EP0258622B2 - Schiffsmaschinenanlage - Google Patents

Schiffsmaschinenanlage Download PDFInfo

- Publication number

- EP0258622B2 EP0258622B2 EP87110850A EP87110850A EP0258622B2 EP 0258622 B2 EP0258622 B2 EP 0258622B2 EP 87110850 A EP87110850 A EP 87110850A EP 87110850 A EP87110850 A EP 87110850A EP 0258622 B2 EP0258622 B2 EP 0258622B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- ship

- engine system

- propeller

- gear unit

- motor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000008878 coupling Effects 0.000 claims description 9

- 238000010168 coupling process Methods 0.000 claims description 9

- 238000005859 coupling reaction Methods 0.000 claims description 9

- 239000011796 hollow space material Substances 0.000 claims 2

- 230000005540 biological transmission Effects 0.000 description 9

- 238000009434 installation Methods 0.000 description 7

- 238000010276 construction Methods 0.000 description 3

- 238000007689 inspection Methods 0.000 description 2

- 206010067482 No adverse event Diseases 0.000 description 1

- 230000004308 accommodation Effects 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 239000010687 lubricating oil Substances 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000012528 membrane Substances 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63H—MARINE PROPULSION OR STEERING

- B63H21/00—Use of propulsion power plant or units on vessels

- B63H21/30—Mounting of propulsion plant or unit, e.g. for anti-vibration purposes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63H—MARINE PROPULSION OR STEERING

- B63H23/00—Transmitting power from propulsion power plant to propulsive elements

- B63H23/02—Transmitting power from propulsion power plant to propulsive elements with mechanical gearing

- B63H23/06—Transmitting power from propulsion power plant to propulsive elements with mechanical gearing for transmitting drive from a single propulsion power unit

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02B—INTERNAL-COMBUSTION PISTON ENGINES; COMBUSTION ENGINES IN GENERAL

- F02B3/00—Engines characterised by air compression and subsequent fuel addition

- F02B3/06—Engines characterised by air compression and subsequent fuel addition with compression ignition

Definitions

- the invention relates to a marine machine system with a medium-speed diesel engine driving the propeller shaft via a transmission.

- Single-acting, slow-running two-stroke diesel engines are characterized by very low fuel consumption and are therefore considered to be relatively inexpensive prime movers.

- the speeds are on average around 100 rpm, so that a direct connection to the waveguide is possible.

- the difficulties in accommodating the large and heavy slow-moving engines led to the development of medium-speed, single-acting four-stroke diesel engines that are built as in-line or V-engines. Their speeds are on average about 500 rpm and require a gearbox to reduce the engine speed to the propeller speed.

- the medium-speed diesel engines are primarily intended to solve the difficulties caused by the limitation of the installation space due to the sharpening of the aft ship.

- the invention is based on the object of creating an even more compact design for an inexpensive installation option in the aft ship.

- the aim is to arrange the drive machine further than was previously possible in the direction of the propeller in the aft ship.

- the invention for solving this problem is characterized by the features specified in the characterizing part of patent claim 1. This results in a particularly compact design with even smaller dimensions, so that the engine can be returned to the rear ship further than before.

- the propeller intermediate shaft area can be used for the motor arrangement, since the length of the motor corresponds approximately to an intermediate wavelength and this is returned below the motor.

- the installation weights are low.

- an adjustable box can be provided on the front of the propeller intermediate shaft.

- the large wheel hub is provided with a cylindrical cavity, the diameter of which is larger than the diameter of the aligned axial bores of the propeller intermediate shaft and the peg-shaped extension of the wheel hub.

- This cavity can serve, for example, to accommodate further elements that can be removed before the radial expansion of the large wheel.

- the formation of the cylindrical cavity is achieved in a simple manner in that the pin-shaped extension of the wheel hub is screwed as a separate section to the large wheel, the large wheel having a conventional hollow hub and being screwed evenly to the intermediate shaft flange. As a result, the cavity is delimited on one end face by the intermediate shaft flange and on the opposite end face by the peg-shaped extension of the wheel hub.

- This training has manufacturing and assembly advantages. Another advantage of the assembly in the confined spaces results from an arrangement of the thrust bearing transmitting the propeller thrust in the transmission.

- the thrust washer can be arranged on the pin-shaped extension of the wheel hub and the pressure segments can be stored in the transmission housing.

- the large wheel After removing the drive pinion and lifting off the top part of the housing, the large wheel can be lifted radially as soon as the fastening screws are loosened. This means that the expansion and subsequent installation work can also be carried out at sea, even with the limited space in the aft ship, using on-board equipment.

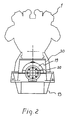

- the motor 1 is connected to the propeller 2, the propeller shaft 3 and the propeller intermediate shaft 4 via a reduction gear 5, which is located on the front of the motor.

- the motor shaft is connected to a drive flange 7a of a flange shaft 7 via a motor output flange 6.

- the flange shaft 7 passes through a drive hollow shaft 8 with the drive pinion 9.

- the flange shaft is supported within the hollow shaft 8 with the aid of a bearing 8a.

- the flange shaft 7 carries a torsionally flexible coupling 10, which transmits the torque to the hollow shaft 8 via the flange disk 10a.

- the large wheel 17 is supported on both sides by bearings 15 and 16.

- a further support bearing 14 is provided on the propeller-side drive unit for the intermediate shaft 4.

- the gear housing consists of a lower part 13 and, for installation reasons, a two-part upper gear part 11, 12.

- the bearing housing lower part 18 on the rear engine side is integrated into the lower part 13 of the gear housing. Only the bearing housing part 19 is attached.

- the propeller thrust is transmitted to the thrust bearing 22 via the shaft pressure ring 21.

- the gear housing lower part 13 forms a unit with the base frame 30 of the motor. From there, the propeller thrust is introduced into the ship's foundation.

- the intermediate shaft 4 carries a flange 20 and is screwed to the propeller shaft 3.

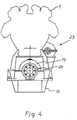

- Deviating in the presentation acc. Fig. 3 is a power take-off 23 for a marine auxiliary machine, not shown.

- the auxiliary drive wheel 24 on the hollow shaft 8 of the main drive pinion transmits the torque to the auxiliary drive pinion 25 of a power take-off shaft 26, which can be connected, for example, to a generator.

- the thrust bearing for receiving the propeller thrust for forward and reverse travel is located outside the actual reduction gear, but exactly aligned with it, since the trough of the thrust bearing and the Gear housing forms a unit.

- a shaft misalignment as a result of misaligned bearings, bending or twisting of the foundation or the hull therefore have no adverse effects within the motor gear block.

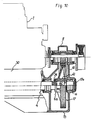

- the variant according to FIGS. 5 and 11 shows the arrangement of the thrust bearing 27, 28, 41, 42 directly next to the large wheel of the transmission.

- the motor foundations are firmly connected to the combined gear-thrust bearing housing.

- a cardanic coupling 34 is installed, which drives the hollow shaft 8 of the drive pinion 9 via the flange shaft 7 and the torsionally flexible coupling 10.

- the flange shaft 7 is supported both in the cardanic coupling 34 and via a spherical bearing 35 and a support plate 10b via the elastic coupling 10 to the hollow drive shaft 8.

- the large wheel 17 is fastened to a flange 4a of the propeller intermediate shaft 4 by screws 36.

- the wheel hub shows a peg-shaped extension 17 a, which is supported in the housing bearing 16.

- an axial cavity extends through the propeller intermediate shaft 4 and the peg-shaped extension 17a of the large wheel hub, which extends from the bores 38 in FIG Propeller intermediate shaft and 39 the large wheel hub.

- a linkage 37 of an adjustable propeller extends through the axial cavity and extends into an adjusting device 40 on the transmission housing 12, 13.

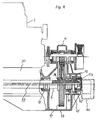

- the embodiment according to FIG. 10 shows an alternative embodiment.

- the pin-shaped hub extension 17a is separated from the large wheel 17 and is only screwed to it.

- the large wheel is designed with a conventional hollow hub 41.

- the diameter of the hub bore is larger than the diameter of the axial bores 38 and 39 for receiving the actuating linkage for the variable pitch propeller.

- the cavity 42 is delimited on the end face by the flange 4a of the propeller intermediate shaft and the peg-shaped extension 17a of the large wheel hub.

- the pin-shaped extension 17b of the wheel hub carries the thrust washer 41, flanked by the pressure segments 42 mounted in the gear housing 12, 13.

- the hub extension 17b has a greater axial extension than the examples according to FIGS. 8 to 10. If this is the case, too Linkage 37 and adjustment device 40, as indicated by the broken line, installed, these parts must be removed in the axial direction to the machine room side before removing the large wheel 17.

- the pressure segments can be removed or installed through an opening provided in the gear housing or after the two-part housing has been separated.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- Ocean & Marine Engineering (AREA)

- General Details Of Gearings (AREA)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3628385 | 1986-08-25 | ||

| DE19863628385 DE3628385A1 (de) | 1986-08-25 | 1986-08-25 | Schiffsmaschinenanlage |

| DE3710792 | 1987-03-31 | ||

| DE3710792 | 1987-03-31 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0258622A1 EP0258622A1 (de) | 1988-03-09 |

| EP0258622B1 EP0258622B1 (de) | 1990-01-17 |

| EP0258622B2 true EP0258622B2 (de) | 1993-03-03 |

Family

ID=25846740

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87110850A Expired - Lifetime EP0258622B2 (de) | 1986-08-25 | 1987-07-27 | Schiffsmaschinenanlage |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0258622B2 (fi) |

| DE (1) | DE3761420D1 (fi) |

| ES (1) | ES2012475B3 (fi) |

| FI (1) | FI873660A (fi) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5242785A (en) * | 1987-06-25 | 1993-09-07 | Fuji Photo Film Co., Ltd. | Silver halide color photographic material containing color stain inhibitors and discoloring inhibitors |

| DE3930514A1 (de) * | 1989-09-13 | 1991-03-21 | Renk Tacke Gmbh | Schiffsantriebsanlage |

| CN114147479A (zh) * | 2021-12-02 | 2022-03-08 | 武汉理工大学 | 一种全回转推进器中间轴系对中工具、系统及方法 |

| CN115009499B (zh) * | 2022-06-17 | 2024-06-11 | 沪东中华造船(集团)有限公司 | 一种锁轴盘对中方法及锁轴盘装置 |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4383829A (en) * | 1979-10-25 | 1983-05-17 | Great Lakes Power Products, Inc. | Drive assembly for inboard speedboat |

| SE454432B (sv) * | 1985-06-26 | 1988-05-02 | Volvo Penta Ab | Upphengningssystem for ett drivaggregat |

-

1987

- 1987-07-27 ES ES87110850T patent/ES2012475B3/es not_active Expired - Lifetime

- 1987-07-27 EP EP87110850A patent/EP0258622B2/de not_active Expired - Lifetime

- 1987-07-27 DE DE8787110850T patent/DE3761420D1/de not_active Expired - Lifetime

- 1987-08-24 FI FI873660A patent/FI873660A/fi not_active Application Discontinuation

Also Published As

| Publication number | Publication date |

|---|---|

| FI873660A (fi) | 1988-02-26 |

| FI873660A0 (fi) | 1987-08-24 |

| ES2012475B3 (es) | 1990-04-01 |

| DE3761420D1 (de) | 1990-02-22 |

| EP0258622A1 (de) | 1988-03-09 |

| EP0258622B1 (de) | 1990-01-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69010363T2 (de) | Ausgewuchtete und steuerbare Kraftübertragung vom Z-Typ. | |

| EP0853577B1 (de) | Schiffsantrieb mit einer antriebsmaschine und direkt angetriebener propellerwelle | |

| DE3348400C2 (de) | Innenbord-Außenbordantrieb | |

| DE69319620T2 (de) | Propellerantrieb | |

| DE60118157T2 (de) | Motoreinheit für schiffe | |

| DE3046679C2 (de) | Abzweiggetriebe für einen Schiffsantrieb | |

| DE3620648A1 (de) | Verbindungsvorrichtung fuer einen heckantrieb eines wasserfahrzeuges | |

| EP0258622B2 (de) | Schiffsmaschinenanlage | |

| DE19834736B4 (de) | Verfahren zum Betreiben eines Dienstschiffes | |

| EP0140010B1 (de) | Schiffsantriebsanlage | |

| EP3793893B1 (de) | Antriebssystem eines schiffes | |

| DE10063338B4 (de) | Vorrichtung zum Antrieb eines Schiffes | |

| DE19729046A1 (de) | Schiffsantrieb mit einer Antriebsmaschine und direkt angetriebener Propellerwelle | |

| DE102008005351B4 (de) | Drehmomentübertragungsvorrichtung für ein Schiff | |

| DE3930514A1 (de) | Schiffsantriebsanlage | |

| DE2805688C2 (de) | Antriebsvorrichtung für ein kleines Wasserfahrzeug | |

| EP1069043A2 (de) | Schiffsantrieb mit Zweimotoren-Sammelgetriebe | |

| EP1134160A2 (de) | Schiffsantrieb mit Diesel- oder Elektromotoren | |

| DE3628385A1 (de) | Schiffsmaschinenanlage | |

| DE8716109U1 (de) | Schiffsmaschineneinrichtung | |

| DE202006010783U1 (de) | Integrierte Schiffsmotor-Halterungs- und Kraftübertragungsvorrichtung | |

| DE3700584C2 (fi) | ||

| DE4230500C2 (de) | Anordnung einer Wellengeneratoranlage an Bord von Schiffen | |

| DE19900003C2 (de) | Bootsantrieb, insbesondere Außenbordantrieb | |

| EP1099624B1 (de) | Schiffsantrieb mit einem Einmotoren-Getriebe |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE ES FR GB IT NL |

|

| 17P | Request for examination filed |

Effective date: 19880414 |

|

| 17Q | First examination report despatched |

Effective date: 19890608 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR GB IT NL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19900117 Ref country code: FR Effective date: 19900117 |

|

| REF | Corresponds to: |

Ref document number: 3761420 Country of ref document: DE Date of ref document: 19900222 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ET | Fr: translation filed | ||

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: CARL HURTH MASCHINEN- UND ZAHNRADFABRIK GMBH & CO. Effective date: 19900801 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: CARL HURTH MASCHINEN- UND ZAHNRADFABRIK GMBH & CO. |

|

| ITTA | It: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19920303 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19920721 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19920722 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19920723 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19920731 Year of fee payment: 6 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 19930303 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): DE ES FR GB IT NL |

|

| NLR2 | Nl: decision of opposition | ||

| EN3 | Fr: translation not filed ** decision concerning opposition | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 19900117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF THE APPLICANT RENOUNCES Effective date: 19940728 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19980618 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 19991007 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050727 |