EP0226907A2 - Relais - Google Patents

Relais Download PDFInfo

- Publication number

- EP0226907A2 EP0226907A2 EP86116890A EP86116890A EP0226907A2 EP 0226907 A2 EP0226907 A2 EP 0226907A2 EP 86116890 A EP86116890 A EP 86116890A EP 86116890 A EP86116890 A EP 86116890A EP 0226907 A2 EP0226907 A2 EP 0226907A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- core

- yoke

- piece

- tab

- coil

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H50/00—Details of electromagnetic relays

- H01H50/16—Magnetic circuit arrangements

- H01H50/36—Stationary parts of magnetic circuit, e.g. yoke

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H50/00—Details of electromagnetic relays

- H01H50/16—Magnetic circuit arrangements

- H01H50/36—Stationary parts of magnetic circuit, e.g. yoke

- H01H2050/365—Stationary parts of magnetic circuit, e.g. yoke formed from a single sheet of magnetic material by punching, bending, plying

Definitions

- the invention relates to a relay according to the preamble of claim 1.

- a relay has become known in various forms; All embodiments have in common that the core and the yoke form two different parts, which are therefore manufactured separately from one another and which are only connected to one another before the relay is assembled.

- the core is connected to the associated yoke via a rivet connection.

- this has the disadvantage that the connection between the core and the yoke in the area of the rivet connection can never be completely smooth, and this results in a slight air gap which increases the magnetic resistance in the flux circuit.

- the invention has for its object to develop a relay of the type mentioned so that the resistance in the magnetic flux circuit, consisting of core, yoke and armature, is further reduced.

- the invention is characterized in that the yoke and core consist of a one-piece U-shaped part.

- the yoke and core consist of a coherent, identical part, as a result of which the air gap described above, which can form in the connecting gap in the case of a two-part part, is avoided. Due to the one-piece construction of the yoke and core, the resistance in the magnetic flux circuit is substantially reduced and, consequently, the efficiency of the relay is improved.

- the core consists of a round-profiled metal part which merges on one side into a flat-profiled connecting flange, which in turn merges into a flat-profiled yoke.

- a round-profiled metal part which merges on one side into a flat-profiled connecting flange, which in turn merges into a flat-profiled yoke.

- Such a part is produced from a round material, the round-profiled core being produced by die-forming this round material. After this shaping, the flat material is bent in a U-shaped manner, after which the round-profiled core is opposite a yoke formed as a flat material.

- the yoke and core consist of a stamped part and this time the core is not flat-profiled by die forming, but only a multiple bending process takes place, after completion of which both the yoke and the core are made of a rectangularly profiled material (flat material ) are formed.

- the core which is still made of a flat material, is round-profiled by die forming.

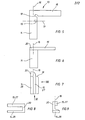

- Fig. 1 only the magnet system of a relay is shown, which in a conventional manner consists of a coil, the coil carrier has a central recess 2 into which a round-profiled core 7 is inserted.

- the round-profiled core 7 opens as shown in FIGS. 1, 2 and 3 in a rectangular profiled connecting flange 8, which in turn is bent through 90 degrees and opens into a yoke 6 with a rectangular profile.

- the armature 4 is pivotally mounted on the end face of the yoke 6 according to FIG. 1 and at its free, pivotable end there is an actuating pin 5 which actuates the contacts of the relay, which are not shown.

- the opposite side of the armature 4 lies as flush as possible on the end face 3 of the core 7.

- 1 - 3 show that the core and yoke consist of a one-piece part which is bent in a U-shape.

- a first bending edge 22 is located between the core 7 and the connecting flange 8, while a second bending edge 21 is located between the connecting flange 8 and the yoke 6.

- FIG. 4 shows an embodiment of the core and yoke that is improved compared to FIG. 1, because the end face 3 of the core 7 near the anchor has an enlarged area there, so that the contact area with the armature 4 is enlarged.

- a head part 10 is pushed onto the end face of the core 7, which is provided with an annular flange 12 and has an inner recess which is pressed onto the core 7 precisely flush.

- the end face 11 of the head part 10 is enlarged compared to the original end face 3 of the core 7.

- the head part 10 is integrally connected to the core 7 by inserting the core into the recess 2 of the coil 1 in the same manner as the head part 10 shows , mushroom-shaped, so that the head part 10 is integrally connected to the core 7.

- 5-9 show the second embodiment of a one-piece connection between a core 27 and a yoke 26.

- this embodiment is an angular stamped part 13, which consists of a flat material.

- a lower bracket 14 is connected in one piece to another bracket 15 at an angle of 90 degrees.

- a recess 18 is provided which extends approximately diagonally to the outer edge approximately to the center of the stamped part 13.

- this part is first bent in the region of the bending edge 17, so that the tab 15 protrudes vertically from the plane of the drawing according to FIG. 6, as shown in FIG. 6.

- the tab 15 is thus connected to the lower tab via a connecting flange 20, the connecting flange being formed by the corner between the tab 14 and the tab 15, which was divided by the recess 18.

- 5 also shows that a further recess 19 can be provided in the area of the bending edge 17 in order to facilitate bending in the area of the bending edge 17 during the transition from FIG. 5 to FIG. 6.

- a U-shaped part results from a flat material, wherein in a further process step the core 27 consisting of the flat material can still be profiled round by die forming.

Landscapes

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Electromagnets (AREA)

- Iron Core Of Rotating Electric Machines (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3544532 | 1985-12-17 | ||

| DE19853544532 DE3544532A1 (de) | 1985-12-17 | 1985-12-17 | Relais |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0226907A2 true EP0226907A2 (fr) | 1987-07-01 |

| EP0226907A3 EP0226907A3 (fr) | 1989-08-30 |

Family

ID=6288613

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP86116890A Withdrawn EP0226907A3 (fr) | 1985-12-17 | 1986-12-04 | Relais |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0226907A3 (fr) |

| DE (1) | DE3544532A1 (fr) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT402579B (de) * | 1991-10-07 | 1997-06-25 | Schrack Components Ag | Relais |

| EP0974994A1 (fr) * | 1998-07-23 | 2000-01-26 | Bticino S.P.A. | Electro-aimant pour un interrupteur automatique avec un noyau plat avec une partie torsadée |

| CN106252161A (zh) * | 2016-08-31 | 2016-12-21 | 漳州宏发电声有限公司 | 一种只有铁芯的磁路系统及其继电器 |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5126199A (en) * | 1988-11-02 | 1992-06-30 | The Dow Chemical Company | Maleic anhydride-grafted polyolefin fibers |

| US5185199A (en) * | 1988-11-02 | 1993-02-09 | The Dow Chemical Company | Maleic anhydride-grafted polyolefin fibers |

| US5082899A (en) * | 1988-11-02 | 1992-01-21 | The Dow Chemical Company | Maleic anhydride-grafted polyolefin fibers |

| AT412926B (de) * | 2001-03-20 | 2005-08-25 | Moeller Gebaeudeautomation Kg | Joch für ein magnetsystem einer kurzschlussauslöseeinrichtung |

| CN110970266A (zh) * | 2018-09-30 | 2020-04-07 | 泰科电子(深圳)有限公司 | 电磁继电器 |

| CN110970268A (zh) * | 2018-09-30 | 2020-04-07 | 泰科电子(深圳)有限公司 | 电磁继电器 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB688370A (en) * | 1950-12-07 | 1953-03-04 | Philips Electrical Ind Ltd | Improvements in or relating to electrical relays |

| GB1007369A (en) * | 1963-08-08 | 1965-10-13 | Ericsson Telephones Ltd | Electromagnetic relay |

| DE2221702A1 (de) * | 1972-04-29 | 1973-11-08 | Paul & Siedler | Elektromagnetisches klappanker-relais in flachbauweise fuer gedruckte schaltungen, insbesondere zum einbau in steckkarten |

| GB1440359A (en) * | 1973-11-08 | 1976-06-23 | Plessey Co Ltd | Electromagnetic relay assemblies |

| JPS5764909A (en) * | 1980-10-07 | 1982-04-20 | Matsushita Electric Works Ltd | Manufacture of iron core |

| EP0058727A1 (fr) * | 1980-09-01 | 1982-09-01 | Fujitsu Limited | Relais electromagnetique et son procede de fabrication |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1280409B (de) * | 1962-08-09 | 1968-10-17 | Siemens Ag | Elektromagnetisches Relais mit Klappanker |

| DE2020150A1 (de) * | 1970-04-24 | 1971-12-02 | Gruner Kg Relais Fabrik | Elektromagnetisches Kleinrelais |

| FR2321181A1 (fr) * | 1975-08-11 | 1977-03-11 | Saparel | Relais sensible a collage sans aimant |

| ATA126182A (de) * | 1982-03-30 | 1987-06-15 | Schrack Elektronik Ag | Elektromagnetisches relais |

| DE8329097U1 (de) * | 1983-10-08 | 1984-01-12 | Eberle Anlagen KG, 8500 Nürnberg | Elektromagnetisches Relais |

-

1985

- 1985-12-17 DE DE19853544532 patent/DE3544532A1/de active Granted

-

1986

- 1986-12-04 EP EP86116890A patent/EP0226907A3/fr not_active Withdrawn

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB688370A (en) * | 1950-12-07 | 1953-03-04 | Philips Electrical Ind Ltd | Improvements in or relating to electrical relays |

| GB1007369A (en) * | 1963-08-08 | 1965-10-13 | Ericsson Telephones Ltd | Electromagnetic relay |

| DE2221702A1 (de) * | 1972-04-29 | 1973-11-08 | Paul & Siedler | Elektromagnetisches klappanker-relais in flachbauweise fuer gedruckte schaltungen, insbesondere zum einbau in steckkarten |

| GB1440359A (en) * | 1973-11-08 | 1976-06-23 | Plessey Co Ltd | Electromagnetic relay assemblies |

| EP0058727A1 (fr) * | 1980-09-01 | 1982-09-01 | Fujitsu Limited | Relais electromagnetique et son procede de fabrication |

| JPS5764909A (en) * | 1980-10-07 | 1982-04-20 | Matsushita Electric Works Ltd | Manufacture of iron core |

Non-Patent Citations (1)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN vol. 6, no. 140 (E-121)(1018) 29 Juli 1982, & JP-A-57 064 909 (MATSUSHITA DENKO K.K.) 20 April 1982, * |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT402579B (de) * | 1991-10-07 | 1997-06-25 | Schrack Components Ag | Relais |

| EP0974994A1 (fr) * | 1998-07-23 | 2000-01-26 | Bticino S.P.A. | Electro-aimant pour un interrupteur automatique avec un noyau plat avec une partie torsadée |

| CN106252161A (zh) * | 2016-08-31 | 2016-12-21 | 漳州宏发电声有限公司 | 一种只有铁芯的磁路系统及其继电器 |

| CN106252161B (zh) * | 2016-08-31 | 2019-03-05 | 漳州宏发电声有限公司 | 一种只有铁芯的磁路系统及其继电器 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3544532A1 (de) | 1987-06-19 |

| EP0226907A3 (fr) | 1989-08-30 |

| DE3544532C2 (fr) | 1989-03-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0160121B1 (fr) | Electro-aimant pour appareils de commutation électrique, notamment pour contacteurs | |

| DE3590369C2 (fr) | ||

| DE4111054C2 (fr) | ||

| DD244231A5 (de) | Verfahren zur herstellung u-foermiger kernbleche und zwischen deren schenkel passendder t-foermiger rueckschlussbleche einer drossel oder eines transformators, insb. fuer gasentladungslampen | |

| DE69734859T2 (de) | Elektromagnetisches Relais | |

| DE69515968T2 (de) | Verbinderanordnung mit zusammenwirkenden Kontaktteilen und ein Verfahren zum Verbinden derselben | |

| DE69707369T2 (de) | Elektromagnetischer Schalter | |

| EP0226907A2 (fr) | Relais | |

| DE3224933C2 (de) | Federkontakt für elektrische Steckverbindungen | |

| DE69319259T2 (de) | Verbesserte Kontakte für den Anschluss von Spulenwicklungen | |

| DE69913397T2 (de) | Schneidklemme | |

| DE69703277T2 (de) | Steckerelement | |

| EP0308819A2 (fr) | Relais électromagnétique | |

| DE69710125T2 (de) | Elektrische Steckbuchse mit verstärkter Dose | |

| EP0707332B1 (fr) | Méthode de fabrication d'un relais électromagnétique | |

| DE2545180C3 (de) | Miniaturrelais | |

| EP0513010B1 (fr) | Relais electromagnetique | |

| DE3025814C2 (de) | Elektromagnetisches Relais | |

| DE69204587T2 (de) | Elektrischer Kontaktstift für gedruckte Schaltungsplatten. | |

| EP0252344A1 (fr) | Relais électromagnétique | |

| DE69103372T2 (de) | Spulenkörper mit winkelrechten Anschlussstiften. | |

| DE3415761A1 (de) | Elektromagnetisches relais | |

| DE3046947C2 (fr) | ||

| DE2419347A1 (de) | Magnetisches rueckschlussgehaeuse | |

| DE3209198A1 (de) | Elektromagnetisches relais |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE FR GB IT LI |

|

| 17P | Request for examination filed |

Effective date: 19870724 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT CH DE FR GB IT LI |

|

| 17Q | First examination report despatched |

Effective date: 19900326 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19901006 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: SCHMITT, GERD |