EP0280596B1 - Ram device for a laterally charged furnace - Google Patents

Ram device for a laterally charged furnace Download PDFInfo

- Publication number

- EP0280596B1 EP0280596B1 EP88400196A EP88400196A EP0280596B1 EP 0280596 B1 EP0280596 B1 EP 0280596B1 EP 88400196 A EP88400196 A EP 88400196A EP 88400196 A EP88400196 A EP 88400196A EP 0280596 B1 EP0280596 B1 EP 0280596B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- counterweight

- stopper

- parallelogram

- displacing

- buffer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000006073 displacement reaction Methods 0.000 claims description 2

- 230000005484 gravity Effects 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/0006—Details, accessories not peculiar to any of the following furnaces

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS, OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D3/00—Charging; Discharging; Manipulation of charge

- F27D3/0024—Charging; Discharging; Manipulation of charge of metallic workpieces

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS, OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D3/00—Charging; Discharging; Manipulation of charge

- F27D3/04—Ram or pusher apparatus

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27B—FURNACES, KILNS, OVENS, OR RETORTS IN GENERAL; OPEN SINTERING OR LIKE APPARATUS

- F27B9/00—Furnaces through which the charge is moved mechanically, e.g. of tunnel type; Similar furnaces in which the charge moves by gravity

- F27B9/30—Details, accessories, or equipment peculiar to furnaces of these types

- F27B9/38—Arrangements of devices for charging

- F27B2009/386—Lateral intake or outtake

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS, OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D99/00—Subject matter not provided for in other groups of this subclass

- F27D2099/0085—Accessories

- F27D2099/009—Bumpers

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T74/00—Machine element or mechanism

- Y10T74/18—Mechanical movements

- Y10T74/18888—Reciprocating to or from oscillating

- Y10T74/1892—Lever and slide

- Y10T74/18944—Link connections

Definitions

- Ovens are known which can be loaded at will by one or the other of their lateral sides.

- the oven has a stopper which is placed in the opening of the door when it is not used in order to block the products which are put in the oven by the other door and put in place on a train of rollers.

- the present invention relates to a stop device for side loading oven with which the stop can easily be retracted when the side of the load is changed.

- This device in which the stopper is suspended from a fixed structure by means of an articulated parallelogram, is characterized in that it comprises, to ensure the deformation of the parallelogram and, consequently, the displacement of the stopper, a mobile counterweight along an axis integral with one of the parts constituting the parallelogram and means for moving this counterweight.

- the counterweight is mounted on one of the wings of an L-shaped part, the other wing of which constitutes one of the elements of the articulated parallelogram.

- the stopper 5 is supported by a structure constituted by three columns 6a, 6b and 6c.

- the stopper 5 is carried by an arm 7 articulated at 8 on the lower end of a connecting rod 9 whose upper end is articulated at 10 on the baluster 6c.

- the end of the arm 7 is articulated at 11 on a part 12 in L which is articulated on the baluster 6a at a point 13 located at the same height as the axis 10.

- the axes 8, 10, 11 and 13 are the vertices a parallelogram; the arm 7 is thereby kept horizontal.

- the axis 13 is substantially at the top of the part 12 in L while the axis 11 is provided in the vicinity of the end of one of its wings.

- a counterweight 14 is movably mounted on an axis 15 along the other wing of the part 12.

- the stopper 5 is disposed in the opening 2 opposite the parts 4 and the axes 8 and 11 are respectively vertical to the axes 10 and 13; the stopper thus prevents the parts from leaving the oven. It will be noted that, in this position, the center of gravity of the counterweight 14 is located substantially vertical to the pivot 13 so that the position of the arm 7, of the connecting rod 9 and of the part 12 is a position of stable equilibrium and , that therefore, the arm 7 with the stopper 5 remains in the position shown.

- the counterweight 14 is moved to bring it to the end of the second wing of the part 12.

- the counterweight thus exerts on the part a torque which tends to make it rotate clockwise.

- This movement has the effect of removing the stopper 5 from the opening 2 and lifting the arm 7 with the stopper ( Figure 2), which clears the passage for charging the pieces 4.

- the arm 7 occupies a position for which the torque exerted by the movable assembly balances that generated by the counterweight 14.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Organic Chemistry (AREA)

- Crystallography & Structural Chemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Manipulator (AREA)

- Forklifts And Lifting Vehicles (AREA)

- Vertical, Hearth, Or Arc Furnaces (AREA)

- Vending Machines For Individual Products (AREA)

- Transmission Devices (AREA)

- Specific Conveyance Elements (AREA)

- Electric Stoves And Ranges (AREA)

- Control Of High-Frequency Heating Circuits (AREA)

- Heat Treatments In General, Especially Conveying And Cooling (AREA)

Abstract

Description

On connaît des fours pouvant être chargés à volonté par l'un ou l'autre de leurs côtés latéraux. A chacune de ses portes latérales le four comporte un butoir qui est mis en place dans l'ouverture de la porte lorsqu'elle celle-ci n'est pas utilisée afin de bloquer les produits qui sont enfournés par l'autre porte et mis en place sur un train de rouleaux.Ovens are known which can be loaded at will by one or the other of their lateral sides. At each of its side doors the oven has a stopper which is placed in the opening of the door when it is not used in order to block the products which are put in the oven by the other door and put in place on a train of rollers.

La présente invention a pour object un dispositif à butoir pour four à chargement latéral avec lequel le butoir peut facilement être escamoté lorsque le côté du chargement est changé.The present invention relates to a stop device for side loading oven with which the stop can easily be retracted when the side of the load is changed.

Ce dispositif dans lequel le butoir est suspendu à une structure fixe par l'intermédiaire d'un parallélogramme articulé, est caractérisé en ce qu'il comporte, pour assurer la déformation du parallélogramme et, par suite, le déplacement du butoir, un contrepoids mobile le long d'un axe solidaire de l'une des pièces constituant le parallélogramme et des moyens pour déplacer ce contrepoids.This device in which the stopper is suspended from a fixed structure by means of an articulated parallelogram, is characterized in that it comprises, to ensure the deformation of the parallelogram and, consequently, the displacement of the stopper, a mobile counterweight along an axis integral with one of the parts constituting the parallelogram and means for moving this counterweight.

Dans un mode de réalisation particulier de l'invention, le contrepoids est monté sur l'une des ailes d'une pièce en L dont l'autre aile constitue l'un des éléments du parallélogramme articulé.In a particular embodiment of the invention, the counterweight is mounted on one of the wings of an L-shaped part, the other wing of which constitutes one of the elements of the articulated parallelogram.

On a décrit ci-après, à titre d'exemple non limitatif, un mode de réalisation du dispositif selon l'invention, avec référence au dessin annexé dans lequel:

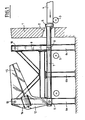

- La Figure 1 est une vue latérale du dispositif, le butoir étant en position active;

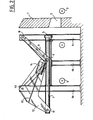

- La Figure 2 en est une vue semblable à la Figure 1, le butoir étant en position escamotée.

- Figure 1 is a side view of the device, the stopper being in the active position;

- Figure 2 is a view similar to Figure 1, the stopper being in the retracted position.

Au dessin, on voit en 1 la paroi latérale d'un four qui comporte une ouverture 2 placée devant une ligne de rouleaux 3. L'ouverture 2 peut servir à volonté à l'enfournement de produits 4 qui sont mis en place sur les rouleaux 3, soit au défourne- ment de produits qui sont enfournés par une ouverture prévue dans la paroi latérale opposée; un butoir éclipsable 5 est prévu pour empêcher dans le second cas les produits 4 enfournés de sortir du four.In the drawing, we see at 1 the side wall of an oven which has an

Le butoir 5 est supporté par une structure constituée par trois colonnettes 6a, 6b et 6c. Le butoir 5 est porté par un bras 7 articulé en 8 sur l'extrémité inférieure d'une bielle 9 dont l'extrémité supérieure est articulée en 10 sur la colonnette 6c. L'extrémité du bras 7 est articulée en 11 sur une pièce 12 en L qui est articulée sur la colonnette 6a en un point 13 situé à la même hauteur que l'axe 10. Les axes 8, 10, 11 et 13 sont les sommets d'un parallélogramme; le bras 7 est de ce fait maintenu horizontal.The

L'axe 13 est sensiblement au sommet de la pièce 12 en L alors que l'axe 11 est prévu au voisinage de l'extrémité de l'une de ses ailes. Un contrepoids 14 est monté mobile sur un axe 15 le long de l'autre aile de la pièce 12. Un vérin ou bien une vis sans fin entraîné par un moteur électrique ou hydraulique, qui n'est pas représenté au dessin, permet de déplacer le contrepoids 14 le long de l'axe 15.The

A la Figure 1 le butoir 5 est disposé dans l'ouverture 2 en regard des pièces 4 et les axes 8 et 11 se trouvent respectivement à la verticale des axes 10 et 13; le butoir empêche ainsi les pièces de sortir du four. On remarquera que, dans cette position, le centre de gravité du contrepoids 14 se trouve sensiblement à la verticale du pivot 13 de sorte que la position du bras 7, de la bielle 9 et de la pièce 12 est une position d'équilibre stable et, que de ce fait, le bras 7 avec le butoir 5 reste dans la position représentée.In Figure 1 the

Si l'ouverture 2 doit servir d'ouverture d'enfournement, on déplace le contrepoids 14 pour l'amener à l'extrémité de la second aile de la pièce 12. Le contrepoids exerce ainsi sur la pièce un couple qui tend à la faire pivoter dans le sens des aiguilles d'une montre. Ce mouvement a pour effet de sortir le butoir 5 de l'ouverture 2 et de lever le bras 7 avec le butoir (Figure 2), ce qui dégage le passage pour l'enfournement des pièces 4. Lorsque le contrepoids 14 est à fin de course, le bras 7 occupe une position pour laquelle le couple exercé par l'ensemble mobile équilibre celui engendré par le contrepoids 14.If the

Lorsque le contrepoids 14 est ramené dans sa position initiale, le couple exercé par l'ensemble mobile tend à ramener celui-ci dans sa position de la Figure 1, le butoir 5 étant de nouveau dans sa position active.When the

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT88400196T ATE60431T1 (en) | 1987-02-10 | 1988-01-28 | RIMMING DEVICE FOR A HORIZONTAL LOADING FURNACE. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8701963 | 1987-02-10 | ||

| FR8701963A FR2610711B3 (en) | 1987-02-10 | 1987-02-10 | STOP DEVICE FOR SIDE LOADING OVEN |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0280596A1 EP0280596A1 (en) | 1988-08-31 |

| EP0280596B1 true EP0280596B1 (en) | 1991-01-23 |

Family

ID=9347972

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP88400196A Expired - Lifetime EP0280596B1 (en) | 1987-02-10 | 1988-01-28 | Ram device for a laterally charged furnace |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4832154A (en) |

| EP (1) | EP0280596B1 (en) |

| AT (1) | ATE60431T1 (en) |

| CA (1) | CA1320045C (en) |

| DE (1) | DE3861596D1 (en) |

| FR (1) | FR2610711B3 (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5370530A (en) * | 1993-03-24 | 1994-12-06 | Italimpianti Of America, Inc. | Rolls for high temperature roller hearth furnaces |

| US5362230A (en) * | 1993-03-24 | 1994-11-08 | Italimpianti Of America, Inc. | Rolls for high temperature roller hearth furnaces |

| US5586855A (en) * | 1993-11-23 | 1996-12-24 | Eshleman; Roger D. | Apparatus and method for infeeding batched materials |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US63444A (en) * | 1867-04-02 | Chakles h | ||

| US1562582A (en) * | 1923-04-02 | 1925-11-24 | Stebler Parker Co | Automatic loading device for elevators |

| GB264114A (en) * | 1925-10-01 | 1927-01-03 | Wiggin & Co Ltd Henry | Improvements relating to annealing and other furnaces, muffles and the like |

| DE665827C (en) * | 1935-10-13 | 1938-10-04 | Schuechtermann & Kremer Baum A | Block printer |

| GB1030349A (en) * | 1962-12-17 | 1966-05-18 | Rud A Hartmann Gross App Und S | Apparatus for continuously sterilising various products in large institutions, particularly hospitals |

| FR1589158A (en) * | 1968-09-13 | 1970-03-23 | ||

| DE2204936B2 (en) * | 1972-02-03 | 1977-11-03 | Fa. Wilhelm Zur Nieden, 4300 Essen | Billet conveyor stop assembly - comprises pivoting vertical plate coupled to damper by pivoting link connected to piston rod |

| FR2222909A5 (en) * | 1973-12-21 | 1974-10-18 | Nippon Steel Corp | Vertical heating furnace charging appts. - guides and centres material in the furnace |

| GB1522202A (en) * | 1975-07-31 | 1978-08-23 | Vacuumatic Ltd | Conveyor apparatus |

-

1987

- 1987-02-10 FR FR8701963A patent/FR2610711B3/en not_active Expired - Lifetime

-

1988

- 1988-01-28 EP EP88400196A patent/EP0280596B1/en not_active Expired - Lifetime

- 1988-01-28 AT AT88400196T patent/ATE60431T1/en not_active IP Right Cessation

- 1988-01-28 DE DE8888400196T patent/DE3861596D1/en not_active Expired - Lifetime

- 1988-02-03 US US07/151,897 patent/US4832154A/en not_active Expired - Fee Related

- 1988-02-04 CA CA000558155A patent/CA1320045C/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| EP0280596A1 (en) | 1988-08-31 |

| DE3861596D1 (en) | 1991-02-28 |

| CA1320045C (en) | 1993-07-13 |

| FR2610711A1 (en) | 1988-08-12 |

| US4832154A (en) | 1989-05-23 |

| ATE60431T1 (en) | 1991-02-15 |

| FR2610711B3 (en) | 1991-01-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0280596B1 (en) | Ram device for a laterally charged furnace | |

| EP0198760B1 (en) | Opening and closing mechanism with locking for a cable car folding-door | |

| US4669625A (en) | Easy opening lid | |

| EP0252342B1 (en) | Device for closing a central upper opening of a vessel, and its use in a bunker for a shaft furnace charging installation | |

| EP0507708B1 (en) | Safety device for hinged manhole cover | |

| EP2979526B1 (en) | Enclosure of an industrial apparatus | |

| EP0233090A1 (en) | Glass container | |

| FR2609253A1 (en) | POCKET POCKET | |

| FR2522716A1 (en) | Folding door for garage - comprises upper and lower panels pivotally interconnected about horizontal axis | |

| FR2577829A1 (en) | DEVICE FOR REMOVABLY CONNECTING A CASTING TUBE TO THE CASTING NOZZLE OF A CONTAINER CONTAINING MOLTEN METAL | |

| CH648268A5 (en) | Lift for vehicles | |

| EP0695456B1 (en) | Device for guiding a fuel assembly during charging | |

| FR2444774A1 (en) | HINGES FOR AUTOMATIC CLOSING DOOR | |

| FR2537121A1 (en) | hoist for access to train carriage | |

| FR2505218A1 (en) | Suspension and control of casting ladle - by an articulated parallelogram linkage | |

| FR2811252A1 (en) | Transport container for stamped sheet metal parts comprises carrying structure with access face and parts support rack on which supports are fixed | |

| FR2695919A1 (en) | Tipping equipment for waste bins - uses single pressure cylinder and actuator with pivoting arm to simultaneously hold lift and tip bin into collection vehicle | |

| FR2557551A1 (en) | Automatic clamp for the handling and lifting of loads. | |

| FR2535633A1 (en) | Steel works trunnion. | |

| CH464075A (en) | Variable tilt telescopic loading ramp | |

| BE1004004A6 (en) | Garage door | |

| FR2591242A1 (en) | Automatic washing and spinning machine | |

| FR2589132A1 (en) | Container lifter | |

| BE502612A (en) | ||

| CH202621A (en) | Lifting device for vehicles. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19880805 |

|

| 17Q | First examination report despatched |

Effective date: 19900508 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 60431 Country of ref document: AT Date of ref document: 19910215 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| REF | Corresponds to: |

Ref document number: 3861596 Country of ref document: DE Date of ref document: 19910228 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| EPTA | Lu: last paid annual fee | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 88400196.7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19981208 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19981217 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19981223 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19981229 Year of fee payment: 12 Ref country code: CH Payment date: 19981229 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19981231 Year of fee payment: 12 Ref country code: BE Payment date: 19981231 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19990129 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19990131 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000128 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000128 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000128 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000131 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000131 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000131 |

|

| BERE | Be: lapsed |

Owner name: S.A. STEIN HEURTEY Effective date: 20000131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000801 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 88400196.7 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20000128 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000929 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20000801 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001101 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050128 |