EP0387414B1 - Vorrichtung zum Verpacken eines Papierstapels - Google Patents

Vorrichtung zum Verpacken eines Papierstapels Download PDFInfo

- Publication number

- EP0387414B1 EP0387414B1 EP89123092A EP89123092A EP0387414B1 EP 0387414 B1 EP0387414 B1 EP 0387414B1 EP 89123092 A EP89123092 A EP 89123092A EP 89123092 A EP89123092 A EP 89123092A EP 0387414 B1 EP0387414 B1 EP 0387414B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- suction

- folding box

- guide rods

- unit

- folding

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000004806 packaging method and process Methods 0.000 title claims abstract description 28

- 230000008878 coupling Effects 0.000 claims description 5

- 238000010168 coupling process Methods 0.000 claims description 5

- 238000005859 coupling reaction Methods 0.000 claims description 5

- 238000010276 construction Methods 0.000 description 3

- 230000000052 comparative effect Effects 0.000 description 2

- 238000010586 diagram Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B25/00—Packaging other articles presenting special problems

- B65B25/14—Packaging paper or like sheets, envelopes, or newspapers, in flat, folded, or rolled form

- B65B25/141—Packaging paper or like sheets, envelopes, or newspapers, in flat, folded, or rolled form packaging flat articles in boxes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B11/00—Wrapping, e.g. partially or wholly enclosing, articles or quantities of material, in strips, sheets or blanks, of flexible material

- B65B11/004—Wrapping, e.g. partially or wholly enclosing, articles or quantities of material, in strips, sheets or blanks, of flexible material in blanks, e.g. sheets precut and creased for folding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B59/00—Arrangements to enable machines to handle articles of different sizes, to produce packages of different sizes, to vary the contents of packages, to handle different types of packaging material, or to give access for cleaning or maintenance purposes

- B65B59/001—Arrangements to enable adjustments related to the product to be packaged

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B59/00—Arrangements to enable machines to handle articles of different sizes, to produce packages of different sizes, to vary the contents of packages, to handle different types of packaging material, or to give access for cleaning or maintenance purposes

- B65B59/003—Arrangements to enable adjustments related to the packaging material

Definitions

- the invention relates generally to packaging a stack of paper. Such stacks of paper are also known as reams.

- the packaging is done by boxing.

- the invention specifically relates to a device for packaging a paper stack, - with a folding box unit and a suction stamp unit, the folding box unit having a receiving plane for a packaging blank and a paper stack pushed thereon, and tool elements for erecting the side parts of the packaging blank into a half-box, the suction stamp unit having one Has a plurality of suction stamps which can be moved up and down at the same time, the heads of which form the receiving plane, and wherein the packaging blank with the paper stack can be lowered by means of the suction stamp through the folding box assembly, and the side parts of the packaging blank can be erected on the tool elements.

- Such a device must be convertible to different formats of the paper stack and the packaging blanks.

- the folding box unit and the suction stamp unit interact functionally in the manner described, but they are structurally largely separated. If a device of the construction described has to be changed over to a different format, then separate and thereby laborious changeover and positioning work is necessary both on the folding box unit and on the suction stamp unit.

- the invention has for its object to develop a device of the structure described above so that the folding box unit and the suction stamp unit can be easily adjusted to different formats together.

- the invention basically teaches that the folding box assembly has a plurality of folding box guide rods intersecting orthogonally in the corners, by means of which or on which the tool elements for setting the format can be adjusted with the aid of actuators, that the suction stamp assembly has suction die guide rods parallel to the folding box guide rods, to which the suction pads are connected via brackets and with which and on which the suction pads can be moved for setting the format, and that the suction pad guide rods are mechanically connected to the folding box guide rods and can be adjusted together with them.

- the device shown in the figures is used to pack a stack of paper.

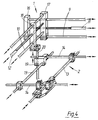

- the basic structure includes a folding box assembly 1 and a suction pad assembly 2. These were initially indicated in FIGS. 1 and 2. In these figures and also in FIGS. 3 and 4, all degrees of freedom of movement of the device are illustrated by arrows or double arrows.

- the folding box assembly 1 has a receiving plane for a packaging blank Z and a paper stack S pushed thereon and tool elements 4.

- the packaging blank Z was fed from the direction of the arrow 5, the paper stack S or the ream was pushed onto the packaging blank Z from the direction of the arrow 6.

- the tool elements 4 serve to erect the side parts of the packaging blank Z into a half-box. 2 shows this half-box, which is pushed out in the direction of arrow 7. can be. It rests on the suction plungers 8 and can be held and released by them.

- the suction pad assembly 2 has a plurality of suction pads 8 which can be moved up and down simultaneously.

- the heads of the suction pads 8 form the receiving plane.

- the packaging blank Z with the paper stack S is lowered with the aid of the suction stamp 8 through the folding box assembly 1, the side parts of the packaging blank Z being erected on the tool elements 4. How this happens in detail can be seen from a comparative view of FIGS. 1 and 2. If in FIG. 2 the erected half-box formed from the packaging blank Z with the paper stack 5 is pushed to the right, the suction stamps 8 of the suction stamp assembly 2 moved back into the position of Fig. 1 and the loading with blank Z and Ries S can be done again. A comparative view of FIGS. 1 and 2 also shows how the tool elements 4 interact with the packaging blank Z and its side parts and tabs, which is part of the prior art.

- the folding box assembly 1 has a plurality of orthogonally crossing in the corners of the folding box guide rods 9, 10, with or on which the tool elements 4 for format adjustment with the help of servomotors 11th , 12 are displaceable.

- the servomotors 11, 12 are, for example, stepper motors which are arranged on the right outside of FIGS. 3 and 4, the adjustment taking place via screw spindles which have been provided with the reference symbols 11 and 12, pars pro toto.

- the suction stamp assembly 2 has the folding box guide rods 9, 10 parallel suction stamp guide rods 13, 14, to which the suction stamps 8 are connected via holders 15 and with which and on which the suction stamps 8 can be displaced for setting the format.

- the suction pad guide rods 13, 14 are also mechanically connected to the folding box guide rods 9, 10 and adjustable together with them.

- the arrangement is such that a first group of folding box guide rods 9, which lie opposite one another on two sides of the folding box assembly 1, are fastened in corner parts 16 of the machine frame, at least one of the guide rods 9 of this first Group is designed as an actuator 11. 3 and 4, a second group of folding box guide rods 10 can be seen on the two other sides of the folding box assembly 1, one of which is designed as an actuator 12.

- This group of folding box guide rods 10 is fastened in guide blocks 17 which are guided on the folding box guide rods 9 of the first group.

- At least one tool holder block 18, the tool elements, is guided on the folding box guide rods 10 of the second group 4 carries.

- the actuating drives 11, 12 allow the guide blocks 17 and the tool holder blocks 18 to be adjusted in the format setting.

- the suction pad guide rods 13, 14 have a driver block 19 which is fastened on one of the suction pad guide rods 13. This runs parallel to the folding box guide rods 10 of the second group, which guide the tool holder block 18.

- the tool holder block 18 is connected via a coupling rod 20 to the driver block 19, which is otherwise movable up and down on the coupling rod 20. If the format is changed, the necessary adjustments in the folding box assembly 1 and in the suction pad assembly 2 are carried out simultaneously with the aid of the described guide rods 9, 10 or 13, 14 and their coupling and with the aid of the actuators 11, 12.

- the embodiment according to the invention has the advantage that the setting of the folding box assembly 1 with respect to the suction dies 8 always remains the same. Readjustment is therefore no longer necessary.

- the folding box assembly 1 and the suction pad assembly 2 form a unit not only in functional terms, but also in terms of construction and control technology.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Supplying Of Containers To The Packaging Station (AREA)

- Basic Packing Technique (AREA)

- Auxiliary Devices For And Details Of Packaging Control (AREA)

- Packaging Of Special Articles (AREA)

- Sheets, Magazines, And Separation Thereof (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT89123092T ATE91989T1 (de) | 1989-03-14 | 1989-12-14 | Vorrichtung zum verpacken eines papierstapels. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3908184 | 1989-03-14 | ||

| DE3908184A DE3908184C1 (enExample) | 1989-03-14 | 1989-03-14 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0387414A1 EP0387414A1 (de) | 1990-09-19 |

| EP0387414B1 true EP0387414B1 (de) | 1993-07-28 |

Family

ID=6376258

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89123092A Expired - Lifetime EP0387414B1 (de) | 1989-03-14 | 1989-12-14 | Vorrichtung zum Verpacken eines Papierstapels |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4982552A (enExample) |

| EP (1) | EP0387414B1 (enExample) |

| JP (1) | JPH02296613A (enExample) |

| AT (1) | ATE91989T1 (enExample) |

| CA (1) | CA2011558A1 (enExample) |

| DE (3) | DE8913550U1 (enExample) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4018024A1 (de) * | 1990-06-05 | 1991-12-12 | Rovema Gmbh | Verfahren und vorrichtung zum verpacken von beuteln |

| DE4210813A1 (de) * | 1992-04-01 | 1993-10-07 | Schmermund Maschf Alfred | Kartoniereinrichtung |

| DE4440107A1 (de) * | 1994-11-10 | 1996-05-15 | Focke & Co | Verfahren und Vorrichtung zum Herstellen von Tray-Packungen |

| DE4441360A1 (de) * | 1994-11-21 | 1996-05-23 | Womako Masch Konstr | Papierstapel mit abgewinkeltem Deckblatt |

| US5600936A (en) * | 1995-04-06 | 1997-02-11 | Moncrief; Frank | Suspended modular partition inserter |

| US5700998A (en) * | 1995-10-31 | 1997-12-23 | Palti; Yoram | Drug coding and delivery system |

| DE19840077C2 (de) * | 1998-09-03 | 2003-12-11 | Winkler & Duennebier Ag | Vorrichtung zum Verpacken von Gegenständen oder von Stapeln |

| FI106015B (fi) * | 1999-04-30 | 2000-11-15 | Pussikeskus Oy | Pakkauslaite ja menetelmä litteiden tavaroiden, kuten kirjojen, pakkaamiseksi |

| US7509790B1 (en) * | 2005-11-13 | 2009-03-31 | Zoltan Filep | Random case former |

| WO2014118629A2 (en) * | 2013-01-29 | 2014-08-07 | Neopost Technologies | Method and system for automatically forming packaging boxes |

| EP3241767B1 (de) * | 2016-05-02 | 2019-03-27 | INDAG Pouch Partners GmbH | Verarbeitungsvorrichtung für folienbeutel |

| CN111377078B (zh) * | 2020-04-24 | 2024-05-10 | 扬州市职业大学(扬州市广播电视大学) | 一种图书包装机 |

| EP4565489A1 (en) * | 2022-08-03 | 2025-06-11 | Sacmi Packaging & Chocolate S.P.A. | Packaging assembly |

| US12384587B1 (en) * | 2023-03-30 | 2025-08-12 | Amazon Technologies, Inc. | Automated containers for packing of multi-item packages |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3242635A (en) * | 1962-06-01 | 1966-03-29 | David G Kobick | Packaging machine |

| US3665675A (en) * | 1970-02-11 | 1972-05-30 | Stone Container Corp | Packaging machine |

| US3782071A (en) * | 1971-06-01 | 1974-01-01 | H Hagedorn | Simultaneous carton former and loader |

| US3834114A (en) * | 1972-08-29 | 1974-09-10 | Stone Container Corp | Packaging machine and method |

| US4149452A (en) * | 1977-05-04 | 1979-04-17 | Talarico Lawrence J | Folding and packaging machine |

-

1989

- 1989-03-14 DE DE8913550U patent/DE8913550U1/de not_active Expired - Lifetime

- 1989-03-14 DE DE3908184A patent/DE3908184C1/de not_active Expired - Fee Related

- 1989-12-14 EP EP89123092A patent/EP0387414B1/de not_active Expired - Lifetime

- 1989-12-14 AT AT89123092T patent/ATE91989T1/de active

- 1989-12-14 DE DE8989123092T patent/DE58905058D1/de not_active Expired - Fee Related

-

1990

- 1990-02-12 US US07/479,064 patent/US4982552A/en not_active Expired - Fee Related

- 1990-03-06 CA CA002011558A patent/CA2011558A1/en not_active Abandoned

- 1990-03-14 JP JP2061325A patent/JPH02296613A/ja active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| DE3908184C1 (enExample) | 1990-01-11 |

| JPH02296613A (ja) | 1990-12-07 |

| DE8913550U1 (de) | 1990-01-25 |

| ATE91989T1 (de) | 1993-08-15 |

| US4982552A (en) | 1991-01-08 |

| EP0387414A1 (de) | 1990-09-19 |

| DE58905058D1 (de) | 1993-09-02 |

| CA2011558A1 (en) | 1990-09-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0387414B1 (de) | Vorrichtung zum Verpacken eines Papierstapels | |

| EP0158866B1 (de) | Werkzeugmaschine zur mechanischen und thermischen Bearbeitung eines Werkstücks | |

| EP0983940A1 (de) | Vorrichtung zum Verpacken von Gegenständen oder von Stapeln | |

| EP0215263B1 (de) | Biegepresse | |

| EP0714839B1 (de) | Verfahren zur Inbetriebnahme oder Umrüstung einer Zargenschweissmaschine sowie ein modulares Magazin zum Durchführen des Verfahrens | |

| DE102007020736A1 (de) | Rollendruckmaschine | |

| WO2012083332A1 (de) | Biegepresse mit werkzeugspeicher | |

| DE3334263A1 (de) | Automatischer laengsschneider | |

| DE3424782A1 (de) | Maschine zum herstellen von kartons, schachteln und dergleichen | |

| EP1927429A1 (de) | Werkzeugmaschine mit Werkzeugmagazin | |

| DE19721613A1 (de) | Presse mit einer Umsetzeinrichtung für Werkstücke | |

| WO2004110871A1 (de) | Arbeitsstation und verpackungsmaschine | |

| EP0856396B1 (de) | Flexible Anlage zum Aufrichten von Kartonzuschnitten | |

| EP0593894A1 (de) | Werkzeug für eine Stanzpresse mit einer Laser-Schweissanlage | |

| DE69722935T2 (de) | Hintergauge | |

| EP0164585B1 (de) | Maschine zum Herstellen von Faltschachteln aus Zuschnitten | |

| DE3931710C2 (de) | Non-Stop-Bogenanleger für Bogenrotationsmaschinen | |

| DE3130816C2 (enExample) | ||

| EP0498071A1 (de) | Verfahren zum Vorstapeln in einem Bogenanleger von Rotationsdruckmaschinen | |

| EP2845663B1 (de) | Biegepresse mit einem Biegewerkzeug aus mehreren Werkzeugelementen | |

| DE3317084C2 (enExample) | ||

| EP1415921A1 (de) | Vorrichtung zum Greifen eines insbesondere mit Tabak befüllten Kartons | |

| DE69732340T2 (de) | IC-Leiterrahmenverarbeitungssystem | |

| DE4416843C2 (de) | Zick-Zack-Vorschubeinrichtung | |

| DE69703978T2 (de) | Vorrichtung zum regeln der grösse eines werkzeugmaschinen-blechhalters |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES FR GB GR LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19901205 |

|

| 17Q | First examination report despatched |

Effective date: 19930112 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB GR LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19930728 Ref country code: NL Effective date: 19930728 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19930728 Ref country code: GB Effective date: 19930728 Ref country code: FR Effective date: 19930728 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19930728 Ref country code: BE Effective date: 19930728 |

|

| REF | Corresponds to: |

Ref document number: 91989 Country of ref document: AT Date of ref document: 19930815 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 58905058 Country of ref document: DE Date of ref document: 19930902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19931214 |

|

| EN | Fr: translation not filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19931231 Ref country code: LI Effective date: 19931231 Ref country code: CH Effective date: 19931231 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 19930728 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19940418 Year of fee payment: 5 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19950901 |