EP0168595B1 - Bras de charnière pour charnière de meuble - Google Patents

Bras de charnière pour charnière de meuble Download PDFInfo

- Publication number

- EP0168595B1 EP0168595B1 EP85106306A EP85106306A EP0168595B1 EP 0168595 B1 EP0168595 B1 EP 0168595B1 EP 85106306 A EP85106306 A EP 85106306A EP 85106306 A EP85106306 A EP 85106306A EP 0168595 B1 EP0168595 B1 EP 0168595B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- hinge bracket

- intermediate plate

- side walls

- profiled track

- angled

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000003780 insertion Methods 0.000 claims abstract description 3

- 230000037431 insertion Effects 0.000 claims abstract description 3

- 229910001229 Pot metal Inorganic materials 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05D—HINGES OR SUSPENSION DEVICES FOR DOORS, WINDOWS OR WINGS

- E05D7/00—Hinges or pivots of special construction

- E05D7/12—Hinges or pivots of special construction to allow easy detachment of the hinge from the wing or the frame

- E05D7/123—Hinges or pivots of special construction to allow easy detachment of the hinge from the wing or the frame specially adapted for cabinets or furniture

- E05D7/125—Hinges or pivots of special construction to allow easy detachment of the hinge from the wing or the frame specially adapted for cabinets or furniture the hinge having two or more pins

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05D—HINGES OR SUSPENSION DEVICES FOR DOORS, WINDOWS OR WINGS

- E05D7/00—Hinges or pivots of special construction

- E05D7/04—Hinges adjustable relative to the wing or the frame

- E05D7/0407—Hinges adjustable relative to the wing or the frame the hinges having two or more pins and being specially adapted for cabinets or furniture

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05D—HINGES OR SUSPENSION DEVICES FOR DOORS, WINDOWS OR WINGS

- E05D5/00—Construction of single parts, e.g. the parts for attachment

- E05D5/02—Parts for attachment, e.g. flaps

- E05D5/0276—Parts for attachment, e.g. flaps for attachment to cabinets or furniture, the hinge having two or more pins

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2600/00—Mounting or coupling arrangements for elements provided for in this subclass

- E05Y2600/50—Mounting methods; Positioning

- E05Y2600/52—Toolless

- E05Y2600/53—Snapping

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES E05D AND E05F, RELATING TO CONSTRUCTION ELEMENTS, ELECTRIC CONTROL, POWER SUPPLY, POWER SIGNAL OR TRANSMISSION, USER INTERFACES, MOUNTING OR COUPLING, DETAILS, ACCESSORIES, AUXILIARY OPERATIONS NOT OTHERWISE PROVIDED FOR, APPLICATION THEREOF

- E05Y2900/00—Application of doors, windows, wings or fittings thereof

- E05Y2900/20—Application of doors, windows, wings or fittings thereof for furniture, e.g. cabinets

Definitions

- the invention relates to a hinge arm for a furniture hinge or the like.

- a hinge arm for a furniture hinge or the like.

- the side walls formed by the profile legs on a rectangular in cross-section guide profile of a base plate attachable to a supporting wall and guided longitudinally with the base plate by a screwable into the guide profile Fixing screw can be clamped.

- a hinge arm of this type is known for example from DE-U-7 517 506.

- the web part of the U-shaped hinge arm is provided in the known hinge part with an elongated hole for the fastening screw, so that the gap between the door or flap and the body part can be adjusted before tightening the fastening screw by moving the hinge arm in the longitudinal direction on the base plate.

- a set screw for side adjustment of the door or height adjustment of the flap is screwed into the hinge arm, which is supported on the base plate.

- hinge arms In addition to hinge arms that have to be screwed onto their base plates connected to a supporting wall, hinge arms are also known, for example, from EP-A-43 903, which can be connected to the base plate by a snap connection by simply sliding them into a guide, so that the often cumbersome and time-consuming screwing of the hinge arms to the base plates is eliminated.

- Such hinge arms with snap connections lead to a considerable simplification of assembly, but they are more expensive because of the required guiding and snap devices, so that they are often not used for this reason only.

- the object of the invention is to provide a hinge arm of the type mentioned, which can be connected to the base plate by a fastening screw or a snap connection without structural changes to the hinge arm itself.

- This object is achieved in that two tabs serving as guides are angled inwards from the side walls of the base plate, the mutually facing end faces of which are at a distance corresponding to the width of the guide profile, that an intermediate plate of U-shaped cross section is optionally provided on the guide profile, which is provided in its web part with a longitudinally extending fastening hole, can be screwed on by the fastening screw that between the front edges of the side walls of the intermediate plate and the base plate on both sides of the guide profile guide grooves are formed at least for the angled tabs in the direction of insertion and that the intermediate plate with the End position of the pushed-on hinge arm defining stops and a self-tightening snap device for locking the hinge arm on the intermediate plate is provided.

- the hinge arm according to the invention can be fastened to the base plate in the usual way with the fastening screw passed through the elongated hole of its web part, the inwardly angled tabs forming guide webs which fix the hinge arm in the lateral direction.

- the intermediate plate with the stops and the snap device is screwed onto the guide profile of the base plate.

- This intermediate plate enables the hinge arm to be attached to the base plate only by sliding it into the guides until the snap device of the intermediate plate also fixes the hinge arm in the longitudinal direction in a self-clamping manner.

- the embodiments with and without a snap connection differ with identical design of the hinge arm itself and the base plate only by the intermediate plate, which can be installed if a snap connection is desired, or can be omitted if this appears too expensive for cost reasons.

- the hinge arm according to the invention can therefore be produced in two embodiments without additional effort, the storage being substantially reduced by the identical design of the hinge arm and the base plate.

- the guide profile expediently consists of H-shaped strip-like webs, the widened central web of which is provided with the threaded bore for the fastening screw.

- the base plate provided with the guide profile is expediently formed symmetrically to its longitudinal and transverse axes, so that simple left and right installation is possible.

- the stops for the hinge arm are formed by the side walls of the intermediate plate in their rear end regions, widening extensions which close off the guide grooves, the intermediate plate being provided with a spring-loaded pivotable latching lever which has a tension curve formed by its eccentric end face, that engages the hinge arm and its rear angled tabs against pushes the extensions.

- the hinge arm is fixed in the longitudinal direction by snap connection only by its rear, mirror-inverted tabs, these form, as it were, an articulated axis which still allows pivoting of the hinge arm by means of an adjusting screw for side adjustment of a door or height adjustment of a flap.

- the tension curve expediently engages the front edge of the rear tabs.

- the locking lever is expediently provided with an opening lever which projects beyond the rear end of the intermediate plate.

- the locking lever protrudes with a flank angled from the tension curve into the guide groove, so that it is pivoted against the spring force by the rear tab of the inserted hinge arm and slides over the tab until the tension curve behind the front edge of the Lappens snaps.

- two tensioning curves engaging on the opposite tabs are provided, which are formed by the front edges of legs bent by the U-shaped locking lever, by means of which the latter is supported in the side walls of the intermediate plate by a hinge pin.

- the set screw screwed into the web part of the hinge arm expediently has an annular groove in its lower end region. If the hinge arm according to the invention is used without an intermediate plate, that is to say without a snap connection, the annular groove does not interfere and the adjusting screw is supported on the base plate with its lower end face.

- the intermediate plate is expediently provided with an elongated hole which is open towards the front and the width of which corresponds to the shaft diameter of the screw in the groove, so that the annular groove can be inserted into the edges of the slot overlapping the edges thereof.

- the set screw is supported on the ring groove on the edges of the elongated hole.

- the hinge arm is expediently provided in its web part with an elongated hole with a keyhole-like widening for the fastening screw, so that the hinge arm can also be placed on the base plate when the fastening screw has already been screwed into it beforehand.

- the front tabs of the hinge arm are expediently arranged in front of the intermediate plate, so that the guide formed by the intermediate plate cannot hinder pivoting of the hinge arm on the base plate.

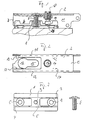

- the design of the base plate 1 and the hinge arm 2 is best seen in FIGS. 1 to 3.

- the base plate 1 consists in the embodiment of die-cast zinc and has a substantially rectangular shape in plan view.

- the webs 3, 4 are provided with material-saving cutouts 6 in the manner shown in FIG. 1.

- the threaded hole 7 for the fastening screw 8 is cut into the central web part 5.

- the fastening bores 9 are arranged between the webs 3, 4.

- the bottom of the mounting plate 1 is profiled for casting reasons to achieve substantially the same wall thicknesses.

- the hinge arm 2 consists of a central web part 10, from which the side walls 11, 12 are angled. From the side walls 11, 12, tabs 13, 14, which are directed inwards and at a distance from one another, are angled and are arranged in mirror image to one another. The distance between the mutually facing end faces of the tabs 13, 14 corresponds to the diameter of the guide profile which is rectangular in cross section and is formed by the web parts 3 to 5.

- the web part 10 of the hinge arm 2 is provided with an elongated hole 15 with a keyhole-like widening 16, the diameter of which is so large that the head of the screw 8 can be passed through it.

- the web part 10 is provided with a flanged bore 17 with an internal thread, into which the set screw 18 is screwed.

- the adjusting screw 18 is provided under its threaded part with an annular groove 19, to which a thread-free shaft part 20 connects, which has its end face for pivoting the hinge arm between the web parts 3, 4 supported on the base plate 1.

- the hinge arm 2 can be fastened on the guide profile 3 to 5 of the base plate 1 by the fastening screw 8, the angled tabs 13, 14 taking over the lateral guidance.

- the hinge arm 2 can be pivoted on the base plate 1 in the usual manner by actuating the fastening screw 8 and the set screw 18.

- an intermediate plate 21 is provided according to the exemplary embodiment in FIGS. 4 to 8.

- the intermediate plate 21 has a web part 22, from which the side walls 23, 24 which partially overlap the guide profile of the base plate are angled.

- the web part 22 is provided with an elongated hole 25 for the fastening screw 26 and at its front end with an elongated hole 27 which is open towards the front and into which the annular groove 19 of the adjusting screw 18 engages.

- the lower end edges of the side walls 23, 24 of the intermediate plate 1 have a distance from the base plate 1 after the intermediate plate 21 has been screwed onto the guide profile such that groove-shaped guides 28 for the tabs 13 angled by the hinge arm 2 are formed on both sides of the guide profile .

- the side walls 23, 24 of the intermediate plate 21 are provided in a mirror image with inward bend, the offset parallel wall parts being provided with extensions 29 which form stops for the tabs 21 projecting into the guide grooves 28.

- the middle web part 22 is cut away, so that the side walls 23, 24 protrude in a fork-shaped manner.

- the locking lever 31 is pivotably mounted on the hinge pin 30 between these projecting side walls 23, 24.

- the locking lever 31 consists of a T-shaped sheet metal stamping, from the transverse web of which the legs 32 are angled, the longitudinal web 34 forming the opening button.

- the angled legs 32 are provided with the bearing bore 34 and on their side facing the opening button 34 with the clamping curve 35 eccentric to the pivot axis.

- the tapered part 36 which lies in the guide groove 28 in the manner shown in FIG. 4, adjoins the tension curve 35 via a step.

- the U-shaped curved leaf spring 37 is supported on the pivot pin 30 with legs bent outwards. The legs are supported on the one hand on the web part 22 of the intermediate plate and on the other hand on the transverse web 31 of the locking lever 32.

- the hinge arm 2 is advanced in the guides 28 between the intermediate plate 21 and the base plate 1, the front edges of the tabs 13 abut the oblique edge 36 of the locking lever 32 and pivot it clockwise in FIG. 4 until the locking lever is above the flap 13 has slipped away and the locking lever snaps into its tensioned position, in which the tensioning curve 35 is supported on the back of the flap 13 and presses it against the stops formed by the projections 29.

- the set screw 18 is also inserted with its annular groove 19 into the elongated hole 27, so that lateral adjustment is possible.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Hinges (AREA)

Claims (12)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT85106306T ATE38871T1 (de) | 1984-07-19 | 1985-05-22 | Scharnierarm fuer ein moebelscharnier o.dgl. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3426672 | 1984-07-19 | ||

| DE19843426672 DE3426672A1 (de) | 1984-07-19 | 1984-07-19 | Scharnierarm fuer ein moebelscharnier o. dgl. |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0168595A2 EP0168595A2 (fr) | 1986-01-22 |

| EP0168595A3 EP0168595A3 (en) | 1986-05-28 |

| EP0168595B1 true EP0168595B1 (fr) | 1988-11-23 |

Family

ID=6241072

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP85106306A Expired EP0168595B1 (fr) | 1984-07-19 | 1985-05-22 | Bras de charnière pour charnière de meuble |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0168595B1 (fr) |

| AT (1) | ATE38871T1 (fr) |

| DE (1) | DE3426672A1 (fr) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3624237A1 (de) * | 1986-03-06 | 1987-09-10 | Grass Alfred Metallwaren | Scharnierband mit leicht loesbarer befestigung des moebelseitigen abdeckbuegels am moebelteil |

| AT383852B (de) * | 1986-04-10 | 1987-09-10 | Blum Gmbh Julius | Scharnier |

| IT206538Z2 (it) * | 1986-04-15 | 1987-08-10 | Ferrari Franco | Cerniera per mobili con ala a braccio su di una base in maniera articolata. |

| DE3775652D1 (de) * | 1986-08-08 | 1992-02-13 | Salice Arturo Spa | Scharnierarm fuer ein moebelscharnier o.dgl. |

| DE3627170C1 (de) * | 1986-08-11 | 1988-03-24 | Salice Arturo Spa | Scharnierarm fuer ein Moebelscharnier o.dgl.,mit Grundplatte direkt oder indirekt verbindbar |

| DE3640012A1 (de) * | 1986-11-24 | 1988-06-01 | Salice Arturo Spa | Zweiteiliger verbindungsbeschlag |

| DE3816838C2 (de) * | 1988-04-11 | 1996-09-26 | Grass Ag | Möbelscharnier mit Aufschnappmechanik |

| DE3920141C1 (fr) * | 1989-06-20 | 1990-08-16 | Arturo Salice S.P.A., Novedrate, Como, It | |

| DE3943210C1 (fr) * | 1989-12-28 | 1991-06-20 | Arturo Salice S.P.A., Novedrate, Como, It | |

| DE3943330C1 (fr) * | 1989-12-29 | 1991-07-11 | Arturo Salice S.P.A., Novedrate, Como, It | |

| DE4342744A1 (de) * | 1993-12-15 | 1995-06-22 | Lautenschlaeger Mepla Werke | Möbelscharnier |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE7517506U (de) * | 1975-06-03 | 1975-12-04 | Hettich P & Co | Scharnierarm |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT337566B (de) * | 1973-12-31 | 1977-07-11 | Blum Gmbh | Langen- und hoheneinstellbares scharnier |

| DE7505604U (de) * | 1974-02-26 | 1975-11-06 | Blum Gmbh | Scharnierbandbefestigung |

| DE7614526U1 (de) * | 1975-06-03 | 1976-10-21 | Arturo Salice S.P.A., Cantu, Como (Italien) | Schnell anbringbarer scharnierbeschlag fuer moebel |

| AT371205B (de) * | 1977-02-28 | 1983-06-10 | Blum Gmbh Julius | Halte- bzw. verriegelungseinrichtung fuer ein zwischenstueck eines scharnieres |

| DE2815816C2 (de) * | 1978-04-12 | 1984-08-02 | Arturo Salice S.P.A., Novedrate, Como | Verstellbarer Scharnierarm |

| DE2849901A1 (de) * | 1978-11-17 | 1980-05-29 | Heinze Richard Gmbh Co Kg | Distanzstueck fuer eine an einem moebelteil befestigbare halteplatte eines moebelscharniers |

| EP0043903B2 (fr) * | 1980-07-15 | 1988-12-28 | Arturo Salice S.p.A. | Bras de charnière avec plaque de fixation |

| DE3043334C2 (de) * | 1980-11-17 | 1985-04-04 | Arturo Salice S.P.A., Novedrate, Como | Scharnierarm mit Befestigungsplatte |

-

1984

- 1984-07-19 DE DE19843426672 patent/DE3426672A1/de active Granted

-

1985

- 1985-05-22 AT AT85106306T patent/ATE38871T1/de not_active IP Right Cessation

- 1985-05-22 EP EP85106306A patent/EP0168595B1/fr not_active Expired

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE7517506U (de) * | 1975-06-03 | 1975-12-04 | Hettich P & Co | Scharnierarm |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3426672C2 (fr) | 1989-04-06 |

| DE3426672A1 (de) | 1986-01-30 |

| ATE38871T1 (de) | 1988-12-15 |

| EP0168595A3 (en) | 1986-05-28 |

| EP0168595A2 (fr) | 1986-01-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0168731B1 (fr) | Charnière pour meuble | |

| DE9110175U1 (de) | Beschlagteil zur Klemmbefestigung in einer mindestens einseitig hinterschnittenen Profilnut | |

| EP0168595B1 (fr) | Bras de charnière pour charnière de meuble | |

| DE2721625C2 (fr) | ||

| EP0256376B1 (fr) | Bras de charnière pour une charnière de meuble | |

| DE29612684U1 (de) | Verstellbarer Scharnierarm | |

| EP0010260B1 (fr) | Serre-joints | |

| DE2356000A1 (de) | Moebelscharnier | |

| DE4018235C2 (fr) | ||

| EP0602456A1 (fr) | Collier pour tuyaux | |

| DE4341422C2 (de) | Topfscharnier | |

| DE19732702A1 (de) | Bandlappen für ein Tür- oder Fensterband | |

| DE3913319C2 (fr) | ||

| EP0255692B1 (fr) | Bras de charnière pour charnière de meuble ou similaire | |

| DE4111144C2 (fr) | ||

| EP0790378A1 (fr) | Plaque de base pour une charnière | |

| DE29822770U1 (de) | Scharnier | |

| EP0205026B1 (fr) | Bras de charnière pour une charnière de meuble avec plaque de montage | |

| DE3516911A1 (de) | Befestigungsvorrichtung zum befestigen eines moebelbeschlagteils an einem moebelstueck | |

| DE20102455U1 (de) | Vorrichtung zur Befestigung eines Einbauelements in die Einbauöffnung einer Tragplatte | |

| EP0843061B1 (fr) | Ferrure pour fenêtre | |

| DE2720096A1 (de) | Moebelscharnier | |

| AT404962B (de) | Möbelscharnier | |

| AT391910B (de) | Scharnier | |

| DD237787A5 (de) | Moebelscharnier |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT FR GB IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19860725 |

|

| 17Q | First examination report despatched |

Effective date: 19871110 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT FR GB IT |

|

| REF | Corresponds to: |

Ref document number: 38871 Country of ref document: AT Date of ref document: 19881215 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19940403 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19940421 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19950522 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19950522 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19960229 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20000518 Year of fee payment: 16 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010522 |