EP0161971B1 - Band und seitliche Klappen enthaltende Verpackung - Google Patents

Band und seitliche Klappen enthaltende Verpackung Download PDFInfo

- Publication number

- EP0161971B1 EP0161971B1 EP85400779A EP85400779A EP0161971B1 EP 0161971 B1 EP0161971 B1 EP 0161971B1 EP 85400779 A EP85400779 A EP 85400779A EP 85400779 A EP85400779 A EP 85400779A EP 0161971 B1 EP0161971 B1 EP 0161971B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- panel

- strip

- web

- packaging

- flaps

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D75/00—Packages comprising articles or materials partially or wholly enclosed in strips, sheets, blanks, tubes, or webs of flexible sheet material, e.g. in folded wrappers

- B65D75/04—Articles or materials wholly enclosed in single sheets or wrapper blanks

- B65D75/14—Articles or materials wholly enclosed in single sheets or wrapper blanks in sheets or blanks folded-up around all sides of the contents from a portion on which the contents are placed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/02—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding or erecting a single blank to form a tubular body with or without subsequent folding operations, or the addition of separate elements, to close the ends of the body

- B65D5/0245—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding or erecting a single blank to form a tubular body with or without subsequent folding operations, or the addition of separate elements, to close the ends of the body with end closures formed by inward folding of flaps, to form a sunken or hollow end wall, e.g. for the packaging of books

Definitions

- a packaging of this type is particularly advantageous when its small faces are set back relative to the general outline of the packaging, because the packaged objects are thus better protected against impacts and lateral pressures.

- This manufacturing process has the disadvantage of creating scraps which are unusable and therefore discarded.

- a packaging of this type therefore has marked advantages with regard to the consumption of raw material, but it has the disadvantage of requiring the mounting of the two flaps added to the strip since this requires the use of non-standard machines. the cost of construction, depreciation and use of which diminish the advantage of the low cost price of the raw material.

- packaging of the type indicated above is generally devoid of integrated closure means, so that it cannot be used with modern automatic packaging machines.

- patent FR-A 2512784 which describes a package comprising a strip intended to wrap objects placed on its so-called “internal" face and provided with two transverse flaps which face each other.

- the present invention provides for taking the surface of the flaps in the extension of the strip itself, so that there is no significant drop and that the finished packaging is obtained without mounting of attachments and does not use generally only standard machines.

- the invention also provides for using the so-called "internal" face of the strip to secure the strip and the flaps and to ensure the closure of the packaging by bringing together the internal face and the external face of the strip after wrapping objects to wrap.

- the present invention is characterized in that the end panel is cut in line with the transverse fold only in the central part of said panel considered between two side edges of width su substantial and parallel to the two longitudinal edges of the strip, a panel which is divided in two to form said transverse flaps by a longitudinal longitudinal slit and which, after folding

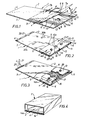

- a package according to the invention which comprises a strip of corrugated cardboard 1 having two longitudinal sides 2 and 3 and two ends respectively 4 and 5 perpendicular to sides 2 and 3, so that the strip has a perfectly rectangular outline.

- This strip is marked with a transverse fold line 6 which, with the longitudinal sides 2 and 3 and the end 5, determines a panel 7.

- this cut comprises two segments 10 and 11 which leave a narrow central tongue or "bridge" 12.

- the panel 7 is divided into two flaps 13 and 14 by a median longitudinal slot 15 on either side of which there are two notches 16 and 17 located face to face.

- the two flaps 13 and 14 are held together by unsplit parts or "bridges" 15a.

- Creasing lines 18 and 19 are provided parallel to each other, and longitudinally with respect to the strip 1, on the panels 13 and 14.

- the panel 7 is intended to be folded along the line 6, then folded down on the so-called "internal" face of the strip 1, according to the arrows F, as is evoked in dotted lines which show an intermediate straightening position 7a and the final position 7b of application of the panel 7 against the internal face of the strip 1.

- an adhesive Before folding the panel 7, an adhesive must be placed along the two lateral edges 8 and 9, either on the strip 1, as shown in FIG. 1, or on the panel 7.

- the folding down of the panel 7 according to the arrows F can be done according to two different methods: - if the user has a packaging machine, the finished article which is delivered to him can be that shown in FIG. 1, the panel 7 not being folded down and, of course, the adhesive not being put in place, or at least not being operational.

- the packaging operation comprises, as a first phase, that which consists in making the adhesive operational (depositing glue or removing a protective tape from an adhesive previously deposited either on the strip 1 , or on the panel 7) on the two lateral edges 8 and 9 and fold down the panel 7 according to the arrows F. Then the objects are packed as said below: - if the user carries out the packaging manually, the finished article delivered to it can be the one shown in FIG. 2, the panel 7 being folded against the strip 1 and kept glued by the adhesive along the two lateral flanges 8 and 9, either on the strip 1 or on panel 7.

- the user packs the objects as described below.

- an adhesive 20 such as glue

- the adhesive can be arranged automatically, by any known means, along lines or points.

- the packaging thus formed absolutely avoids the displacement of the objects and the deformation which could result therefrom for the flaps 13 and 14. It therefore provides a degree of protection unknown to this day.

- the packaging has a perfect rectangular shape, without any extra thickness and without any protruding part.

- the folding down of the panel 7 only concerns part of the strip 1, so that the latter can be well maintained by its other part, by means of organs of manufacturing, packaging machines, etc.

- the adhesive intended to secure the strip 1 and the flaps 13 and 14 can be placed either on the flaps 13 and 14 themselves, or on the internal face of the strip 1, approximately at the places referenced 20a and 20b in FIG. 2.

- This solution can be advantageous because the three locations 20, 20a and 20b are situated at the same, invariable level, of the internal face of the strip 1.

- the adhesive is of the immediate action type, such as glue, the composition and placement of which are perfectly mastered by the skilled person.

- such packaging makes it possible to wrap one or more objects A of different thicknesses since the flaps 13 and 14 can bend exactly to the desired height according to one of their crease lines 18 and 19 and that the part of the strip 1 located between the end 4 and the edge 5 folds at the desired location by surrounding the assembly formed by the packaged objects A, by the flaps 13 and 14 folded down and by the lower part of the strip 1 serving basic.

- the end 4 therefore applies to different places on the underside of the packaging (as seen in FIG. 4) depending on the thickness of the objects A and the adhesive 20 allows it to be fixed at a place any of this face.

- This packaging is characterized by the fact that the flap 7 is narrower than the strip 1, as a result of cuts of a few millimeters which release the strip 1 in lateral zones 1a and 1b. 1a width y of these areas is such that the panel 7 has a remaining width 1 smaller than the width L of the strip 1 and, therefore, smaller than the spacing of the sides of the belts located face to face.

- the belts act over the entire length of the packaging (strip 1 proper and zones 1 a and 1 b) while allowing the panel 7, entirely located between these belts, to be folded down without discomfort.

- zones 1a and 1b remain clear and the belts of the machine continue their function: guidance and displacement.

- the packaging of FIG. 6 is characterized by the fact that the sides 2 and 3 of the strip 1 have reinforcements 2a and 3a constituted by the wings of the strip 1 folded over the internal face of the latter, along the edges 2 and 3, and held together by an adhesive placed at the same time as that of the flanges 8 and 9.

- the wings extend to the immediate vicinity of the edge 5 after the panel 7 has been folded down. There are therefore two small falls formed by the withdrawal of the part of the wings 2a and 3a which originally extended over the entire length of the strip 1 before folding the panel 7.

- the wings 2a and 3a exceed the width of the panel 7 and cooperate with the conveyor belts of the machines, as has been explained above.

- the packaging is therefore properly maintained and guided.

- the panel 7, located between these belts can, here again, be folded transversely without discomfort against the strip 1.

- the wings 2a and 3a are then folded in turn, but longitudinally, against the strip 1 as is known to the skilled person. They are preferably maintained by an adhesive previously deposited in the desired places.

- the wings 2a and 3a are so killed inside the contour of the strip 1 and constitute reinforcements which are likely to better protect the packaged objects.

- the wings 2a and 3a do not extend to the edge 4 because the strip 1 is cut in a slight bevel to form a sort of transverse tab 1c provided, here again, with an adhesive 20 and a protective tape 21 along the edge 4.

- the packages delivered to customers and of the type of those in FIGS. 2, 3 and 5 have a double thickness at the location of the flaps 13 and 14. When they are stacked, they appear, seen from the side, as shown Figure 7. This asymmetrical arrangement is acceptable when the packaging must be used manually. First, for their delivery, they can be bêtveté by group, to compensate for angular shifts. Then, for their use, they can be unstacked one by one, without inconvenience, by an operator.

- packaging is used for series of one or more objects having a constant thickness, it is possible to use an external closure system different from an adhesive and such as that illustrated in FIGS. 9 and 10.

- Figure 9 shows a package in the same situation as that of Figure 1 and the same elements have the same references.

- the part of the strip 1 which is to be covered by the folded panel 7 comprises a slot 30 while a closing tab 31 is provided at the end 4 of the strip 1.

- the procedure is as explained above but the thickness of the objects to be packaged being known, the end 4 of the strip 1 is always located in the same place with respect to the face on which it is after wrapping, so that the tab 31 enters the slot 30 and is blocked there by tabs 32 and 33, thus that this is known per se.

- FIG. 9 the variant is shown which consists in providing reinforcements 2a and 3a because the packaging of objects of invariable dimensions lends itself particularly well to mechanization and it is therefore better to provide this type of packaging with means allowing it to be stacked flat, after folding down the panel 7, according to the diagram in FIG. 8.

- single-layer packaging can be used when the panel 7 is folded down only at the time of packaging. Then, no element for compensating for the thickness of the panel 7 (such as the wings 2a and 3a) is necessary.

- the machines available accept 150 cm plates and if a package is 51 cm wide, we can only provide two side by side with a fall of 48 cm wide.

- the packaging according to the invention being narrower than those of the prior art, it is possible to place more than two of them in the same width and reduce the residual drop accordingly.

- Standard machines called "folder-gluers” allow the manufacture of packaging according to the invention as well as other products and they equip most workshops in which boxes made of cardboard are manufactured.

- the simplicity of manufacture of packaging according to the invention also makes it possible to operate these machines at a rapid rate and to obtain a cost price further lowered.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Packages (AREA)

- Cartons (AREA)

- Basic Packing Technique (AREA)

- Packaging Of Annular Or Rod-Shaped Articles, Wearing Apparel, Cassettes, Or The Like (AREA)

- Supplying Of Containers To The Packaging Station (AREA)

- Wrappers (AREA)

- Making Paper Articles (AREA)

- Package Frames And Binding Bands (AREA)

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT85400779T ATE45549T1 (de) | 1984-04-19 | 1985-04-19 | Band und seitliche klappen enthaltende verpackung. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8406225A FR2563192B1 (fr) | 1984-04-19 | 1984-04-19 | Emballage comprenant une bande et des volets lateraux |

| FR8406225 | 1984-04-19 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0161971A1 EP0161971A1 (de) | 1985-11-21 |

| EP0161971B1 true EP0161971B1 (de) | 1989-08-16 |

Family

ID=9303326

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP85400779A Expired EP0161971B1 (de) | 1984-04-19 | 1985-04-19 | Band und seitliche Klappen enthaltende Verpackung |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US4589552A (de) |

| EP (1) | EP0161971B1 (de) |

| AT (1) | ATE45549T1 (de) |

| CA (1) | CA1237102A (de) |

| DE (1) | DE3572338D1 (de) |

| ES (1) | ES295826Y (de) |

| FR (1) | FR2563192B1 (de) |

Families Citing this family (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB8607781D0 (en) * | 1986-03-27 | 1986-04-30 | Unilever Plc | Package |

| US4758229A (en) * | 1987-09-24 | 1988-07-19 | Hollister Incorporated | Needle-stick injury prevention device and method |

| US5197260A (en) * | 1988-10-31 | 1993-03-30 | L Emballage Carton Sa (Societe Anonyme) | Method for packing articles, and machine for performing the method |

| FI82818C (fi) * | 1989-04-19 | 1991-04-25 | Pussikeskus Oy | Foerfarande foer foerpackning av boecker. |

| EP0431144B1 (de) * | 1989-06-28 | 1996-01-10 | Chevalier, Pierre | Verfahren und vorrichtung zum herstellen eines produktes, welches aus einer unterlage mit einer klebefläche langzeitiger klebefähigkeit und einem schutzband besteht |

| US4974770A (en) * | 1989-12-12 | 1990-12-04 | Eastman Kodak Company | Customized packaging |

| FI91052C (fi) * | 1991-05-02 | 1994-05-10 | Pussikeskus Oy | Kirjapakkausaihio ja menetelmä ja kone sen valmistamiseksi |

| FR2688199B1 (fr) * | 1992-03-05 | 1995-05-05 | Pierre Chevalier | Contenant comprenant une bande en carton ondule devant etre pliee transversalement selon des lignes nettes autour d'un contenu. |

| FR2692558A1 (fr) * | 1992-06-19 | 1993-12-24 | Emballage Carton Sa | Contenant à capacité variable destiné à la présentation d'articles en libre-service. |

| FI99196C (fi) * | 1995-02-28 | 1997-10-27 | Pussikeskus Oy | Menetelmä ja laite pakkausaihioiden valmistamiseksi jatkuvatoimisesti |

| GB9615855D0 (en) * | 1996-07-29 | 1996-09-11 | Kelso Clifford W | Fibreboard packing case |

| FR2788748A1 (fr) * | 1999-01-25 | 2000-07-28 | Chevalier Pierre | Contenant en carton obtenu par pliage d'une bande, destine a des objets de hauteur variable et ayant des moyens de maintien en position intermediaire entre la presentation a plat et la fermeture |

| US6394336B1 (en) | 2000-03-01 | 2002-05-28 | Motion Design, Inc. | Adjustable container and a method for forming an adjustable container |

| FR2800359A1 (fr) * | 2000-10-24 | 2001-05-04 | Chevalier Pierre | Flan en carton comprenant des volets lateraux et destine a l'obtention d'un contenant pour des objets de hauteur variable, et ayant des moyens de maintien en position intermediaire entre la presentation a plat et la fermeture |

| US20080029584A1 (en) * | 2002-08-29 | 2008-02-07 | Todd Van Gordon | Soap Bar Wrapper |

| FR2926288A1 (fr) * | 2008-01-16 | 2009-07-17 | Chevalier Simone | Emballage en carton avec maintien des volets en position ouverte. |

| ES1077714Y (es) * | 2012-07-31 | 2012-12-20 | Gutierrez Jose Ramon Perez | Envase de madera |

| GB201303009D0 (en) * | 2013-02-20 | 2013-04-03 | Packaging One Ltd | Media wrap with load bearing foam |

| USD750478S1 (en) * | 2014-04-02 | 2016-03-01 | Tile, Inc. | Folding container |

| EP3122651B1 (de) * | 2014-07-02 | 2018-01-10 | Bedford Industries, Inc. | Etikettanordnung zum halten und auslegen von produkten |

| US10052754B1 (en) * | 2017-04-12 | 2018-08-21 | Ullman Devices Corporation | Magnetic tool holder |

| GB2564428A (en) * | 2017-07-07 | 2019-01-16 | Lil Packaging Ltd | Wrap container |

| JP7363326B2 (ja) * | 2019-10-08 | 2023-10-18 | Tdk株式会社 | 梱包体及び緩衝具 |

| EP4061730A4 (de) | 2019-11-22 | 2024-01-03 | Pac Worldwide Corp | Anpassbarer wiederverwendbarer transportbehälter |

| GB2593923B (en) * | 2020-04-09 | 2022-06-29 | Packaging One Ltd | Wrap around container |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2274253A (en) * | 1939-04-24 | 1942-02-24 | Pharma Craft Corp Inc | Display carton |

| US2253770A (en) * | 1940-04-05 | 1941-08-26 | Read Machinery Co Inc | Method of continuously manufacturing bread |

| US2449334A (en) * | 1944-05-04 | 1948-09-14 | Package Machinery Co | Method of packaging |

| US2846060A (en) * | 1954-11-15 | 1958-08-05 | Stanley G Yount | Wrapping means for articles of sheet form |

| US3260359A (en) * | 1965-06-09 | 1966-07-12 | Procter & Gamble | Package improvement |

| FR2082000A5 (de) * | 1969-12-05 | 1971-12-10 | Emballage Carton | |

| US3666166A (en) * | 1970-05-22 | 1972-05-30 | Gen Corrugated Machinery Co In | Wrapping set and package formed therefrom |

| US3847282A (en) * | 1973-01-02 | 1974-11-12 | Container Corp | Display carton |

| FR2284529A1 (fr) * | 1974-09-16 | 1976-04-09 | Etudes De Machines Speciales | Emballage inviolable et dispositif pour sa mise en oeuvre |

| FR2415048A1 (fr) * | 1978-01-20 | 1979-08-17 | Emballage Carton Sa | Emballage preconforme a mise en volume rapide autour d'un objet a emballer |

| US4300679A (en) * | 1980-08-27 | 1981-11-17 | Container Corporation Of America | Self locking folder |

| FR2512784A1 (fr) * | 1981-09-11 | 1983-03-18 | Chevalier Pierre | Emballage muni d'une bande adhesive de fermeture utilisable selectivement soit pour " envoi non clos " soit comme fermeture inviolable |

| DE3318549C2 (de) * | 1983-05-20 | 1994-11-10 | Nestler Robert Wellpappen | Flächenstück aus Pappe, Karton oder dgl. für die Ausbildung einer Verpackung für plattenförmiges Verpackungsgut |

-

1984

- 1984-04-19 FR FR8406225A patent/FR2563192B1/fr not_active Expired

-

1985

- 1985-04-18 CA CA000479476A patent/CA1237102A/fr not_active Expired

- 1985-04-19 EP EP85400779A patent/EP0161971B1/de not_active Expired

- 1985-04-19 US US06/724,836 patent/US4589552A/en not_active Expired - Lifetime

- 1985-04-19 ES ES1985295826U patent/ES295826Y/es not_active Expired

- 1985-04-19 DE DE8585400779T patent/DE3572338D1/de not_active Expired

- 1985-04-19 AT AT85400779T patent/ATE45549T1/de not_active IP Right Cessation

Also Published As

| Publication number | Publication date |

|---|---|

| ES295826Y (es) | 1988-01-01 |

| FR2563192A1 (fr) | 1985-10-25 |

| EP0161971A1 (de) | 1985-11-21 |

| DE3572338D1 (en) | 1989-09-21 |

| ES295826U (es) | 1987-07-01 |

| FR2563192B1 (fr) | 1986-08-14 |

| ATE45549T1 (de) | 1989-09-15 |

| US4589552A (en) | 1986-05-20 |

| CA1237102A (fr) | 1988-05-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0161971B1 (de) | Band und seitliche Klappen enthaltende Verpackung | |

| WO1997010137A2 (fr) | Contenant livre a plat, puis mis en volume en deux phases distinctes, et portant de l'adhesif a effet prolonge | |

| CH394033A (fr) | Emballage de carton | |

| EP0443930B1 (de) | Aus Pappe, Wellpappe oder anderem passend geschnittenem und gefaltetem Folienmaterial hergestellte Verpackung mit einem wiederverschliessbaren, mit einem Handgriff versehenen Deckel und entsprechender Zuschnitt | |

| FR2498562A1 (fr) | Separatif pour bouteilles ou analogues | |

| EP0904235B1 (de) | Verfahren zur herstellung einer verpackung mit einem aufsteckbaren deckel aus einem zuschnitt | |

| FR2609965A1 (fr) | Emballage du genre caisse, en particulier caisse a legumes en carton, carton ondule ou autre materiau en feuille | |

| FR2591998A1 (fr) | Emballage perfectionne pour livres, disques et objets analogues | |

| EP0114772B1 (de) | Zuschnitt für eine mit einem Handgriff versehene Verpackung und übereinstimmender Verpackungsentwurf und Verpackung | |

| EP1348635B1 (de) | Behälterzuschnitt aus halbsteifen Material wobei eine Oberfläche mit einem Schrumpffilm versehen ist | |

| FR2883847A1 (fr) | Palette en carton avec au moins une languette de verrouillage, procede de fabrication de la palette, ensemble d'une palette avec un emballage | |

| FR2806379A1 (fr) | Flan en carton ou materiau similaire comprenant un bandeau et deux pattes munis tous trois d'un adhesif en vue de la constitution en volume d'un contenant a fermeture inviolable | |

| EP0074293A1 (de) | Verpackung mit Klebelaschen | |

| FR2757489A1 (fr) | Conditionnement pour article fragile | |

| EP0887275B1 (de) | Verpackung für einen rechteckigen flachen Gegenstand wie eine Fahrzeug-Motorhaube | |

| EP1228970B1 (de) | Oben offene Kartonschachtel mit Kartonhülle | |

| FR2915738A1 (fr) | Emballage en un materiau semi-rigide pour le conditionnement d'au moins un objet | |

| FR2679207A1 (fr) | Element de calage en carton, carton ondule ou autre materiau en feuille convenablement decoupe et plie, et flan correspondant, notamment pour appareil electrique. | |

| FR2798648A1 (fr) | Article de conditionnement du type boite en carton et son utilisation pour le conditionnement des medicaments | |

| FR2690416A1 (fr) | Boîte en carton ou analogue, notamment destinée à contenir des pots pour produits laitiers, et flan pour la réalisation d'une telle boîte. | |

| WO2000043283A2 (fr) | Contenant en carton obtenu par pliage d'une bande, destine a des objets de hauteur variable | |

| FR2688199A1 (fr) | Contenant comprenant une bande en carton ondule devant etre pliee transversalement selon des lignes nettes autour d'un contenu. | |

| FR2613697A1 (fr) | Emballage formant presentoir en carton, carton ondule, ou autre materiau en feuille, en particulier pour verres, et flans correspondants | |

| FR2867753A1 (fr) | Emballage individuel et boite d'emballage secable | |

| FR2672874A1 (fr) | Caisse-outre a fond automatique et son procede d'assemblage. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19860517 |

|

| 17Q | First examination report despatched |

Effective date: 19871106 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 45549 Country of ref document: AT Date of ref document: 19890915 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed |

Owner name: ING. A. GIAMBROCONO & C. S.R.L. |

|

| REF | Corresponds to: |

Ref document number: 3572338 Country of ref document: DE Date of ref document: 19890921 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19930429 Year of fee payment: 9 |

|

| EPTA | Lu: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19940419 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 85400779.6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19950425 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19950428 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19950510 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19960419 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19960420 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19960430 Ref country code: CH Effective date: 19960430 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19960628 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| EUG | Se: european patent has lapsed |

Ref document number: 85400779.6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980101 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19991029 Year of fee payment: 15 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001101 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20001101 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20010528 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020430 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20040430 Year of fee payment: 20 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20050418 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 |