EP0336093A1 - Verfahren zum Absenken des Grundwasserspiegels sowie Anordnung hierfür - Google Patents

Verfahren zum Absenken des Grundwasserspiegels sowie Anordnung hierfür Download PDFInfo

- Publication number

- EP0336093A1 EP0336093A1 EP89103062A EP89103062A EP0336093A1 EP 0336093 A1 EP0336093 A1 EP 0336093A1 EP 89103062 A EP89103062 A EP 89103062A EP 89103062 A EP89103062 A EP 89103062A EP 0336093 A1 EP0336093 A1 EP 0336093A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- standpipe

- drainage

- pump

- drainage line

- excavator

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D19/00—Keeping dry foundation sites or other areas in the ground

- E02D19/06—Restraining of underground water

- E02D19/10—Restraining of underground water by lowering level of ground water

Definitions

- the invention relates to a method for lowering the groundwater level in the ground, in which at least one drainage line is laid in the ground and from this the water collecting therein is drawn off and pressed up to the surface by means of a standpipe using a pump.

- the invention further relates to an arrangement for performing this method.

- the invention has for its object to further develop the generic method so that drainage of the soil can be carried out even at greater depths, for example at a depth of 10 m.

- the object is achieved in that the standpipe and drainage line are exposed to a vacuum and that the water is collected in a pump sump.

- An arrangement for carrying out this method is the subject of claim 3. If the floor above the drainage pipe is very permeable, it is expedient that the floor above the drainage pipe is covered with a sealing layer.

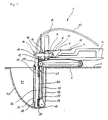

- the trench excavator (1) shown in side view in FIG. 1 is designed as a slow-moving tracked vehicle. He is standing on the floor (3) with his chain chassis (2). It has a housing (4) in which the motor for driving the chain chassis (2) is encapsulated.

- a fixed strut (5) is provided to the left of the housing (4). In the lower area, it has a horizontal pivot bearing (6) which runs transversely to the direction of travel of the trench excavator (1) and on which a guide housing (8) is pivotably mounted via a bracket (7).

- a hydraulic cylinder (9) is provided for the pivoting, the cylinder (10) of which is pivotable at the upper end of the strut (5) and the piston rod (11) of which is pivotably articulated on the guide housing (8).

- Guide plates (12) are fastened to the guide housing (8), between which an excavator mast (13) designed as a double-T support is slidably mounted.

- a chain wheel (14, 15) is rotatably mounted at the upper and lower ends of the excavator mast (13).

- the upper chain wheel (14) is driven by the motor of the trench excavator (1) via a chain drive (16) which is encapsulated in chain protection housings (17, 18) which are articulated to one another so that the chain drive (16) vertical movements of the excavator boom ( 13) can participate.

- the excavator mast (13) has cover disks on both sides of the chain wheel (15).

- a digging shovel (20) runs around both sprockets (14, 15), which is indicated in FIG. (1) by a dash-dotted line. This digging shovel consists of a plurality of digging buckets (21) (FIG. 2) arranged one behind the other, which run upwards on the right run and downwards on the left run.

- Guide brackets (22, 23) are attached to the excavator mast (13), the free ends of which are provided with T-shaped grooves.

- T-shaped guide rails (24, 25) engage in these guide grooves and are fastened to a guide shaft (26).

- the guide shaft (26) is displaceably mounted in relation to the excavator mast (13), namely parallel to its longitudinal extent.

- the guide shaft (26) is open on the underside and has a filling funnel (27) on the top.

- a guide tube (28) (FIG. 2) runs through this filling funnel (27) and the guide shaft (26), which ends horizontally to the left in a guide bend (29).

- a drainage hose is through the guide tube (28) (30) directed, which is subtracted from a role not shown here.

- a holding rail (31) On the free side of the guide shaft (26) there is a holding rail (31) in which a standpipe (32) is held.

- the standpipe (32) is provided at the lower end with a pump sump (33).

- a connection piece (34) Above this pump sump (33) there is a connection piece (34) in the direction of the mouth of the guide tube (28). The lower end of the drainage hose (30) is placed over this connecting piece (34) and connected to it.

- An immersion pump (35) is arranged in the lower end of the standpipe (31). It has a maximum output of 0.3 m3 / min. at a head of 15 m.

- the submersible pump (35) is connected to a pressure pipe (36) leading upwards, which is led out through a sealing plug (37) at the upper end of the standpipe (32).

- the sealing plug (37) also provides a shortened electrical line (38) for the electrical supply to the submersible pump (35) and a pipe socket (39). This pipe socket (39) is connected to a vacuum pump, not shown. Otherwise, the sealing plug (37) is tight, so that a vacuum can be generated in the standpipe (32) and the connected drainage hose (30) with the aid of the vacuum pump.

- the burying of the drainage hose (30) and the standpipe (32) takes place as described in DE-OS 23 40 565.

- the guide housing (8) and thus also the excavator mast (13) with guide shaft (26) are in a horizontal position, that is above the level of the ground (3).

- the free end of the drainage hose (30) is then inserted into the guide tube (28) until it looks out of the end of the guide bend (29). There it can be connected to the socket (34) of the standpipe (32).

- the standpipe (32) is then attached to the holding rail (31).

- the digging shovel (20) is then started to dig in.

- the excavator mast (13) is shifted relative to the guide housing (8) in such a way that the upper sprocket (14) is located approximately at the free end of the guide housing (8), that is to say in a position opposite to that shown in FIG. (1).

- the guide shaft (26) is also displaced in the same direction with respect to the excavator mast (13).

- the guide housing (8) With the digging shovel mechanism (20) running, the guide housing (8) is now pivoted counterclockwise, so that the excavator mast (13) slowly digs into the ground (3).

- the excavator mast (13) is continuously extended, ie moved relative to the guide housing (8).

- the slot trench (41) shown in FIG. 1 is formed.

- the excavator mast (13) has reached its lowest position relative to the guide housing (8).

- the trench excavator (1) is then moved a bit in the direction of arrow A, that is to the right, the digging shovel (20) decreasing with the upward run of the soil from the end face (42) of the trench (41). In this way, space is created for lowering the guide shaft (26) into the position shown.

- the standpipe (32) is then detached from the holding rail (31) and temporarily secured until the slot trench (41) is refilled.

- the actual laying process can begin by slowly moving the trench excavator in the direction of arrow A.

- the slot trench (41) is then continued by continuous removal of soil at the end face (42).

- the drainage hose (30) is continuously guided downwards through the guide tube (28) and exits there at the depth specified by the guide bend (29), in accordance with the continuously increasing distance from the standpipe (32).

- gravel (43) or other loose and loose filter material is supplied via the hopper (27) and the guide shaft (26), so that the drainage hose (30) is covered immediately.

- the feed can be done so that the slot trench (41) is filled up to the top again.

- the drainage can be carried out.

- a vacuum is generated in the standpipe (32) and thus also in the connected drainage hose (30) by means of the vacuum pump, which supports the collection of the water in the drainage hose (30) provided with corresponding openings and its feeding into the pump sump (33).

- the water collecting there is sucked in by the submersible pump (35) and pumped up through the pressure pipe (36). It can then be continued.

- the slot trench (41) is provided on the top side with a largely air-impermeable sealing layer (44).

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Hydrology & Water Resources (AREA)

- Environmental & Geological Engineering (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Mining & Mineral Resources (AREA)

- Paleontology (AREA)

- Civil Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Earth Drilling (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19883811705 DE3811705C1 (sv) | 1988-04-08 | 1988-04-08 | |

| DE3811705 | 1988-04-08 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0336093A1 true EP0336093A1 (de) | 1989-10-11 |

Family

ID=6351570

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89103062A Withdrawn EP0336093A1 (de) | 1988-04-08 | 1989-02-22 | Verfahren zum Absenken des Grundwasserspiegels sowie Anordnung hierfür |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0336093A1 (sv) |

| DE (1) | DE3811705C1 (sv) |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2064668A1 (de) * | 1970-12-31 | 1972-07-13 | Hochtief AG für Hoch- und Tiefbauten vorm. Gebr. Helfmann, 4300 Essen | Anordnung zur Grundwasserabsenkung |

| DE2732281A1 (de) * | 1977-07-16 | 1979-01-18 | Gkn Keller Gmbh | Brunnenausbildung fuer die entwaesserung von mehreren bodenschichten |

| BE880231A (nl) * | 1979-11-23 | 1980-03-17 | Camar P V B A | Werkwijze en inrichting voor het neerslagen van de waterspiegel in grondlagen met verschillende structuren en waterhuishouding bij middel van een samengestelde bron |

| US4260334A (en) * | 1976-02-11 | 1981-04-07 | Kelley Contract Dewatering Company | Ground dewatering system |

| JPS5813819A (ja) * | 1981-07-19 | 1983-01-26 | Kato Seisakusho:Kk | 地下水位低下工法 |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL148366B (nl) * | 1972-08-11 | 1976-01-15 | Steenbergen A H Bv | Werkwijze voor het aanbrengen van een horizontale bronneringsinstallatie, aldus aangebrachte bronneringsinstallatie en inrichting voor het uitvoeren van die werkwijze. |

-

1988

- 1988-04-08 DE DE19883811705 patent/DE3811705C1/de not_active Expired

-

1989

- 1989-02-22 EP EP89103062A patent/EP0336093A1/de not_active Withdrawn

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2064668A1 (de) * | 1970-12-31 | 1972-07-13 | Hochtief AG für Hoch- und Tiefbauten vorm. Gebr. Helfmann, 4300 Essen | Anordnung zur Grundwasserabsenkung |

| US4260334A (en) * | 1976-02-11 | 1981-04-07 | Kelley Contract Dewatering Company | Ground dewatering system |

| DE2732281A1 (de) * | 1977-07-16 | 1979-01-18 | Gkn Keller Gmbh | Brunnenausbildung fuer die entwaesserung von mehreren bodenschichten |

| BE880231A (nl) * | 1979-11-23 | 1980-03-17 | Camar P V B A | Werkwijze en inrichting voor het neerslagen van de waterspiegel in grondlagen met verschillende structuren en waterhuishouding bij middel van een samengestelde bron |

| JPS5813819A (ja) * | 1981-07-19 | 1983-01-26 | Kato Seisakusho:Kk | 地下水位低下工法 |

Non-Patent Citations (1)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN, Band 7, Nr. 89 (M-207)[1234], 13. April 1983; & JP-A-58 13 819 (KATOU SEISAKUSHO K.K.) 26-01-1983 * |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3811705C1 (sv) | 1989-07-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE1902137A1 (de) | Verfahren und Vorrichtung zum Anlegen von Draenage-Dichtungsschuerzen im Boden | |

| DE2815673A1 (de) | Geraet zum unterseeischen verlegen von leitungen | |

| DE3724251C2 (sv) | ||

| DE3439858C2 (sv) | ||

| WO2021069154A1 (de) | Unterwasser-abtragsvorrichtung und verfahren zum abtragen von bodenmaterial unter wasser | |

| DE19514052A1 (de) | Ausgrabungsverfahren und Vorrichtung zur Durchführung desselben | |

| DE3811705C1 (sv) | ||

| DE102017004302B3 (de) | Kabelverlegemaschine | |

| DE60118417T2 (de) | Verfahren und vorrichtung zur bodenverfestigung | |

| EP0206371B1 (de) | Schneidkopf für den Vortrieb vorgefertigter Betonrohre zur Herstellung von Stollen oder Tunneln | |

| DE2153468A1 (de) | Zweiteiliger ausleger fuer einen hydraulisch angetriebenen erdbagger | |

| DE10337977B3 (de) | Vorrichtung zum Erstellen einer Ausschachtung und zum Verlegen eines Kabelkanals entlang von Gleisen | |

| EP0103706A1 (de) | Verbaukorb zum Verbau eines Kanalgrabens | |

| DE7602174U1 (de) | Grabenreiniger | |

| EP0225963B1 (de) | Vorrichtung zum Einbringen einer wasserundurchlässigen Schicht ins Erdreich | |

| DE2340565C2 (de) | Verfahren zum Verlegen eines im wesentlichen horizontalen Dränagesystems und Grabenbagger zur Durchführung des Verfahrens | |

| DE3735679A1 (de) | Anordnung zum anheben des grundwasserspiegels, verfahren zur herstellung der anordnung und vorrichtung zur durchfuehrung dieses verfahrens | |

| DE29811653U1 (de) | Vorrichtung zur Aufnahme oder Ablage von Sedimenten von oder auf einem Gewässerboden | |

| DE2058336A1 (de) | Einrichtung zum Verlegen von Rohren,Kanalteilen u.dgl. in das Erdreich | |

| DE2538011A1 (de) | Maschine zur ausbildung von graeben fuer leitungen im meeresgrund | |

| DE2436060A1 (de) | Pumpvorrichtung | |

| DE10212296A1 (de) | Unbemannter Schwimmbagger zum Fördern eines Sand oder Kies und Wasser aufweisenden Fördergutes aus einem See an Land | |

| DE19931839C1 (de) | Rohrvorpresseinrichtung | |

| DE3710284C2 (de) | Vorrichtung und Verfahren zum Abtragen von Erdreich | |

| EP4198204A1 (de) | Fräsvorrichtung und verfahren zum fräsen von boden |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE DE FR GB NL |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19900412 |