EP0458317B1 - Blattendbearbeitungsgerät - Google Patents

Blattendbearbeitungsgerät Download PDFInfo

- Publication number

- EP0458317B1 EP0458317B1 EP91108323A EP91108323A EP0458317B1 EP 0458317 B1 EP0458317 B1 EP 0458317B1 EP 91108323 A EP91108323 A EP 91108323A EP 91108323 A EP91108323 A EP 91108323A EP 0458317 B1 EP0458317 B1 EP 0458317B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- stapling

- sheets

- sheet

- clinching

- lever

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000007599 discharging Methods 0.000 claims description 6

- 230000009471 action Effects 0.000 claims description 2

- 238000012423 maintenance Methods 0.000 claims description 2

- 230000007246 mechanism Effects 0.000 description 27

- 230000002441 reversible effect Effects 0.000 description 5

- 230000003028 elevating effect Effects 0.000 description 3

- 230000004044 response Effects 0.000 description 3

- 238000004140 cleaning Methods 0.000 description 2

- 230000000994 depressogenic effect Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 238000005286 illumination Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H37/00—Article or web delivery apparatus incorporating devices for performing specified auxiliary operations

- B65H37/04—Article or web delivery apparatus incorporating devices for performing specified auxiliary operations for securing together articles or webs, e.g. by adhesive, stitching or stapling

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03G—ELECTROGRAPHY; ELECTROPHOTOGRAPHY; MAGNETOGRAPHY

- G03G15/00—Apparatus for electrographic processes using a charge pattern

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42C—BOOKBINDING

- B42C1/00—Collating or gathering sheets combined with processes for permanently attaching together sheets or signatures or for interposing inserts

- B42C1/12—Machines for both collating or gathering and permanently attaching together the sheets or signatures

- B42C1/125—Sheet sorters combined with binding devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2403/00—Power transmission; Driving means

- B65H2403/50—Driving mechanisms

- B65H2403/51—Cam mechanisms

- B65H2403/511—Cam mechanisms involving cylindrical cam, i.e. cylinder with helical groove at its periphery

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2408/00—Specific machines

- B65H2408/10—Specific machines for handling sheet(s)

- B65H2408/11—Sorters or machines for sorting articles

- B65H2408/113—Sorters or machines for sorting articles with variable location in space of the bins relative to a stationary in-feed path

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2408/00—Specific machines

- B65H2408/10—Specific machines for handling sheet(s)

- B65H2408/11—Sorters or machines for sorting articles

- B65H2408/114—Sorters or machines for sorting articles means for shifting articles contained in at least one bin, e.g. for displacing the articles towards processing means as stapler, perforator

- B65H2408/1141—Sorters or machines for sorting articles means for shifting articles contained in at least one bin, e.g. for displacing the articles towards processing means as stapler, perforator performing alignment in the totality or a large number of bins at a time

Definitions

- the present invention relates to a sheet finisher according to the preamble of claim 1 for clinching sheet materials discharged from an image forming apparatus such as a copying machine.

- Some of copying machines or the like are equipped with a sheet finisher to automatically clinching the sheets into one or more sets of sheets, after the sheets receive images and are discharged from the main assembly of the copying apparatus.

- the stapler used for clinching the sheets in the sheet finisher is the one which has been developed exclusively for such use, and therefore, the stapler is expensive.

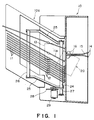

- a sheet finisher 10 is in the form of a sorter provided with an automatic stapler and is coupled with a copying machine.

- the sorter 10a has ten sheet discharge trays 11 which are vertically stacked.

- Each of the trays 11 has pins 12 and 12 at its lateral sides.

- the pins 12 and 12 are engaged with a helical groove formed in a circumferential surface of each of elevating rotatable members 13 and 13. By one full-rotation of each of the elevating rotatable members 13 and 13, the trays 11 are elevated or lowered one by one.

- a sheet is subjected to a copying operation by a copying machine (not shown) and is discharged through a discharge passage 15, provided by top and bottom guide plates 14 and 14, to one of trays 11 by the top and bottom discharging rollers 16 and 16.

- the structure of the sorter 10a may be any of known structure, and therefore, the detailed description thereof is omitted.

- the automatic stapler 20 in the sorter 10a clinches the sheets 21a, 21b on the tray 11a supported by the elevating rotatable members 13 and 13.

- the automatic stapler 20 is also inclined ( Figure 1).

- the automatic stapler 20 is disposed adjacent a lateral side at a front part of the tray 11.

- the non-stapling position thereof is determined so as not to obstruct the sheet discharge.

- the stapler 20 is moved to its clinching position A for clinching the sheets 21a and 21b.

- a lateral aligning mechanism 22 Adjacent the opposite lateral side from the automatic stapler 20, there is provided a lateral aligning mechanism 22 for the sheets 21a and 21b.

- the lateral shifting mechanism 22 is adapted for a plurality of sizes of the sheets and is effective to urge the sheets 21a and 21b to a reference wall 23 so as to align the sheets 21a and 21b to a clinching position A.

- the lateral shifting or aligning mechanism 22 has the following structure. It comprises a rotatable shaft 24 which is rotatably supported at the top and bottom ends. Adjacent the top and bottom ends, swingable arms 25 and 25 are fixed to the rotatable shaft 24. Between the other ends of the swingable arms 25 and 25, a lateral shifting bar 26 is extended.

- Each of the trays 11 has an arcuate opening 17 for permitting swinging movement of the lateral shifting bar 26.

- the lateral shifting bar 26 has a vertical length sufficient to be actable on the sheets on all of the trays 11.

- a sector gear 27 is fixed to the bottom end of the rotatable shaft 24, a sector gear 27 is fixed.

- the sector gear 27 is operatively connected with a reversible motor 29 through a reduction gear 28.

- the lateral shifting lever 26 swings toward the center of the tray 11 to urge the sheets 21a and 21b to the reference wall 23, thus aligning the sheets 21a and 21b.

- the lateral shifting mechanism 22 is operated in synchronism with the operation of the automatic stapler 20, as will be described hereinbefore. However, it is operable during the sheet discharging to effect the aligning operation simultaneously with the sheet discharging.

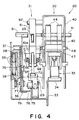

- the automatic stapler 20 has a clinching mechanisms 30 and a moving mechanism 31 which are juxtaposed with each other.

- a slidable frame 33 carrying the stapler 32 bridges between the mechanisms 30 and 31.

- the stapler 32 comprises a clincher 32a, a magazine 32b for accommodating staples and an anvil 32c.

- the clincher 32a is urged by an unshown spring to return to a position which is a predetermined distance away from the anvil 32c.

- the stapler 32 is the one sold in a usual market as office equipment.

- the slidable frame 33 is small in size in a top plan view at the clinching mechanism side and is large in the moving mechanism side (Figure 3). It has a U-shaped cross-section ( Figure 4). In a back side view, the side thereof adjacent the clinching mechanism 30 is low and horizontal. It has a stapler supporting portion 34 as a bent portion. The moving mechanism side thereof is at a high level and is provided with four guiding rollers 35 at the inside ( Figure 6).

- the stapler 32 is the one readily available in the market.

- a rear end 32d of the stapler 32 is engaged with a mounting portion 34a of the mounting portion 34, as shown in Figure 5.

- the front side of the stapler 32 is fixed on the mounting portion 34 by a screw 34b. Therefore, the staple 32 is detachably mounted by the screw 34b.

- the guide rollers 35 are engaged to upper and lower surfaces 38 and 38 of a channel like rail 37 fixed on a fixed frame 36 mounted on the sorter 10a.

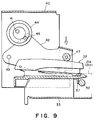

- the slidable frame 33 is guided between the non-clinching position to the clinching position A and between the clinching portion A and an outside staple loading position.

- a spring 39 is stretched between the fixed frame 36 and a slidable frame 33 to urge the slidable frame 33 to the loading position.

- the moving mechanism 31 is effective to move the slidable frame from the non-clinching position to the clinching position A, and the spring 39 moves the moving mechanism 31 from the non-stapling position to the loading position by releasing the moving mechanism 31 therefrom.

- a driving shaft 41 is rotatably supported and is extended out to the moving mechanism 31.

- the driving shaft 41 rotates through one full rotation by a motor through unshown reduction gears.

- a clinching lever 42 is disposed which has a reverse U-shape at its front side, and is rotatably supported on the fixed frame 40 by a pin 43 at its rear or base side.

- a pair of eccentric cams 44 is fixed so as to be operatively contactable to the clinching lever 42.

- the outside surface of the rotatable cam 44 has a cam groove 45 with which a pin 46 planted in the clinching lever 42 is engaged ( Figure 5).

- a clinching roller 47 Adjacent the free end of the clinching lever 42, a clinching roller 47 is mounted.

- the clinching roller 47 has a shaft 48 engaged with elongated slots 49 to permit vertical displacement of the roller 47.

- the shaft is urged down by a strong spring 50. Therefore, when the clinching lever 42 is urged by extremely large pressure, the clinching roller 47 retracts against the spring 50, thus avoiding application of extreme pressure.

- the front end of the mounting portion 34 for the stapler 32 is formed into a tongue 51 which abuts a stopper 52 fixed on the fixed frame 36 when the stapler 32 moves to the clinching position A, so that the stapler 32 is correctly positioned at the clinching position A.

- a generally heart mark shaped cam 60 is fixed to an end of the driving shaft 41.

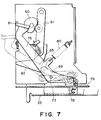

- the upper end portion of the swingable lever 61 is swingably supported on the fixed frame 40 by a pin 62.

- a roller 63 is rotatably supported on the swingable lever 61, and the roller 63 is contactable to the rotatable cam 60.

- a spring 64 is engaged at one end to the fixed frame 40 and is engaged at the other end with the swingable lever 61, so that the swingable lever 61 is normally urged to the rotatable cam 60 so as to establish a normal press-contact between the roller 63 and the rotatable cam 60.

- the bottom portion of the swingable lever 61 has an urging member 65 rotatably supported by a pin 66.

- the urging member 65 has an abutment part 67 at its upper front side so as to be contactable to the front surface 61a of the swingable lever 61 to urge it by a spring 68.

- the urging member 65 rotates against the spring 68 when the slidable frame 33 is extremely urged in the sliding direction.

- a contacting lever 69 At the top surface of the bottom portion of the slidable frame 33, there is a contacting lever 69 at such a position as to face the above-described urging member 65.

- the middle portion of the contacting lever 69 is rotatably supported by a pin 71 on a supporting member 70 fixed on the top surface of the bottom portion of the slidable frame 33.

- a roller 72 contactable to the urging member 65 is rotatably supported.

- the bottom surface at the front side thereof is contacted to the stopper 73 extended from the supporting member 70, so that the position of contact between the roller 72 and the urging member 65 is limited, wherein the spring 74 provides the urging force.

- the urging member 65 urges the contacting lever 69, so that the swingable frame 33 moves to the clinching position A.

- the spring 39 urging the slidable frame 33 retracts the swingable frame 33 to the retracted position.

- the contacting lever 69 has a rotatably mounted releasing roller 75.

- the roller 75 is operated by the releasing lever 76.

- the bent portion of the releasing lever 76 is rotatably mounted on the fixed frame 36 by a pin 77, and the bottom portion is bent into a contactable part 78.

- the contactable part 78 is contactable to a bent portion 79 of the fixed frame 36. It is urged by a spring 80 having an end fixed to the fixed frame 36.

- the upper part of the releasing lever 76 has an operating part 81.

- the copying machine 100 comprises an original supporting platen glass 151, scanning mirrors 152, 153, 154 and 155 for folding the optical path for the light reflected by the original, a variable focus lens 156. It further comprises a photosensitive drum 157, a high voltage unit 158, a developing device 159, an image transfer charger 159 and a cleaning device 160.

- the copying machine 100 is provided with an upper cassette 161, a bottom cassette 162, sheet feeding rollers 164, 165 and 166 and a registration roller 167.

- the sheet on which an image has been formed is conveyed to a fixing device 169 along a conveyor belt 168 with the aid of a conveying roller 171 and a sheet sensor 171a.

- the sheet may be manually fed from a manual tray 175.

- the photosensitive drum 157 rotates in the direction of an arrow in response to depression of a copy start key which will be described hereinafter. Then, the drum 157 is rotated for a predetermined period of time, and the electric potential thereof is controlled. An original is illuminated by an illumination lamp not shown, and the light reflected from the original is imaged on the photosensitive drum 157 by way of the scanning mirrors 152, 153, 154 and 155 and the lens 156.

- the photosensitive drum 157 has been charged by a corona charger supplied with the electric voltage from the high voltage source 158.

- the charged surface of the drum 157 is exposed to the light image of the original through the mirrors and lenses and through a slit, so that an electrostatic latent image is formed on the photosensitive drum 157.

- the electrostatic latent image is developed by a developing roller 159a of the developing device on the photosensitive drum 157 into a toner image.

- the toner image is transferred onto a transfer sheet by the transfer charger 159.

- the sheets in the upper cassette 161, the lower cassette 162 and the sheet deck 163 are fed out by the sheet feeding rollers 164, 165 and 166, respectively.

- the sheet fed out of one of them is once stopped by the registration roller 167, so that a loop of the sheet is formed.

- the registration roller 167 starts to feed the sheet at such a timing that a leading edge of the toner image formed on the rotating photosensitive drum 157 is aligned with the leading edge of the sheet.

- the toner image is transferred from the photosensitive drum 157 onto the transfer sheet.

- the sheet After the completion of the image transfer, the sheet is separated from the photosensitive drum 157, and is conveyed on the conveying belt 168 to the fixing device 169, where the toner image is fixed thereon by heat and pressure. Then, the sheet is discharged from the apparatus by the feeding rollers 171.

- the photosensitive drum 157 after the image transfer continues its rotation, so that the surface thereof is cleaned by the cleaning device 160.

- the copying apparatus is equipped with an automatic original feeder 200, which comprises a stacking tray 201 for stacking the originals, sensors 202 and 203 for detecting the size of the original.

- the sensors are spaced from each other by a predetermined distance in a direction perpendicular to the sheet of drawing.

- the lateral dimension of the original is determined on the basis of whether both of the sensors 202 and 203 detect the original or whether only one 203 of the sensors detects the original, the sensor 203 is at the rear side.

- the longitudinal dimension of the original is discriminated on the basis of time duration in which the sensor 202 or 203 detects the original (the time period required for the original passage).

- the original fed from the stacking tray 201 to the original supporting platen 151 along the sheet path 204 is stacked again on the tray 201 through the sheet passage 205.

- the automatic stapler 21 is disposed at the retracted position where the stapler 20 does not obstruct the sheet discharging action.

- the lateral shifting mechanism 22 After the completion of a predetermined amount of copying operations by the copying machine, and when the automatic stapling mode is selected, the lateral shifting mechanism 22 operates at the initial stage of the operation in that mode to align all of the sheets 21a and 21b on all of the trays 11 to the clinching position A side ( Figure 2).

- a manual switch not shown is depressed after the completion of the copying operation, in response to which the above operation is started.

- the lateral shifting or aligning bar 26 makes one reciprocation, by which the sheets 21a and 21b on all of the trays 11 are aligned to the reference wall 23 adjacent the clinching position A so that the sheets 21a and 21b are aligned to the clinching position.

- the driving shaft 41 is rotated one-full turn to effect the clinching operation.

- the rotatable cam 60 shown in Figure 6 starts to rotate. About 60 degrees of the rotational position, the reciprocal movement of the swingable lever 61 is completed. By the reciprocal movement, the urging member 65 of the swingable lever 61 pushes the contacting lever 69 out. Therefore, as shown in Figure 8, the slidable frame 33 is moved to the clinching position, and the tongue 51 of the mounting portion 34 of the swingable frame 33 is contacted to the stopper 52, by which the position thereof is limited (Figure 9).

- This state is maintained from the initial stage of the rotation of the cam 60 to the angular position thereof of about 300 degrees.

- the eccentric rotatable cam 44 starts to rotate from the position shown in Figure 5 to lower the clinching lever 42.

- the cam 44 angular position of about 70 degrees the clinching roller 47 is contacted to the top surface of the stapler 32.

- the forward (downward) movement of the clinching lever 42 is completed by approximately 180 degrees rotation from the start of the rotation.

- the clinching roller 47 presses the stapler 32 at its top part.

- the sheets 21a or 21b disposed at the clinching position A are stapled.

- the slidable frame 33 is permitted to move from the retracted position to the loading position by the spring 39.

- the stapler 32 is drawn out. Then, the upper part is opened, so that the staples can be loaded.

- the slidable frame 33 is manually urged toward inside. Then, the roller 72 of the contacting lever 69 is lowered by the inclined guiding surface 82 of the pressing part 65 of the swingable lever 61. It is then locked at the front side of the pressing portion 65, so that it can be restored to the retracted position.

- the stapler 32 is mounted on the mounting portion 34 of the slidable frame 33.

- the stapler 32 is the one readily available in the market as office equipment. Therefore, the cost is very low.

- the stapler 32 may be replaced with new one, and therefore, the maintenance is easy.

- the rotatable cams 44 and 60 are driven by a one driving shaft 41 to move the slidable frame 33 and the clinching lever 42, and therefore, the structure is simplified, and the height of the structure is reduced, thus minimizing the size of the device.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Textile Engineering (AREA)

- Mechanical Engineering (AREA)

- Folding Of Thin Sheet-Like Materials, Special Discharging Devices, And Others (AREA)

- Paper Feeding For Electrophotography (AREA)

- Collation Of Sheets And Webs (AREA)

- Dovetailed Work, And Nailing Machines And Stapling Machines For Wood (AREA)

Claims (10)

- Blatt-Endbearbeitungs-Vorrichtung, umfassend:

Blatt-Halte-Mittel (11) zum Halten eines Stapels von Blättern;

Heft-Mittel (32) zum Heften des Stapels von Blättern, der durch die Blatt-Halte-Mittel gehalten wird;

wobei die Heft-Mittel (32) zwischen einer ersten Stellung (A) zum Heften der Blätter und einer zweiten Stellung, in der die Heft-Mittel (32) den Blatt-Ausgabe-Vorgang nicht behindern, bewegbar ist;

Bewegungs-Mittel (31) zum Bewegen der Heft-Mittel (32) zwischen der ersten und der zweiten Stellung; dadurch gekennzeichnet, daß

das Heft-Mittel (32) zusätzlich von der zweiten Stellung in eine dritte Stellung bewegbar ist, indem das Heft-Mittel (32) von dem Bewegungsmittel (31) in der zweiten Stellung freigegeben wird,

wobei es die dritte Stellung ermöglicht, daß das Heft-Mittel (32) seinem Instandhaltungsvorgang unterworfen wird. - Vorrichtung nach Anspruch 1, wobei das Heft-Mittel (32) in der dritten Stellung abnehmbar ist.

- Vorrichtung nach Anspruch 1, wobei in der dritten Stellung das Heft-Mittel (32) mit Heftklammern beladbar ist.

- Vorrichtung nach Anspruch 1, weiters umfassend Verriegelungs-Mittel zum Unterbinden der Bewegung der Heft-Mittel (32), sowie Freigabe-Mittel (75) zum Losen der Verriegelungs-Mittel.

- Vorrichtung nach Anspruch 4, wobei das Freigabe-Mittel (75) händisch betätigbar ist.

- Vorrichtung nach Anspruch 1, wobei das Halte-Mittel mehrere Körbe (11) zum Halten von Stapeln von Blättern und Korb-Bewegungs-Mittel zum Bewegen der Körbe (11) umfaßt, die die in der Heft-Stellung zu heftenden Blätter halten.

- Vorrichtung nach Anspruch 1, wobei das Bewegungs-Mittel (31) einen schwenkbaren Hebel (61) umfaßt, der durch die Antriebs-Quelle (41) schwenkbar ist, wobei das Heft-Mittel (32) zwischen der ersten Stellung und der zweiten Stellung durch die Schwenk-Bewegung des schwenkbaren Hebels (61) bewegt wird.

- Vorrichtung nach Anspruch 1, wobei das Halte-Mittel mit einem Ausrichtungs-Mittel (22) zum Ausrichten der Blätter versehen ist, um die darauf befindlichen Blätter vor dem Heft-Vorgang der Heft-Mittel (32) auszurichten.

- Vorrichtung nach Anspruch 8, wobei das Ausrichtungs-Mittel (22) mit einem Bezugs-Anschlag (52) im Bereich der Heft-Stelle und mit einer Andruck-Stange zum Andrücken der Blätter an den Bezugs-Anschlag (52) versehen ist.

- Bilderzeugungsvorrichtung, mit:

einer Bilderzeugungseinrichtung (100) für die Erzeugung eines Bildes auf einem Bogen; und

einer Bogen-Endbearbeitungs-Vorrichtung gemäß einem der vorhergehenden Ansprüche.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP93119230A EP0589493B1 (de) | 1990-05-23 | 1991-05-22 | Blattendbearbeitungsgerät |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2132797A JP2783649B2 (ja) | 1990-05-23 | 1990-05-23 | 複写機の自動ステイプラ |

| JP132797/90 | 1990-05-23 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93119230.6 Division-Into | 1991-05-22 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0458317A1 EP0458317A1 (de) | 1991-11-27 |

| EP0458317B1 true EP0458317B1 (de) | 1995-11-02 |

Family

ID=15089791

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93119230A Expired - Lifetime EP0589493B1 (de) | 1990-05-23 | 1991-05-22 | Blattendbearbeitungsgerät |

| EP91108323A Expired - Lifetime EP0458317B1 (de) | 1990-05-23 | 1991-05-22 | Blattendbearbeitungsgerät |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93119230A Expired - Lifetime EP0589493B1 (de) | 1990-05-23 | 1991-05-22 | Blattendbearbeitungsgerät |

Country Status (4)

| Country | Link |

|---|---|

| EP (2) | EP0589493B1 (de) |

| JP (1) | JP2783649B2 (de) |

| KR (1) | KR970001196B1 (de) |

| DE (2) | DE69123061T2 (de) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101073403B1 (ko) | 2004-09-09 | 2011-10-17 | 엘지디스플레이 주식회사 | 액정표시소자 및 그 제조방법 |

| KR101192746B1 (ko) | 2004-11-12 | 2012-10-18 | 엘지디스플레이 주식회사 | 폴리형 박막 트랜지스터 기판의 제조방법 |

| KR101066489B1 (ko) | 2004-11-12 | 2011-09-21 | 엘지디스플레이 주식회사 | 폴리형 박막 트랜지스터 기판 및 그 제조 방법 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4313670A (en) * | 1979-10-30 | 1982-02-02 | Xerox Corporation | Reproduction machine with a pivotal stapling device |

| DE3304875C2 (de) * | 1983-02-12 | 1986-10-23 | Agfa-Gevaert Ag, 5090 Leverkusen | Kopienablagetisch |

| DE3577824D1 (en) * | 1985-04-23 | 1990-06-28 | Xerox Corp | Blaettersortierer. |

-

1990

- 1990-05-23 JP JP2132797A patent/JP2783649B2/ja not_active Expired - Fee Related

-

1991

- 1991-05-22 DE DE69123061T patent/DE69123061T2/de not_active Expired - Fee Related

- 1991-05-22 DE DE69114182T patent/DE69114182T2/de not_active Expired - Lifetime

- 1991-05-22 EP EP93119230A patent/EP0589493B1/de not_active Expired - Lifetime

- 1991-05-22 EP EP91108323A patent/EP0458317B1/de not_active Expired - Lifetime

- 1991-05-23 KR KR1019910008396A patent/KR970001196B1/ko not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JPH0427592A (ja) | 1992-01-30 |

| EP0589493B1 (de) | 1996-11-06 |

| KR970001196B1 (ko) | 1997-01-29 |

| DE69123061D1 (de) | 1996-12-12 |

| JP2783649B2 (ja) | 1998-08-06 |

| EP0589493A1 (de) | 1994-03-30 |

| DE69114182T2 (de) | 1996-04-18 |

| DE69123061T2 (de) | 1997-03-20 |

| DE69114182D1 (de) | 1995-12-07 |

| KR910020511A (ko) | 1991-12-20 |

| EP0458317A1 (de) | 1991-11-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4379561B2 (ja) | シート処理装置及びこれを備えた画像形成装置 | |

| JP3639737B2 (ja) | シート整合回転体を備えるシート処理装置及び画像装置 | |

| EP0371403B1 (de) | Vorrichtung zur Bogenweiterverarbeitung und Vorrichtung zur Bilderzeugung | |

| US5137265A (en) | Sheet post-processing apparatus | |

| JPH0667675B2 (ja) | 用紙ステープラ装置を備えた複写機 | |

| US6773005B2 (en) | Sheet post-processing apparatus with fixed and auxiliary guide members | |

| US5374043A (en) | Sorter with stapler actived release gate mechanism | |

| US6607188B2 (en) | Sheet post-processing apparatus | |

| US5279494A (en) | Sheet finisher with standard type stapler | |

| EP0458317B1 (de) | Blattendbearbeitungsgerät | |

| JP4329918B2 (ja) | シート処理装置及びこれを備えた画像形成装置 | |

| JP3877510B2 (ja) | 画像形成装置の用紙排出装置 | |

| US11274010B2 (en) | Sheet post-processing apparatus and image forming system equipped with same | |

| JP4302280B2 (ja) | 折りシート積載装置とこの装置を備えた画像形成装置 | |

| JP2703282B2 (ja) | 画像形成装置 | |

| JP2780787B2 (ja) | 画像形成装置 | |

| JP2780804B2 (ja) | 画像形成装置 | |

| JP2758195B2 (ja) | ステープラ付きソータ | |

| JP2912378B2 (ja) | ステープラ付ソータ | |

| JP2860837B2 (ja) | ステイプラ装置を備えたソータ | |

| JP2680109B2 (ja) | ステープラ付ソータ | |

| JP2680108B2 (ja) | 画像形成装置の後処理装置 | |

| JP2638882B2 (ja) | 用紙収容装置 | |

| JP2920425B2 (ja) | ステイプラ装置を備えたソータ | |

| JPH0223154A (ja) | 画像形成用紙後処理装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19910621 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB IT |

|

| 17Q | First examination report despatched |

Effective date: 19920526 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT |

|

| XX | Miscellaneous (additional remarks) |

Free format text: TEILANMELDUNG 93119230.6 EINGEREICHT AM 22/05/91. |

|

| REF | Corresponds to: |

Ref document number: 69114182 Country of ref document: DE Date of ref document: 19951207 |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20100324 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20100603 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20100525 Year of fee payment: 20 Ref country code: DE Payment date: 20100531 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 69114182 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20110521 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20110521 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20110523 |