EP0338192A2 - Dispositif de netoyage pour électrodes imprimantes - Google Patents

Dispositif de netoyage pour électrodes imprimantes Download PDFInfo

- Publication number

- EP0338192A2 EP0338192A2 EP89101430A EP89101430A EP0338192A2 EP 0338192 A2 EP0338192 A2 EP 0338192A2 EP 89101430 A EP89101430 A EP 89101430A EP 89101430 A EP89101430 A EP 89101430A EP 0338192 A2 EP0338192 A2 EP 0338192A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- cleaning

- cleaning device

- brushes

- electrode

- housing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F35/00—Cleaning arrangements or devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41P—INDEXING SCHEME RELATING TO PRINTING, LINING MACHINES, TYPEWRITERS, AND TO STAMPS

- B41P2235/00—Cleaning

- B41P2235/10—Cleaning characterised by the methods or devices

- B41P2235/20—Wiping devices

- B41P2235/23—Brushes

Definitions

- the present invention relates to a cleaning device for charging or discharging electrodes of printing presses and a method for cleaning such electrodes using the cleaning device.

- the charging electrodes In a conventional printing system for four-color printing, which contains eight printing units, for example, the charging electrodes must be cleaned at intervals of about 24 hours. Cleaning the electrodes is time consuming. In a printing system with eight printing units, a print interruption of about 2 hours is required.

- the object of the present invention is to provide a device and a method for cleaning such electrodes, with which the time-consuming cleaning process can be shortened and a pressure interruption is no longer necessary.

- the device according to the invention contains cleaning brushes which rotate about their axes in such a way that they abut the electrode to be cleaned in a rotating manner. Since organic solvents, such as toluene, are generally used as cleaning agents, it must be avoided that the cleaning device in any form can stop sparking.

- the cleaning brushes are therefore encapsulated in a solvent-tight housing, and the cleaning brushes are driven by compressed air motors.

- a separate compressed air motor can optionally be provided for each of the cleaning brushes, but several cleaning brushes can also be driven by the compressed air motors via gears.

- the air motors can be located outside or inside the housing.

- the cleaning device can be driven on the electrode either by the propulsion generated by the brushes, but it can also be done by ropes that move the cleaning device over the electrode by means of a suitable drive device.

- the following embodiment has proven to be particularly useful:

- All cleaning brushes rotate in the same direction as the electrode to be cleaned, that is to say that the sides of the brush surfaces facing the electrodes move in the same direction.

- the brush rotation provides the cleaning device with propulsion on the electrode, by means of which it is moved along the electrode.

- the housing of the cleaning device is connected to a brake cable, which is operatively connected to a braking device in such a way that a slight braking effect is produced compared to the driving force exerted by the brushes.

- the propulsion force exerted by the brushes results in the cleaning brushes slipping on the electrode as a result of the braking action by the brake cable, which leads to an increased cleaning action. Because of the slippage, the brushes have a greater tangential peripheral speed than the advancing speed at the electrode.

- the cleaning instructions direction during this forward operation has passed the entire electrode length, the braking effect acting on the brake cable is canceled and the cleaning device is pulled back into its starting position with the aid of the cable.

- the compressed air motors used to drive the brushes can be switched off, but they can also continue to run, so that the cleaning brushes have a rotation during reverse operation which is opposite in their direction to the backward movement. This can further increase the cleaning effect.

- the cleaning time for an electrode can be kept so short that it is possible to switch off the voltage on the electrode during the short cleaning process without interrupting the printing process. This enables the electrodes to be cleaned without interruption during the printing process.

- the housing of the cleaning device can contain a reservoir which holds at least as much cleaning agent as is required for an entire cleaning process.

- the reservoir can, for example, engage with idle coupling valves which fill the reservoir again with cleaning agents. Since it is essential to prevent detergent from dripping onto the paper webs passing under the electrode in order to avoid tearing of the paper webs, it is expedient to arrange the entire cleaning device in a solvent-tight housing. Furthermore, an additional separate collecting plate can be arranged below the cleaning device. The passage points of the electrode through the cleaning device can be sealed by additional sealing lips in order to prevent cleaning agents from dripping out of the device.

- the cleaning device according to the invention can be combined, for example, with an automatic device which measures the degree of contamination of the electrode and then initiates a cleaning cycle if necessary.

- the device can also be put into operation manually.

- the cleaning device can have ball race shells which engage with corresponding counter surfaces on the electrode during operation of the cleaning device.

- balls can be pressed into the edges in rigid edges on the electrode, which engage the ball race shells on the electrode and thus ensure reliable guidance of the cleaning device.

- the arrangement of the brushes within the cleaning device depends on the shape of the electrodes to be cleaned. Since the usual pressure electrodes have a U-shape, an arrangement is preferred in which two cleaning brushes are arranged rotatingly parallel to one another, while a third cleaning electrode is arranged at right angles to the first two so that the three cleaning brushes form the shape of an open U. With such an arrangement, it is expedient if the two parallel vertical brushes are each individually driven by a compressed air motor, while the perpendicular brush is driven by a gearbox that connects one or both of the vertical brushes with the third brush .

- the invention further relates to a method for cleaning electrodes for printing presses, which is characterized in that in a short time cleaning cycle, the cleaning brushes are guided over the electrode, the voltage being switched off during the cleaning cycle.

- the brushes can be guided over the electrode so that, for example, the brushes propel and clean in the forward mode, with a braking effect on the device, so that there is a slip on the brushes, while in reverse operation a train is exercised, which is opposite to the direction of the brush advance.

- the brushes can keep their old direction of rotation in reverse or take the direction of rotation caused by the reverse pull.

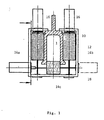

- the cleaning device 10 contains in a housing 12 two vertical cleaning brushes 14a, 14b which run parallel to one another and are driven by motors 16.

- a third cleaning brush 14c is arranged at right angles to the other two cleaning brushes 14a, 14b and is located in the lower part of the cleaning device. It is driven by a gear 18, but can also be driven by a laterally flange-mounted motor 16.

- the electrode 1, which in the present case has the shape of a U which is open at the bottom, is guided through the cleaning device in such a way that the two parallel brushes 14a, 14b clean the electrode laterally, while the lower horizontal brush 14c cleans the lower inner edge of the electrode .

- the front and back of the cleaning device is covered by a front wall 30 and a corresponding rear wall, respectively, which is shown in FIG. 2.

Landscapes

- Cleaning In General (AREA)

- Impression-Transfer Materials And Handling Thereof (AREA)

- Inking, Control Or Cleaning Of Printing Machines (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3813444 | 1988-04-21 | ||

| DE19883813444 DE3813444A1 (de) | 1988-04-21 | 1988-04-21 | Reinigungsvorrichtung fuer druckelektroden |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0338192A2 true EP0338192A2 (fr) | 1989-10-25 |

| EP0338192A3 EP0338192A3 (fr) | 1990-08-16 |

Family

ID=6352569

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89101430A Withdrawn EP0338192A3 (fr) | 1988-04-21 | 1989-01-27 | Dispositif de netoyage pour électrodes imprimantes |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0338192A3 (fr) |

| JP (1) | JPH0211381A (fr) |

| DE (1) | DE3813444A1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1190780A3 (fr) * | 2000-09-22 | 2003-05-07 | Klaus Lochbühler | Dispositif de nettoyage de broches à fumer |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009036909A (ja) | 2007-07-31 | 2009-02-19 | Sharp Corp | 表示システム |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1331984A (en) * | 1919-04-05 | 1920-02-24 | Fiorentini Herman | Plate-cleaning machine |

| US2872693A (en) * | 1956-04-27 | 1959-02-10 | Western Electric Co | Apparatus for cleaning relays |

| US3460475A (en) * | 1967-05-25 | 1969-08-12 | Cutler Hammer Inc | Apparatus for returning ink mist back to its source |

| FR2254187A5 (en) * | 1973-11-07 | 1975-07-04 | Kempf Henri | Fire hose cleaning device for re-use of hose - has split housing containing rotary brushes supplied with wash water |

| US3903561A (en) * | 1974-08-19 | 1975-09-09 | Anaconda Co | Cleansing apparatus |

| JPS567479Y2 (fr) * | 1974-10-14 | 1981-02-18 | ||

| US4326316A (en) * | 1980-10-06 | 1982-04-27 | Dolenti Alfred N | Hot stick rotary brush for cleaning aerial conductors |

| BG41700A1 (en) * | 1985-01-31 | 1987-08-14 | Petkov | Device for hydromechanical cleansing and polishing |

| FR2589089B3 (fr) * | 1985-10-25 | 1987-10-30 | Bertholet Louis | Appareil pour le nettoyage des tuiles |

-

1988

- 1988-04-21 DE DE19883813444 patent/DE3813444A1/de not_active Ceased

-

1989

- 1989-01-27 EP EP89101430A patent/EP0338192A3/fr not_active Withdrawn

- 1989-04-10 JP JP1091693A patent/JPH0211381A/ja active Pending

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1190780A3 (fr) * | 2000-09-22 | 2003-05-07 | Klaus Lochbühler | Dispositif de nettoyage de broches à fumer |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3813444A1 (de) | 1989-11-02 |

| JPH0211381A (ja) | 1990-01-16 |

| EP0338192A3 (fr) | 1990-08-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CH652905A5 (de) | Geraet zur reinigung von textilen flaechen. | |

| DE2947994A1 (de) | Elektrobuerste fuer staubsauger | |

| DE3512190A1 (de) | Mittels elektromotor angetriebenes schleif- oder buerstgeraet | |

| DE4426079A1 (de) | Gerät zur Reinigung von Walzen | |

| DE4437763C2 (de) | Verfahren zur Reinigung von Rolltreppenstufen und Vorrichtung zur Durchführung des Verfahrens | |

| EP0639530A1 (fr) | Dispositif pour séparer mécaniquement des capuchons à vis de bouteilles | |

| EP0338192A2 (fr) | Dispositif de netoyage pour électrodes imprimantes | |

| DE10348828A1 (de) | Antrieb für eine Druckmaschine | |

| DE29909258U1 (de) | Waschvorrichtung für Autofußmatten aus vorzugsweise gummiartigem Material | |

| DE2659258A1 (de) | Schmiervorrichtung | |

| DE69814569T2 (de) | Vorrichtung zur Absaugung und Sammlung der Abgase eines Fahrzeuges | |

| EP1140506B1 (fr) | Dispositif pour nettoyer un cylindre | |

| DE102019212570B3 (de) | Kettenantrieb zur Bodenreinigung und Fortbewegung eines Reinigungsroboters, Reinigungsroboter, Reinigungs- und Antriebskette für einen Kettenantrieb und Verfahren zum Betreiben eines Reinigungsroboters mit einem Kettenantrieb | |

| DE4407503C1 (de) | Videoband-Reinigungsvorrichtung | |

| EP0616504A1 (fr) | Machine a nettoyer les sols. | |

| DE29518431U1 (de) | Vorrichtung zu Reinigung von Rolltreppenstufen | |

| EP0320048B1 (fr) | Machine de bureau munie d'une cassette à papier | |

| EP1049400A1 (fr) | Appareil combine de nettoyage et d'aspiration a haute pression | |

| EP1601533A1 (fr) | Dispositif de nettoyage pour cylindres d'impression | |

| EP1238803B1 (fr) | Dispositif et procédé permettant de nettoyer un rouleau | |

| DE3145946A1 (de) | "maschine zum behandeln von wandoberflaechen" | |

| DE102012018895A1 (de) | Reinigungsvorrichtung | |

| DE19928065A1 (de) | Fahrbare Bodenreinigungsmaschine | |

| DE29618216U1 (de) | Reinigungsvorrichtung für Schuhwerk | |

| CH512696A (de) | Olnebelschutz an Werkzeugmaschinen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): BE DE FR GB LU NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): BE DE FR GB LU NL |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19910219 |