EP0284784A2 - Ensemble de filage pour des fibres à deux composants avec une structure âme-gaine - Google Patents

Ensemble de filage pour des fibres à deux composants avec une structure âme-gaine Download PDFInfo

- Publication number

- EP0284784A2 EP0284784A2 EP88102885A EP88102885A EP0284784A2 EP 0284784 A2 EP0284784 A2 EP 0284784A2 EP 88102885 A EP88102885 A EP 88102885A EP 88102885 A EP88102885 A EP 88102885A EP 0284784 A2 EP0284784 A2 EP 0284784A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- nozzle

- plate

- intermediate plate

- nozzles

- nozzle plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01D—MECHANICAL METHODS OR APPARATUS IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS

- D01D5/00—Formation of filaments, threads, or the like

- D01D5/28—Formation of filaments, threads, or the like while mixing different spinning solutions or melts during the spinning operation; Spinnerette packs therefor

- D01D5/30—Conjugate filaments; Spinnerette packs therefor

- D01D5/34—Core-skin structure; Spinnerette packs therefor

Definitions

- Synthetic bicomponent threads with a core-sheath structure are produced in order to combine the advantageous properties of different components.

- a polymer with high strength and low elongation as the core, and as a sheath a polymer that gives the thread good dyeability or a pleasant feel.

- a defined thread structure is required, in which the jacket coaxially envelops the core in a constant thickness. This requirement can be easily met with complicated nozzle arrangements.

- mass production however, it is necessary to accommodate a large number of suitable nozzles in a very small space. This creates considerable technical difficulties.

- DE-OS 20 04 431 describes a nozzle package, the nozzle plate of which has six nozzles which are arranged on the corners of a regular hexagon.

- the intermediate plate is provided with six spinning inserts, each of which protrudes with a projecting conical part into the inlet funnel of the nozzles.

- the spinning inserts have axial bores for the supply of the core component, which are essentially aligned with the nozzles.

- the intermediate plate has an axial feed line for the jacket component, which is connected to the inlet funnels of the nozzles by a channel system. Due to the design principle, this nozzle package is limited to a small number of nozzles which are arranged at large mutual distances.

- Another nozzle package with a large number of closely arranged nozzles is the subject of EP-A2-0 128 013.

- two separate, nested channel systems are accommodated on the top of the intermediate plate, each of which consists of a number of grooves.

- Each groove has a series of holes at the bottom of the groove, so that a system of holes is assigned to each channel system.

- the holes of one system are aligned with the nozzles and serve to feed the core component.

- the holes in the other system are arranged so that each hole in the first system is surrounded by several holes in the other system.

- Through holes in a third plate the one channel system of the intermediate plate is connected to a feed chamber for the core component, the other channel system is connected to a feed chamber for the jacket component.

- the inflow conditions are the same for all nozzles, but the supply of the jacket component does not guarantee an exactly concentric thread structure.

- the height of the nozzle package is relatively high because of the additional third plate required.

- the invention has for its object to provide a nozzle package according to the preamble of claim 1, which enables the production of numerous bicomponent threads with a uniform coaxial structure in a confined space and is easy to manufacture and has a low overall height.

- the two polymer components are kept separate in the space between the nozzle plate and the intermediate plate and are fed to the individual nozzles in precisely guided, separate streams.

- This advantage which was previously only achievable with individual nozzles or with complicated arrangements of a few nozzles, is realized by the invention in a nozzle package in which many hundreds or even a few thousand nozzles can be installed in a very small space.

- the nozzle package consists of a few components that are produced by simple milling and drilling.

- the feature of claim 2 has extraordinary manufacturing advantages.

- the feature of claim 3 has the advantage that the channels are short, so that the pressure drop is kept low.

- the nozzle package essentially consists of three superimposed parts which are firmly connected by screws, namely a nozzle plate 1, an intermediate plate 2 and a hood 3. Seals are inserted between the individual parts.

- the nozzle package has the shape of a rectangle, the length of which is approximately four times the width.

- Two functionally separate systems 4, 5 are accommodated in the nozzle package. Since one system is completely the same as the other, it is sufficient to describe only one of the two systems.

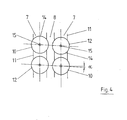

- the nozzle plate 1 has the shape of a rectangular flat bowl with a raised edge. It is divided in the middle into two compartments by a transverse dividing wall 6, the upper edge of which lies in the same plane as the upper edge of the edge, one of which belongs to the system 4 and the other to the system 5. In each compartment, the bottom surface is provided with longitudinal, parallel grooves 7, between which narrow webs 8 have remained. The grooves 7 are interrupted in the middle of the compartment by a transverse wide threshold 9, the height of which corresponds to the height of the webs 8.

- Each groove 7 has mirror-symmetrical extensions 10, which are segment-like in plan view, at equal intervals on both sides.

- the side walls of the groove 7 therefore consist alternately of flat and cylindrical shell-shaped wall sections 11, 12.

- the groove base is provided with a series of nozzles 13, the axes of which the axes of curvature of the cylindrical shell-shaped wall sections 12 coincide.

- Each nozzle 13 consists of an inlet funnel 14, the mouth radius of which corresponds to the radius of curvature of the cylindrical shell-shaped wall sections 12, and a capillary bore 15.

- the nozzles 13 of two adjacent grooves 7 are arranged offset to one another, i.e. their axes lie in a top view on the corners of an oblique grid; this can be seen in FIGS. 4 and 6, in which the deviation of the cutting angle from a right angle is designated by ⁇ .

- the intermediate plate 2 has longitudinal slats 16 on the underside, the lower parts of which penetrate into the grooves 7 of the nozzle plate 1 as far as the bottom of the groove.

- the width of a lamella is approximately equal to the distance between two opposite flat wall sections 11 of the groove wall, so that the lamella 16 is seated in the groove 7 without any significant play.

- the cross section of the intermediate plate 2 which can be seen best in FIG. 3, resembles a comb.

- Each lamella 16 is provided with a series of vertical bores 17 so that each bore 17 is aligned with a nozzle 13.

- the bores 17 - as can best be seen from FIG. 5 - have a much larger diameter than the capillary bores 15 over most of their length. They are narrowed like a capillary only on a short piece near the lower end. At the upper end, each hole is chamfered at the edge ( Figure 3).

- a filter screen 18 covers the entire surface of the intermediate plate 2 provided with bores 17.

- the slats 16 are interrupted by a transverse, continuous distribution channel 19, the width of which corresponds to the width of the threshold 9.

- Rectangular channels 20 are located between the slats 16 above the level up to which the webs 8 extend.

- the upper boundary surfaces 21 of the channels 20 lie in a slightly inclined plane, so that the height, which is immediately next to the distribution channel 19 with the height of the distribution channel 19 coincides, decreases in the direction of the edge or in the direction of the partition 6.

- the channels 20 are in open connection with the distribution channel 19.

- the hood 3 consists of a thick metal plate, from which two vault-shaped chambers 22 are worked out on the underside. These correspond to the two compartments of the nozzle plate 1.

- a bore 23 opens into each of the two chambers 22 and penetrates the chamber ceiling.

- a pipe section 24 sits in a second bore, which passes through the chamber 22, penetrates the intermediate plate 2 and opens into the distribution channel 19 from above.

- the core component is fed by means of a spinning pump through a pipe connected to the bore 23 and fills the chamber 22. It is pressed through the bores 17 and arrives in the form of thread-like streams in the inlet funnel 14. Because the bores 17 on the largest part their length has a relatively large diameter, the flow resistance is low.

- the jacket component is also pressed by means of a spinning pump via the pipe 24 into the distribution channel 19 and distributed to the channels 20 on both sides.

- the extensions 10 form passages that the jacket component perpendicular steer downward into the inlet funnel 14, where it surrounds the thread-like streams of the core component emerging from the bores 17.

- a thin, coaxial layer of the cladding component is carried away by the core component due to the injector action.

- the emerging threads are cooled in the usual way by an air stream; the offset arrangement of the nozzles 13 prevents the individual threads from lying in the slipstream.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Textile Engineering (AREA)

- Spinning Methods And Devices For Manufacturing Artificial Fibers (AREA)

- Multicomponent Fibers (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT88102885T ATE69470T1 (de) | 1987-04-01 | 1988-02-26 | Duesenpaket zum spinnen von bikomponentenfaeden mit kern-mantel-struktur. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19873710946 DE3710946A1 (de) | 1987-04-01 | 1987-04-01 | Duesenpaket zum spinnen von bikomponentenfaeden mit kern-mantel-struktur |

| DE3710946 | 1987-04-01 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0284784A2 true EP0284784A2 (fr) | 1988-10-05 |

| EP0284784A3 EP0284784A3 (en) | 1989-11-29 |

| EP0284784B1 EP0284784B1 (fr) | 1991-11-13 |

Family

ID=6324617

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP88102885A Expired - Lifetime EP0284784B1 (fr) | 1987-04-01 | 1988-02-26 | Ensemble de filage pour des fibres à deux composants avec une structure âme-gaine |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4846653A (fr) |

| EP (1) | EP0284784B1 (fr) |

| JP (1) | JPS63256709A (fr) |

| AT (1) | ATE69470T1 (fr) |

| DE (2) | DE3710946A1 (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0995822A1 (fr) * | 1998-10-19 | 2000-04-26 | Rosaldo Faré | Dispositif et procédé pour la fabrication de fibres continues à deux composants utilisant des conduits flexibles |

| DE102019004890A1 (de) * | 2019-07-11 | 2021-01-14 | Rheinisch-Westfälische Technische Hochschule (Rwth) Aachen | Textilfaser, Textil und Verfahren zur Herstellung einer Textilfaser |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3941824A1 (de) * | 1989-12-19 | 1991-06-27 | Corovin Gmbh | Verfahren und spinnvorrichtung zur herstellung von mikrofilamenten |

| IT1255891B (it) * | 1992-10-19 | 1995-11-17 | Testa di estrusione per filati bicomponenti con filiera ad alta densita' di fori | |

| US6402841B1 (en) * | 1997-02-21 | 2002-06-11 | Akzo Nobel N.V. | Glue application device with glue conduit surrounding hardener conduit |

| US5853635A (en) * | 1997-06-18 | 1998-12-29 | Kimberly-Clark Worldwide, Inc. | Method of making heteroconstituent and layered nonwoven materials |

| DE19750723C1 (de) * | 1997-11-15 | 1999-10-07 | Reifenhaeuser Masch | Vorrichtung zum Herstellen eines Spinnvlieses aus Bikomponentenfäden |

| DE19750724C2 (de) * | 1997-11-15 | 2003-04-30 | Reifenhaeuser Masch | Vorrichtung zum Herstellen eines Spinnvlieses aus Kern-Mantel-Struktur aufweisenden Bikomponentenfäden |

| US6168409B1 (en) * | 1998-11-13 | 2001-01-02 | Rosaldo Fare | Apparatus for making two component fibers or continuous filaments using flexible tube inserts |

| US6413071B1 (en) | 2000-03-27 | 2002-07-02 | Basf Corporation | Thin plate spinnerette assembly |

| US6474967B1 (en) | 2000-05-18 | 2002-11-05 | Kimberly-Clark Worldwide, Inc. | Breaker plate assembly for producing bicomponent fibers in a meltblown apparatus |

| US6461133B1 (en) | 2000-05-18 | 2002-10-08 | Kimberly-Clark Worldwide, Inc. | Breaker plate assembly for producing bicomponent fibers in a meltblown apparatus |

| DE10037906A1 (de) * | 2000-08-03 | 2002-02-14 | Hdw Isoliertechnik Gmbh | Vielkammerprofile sowie Vorrichtung und Verfahren zur Herstellung derselben |

| US7014442B2 (en) * | 2002-12-31 | 2006-03-21 | Kimberly-Clark Worldwide, Inc. | Melt spinning extrusion head system |

| CN109592897B (zh) * | 2019-01-16 | 2024-01-30 | 河南光远新材料股份有限公司 | 一种电子纱拉丝设备的漏板 |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1435559A1 (de) * | 1962-06-25 | 1970-02-12 | Monsanto Co | Spinnduese |

| DE1435527B1 (de) * | 1963-12-07 | 1970-06-04 | Kanegafuchi Spinning Co Ltd | Verfahren zur Herstellung kraeuselbarer Verbundfaeden |

| US3526571A (en) * | 1965-12-01 | 1970-09-01 | Kanebo Ltd | Highly shrinkable polyamide fibres |

| DE2004431A1 (en) * | 1970-01-31 | 1971-08-05 | Deutsche Gold- Und Silber-Scheideanstalt Vormals Roessler, 6000 Frankfurt | Compound filament spinning orifice |

| DE1760216A1 (de) * | 1967-04-18 | 1971-12-02 | Du Pont | Verfahren zur Herstellung von Mantel-Kern-Faeden |

| DE1660702A1 (de) * | 1967-10-14 | 1972-03-09 | Schwarza Chemiefaser | Duesenplatte zum Herstellen von Mehrkomponentenfaeden und -fasern |

| DE1660513A1 (de) * | 1964-06-19 | 1972-03-23 | Snia Viscosa Societa Naz Ind A | Verfahren zur Herstellung von kraeuselbaren synthetischen Faeden |

| EP0128013A2 (fr) * | 1983-06-01 | 1984-12-12 | Chisso Corporation | Appareil pour le filage |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL126668C (fr) * | 1957-12-14 | |||

| US3531368A (en) * | 1966-01-07 | 1970-09-29 | Toray Industries | Synthetic filaments and the like |

| CH486570A (de) * | 1966-09-21 | 1970-02-28 | Inventa Ag | Vorrichtung zur Herstellung von aus mindestens zwei verschiedenen Polymeren bestehenden Verbundfäden |

| US3559327A (en) * | 1968-12-02 | 1971-02-02 | Bernard A Christopher | Fish warning device |

| US3807918A (en) * | 1971-02-12 | 1974-04-30 | Chevron Res | Extrusion die for forming a multicomponent continuous film of thermoplastic polymer |

| JPS5115124B1 (fr) * | 1971-05-04 | 1976-05-14 | ||

| DE2534724C3 (de) * | 1975-08-04 | 1981-08-13 | Dynamit Nobel Ag, 5210 Troisdorf | Vorrichtung zum Extrudieren von gemusterten Bahnen oder Platten aus thermoplastischen Kunststoffmassen |

| JPS5674074U (fr) * | 1979-11-12 | 1981-06-17 | ||

| US4406850A (en) * | 1981-09-24 | 1983-09-27 | Hills Research & Development, Inc. | Spin pack and method for producing conjugate fibers |

| JPS58110073U (ja) * | 1982-01-20 | 1983-07-27 | 日本エステル株式会社 | 同心型芯鞘状複合繊維紡糸用口金 |

-

1987

- 1987-04-01 DE DE19873710946 patent/DE3710946A1/de not_active Withdrawn

-

1988

- 1988-02-24 US US07/159,835 patent/US4846653A/en not_active Expired - Fee Related

- 1988-02-26 AT AT88102885T patent/ATE69470T1/de not_active IP Right Cessation

- 1988-02-26 DE DE8888102885T patent/DE3866145D1/de not_active Expired - Fee Related

- 1988-02-26 EP EP88102885A patent/EP0284784B1/fr not_active Expired - Lifetime

- 1988-03-30 JP JP63077945A patent/JPS63256709A/ja active Granted

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1435559A1 (de) * | 1962-06-25 | 1970-02-12 | Monsanto Co | Spinnduese |

| DE1435527B1 (de) * | 1963-12-07 | 1970-06-04 | Kanegafuchi Spinning Co Ltd | Verfahren zur Herstellung kraeuselbarer Verbundfaeden |

| DE1660513A1 (de) * | 1964-06-19 | 1972-03-23 | Snia Viscosa Societa Naz Ind A | Verfahren zur Herstellung von kraeuselbaren synthetischen Faeden |

| US3526571A (en) * | 1965-12-01 | 1970-09-01 | Kanebo Ltd | Highly shrinkable polyamide fibres |

| DE1760216A1 (de) * | 1967-04-18 | 1971-12-02 | Du Pont | Verfahren zur Herstellung von Mantel-Kern-Faeden |

| DE1660702A1 (de) * | 1967-10-14 | 1972-03-09 | Schwarza Chemiefaser | Duesenplatte zum Herstellen von Mehrkomponentenfaeden und -fasern |

| DE2004431A1 (en) * | 1970-01-31 | 1971-08-05 | Deutsche Gold- Und Silber-Scheideanstalt Vormals Roessler, 6000 Frankfurt | Compound filament spinning orifice |

| EP0128013A2 (fr) * | 1983-06-01 | 1984-12-12 | Chisso Corporation | Appareil pour le filage |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0995822A1 (fr) * | 1998-10-19 | 2000-04-26 | Rosaldo Faré | Dispositif et procédé pour la fabrication de fibres continues à deux composants utilisant des conduits flexibles |

| DE102019004890A1 (de) * | 2019-07-11 | 2021-01-14 | Rheinisch-Westfälische Technische Hochschule (Rwth) Aachen | Textilfaser, Textil und Verfahren zur Herstellung einer Textilfaser |

Also Published As

| Publication number | Publication date |

|---|---|

| JPH0347324B2 (fr) | 1991-07-19 |

| DE3866145D1 (de) | 1991-12-19 |

| EP0284784A3 (en) | 1989-11-29 |

| ATE69470T1 (de) | 1991-11-15 |

| JPS63256709A (ja) | 1988-10-24 |

| EP0284784B1 (fr) | 1991-11-13 |

| DE3710946A1 (de) | 1988-10-13 |

| US4846653A (en) | 1989-07-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0284784B1 (fr) | Ensemble de filage pour des fibres à deux composants avec une structure âme-gaine | |

| DE69425537T2 (de) | Schmelzblasdüse | |

| DE3685730T2 (de) | Spinnvorrichtung zum spinnen von verbundfaeden. | |

| EP0742851A1 (fr) | Collecteur-repartiteur permettant de filer une pluralite de fils synthetiques et installations de filage pourvues de ce type de collecteur-repartiteur | |

| DE2229881A1 (de) | Vorrichtung zur Herstellung von Kern/ Hülle-Kompositfäden | |

| DE2752736A1 (de) | Spinnduesenpaket fuer mantelfasern | |

| DE1435369B2 (de) | Spinnduese zur herstellung von verbundfaeden | |

| EP0770469B1 (fr) | Tête d'extrusion pour la fabrication de préformes tubulaires, fabriquées à partir de matière plastique extrudable | |

| WO2003063240A2 (fr) | Dispositif de refroidissement | |

| WO2009112082A1 (fr) | Dispositif de filature à chaud de fibres à plusieurs composants | |

| DD141171A5 (de) | Verfahren und vorrichtung zur erzielung von bikomponenten-faeden | |

| DE19750724C2 (de) | Vorrichtung zum Herstellen eines Spinnvlieses aus Kern-Mantel-Struktur aufweisenden Bikomponentenfäden | |

| EP0978874A2 (fr) | Refroidisseur | |

| DE19540907C5 (de) | Spinnbalken zum Spinnen einer Mehrzahl von synthetischen Fäden und dessen Herstellung | |

| DE4224652C2 (de) | Spinnvorrichtung zum Schmelzspinnen insbesondere thermosplastischer Mehrkomponentenfäden | |

| DE3113495C2 (de) | Spinnbalken für Schmelzspinnanlagen für synthetische Hochpolymere | |

| DE69002253T2 (de) | Spinnvorrichtung für zusammengesetzte Fasern mit exzentrischer Kernmantelform. | |

| DE68901978T2 (de) | Spinnvorrichtung fuer kern-huelle-verbundfasern. | |

| DE69611346T2 (de) | Verfahren und Vorrichtung zur Herstellung von Bikomponentenfasern | |

| EP0273191B1 (fr) | Distributeur de liquides pour des colonnes à transfert de masse et de chaleur | |

| DE3150187C2 (de) | Verdampfer, insbesondere für Klimaanlagen in Kraftfahrzeugen | |

| DE1660398B2 (de) | Schmelzspinnkopf | |

| EP0123192A2 (fr) | Clé pour serrures cylindriques | |

| DE4447420A1 (de) | Spinndüsenanordnung für Mehrkomponentenfäden | |

| DE19750723C1 (de) | Vorrichtung zum Herstellen eines Spinnvlieses aus Bikomponentenfäden |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB IT LI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB IT LI |

|

| 17P | Request for examination filed |

Effective date: 19891209 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: NEUMAG - NEUMUENSTERSCHE MASCHINEN- UND ANLAGENBAU |

|

| 17Q | First examination report despatched |

Effective date: 19910430 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB IT LI |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 19911113 Ref country code: BE Effective date: 19911113 Ref country code: GB Effective date: 19911113 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19911113 |

|

| REF | Corresponds to: |

Ref document number: 69470 Country of ref document: AT Date of ref document: 19911115 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3866145 Country of ref document: DE Date of ref document: 19911219 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19920226 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Effective date: 19920229 Ref country code: LI Effective date: 19920229 |

|

| EN | Fr: translation not filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19920403 |

|

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19921103 |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |