4120014C1/de not_active Expired - Fee Related

-

1992

- 1992-05-14 WO PCT/EP1992/001056 patent/WO1992022227A1/de active IP Right Grant

- 1992-05-14 ES ES92910145T patent/ES2085013T3/es not_active Expired - Lifetime

- 1992-05-14 AT AT92910145T patent/ATE135539T1/de not_active IP Right Cessation

- 1992-05-14 DE DE59205775T patent/DE59205775D1/de not_active Expired - Fee Related

- 1992-05-14 EP EP92910145A patent/EP0589907B1/de not_active Expired - Lifetime

- 1992-05-14 JP JP4509188A patent/JPH06508771A/ja active Pending

-

1993

- 1993-12-14 US US08/169,575 patent/US5458607A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JPH06508771A (ja) | 1994-10-06 |

| EP0589907A1 (de) | 1994-04-06 |

| US5458607A (en) | 1995-10-17 |

| DE4120014C1 (ja) | 1992-06-17 |

| ATE135539T1 (de) | 1996-04-15 |

| WO1992022227A1 (de) | 1992-12-23 |

| DE59205775D1 (de) | 1996-04-25 |

| ES2085013T3 (es) | 1996-05-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3519566C2 (ja) | ||

| EP0510248B1 (de) | Epilationsgerät | |

| DE19500944A1 (de) | Antrieb für einen Flügel einer Tür, Fenster oder dergleichen | |

| WO1998042938A1 (de) | Hebelverschluss | |

| DE69600971T2 (de) | Elektrische fensterbedienung | |

| DE2813435A1 (de) | Getriebe fuer fenster- und tuerverschluesse o.dgl. | |

| EP0589907B1 (de) | Zupfkopf für epiliergeräte | |

| DE2619298A1 (de) | Uhrmechanismus | |

| EP0763641A1 (de) | Betätigungsvorrichtung | |

| DE2652978B2 (de) | Fernverstellbarer Außenrückblickspiegel für Kraftfahrzeuge | |

| DE3134515C2 (ja) | ||

| DE2109138C3 (de) | GroBuhrwerk mit Westminsterschlag oder dergl. Spielwerk und mittels Batterie angetriebenem Getriebemotor für das Schlagwerk | |

| DE3220441A1 (de) | Auf eine welle aufwickelbares rollo | |

| WO2004111425A1 (de) | Stellantrieb zur reversiblen bewegung einer ventilklappe eines ventils | |

| EP0113655A2 (de) | Türöffner und -schliesser | |

| WO1992001405A1 (de) | Zupfkopf für motorisch betriebene epiliergeräte | |

| EP2647878B1 (de) | Vorrichtung zur Erzeugung einer unidirektionalen Drehbewegung sowie Schwenkgriffanordnung mit einer solchen Vorrichtung | |

| DE2104577C3 (de) | Uhrwerk | |

| DE3342191A1 (de) | Getriebe fuer treibstangen an fenstern, tueren o.dgl. | |

| DE19744944A1 (de) | Verstellmechanik für eine stufenlose Dreh-Verstellung eines Abtriebs-Wirkteiles | |

| EP0547390A1 (de) | Epilationsgerät | |

| WO2019223992A1 (de) | Ratschenschluessel | |

| DE2236034C3 (de) | Drehschlagschrauber | |

| DE4313996C1 (de) | Handzange | |

| DE2932295A1 (de) | Antriebsvorrichtung fuer das heben und senken von fensterscheiben |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19931122 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES FR IT LI NL |

|

| 17Q | First examination report despatched |

Effective date: 19950428 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: BRAUN AKTIENGESELLSCHAFT |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR IT LI NL |

|

| REF | Corresponds to: |

Ref document number: 135539 Country of ref document: AT Date of ref document: 19960415 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: PATENTANWALTSBUREAU BOSSHARD UND LUCHS |

|

| REF | Corresponds to: |

Ref document number: 59205775 Country of ref document: DE Date of ref document: 19960425 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2085013 Country of ref document: ES Kind code of ref document: T3 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19960621 Year of fee payment: 5 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19970527 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970531 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970531 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19980518 Year of fee payment: 7 Ref country code: ES Payment date: 19980518 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19980527 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980531 |

|

| BERE | Be: lapsed |

Owner name: BRAUN A.G. Effective date: 19980531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990517 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19991201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000131 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19991201 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20010503 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20020510 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20020522 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030514 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20031202 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050514 |