EP0248371B1 - Sackfüllmaschine - Google Patents

Sackfüllmaschine Download PDFInfo

- Publication number

- EP0248371B1 EP0248371B1 EP87107863A EP87107863A EP0248371B1 EP 0248371 B1 EP0248371 B1 EP 0248371B1 EP 87107863 A EP87107863 A EP 87107863A EP 87107863 A EP87107863 A EP 87107863A EP 0248371 B1 EP0248371 B1 EP 0248371B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- machine

- filling

- parallel links

- parallel

- bag support

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000005303 weighing Methods 0.000 claims abstract description 8

- 230000008878 coupling Effects 0.000 abstract description 5

- 238000010168 coupling process Methods 0.000 abstract description 5

- 238000005859 coupling reaction Methods 0.000 abstract description 5

- 230000006735 deficit Effects 0.000 abstract description 2

- 238000005259 measurement Methods 0.000 description 5

- 238000004519 manufacturing process Methods 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 241000309551 Arthraxon hispidus Species 0.000 description 2

- 238000005452 bending Methods 0.000 description 2

- 238000005429 filling process Methods 0.000 description 2

- 230000002411 adverse Effects 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B1/00—Packaging fluent solid material, e.g. powders, granular or loose fibrous material, loose masses of small articles, in individual containers or receptacles, e.g. bags, sacks, boxes, cartons, cans, or jars

- B65B1/30—Devices or methods for controlling or determining the quantity or quality or the material fed or filled

- B65B1/32—Devices or methods for controlling or determining the quantity or quality or the material fed or filled by weighing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B1/00—Packaging fluent solid material, e.g. powders, granular or loose fibrous material, loose masses of small articles, in individual containers or receptacles, e.g. bags, sacks, boxes, cartons, cans, or jars

- B65B1/04—Methods of, or means for, filling the material into the containers or receptacles

- B65B1/18—Methods of, or means for, filling the material into the containers or receptacles for filling valve-bags

Definitions

- the invention relates to a sack filling machine with an electronic weighing device, which has a force transducer acted upon by a sack chair column, and with a sack chair guide, which consists of two upper and lower parallel bars, which are arranged on both sides of the sack chair column and whose two bearing points are designed as rod ends.

- Such a bag filling machine is known from DE-PS 2 704 138.

- links with rod ends for example self-aligning ball bearings

- certain manufacturing tolerances in the manufacture of the links can be compensated. Since the deflection of the sack chair is only a few millimeters on an electronic scale, there is a sufficiently good approximation of a vertical movement of the sack chair column.

- wishbones are provided which engage the sack chair column in the upper and lower area and prevent a possible tilting movement.

- the wishbones Since the wishbones have a fixed length, they somewhat hinder the vertical movement of the sack chair column, as is made possible by the parallel arms. This can adversely affect the weighing process.

- the invention is therefore based on the object of designing a sack filling machine of the type mentioned at the outset in such a way that a tilting movement of the sack chair column between the parallel cores is reliably prevented and yet there is no impairment of the vertical movement of the sack chair column.

- Sack filling machines which are provided for filling valve sacks have a filling tube which can be inserted into the sack valve.

- the filling tube is regularly inclined downwards, for example by 20 ° with respect to the horizontal. It has been shown that a measurement error occurs during the filling process, during which the weighing process takes place continuously. Studies have shown that this measurement error is due to the fact that the filling material coming from the filling tube hits the side wall of the sack at approximately the angle of the filling tube. This creates a vertical force component that falsifies the weighing result.

- the parallel links are parallel to an inclined filling tube.

- the parallel links are also inclined downwards at an angle of 20 °.

- the force transducer can still be aligned horizontally so that its measuring direction is aligned perpendicular.

- the force transducer can also be oriented in such a way that its measuring direction is oriented perpendicular to the parallel core, so that in the example mentioned it is tilted 20 ° from the vertical. This leads to the sensor measuring only one weight component, namely the weight multiplied by cos 20 °. To get the exact measurement result, the electronics of the balance must multiply the measurement result by 1 / cos 20 °.

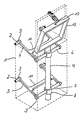

- a fixed machine frame 1 is shown in dashed lines.

- joint heads 3 of upper parallel core 4 and lower parallel core 5 designed as self-aligning ball bearings are attached.

- the other ends of the parallel links are connected to an upper axle 6 or lower axle 7 via corresponding joint heads 3.

- sleeves 8 are arranged which enclose a bag chair column 9 and hold it firmly.

- the upper parallel link 4 are connected by a rigid coupling rod 10 and the lower parallel link 5 by a rigid coupling rod 11.

- the coupling rod 10 and 11, with the associated parallel link core 4 and 5, thus forms a rigid frame which prevents the axis 6, 7 from tilting sideways out of the plane formed by the parallel link link 4 and 5. This also prevents the bag chair column 8 from tilting.

- the parallel links 4,5 are inclined 20 ° downwards from the horizontal. This inclination corresponds to the inclination of the filling tube (not shown) of the bag filling machine.

- this has a rectangular frame 12, the upper cross bar of which is connected to a force transducer 13.

- the frame 12 is inclined forward from the vertical by 20 °, so that it is perpendicular to the planes formed by the parallel links 4 and 5, respectively.

- the force transducer 13 is oriented such that its effective measuring direction is oriented perpendicular to the links 4 and 5 - and thus also perpendicular to the upper crossbar of the frame 12.

- the force transducer 13 is formed by a bending rod which is fastened to the machine frame 1 parallel to the parallel core 4 or 5.

- the parallel links 4 and 5 are parallel to the filling tube of the bag filling machine and parallel to the longitudinal axis of the bending rod serving as a force transducer 13.

- the force transducer 13 does not measure the weight G of the filled bag, but a weight component G - cos 20 °.

- the evaluation electronics is therefore set so that it multiplies the weight measured by the force transducer 13 by the constant factor 1 / cos 20 °. In this way, the correct absolute value is determined by the weighing device.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Quality & Reliability (AREA)

- Basic Packing Technique (AREA)

- Weight Measurement For Supplying Or Discharging Of Specified Amounts Of Material (AREA)

- Supplying Of Containers To The Packaging Station (AREA)

- Containers And Plastic Fillers For Packaging (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT87107863T ATE44925T1 (de) | 1986-06-03 | 1987-05-30 | Sackfuellmaschine. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3618648 | 1986-06-03 | ||

| DE19863618648 DE3618648A1 (de) | 1986-06-03 | 1986-06-03 | Sackfuellmaschine |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0248371A1 EP0248371A1 (de) | 1987-12-09 |

| EP0248371B1 true EP0248371B1 (de) | 1989-07-26 |

Family

ID=6302189

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87107863A Expired EP0248371B1 (de) | 1986-06-03 | 1987-05-30 | Sackfüllmaschine |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US4708216A (enExample) |

| EP (1) | EP0248371B1 (enExample) |

| AT (1) | ATE44925T1 (enExample) |

| AU (1) | AU582086B2 (enExample) |

| CA (1) | CA1277644C (enExample) |

| DE (2) | DE3618648A1 (enExample) |

| ES (1) | ES2010690B3 (enExample) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD318353S (en) | 1989-06-23 | 1991-07-16 | French Can-Can, Inc. | Wall mounted bag holding rack |

| US5735494A (en) * | 1996-03-07 | 1998-04-07 | Kurk; Robert | Bag holder |

| US6894232B2 (en) * | 2002-08-12 | 2005-05-17 | Mettler-Toledo | Bagger scale |

| CA135055S (en) * | 2009-11-12 | 2010-11-26 | Kupri Beheer B V | Rubbish bag holder |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US447686A (en) * | 1891-03-03 | Bag-holder | ||

| US1520372A (en) * | 1922-04-27 | 1924-12-23 | Paul R Syers | Combined laundry-bag holder and weight indicator |

| DE1299249B (de) * | 1965-11-09 | 1969-07-10 | Nakashima Shigeo Makagyo | Vorrichtung zum Einfuellen von pulverfoermigem Gut in Ventilsaecke |

| US3620317A (en) * | 1970-05-04 | 1971-11-16 | Nelson R Henry | Automatic filling and weighing mechanism |

| DE2312851C2 (de) * | 1973-03-15 | 1982-08-19 | Erwin Behn Verpackungsbedarf Gmbh, 4150 Krefeld | Wägeeinrichtung für Ventilsackfüllmaschinen |

| DE2704138C2 (de) * | 1977-02-02 | 1982-05-06 | Natronag Papierproduktion Gmbh & Co, Papiersackfabriken Kg, 3380 Goslar | Parallelführung einer Sackstuhlsäule einer Ventilsack-Füllmaschine |

-

1986

- 1986-06-03 DE DE19863618648 patent/DE3618648A1/de active Granted

- 1986-12-22 US US06/944,186 patent/US4708216A/en not_active Expired - Fee Related

-

1987

- 1987-05-29 AU AU73671/87A patent/AU582086B2/en not_active Ceased

- 1987-05-30 DE DE8787107863T patent/DE3760355D1/de not_active Expired

- 1987-05-30 EP EP87107863A patent/EP0248371B1/de not_active Expired

- 1987-05-30 AT AT87107863T patent/ATE44925T1/de not_active IP Right Cessation

- 1987-05-30 ES ES87107863T patent/ES2010690B3/es not_active Expired

- 1987-06-02 CA CA000538622A patent/CA1277644C/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| ATE44925T1 (de) | 1989-08-15 |

| DE3760355D1 (en) | 1989-08-31 |

| DE3618648C2 (enExample) | 1988-03-10 |

| EP0248371A1 (de) | 1987-12-09 |

| AU582086B2 (en) | 1989-03-09 |

| AU7367187A (en) | 1987-12-10 |

| DE3618648A1 (de) | 1987-12-10 |

| US4708216A (en) | 1987-11-24 |

| ES2010690B3 (es) | 1989-12-01 |

| CA1277644C (en) | 1990-12-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0340316B1 (de) | Kalibriereinrichtung für eine interne Windkanalwaage | |

| DE2005646B2 (de) | Elektromagnetische Wägeeinrichtung | |

| DE1923762C3 (de) | Meßeinrichtung zur geometrischen Überprüfung und/oder Berichtigung von Eisenbahngleisen | |

| EP0501041B1 (de) | Verfahren zur Seilspannungsmessung und Vorrichtung zu seiner Durchführung | |

| DE10322333A1 (de) | Vorrichtung zur Messung der Gewichtskraft eines Ballens | |

| EP0248371B1 (de) | Sackfüllmaschine | |

| CH659520A5 (de) | Vorrichtung zum ausmessen der lenkgeometrie von kraftfahrzeugen. | |

| DE2132285B2 (de) | Weitbereichs-laengenmessvorrichtung | |

| DE10322336A1 (de) | Vorrichtung zur Messung der Gewichtskraft einer Last | |

| DE3141767A1 (de) | Kraftwandler | |

| DE2040987B2 (de) | Vorrichtung zur lastanzeige | |

| DE2847295C2 (de) | Vorrichtung zur Bestimmung der Unwucht eines von einer Aufnahme einer Auswuchtmaschine mit Lagerständer gehaltenen Rotationskörpers | |

| DE2516803A1 (de) | Zugkraftfuehlvorrichtung fuer zugmaschinen | |

| DE2926213A1 (de) | Pyramidenwaage zur ermittlung von kraeften und momenten, insbesondere in windkanaelen | |

| DE4430463C1 (de) | Vorrichtung zur Messung der Betätigungskräfte für einen Schalthebel | |

| DE7530767U (de) | Landwirtschaftlicher schlepper | |

| DE4216973A1 (de) | Vorrichtung zur Kalibrierung einer Drehmomentmeßwelle | |

| DE2704138C2 (de) | Parallelführung einer Sackstuhlsäule einer Ventilsack-Füllmaschine | |

| DE2857525A1 (de) | Massen- und kraftmesser | |

| DE2223159C3 (de) | Vorrichtung zum Messen der Unwucht von Kraftfahrzeugrädern an Kraftfahrzeugen | |

| DE2755793C2 (de) | Gerät zum Prüfen von Federn, insbesondere von Gummifedern | |

| DE3820680C2 (enExample) | ||

| DE2830071C3 (de) | Wagebrücke mit Abstützung auf Meßdosen | |

| DE2641890C3 (de) | Fahrbare Lagerabstützung | |

| DE2818312A1 (de) | Vorrichtung zur messung von fluchtungs- oder geraderichtungsfehlern einer spur oder bahn |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE ES FR GB IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19871020 |

|

| 17Q | First examination report despatched |

Effective date: 19881026 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB IT LI NL SE |

|

| REF | Corresponds to: |

Ref document number: 44925 Country of ref document: AT Date of ref document: 19890815 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3760355 Country of ref document: DE Date of ref document: 19890831 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19900502 Year of fee payment: 4 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19900521 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19900522 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19900528 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19900530 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19900531 Year of fee payment: 4 Ref country code: AT Payment date: 19900531 Year of fee payment: 4 |

|

| 26 | Opposition filed |

Opponent name: GEBRUEDER BUEHLER AG Effective date: 19900426 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19900712 Year of fee payment: 4 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: GEBRUEDER BUEHLER AG . |

|

| ITTA | It: last paid annual fee | ||

| RDAG | Patent revoked |

Free format text: ORIGINAL CODE: 0009271 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT REVOKED |

|

| 27W | Patent revoked |

Effective date: 19910318 |

|

| GBPR | Gb: patent revoked under art. 102 of the ep convention designating the uk as contracting state | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| NLR2 | Nl: decision of opposition | ||

| BERE | Be: lapsed |

Owner name: NATRONAG G.-FUR VERPACKUNGSSYSTEME M.B.H. Effective date: 19910531 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 87107863.0 Effective date: 19910807 |