EP0349764A2 - Appareil de combustion à lit fluidisé - Google Patents

Appareil de combustion à lit fluidisé Download PDFInfo

- Publication number

- EP0349764A2 EP0349764A2 EP89109975A EP89109975A EP0349764A2 EP 0349764 A2 EP0349764 A2 EP 0349764A2 EP 89109975 A EP89109975 A EP 89109975A EP 89109975 A EP89109975 A EP 89109975A EP 0349764 A2 EP0349764 A2 EP 0349764A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- secondary air

- fluidized bed

- free space

- fluidised

- bed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23M—CASINGS, LININGS, WALLS OR DOORS SPECIALLY ADAPTED FOR COMBUSTION CHAMBERS, e.g. FIREBRIDGES; DEVICES FOR DEFLECTING AIR, FLAMES OR COMBUSTION PRODUCTS IN COMBUSTION CHAMBERS; SAFETY ARRANGEMENTS SPECIALLY ADAPTED FOR COMBUSTION APPARATUS; DETAILS OF COMBUSTION CHAMBERS, NOT OTHERWISE PROVIDED FOR

- F23M9/00—Baffles or deflectors for air or combustion products; Flame shields

- F23M9/02—Baffles or deflectors for air or combustion products; Flame shields in air inlets

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C10/00—Fluidised bed combustion apparatus

- F23C10/18—Details; Accessories

Definitions

- the invention relates to a fluidized bed furnace with a stationary fluidized bed according to the preamble of claim 1.

- an effective measure for reducing nitrogen oxide emissions is to carry out the combustion in the fluidized bed with a lack of oxygen and to burn out the carbon monoxide contained in the rising gas with a supply of secondary air over the fluidized bed.

- a particular problem with stationary fluidized bed furnaces is that the flying dust still contains combustible carbon particles.

- the rising gas is also loaded with volatile, hydrocarbon-like components. The flammable solid and gaseous substances can be burned out in the free space with a secondary air supply.

- a prerequisite for a good burnout is a homogeneous mixing of the secondary air with the rising gas-solid mixture. This is not easy to achieve due to the high toughness of the hot gas.

- a static mixing device is arranged in the free space.

- the secondary air supply can be, for example, partly by means of a balance right, sometimes obliquely downward pipes are made, which are arranged between the fluidized bed and the static mixing device.

- the static mixing device itself is designed as a secondary air supply.

- a calming space is provided above the fluidized bed, which merges into a post-combustion chamber via a constriction.

- Horizontal secondary air nozzles are arranged in the wall in the area of the constriction.

- the calming room serves to largely avoid entrainment of solid particles from the fluidized bed.

- the constriction acts as a mixing section for the hot gas and the secondary air.

- the invention has for its object to equalize the admixture of the secondary air in a fluidized bed combustion of the type specified in the preamble of claim 1 with simple means and to create the possibility of increasing the temperature in the open space by additional heat.

- the feature of claim 3 enables a targeted adaptation of the amount of secondary air to the operating conditions.

- the feature of claim 5 has the effect that the heat supplied to the free space is concentrated in particular on the lower region which is important for the ignition. The mixing effect is further improved. Dust streak formation is also counteracted.

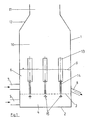

- the fluidized bed combustion system shown in FIG. 1 has a combustion chamber with a rectangular outline, which is enclosed by side walls 1. Between its base 2 and an inflow base 3 there is an air box 4 with a connecting pipe 5 for the supply of combustion air.

- the inflow floor 3 has numerous passages for primary air.

- a side-mounted charging device 7 is used to supply the fuel, optionally with an additive, such as lime, for example.

- An ash extractor 8 is arranged in a side wall 1 directly above the inflow floor 3.

- There is a free space 10 above the surface 9 of the fluidized bed 6 which merges into a flue gas flue 11.

- the transition 12 between the free space 10 and the flue gas flue 11 has the shape of an inverted funnel.

- the fluidized bed combustion shown in Figure 1 corresponds to the prior art.

- the fluidized bed furnace can also be equipped, for example, with heat exchangers which are immersed in the fluidized bed.

- the wall surfaces of the combustion chamber can be designed in whole or in part in a known manner as heat exchange surfaces.

- the pipe sections 13 dip with part of their length - For example about half - in the fluidized bed 6, so that the lower tube ends are, for example, in the middle of the fluidized bed 6, in any case at a distance above the inflow floor 3.

- the upper ends protrude into the free space 10.

- a secondary air nozzle 14 directed vertically upward is set in the manner of an injector. This has the shape of a tube, the outer diameter of which is smaller than the inside diameter of the tube piece 13, so that there is an annular gap between the secondary air nozzle 14 and the associated tube piece 13.

- the secondary air nozzles 14 are fastened to the inflow floor 3 and are connected directly to the air box 4 through coaxial bores in the inflow floor 3.

- the secondary air nozzles 14 are equipped with actuators 15 which can be operated together from the outside. For example, they are designed as lifting and lowering valve cones.

- the amount of primary air blown in, which penetrates through the passages of the inflow floor 3 into the fluidized bed 6, is so matched to the grain size of the bed material that only a small part of the Bed material with the rising gas is discharged from the fluidized bed 6.

- the main mass of the bed material is brought into a liquid-like state and thereby only slightly expanded, so that there is a sudden difference in density between the fluidized bed 6 and free space 10, recognizable as a pronounced surface of the fluidized bed 6.

- the term "stationary fluidized bed” has become common.

- the ash is mainly discharged through the ash extractor 8. This does not rule out that a small amount of fly ash is carried along by the gas stream and, if necessary, is recirculated into the fluidized bed 6 after separation.

- a part of the supplied air is blown into the free space 10 as secondary air through the secondary air nozzles 14 and the pipe pieces 13. Since - due to the pressure drop in the fluidized bed - there is a considerable pressure difference between air box 4 and free space 10, the secondary air jets have a high speed.

- the amount of secondary air can be metered using the actuators 15.

- granular fluidized bed material is entrained by the annular gap 17 existing between the secondary air nozzle 14 and the pipe section 13 and is thrown into the free space 10 like a fountain.

- the secondary air heats up on the way through the secondary air nozzle 14 and the pipe section 13 by touching the wall and by bed material carried along and causes an increase in temperature in the free space 10. Heat is also supplied to the free space by the fluidized bed material carried along.

- the heat transfer between the grains falling back into the fluidized bed and the rising gas flow is particularly intensive because of the high relative speed.

- the particles flying up and down create a stirring effect in the free space 10, which promotes the homogeneous mixing of the secondary

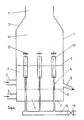

- the secondary air nozzles 14 are connected to a separate air supply. This is designed as a distributor pipe 18 which is equipped with an actuator 19.

- Impact devices 20 are attached at a distance above the upper ends of the tube pieces 13. These are connected to the tube pieces 13 by simple fastening means (not shown), for example similar to the holding plates 16 which can be seen in FIGS. 2 and 3. Otherwise, the exemplary embodiment according to FIG. 4 corresponds to the previously described exemplary embodiment.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Fluidized-Bed Combustion And Resonant Combustion (AREA)

- Devices And Processes Conducted In The Presence Of Fluids And Solid Particles (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3822999A DE3822999C1 (fr) | 1988-07-07 | 1988-07-07 | |

| DE3822999 | 1988-07-07 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0349764A2 true EP0349764A2 (fr) | 1990-01-10 |

| EP0349764A3 EP0349764A3 (fr) | 1991-01-30 |

| EP0349764B1 EP0349764B1 (fr) | 1993-05-12 |

Family

ID=6358153

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89109975A Expired - Lifetime EP0349764B1 (fr) | 1988-07-07 | 1989-06-02 | Appareil de combustion à lit fluidisé |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0349764B1 (fr) |

| DE (2) | DE3822999C1 (fr) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2001044719A1 (fr) * | 1999-12-16 | 2001-06-21 | Livite Oy | Procede brulage de materiau dans une chaudiere a lit fluidise et chaudiere a lit fluidise |

| CN100557308C (zh) * | 2007-12-21 | 2009-11-04 | 哈尔滨工业大学 | 壁面-中心复合供给二次风的流化床燃烧装置 |

| CN104132335A (zh) * | 2013-05-03 | 2014-11-05 | 国家电网公司 | 带有底部插入二次风管的循环流化床锅炉炉膛 |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10260733B4 (de) | 2002-12-23 | 2010-08-12 | Outokumpu Oyj | Verfahren und Anlage zur Wärmebehandlung von eisenoxidhaltigen Feststoffen |

| DE10260734B4 (de) | 2002-12-23 | 2005-05-04 | Outokumpu Oyj | Verfahren und Anlage zur Herstellung von Schwelkoks |

| DE10260739B3 (de) | 2002-12-23 | 2004-09-16 | Outokumpu Oy | Verfahren und Anlage zur Herstellung von Metalloxid aus Metallverbindungen |

| DE10260736A1 (de) * | 2002-12-23 | 2004-09-02 | Outokumpu Oyj | Verfahren und Anlage zur Wärmebehandlung von feinkörnigen Feststoffen |

| DE10260738A1 (de) | 2002-12-23 | 2004-07-15 | Outokumpu Oyj | Verfahren und Anlage zur Förderung von feinkörnigen Feststoffen |

| DE10260741A1 (de) * | 2002-12-23 | 2004-07-08 | Outokumpu Oyj | Verfahren und Anlage zur Wärmebehandlung von feinkörnigen Feststoffen |

| DE10260731B4 (de) | 2002-12-23 | 2005-04-14 | Outokumpu Oyj | Verfahren und Anlage zur Wärmebehandlung von eisenoxidhaltigen Feststoffen |

| DE10260737B4 (de) | 2002-12-23 | 2005-06-30 | Outokumpu Oyj | Verfahren und Anlage zur Wärmebehandlung von titanhaltigen Feststoffen |

| DE10260745A1 (de) * | 2002-12-23 | 2004-07-01 | Outokumpu Oyj | Verfahren und Anlage zur thermischen Behandlung von körnigen Feststoffen |

| DE102008061743B4 (de) | 2008-12-12 | 2014-12-04 | Outotec Oyj | Verfahren zur Herstellung eines hydraulisch wirkenden Produkts |

| CN105465775B (zh) * | 2016-01-01 | 2018-08-17 | 广州环峰能源科技股份有限公司 | 一种生物质高低差燃烧室 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2884303A (en) * | 1956-03-06 | 1959-04-28 | Exxon Research Engineering Co | High temperature burning of particulate carbonaceous solids |

| FR2198605A5 (en) * | 1972-09-01 | 1974-03-29 | Braun Angott Kg Maschine Anlag | Powder additive system for furnaces - metering magnesia powder flow rate by throttle valve in compressed air line |

| FR2410786A1 (fr) * | 1977-12-01 | 1979-06-29 | Dorr Oliver Inc | Procede et systeme d'incineration de matieres humides telles que des boues des eaux d'egout |

| GB1559953A (en) * | 1977-12-15 | 1980-01-30 | Kitchiner A G | Heat transfer apparatus |

| AU517419B2 (en) * | 1977-11-09 | 1981-07-30 | Energy Products Of Idaho | Fluidised bed incinerator |

| US4745884A (en) * | 1987-05-28 | 1988-05-24 | Riley Stoker Corporation | Fluidized bed steam generating system |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3900554A (en) * | 1973-03-16 | 1975-08-19 | Exxon Research Engineering Co | Method for the reduction of the concentration of no in combustion effluents using ammonia |

| DE3003245A1 (de) * | 1980-01-30 | 1981-11-12 | Deutsche Babcock Ag, 4200 Oberhausen | Verfahren und vorrichtung zum verbrennen von stoffen mit schwer ausbrennenden bestandteilen |

| CH662405A5 (de) * | 1984-04-11 | 1987-09-30 | Sulzer Ag | Wirbelbettfeuerung. |

| JPH07101088B2 (ja) * | 1986-01-22 | 1995-11-01 | 石川島播磨重工業株式会社 | 流動床炉の無触媒脱硝法 |

-

1988

- 1988-07-07 DE DE3822999A patent/DE3822999C1/de not_active Expired - Lifetime

-

1989

- 1989-06-02 DE DE8989109975T patent/DE58904316D1/de not_active Expired - Fee Related

- 1989-06-02 EP EP89109975A patent/EP0349764B1/fr not_active Expired - Lifetime

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2884303A (en) * | 1956-03-06 | 1959-04-28 | Exxon Research Engineering Co | High temperature burning of particulate carbonaceous solids |

| FR2198605A5 (en) * | 1972-09-01 | 1974-03-29 | Braun Angott Kg Maschine Anlag | Powder additive system for furnaces - metering magnesia powder flow rate by throttle valve in compressed air line |

| AU517419B2 (en) * | 1977-11-09 | 1981-07-30 | Energy Products Of Idaho | Fluidised bed incinerator |

| FR2410786A1 (fr) * | 1977-12-01 | 1979-06-29 | Dorr Oliver Inc | Procede et systeme d'incineration de matieres humides telles que des boues des eaux d'egout |

| GB1559953A (en) * | 1977-12-15 | 1980-01-30 | Kitchiner A G | Heat transfer apparatus |

| US4745884A (en) * | 1987-05-28 | 1988-05-24 | Riley Stoker Corporation | Fluidized bed steam generating system |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2001044719A1 (fr) * | 1999-12-16 | 2001-06-21 | Livite Oy | Procede brulage de materiau dans une chaudiere a lit fluidise et chaudiere a lit fluidise |

| CN100557308C (zh) * | 2007-12-21 | 2009-11-04 | 哈尔滨工业大学 | 壁面-中心复合供给二次风的流化床燃烧装置 |

| CN104132335A (zh) * | 2013-05-03 | 2014-11-05 | 国家电网公司 | 带有底部插入二次风管的循环流化床锅炉炉膛 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE58904316D1 (de) | 1993-06-17 |

| DE3822999C1 (fr) | 1990-01-04 |

| EP0349764A3 (fr) | 1991-01-30 |

| EP0349764B1 (fr) | 1993-05-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0349764B1 (fr) | Appareil de combustion à lit fluidisé | |

| DE2929056C2 (fr) | ||

| DE69730702T3 (de) | Vorrichtung und verfahren zur verbrennung von brennstoff | |

| DE2421452A1 (de) | Verfahren und vorrichtung zur verfeuerung von kohlenstaub | |

| EP0204176A2 (fr) | Chambre de combustion pour un appareil à combustion à lit fluidisé | |

| DE2612796C3 (de) | Vorrichtung zur Rauchgaskühlung in Abfallverbrennungsanlagen, insbesondere Müllverbrennungsanlagen ohne Wärmeverwertung | |

| DE3335537C1 (de) | Anlage fuer die Entlackung von metallischen und keramischen Gegenstaenden | |

| DE3335539C1 (de) | Anlage fuer die Entlackung von metallischen und keramischen Gegenstaenden | |

| EP0063173B1 (fr) | Four à lit fluidisé | |

| DE2745756B2 (de) | Verbrennungsofen | |

| DE3417445C2 (fr) | ||

| DE3109685A1 (de) | Vorrichtung zum nachverbrennen von brennbaren schwebebestandteilen aus den rauchgasen einer wirbelschichtfeuerung | |

| DE3705406A1 (de) | Feststoffvergasungsheizkessel | |

| DE4101704C1 (en) | Gasifier heating boiler - has combustion chamber with oxygen feed nozzle assembly and burner with back=up | |

| EP0386527B1 (fr) | Procédé et dispositif d'injection et de combustion de combustibles à teneur faible en résidus | |

| DE4106136C1 (en) | Converting granular ion-exchange resins into combustible gas - where resin in reactor passes by gravity through drying zone and then through low-temp. carbonisation zone | |

| DE3213394C2 (de) | Vergaser für die Erzeugung von brennbaren Gasen aus festen organischen Stoffen | |

| DE677148C (de) | Kohlenstaubfeuerung | |

| WO1984004953A1 (fr) | Procede pour la mise en action d'une chambre de combustion a mouvement tourbillonnant | |

| DE1141767B (de) | Raumheizofen für Abfallbrennstoff. | |

| DE2736493A1 (de) | Verfahren und vorrichtung zum verbrennen von kohle | |

| DE31347C (de) | Neuerung an Kesselfeuerungen zur Rauchverbrennung | |

| EP0489226A1 (fr) | Procédé et installation pour améliorer la combustion de la masse du lit pendant le chauffage du lit fluidisé | |

| EP0289932A1 (fr) | Procédé et installation de combustion de combustibles solides fluidisés | |

| WO1990006474A1 (fr) | Procede et dispositif pour traiter les cendres volantes carbonees contenues dans les gaz de combustion |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE GB SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE GB SE |

|

| 17P | Request for examination filed |

Effective date: 19910212 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: DEUTSCHE BABCOCK ENERGIE- UND UMWELTTECHNIK AKTIEN |

|

| 17Q | First examination report despatched |

Effective date: 19920210 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE GB SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19930512 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19930603 |

|

| REF | Corresponds to: |

Ref document number: 58904316 Country of ref document: DE Date of ref document: 19930617 |

|

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 19930512 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19940301 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 89109975.6 Effective date: 19940210 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |