EP0157421B1 - Projectile fumigène - Google Patents

Projectile fumigène Download PDFInfo

- Publication number

- EP0157421B1 EP0157421B1 EP85104036A EP85104036A EP0157421B1 EP 0157421 B1 EP0157421 B1 EP 0157421B1 EP 85104036 A EP85104036 A EP 85104036A EP 85104036 A EP85104036 A EP 85104036A EP 0157421 B1 EP0157421 B1 EP 0157421B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- smoke

- projectile according

- contact head

- charge

- smoke projectile

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 239000000779 smoke Substances 0.000 title claims abstract description 65

- 239000003380 propellant Substances 0.000 claims abstract description 57

- 239000000843 powder Substances 0.000 claims abstract description 14

- 239000000203 mixture Substances 0.000 claims abstract description 13

- 239000000463 material Substances 0.000 claims abstract description 10

- 239000000020 Nitrocellulose Substances 0.000 claims abstract description 8

- 229920001220 nitrocellulos Polymers 0.000 claims abstract description 8

- SNIOPGDIGTZGOP-UHFFFAOYSA-N Nitroglycerin Chemical compound [O-][N+](=O)OCC(O[N+]([O-])=O)CO[N+]([O-])=O SNIOPGDIGTZGOP-UHFFFAOYSA-N 0.000 claims abstract description 7

- 229960003711 glyceryl trinitrate Drugs 0.000 claims abstract description 7

- 239000004952 Polyamide Substances 0.000 claims abstract description 4

- 229920002647 polyamide Polymers 0.000 claims abstract description 4

- 229910000831 Steel Inorganic materials 0.000 claims description 12

- 239000010959 steel Substances 0.000 claims description 12

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 10

- 229910052782 aluminium Inorganic materials 0.000 claims description 8

- 239000011888 foil Substances 0.000 claims description 6

- XLOMVQKBTHCTTD-UHFFFAOYSA-N Zinc monoxide Chemical compound [Zn]=O XLOMVQKBTHCTTD-UHFFFAOYSA-N 0.000 claims description 5

- 239000003822 epoxy resin Substances 0.000 claims description 5

- VHHHONWQHHHLTI-UHFFFAOYSA-N hexachloroethane Chemical compound ClC(Cl)(Cl)C(Cl)(Cl)Cl VHHHONWQHHHLTI-UHFFFAOYSA-N 0.000 claims description 5

- 229920000647 polyepoxide Polymers 0.000 claims description 5

- 230000015572 biosynthetic process Effects 0.000 claims description 4

- NLSCHDZTHVNDCP-UHFFFAOYSA-N caesium nitrate Chemical compound [Cs+].[O-][N+]([O-])=O NLSCHDZTHVNDCP-UHFFFAOYSA-N 0.000 claims description 4

- 230000006378 damage Effects 0.000 claims description 4

- JEIPFZHSYJVQDO-UHFFFAOYSA-N iron(III) oxide Inorganic materials O=[Fe]O[Fe]=O JEIPFZHSYJVQDO-UHFFFAOYSA-N 0.000 claims description 4

- 229920003002 synthetic resin Polymers 0.000 claims description 4

- 239000000057 synthetic resin Substances 0.000 claims description 4

- UQSXHKLRYXJYBZ-UHFFFAOYSA-N Iron oxide Chemical compound [Fe]=O UQSXHKLRYXJYBZ-UHFFFAOYSA-N 0.000 claims description 3

- 239000011230 binding agent Substances 0.000 claims description 3

- 238000004519 manufacturing process Methods 0.000 claims description 3

- 229920002379 silicone rubber Polymers 0.000 claims description 3

- 239000004945 silicone rubber Substances 0.000 claims description 3

- 229910021346 calcium silicide Inorganic materials 0.000 claims description 2

- LIKBJVNGSGBSGK-UHFFFAOYSA-N iron(3+);oxygen(2-) Chemical compound [O-2].[O-2].[O-2].[Fe+3].[Fe+3] LIKBJVNGSGBSGK-UHFFFAOYSA-N 0.000 claims description 2

- 239000011787 zinc oxide Substances 0.000 claims description 2

- 239000004411 aluminium Substances 0.000 claims 3

- 239000003595 mist Substances 0.000 description 23

- 239000007789 gas Substances 0.000 description 8

- 239000000006 Nitroglycerin Substances 0.000 description 5

- 238000002485 combustion reaction Methods 0.000 description 3

- 239000004020 conductor Substances 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- LQBJWKCYZGMFEV-UHFFFAOYSA-N lead tin Chemical compound [Sn].[Pb] LQBJWKCYZGMFEV-UHFFFAOYSA-N 0.000 description 3

- 230000035939 shock Effects 0.000 description 3

- 230000007797 corrosion Effects 0.000 description 2

- 238000005260 corrosion Methods 0.000 description 2

- 238000004880 explosion Methods 0.000 description 2

- 238000010304 firing Methods 0.000 description 2

- 238000009413 insulation Methods 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- JTJMJGYZQZDUJJ-UHFFFAOYSA-N phencyclidine Chemical compound C1CCCCN1C1(C=2C=CC=CC=2)CCCCC1 JTJMJGYZQZDUJJ-UHFFFAOYSA-N 0.000 description 2

- 239000002760 rocket fuel Substances 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 229910001128 Sn alloy Inorganic materials 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000003111 delayed effect Effects 0.000 description 1

- 229920001971 elastomer Polymers 0.000 description 1

- 239000002360 explosive Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 239000008188 pellet Substances 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 238000001556 precipitation Methods 0.000 description 1

- 239000003566 sealing material Substances 0.000 description 1

- 125000006850 spacer group Chemical group 0.000 description 1

- 230000002269 spontaneous effect Effects 0.000 description 1

- 230000001502 supplementing effect Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F42—AMMUNITION; BLASTING

- F42B—EXPLOSIVE CHARGES, e.g. FOR BLASTING, FIREWORKS, AMMUNITION

- F42B5/00—Cartridge ammunition, e.g. separately-loaded propellant charges

- F42B5/02—Cartridges, i.e. cases with charge and missile

- F42B5/08—Cartridges, i.e. cases with charge and missile modified for electric ignition

-

- C—CHEMISTRY; METALLURGY

- C06—EXPLOSIVES; MATCHES

- C06D—MEANS FOR GENERATING SMOKE OR MIST; GAS-ATTACK COMPOSITIONS; GENERATION OF GAS FOR BLASTING OR PROPULSION (CHEMICAL PART)

- C06D3/00—Generation of smoke or mist (chemical part)

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F42—AMMUNITION; BLASTING

- F42B—EXPLOSIVE CHARGES, e.g. FOR BLASTING, FIREWORKS, AMMUNITION

- F42B12/00—Projectiles, missiles or mines characterised by the warhead, the intended effect, or the material

- F42B12/02—Projectiles, missiles or mines characterised by the warhead, the intended effect, or the material characterised by the warhead or the intended effect

- F42B12/36—Projectiles, missiles or mines characterised by the warhead, the intended effect, or the material characterised by the warhead or the intended effect for dispensing materials; for producing chemical or physical reaction; for signalling ; for transmitting information

- F42B12/46—Projectiles, missiles or mines characterised by the warhead, the intended effect, or the material characterised by the warhead or the intended effect for dispensing materials; for producing chemical or physical reaction; for signalling ; for transmitting information for dispensing gases, vapours, powders or chemically-reactive substances

- F42B12/48—Projectiles, missiles or mines characterised by the warhead, the intended effect, or the material characterised by the warhead or the intended effect for dispensing materials; for producing chemical or physical reaction; for signalling ; for transmitting information for dispensing gases, vapours, powders or chemically-reactive substances smoke-producing, e.g. infrared clouds

Definitions

- the invention relates to a mist launcher, in particular for firing from throwing cups with a centrally located propellant charge, consisting of a can with a mist set therein and an ignition charge and a contact head connected to the can with a bridge igniter, delay set and a sleeve surrounding the contact head, preferably made of polyamide. with contact rings. (See e.g. GB-A 2056632).

- Such throwing bodies are fired from throwing cups (launchers) which are fastened to a tank or to another vehicle which is supposed to be able to change positions without being seen by the opponent.

- throwing cups launchers

- a fog is generated very quickly, which takes away the opponent's view in a larger area. Since these missiles have to develop fog during the flight in order to reliably fulfill the camouflage purposes, such smoke towers are also referred to as rapid smoke towers.

- These smoke projectors usually consist of a contact head with contact rings for the ignition of a propellant charge, with the aid of which the projectiles are expelled from the throwing cups.

- a smoke impact body has become known from DE-A 2908116.

- the propellant charge is enclosed in a room that is located in a contact head made of plastic.

- Black powder is conventionally used as the propellant charge in this case, as in other known smoke projectors.

- black powder does not burn residue-free, so the throwing cups have to be cleaned constantly to avoid corrosion of the walls of the cups by these residues. Corrosion would render the cups unusable.

- Propellant charges that burn completely without leaving residues e.g. Nitroglycerin or nitrocellulose cannot be used as a powder or in block form in such throwing bodies, since on the one hand a gas pressure of about 13.5 bar within 2 milliseconds must not be exceeded in the throwing cups and on the other hand the throwing bodies at the extremely high, about 10 times that occurring Pressures having value would be destroyed.

- rupture discs do not reduce the expulsion pressure; after its destruction when the thrust is inserted, this acts in full on the throwing cup base, which is usually held with a spring ring.

- the invention is therefore based on the object of improving smoke throwers of the type mentioned at the outset such that materials which burn completely without residues, such as nitrocellulose and nitroglycerin, as a powder or in block form, can be used as propellants while maintaining the required maximum firing pressure.

- the object is achieved by a smoke throwing body with the features of claim 1.

- the contact heads are usually made of aluminum for weight and manufacturing reasons. However, this is unable to withstand the high explosion pressures of the propellant charges to be used according to the invention with acceptable wall thicknesses. Only by using the insert made of high-strength material, e.g. made of steel, it is possible to use nitrocellulose or nitroglycerin powder or blocks for the propellant charge.

- the contact head is made of aluminum or steel and the insert is made of high-strength steel, the insert being firmly connected to the contact head, e.g. screwed or pressed in excess.

- the contact head and the insert are preferably made in one piece and then made of high-strength steel. It would be advantageous to arrange the deceleration set in the contact head by means of a base plate and to connect it to the propellant charge.

- the contact head is annular.

- the insert passes through the contact head, the insert being screwed to a cover or threaded part, the cover or the threaded part carrying the deceleration set.

- the insert can have a first cup-shaped part which is fastened in the contact head and a second threaded part which is fastened within the first part which carries a thread and is connected to the deceleration set.

- the delay unit is preferably connected to the propellant unit via a bore, the delay unit being advantageously arranged in the second threaded part.

- the contact head is ring-shaped and the insert is screwed through the ring, the result is a particularly simple construction which also reduces the risk of propellant particles penetrating into threads and the risk of the propellant igniting during screwing.

- the delay set and the ignition set can preferably be accommodated together, forming a unit, in a bore in a housing element designed as a threaded piece, the bore having a narrowed through opening.

- the deceleration set is located on the side of the hole facing the propellant charge. This has the advantage that an immediate and direct continuation of the ignition from the delay set to ignite with a too fast ignition of the fog set.

- the housing piece for receiving the deceleration and ignition charge is preferably the second threaded part of the insert.

- the part which closes the cup-shaped or cup-shaped threaded part of the insert also becomes the carrier of the delay and ignition charge.

- the delay set is preferably connected directly to the space for receiving the propellant set. This leads to an improved ignition of the delay set.

- An advantageous embodiment of the invention consists in the fact that the nozzles from which the propellant gases flow out are cast with a synthetic resin, preferably with epoxy resin. This ensures that the pressure inside the room that receives the propellant initially reaches a certain value and can only flow out of the room after the epoxy resin has burned through.

- An advantageous embodiment consists in that the nozzles are additionally covered with a plate, preferably made of silicone rubber. This protects the epoxy resin from mechanical destruction.

- At least three outwardly directed nozzles are preferably provided, which have a diameter of approximately 2 mm and / or a cross section of 2 mm 2 , the gas space being able to comprise approximately 1.5 to 2 cm 3 .

- the nozzles are arranged on a circle which is larger than the diameter of the spacer mandrel arranged on the base of the throwing cup.

- the nozzles for generating a gas cone are preferably arranged in an inclined manner, wherein in a further embodiment the nozzle axes can also run at an angle to the axis of the smoke throwing body for generating a swirl. If a smaller number of nozzles is provided, asymmetrical movements of the smoke throwing body can occur, which negatively influences its flight stability.

- the nozzle axes for generating a swirl should not run through the axis of the throwing body, since it is then possible to impart a swirl to the fog throwing body, which significantly increases flight stability.

- the pressure in the throwing cup is reduced to the desired values and, on the other hand, the propellant pressure is reduced with a delay, so that the smoke throwing body is driven out - as if with a rocket motor - which can lead to more stable behavior and also greater ranges. It is also possible to influence the rate at which the deceleration charge burns up by adjusting the amount of propellant charge.

- the burn-up of the (specified) deceleration charge is also accelerated, so that the ignition of the smoke set can now be brought forward to a point in time immediately after leaving the throwing cup or to an adjustable distance behind, whereby only the charge quantity of the Propellant needs to be adjusted.

- the delay includes a backup system that prevents the delay set from being blown out. Without this safeguard, the deceleration is blown out by the high pressure in the high-pressure section and the blowout process ignites the fog set directly (without delay) and already mists in the throwing cup. This fog process, which begins in the throw cup, contaminates the throw cup.

- the insert have a bore to the bridge igniter running laterally and transversely to the axis of the contact body, the diameter of which is smaller than that of the bridge igniter .

- the through opening of the bore is preferably significantly smaller than the diameter of the bridge igniter.

- the propellant charge is preferably designed as a star burner made of rocket fuel - preferably as a degressive minister burner.

- the star burner is preferably arranged at a distance from the bottom of the insert having the bores, the bridge igniter preferably being arranged in the interior of the star burner and the connecting leads to the igniter being led through the bores, the strengths of the connecting leads approximately corresponding to the diameter of the bores and wherein the bridge igniter is preferably arranged in the pot bottom of the area of the star burner in use and is suspended from the connecting lines.

- the propellant charge preferably consists of nitrocellulose or nitroglycerin powder as base components with a binder with degressive burnup, it being extruded or pressed.

- a particularly advantageous embodiment of the invention is that the insert is followed by a nozzle ring connected via an edge-side seal, spaced apart from it, which the delay set penetrates and that the can ends at the seal in such a way or protrudes at a short distance such that when the The hot fog through the nozzle openings of the nozzle ring with peripheral destruction of the seal between the contact head and socket, optionally through an annular space arranged in the contact head.

- the can can be disassembled, after which the fog either spreads out in the air in a spherical manner, or in a dome shape lying on the ground, or also by the fact that the fog is ejected from the ends of the throwing bodies, resulting in an approximately cylindrical fog pattern arises.

- the roller shape has the disadvantage of having relatively small diameters in flight.

- the flight distance is limited by the amount of the propellant. The enlargement of the diameter of the fog formation and the improvement of the throwing distances are achieved as follows: After the deceleration charge is ignited and burned off by a propellant charge, the ignition charge is activated and ultimately the fog charge is ignited.

- the hot gases formed pass through the nozzle ring and meet the material of the seal. This burns and allows the fog to emerge peripherally.

- the high internal pressure in the can accelerates it radially, which means that considerably larger smoke wall diameters can be achieved in flight than was previously possible.

- the axial vector is so large that the mist launcher is accelerated further and the mist set itself acts as a rocket motor. In particular in cooperation with the above-described insert having the nozzle in the contact head, this results in further additional advantages. Since the seal e.g.

- the fog can be caused by intentionally set inhomogeneities not to immediately burn evenly over the entire circumference, the fog can initially only emerge from the interior at one or more points under strong pressure. This leads to a deliberate wobbling movement that enlarges the wall of fog. If the smoke nozzle has a twist, this creates a helical ejection characteristic, which leads to homogeneous fog walls of large diameter. In contrast to conventional throwing bodies, after such a smoke impact body strikes the ground, it does not remain there, but the mist that continues to flow allows the smoke impact body to roll further in the direction of the throw, which also causes the smoke wall to expand.

- a variant of this embodiment consists in that the nozzle openings are arranged conically and coaxially in the edge region of the nozzle ring and are closed by the seal, the seal being conical with the aid of a projection of the upper edge of the can and a chamfering of the lower edge of the contact button lying between them Section forms in the extension of which the nozzle openings are.

- the axis of the nozzle openings and that of the conical sections of the seals preferably form an angle of 45 ° to the axis of the can.

- the nozzle ring can be arranged in a collar directed into the can, with the aid of which both parts can be firmly connected to one another.

- the collar with the nozzle ring and the socket can thus be securely attached to the contact head by simply screwing them together.

- a further preferred embodiment consists in that the central axes of the nozzle openings form an angle of approximately 45 ° with the throwing body axis and, if appropriate, preferably run coaxially skewed at an angle ( ⁇ ) to the central axis of the fog throwing body for swirl formation.

- the nozzle openings of the nozzle ring against the fog set are closed with the aid of a foil, preferably a lead-tin foil. This material is destroyed by the burning temperatures, which releases the nozzles.

- the propelling force of the emerging mist can advantageously be increased in that the mist set is designed as a driving mist set, with at least the first being the driving mist set in the case of a plurality of mist sets.

- a particularly advantageous embodiment consists in that at least the mist set that burns first has a convex or conical projecting contact surface with the correspondingly recessed second mist set.

- the fog sets usually consist of pellets. Due to the manufacture, the height of these disc-shaped bodies is limited. However, one has to rely on stacking several compacts, which has the following disadvantage: Normally, the burning rate is not uniform over the cross-section of the compacts, because the deceleration set preferably ignites the mists in the middle, from where the Spreads the ignition spot. But this leads to the fact that the subsequent compact is also ignited in a punctiform manner, which happens exactly at the moment when the effect of the first compact diminishes. This results in the "holes” in the fog wall that can be observed particularly clearly during flight.

- the invention provides a quick-release smoke missile with long ranges and at the same time a significantly improved fog effect.

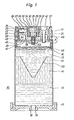

- Fig. 1 shows a section through a smoke nozzle 10 with an aluminum contact head 11 of a box 12, in which fog sets 13, 14 and 15 are housed.

- mist set 15 which is designed as a propellant mist set in the present embodiment, there is an ignition set 16.

- ignition set 16 At the lower edge of the can 12, a rubber plate 17 is fastened by means of a nut 18 and secured with an adhesive 19 to secure the shock.

- the contact surface 20 between the fog sets 15 and 14 is frustoconical.

- the fog set 15 engages in the fog set 14.

- the contact head 11 which is made of aluminum, is surrounded by an insulating sheath 21 which is made of polyamide and is arranged all around on the contact rings 22 and 23.

- the contact rings 22 and 23 are connected via connecting lines 24 and 25, which run through unspecified openings of the insulating sleeve 21 to the inside, with a bridge igniter 26, which is accommodated in a bore 27 in the contact head 11 and via an opening 28 with the Receiving space 29 for a propellant charge 30 is connected.

- the insert 32 is pot-shaped, its bottom region 33 is directed upwards and contains a plurality of nozzles 34 which are poured out with epoxy resin and are additionally closed to the outside by means of a metal foil 35.

- the insulating sleeve 21 lies against a shock protection 36 on a flange-like collar 37 at the upper end of the contact head 11.

- the contact head 11 has a cylindrical extension 38, which is surrounded by a hollow cylindrical projection 40 to form an annular space 39, the extension 38 projecting slightly beyond the hollow cylindrical projection 40.

- the contact head 11 is placed with its extension 38 on a plate 41 and fastened to it by means of screw connections 42 or connected to it. Between the surface of the plate 41 and the hollow cylindrical projection 40 there is a gap 44, which corresponds to a gap between the insulating sleeve 21 and the surface of the plate 41; in the gap between the insulating sleeve 21 and the plate 41 there is a seal 43 (see FIGS. 8 and 9). Due to the different dimensions of the extension 38 and the projection 40, the seal 43 is prevented from being crushed when the screw connection 42 is tightened (several screws are provided).

- nozzle ring 45 with a plurality of nozzles arranged on the plate edge, which, as can be seen in particular from FIGS. 8 and 9, are directed directly at the seal 43. There is also the possibility that they open into the annular space 39, which leaves access to the seal 43 via the gap 44.

- the nozzle ring 45 is secured against the igniter 16 by means of a lead-tin foil 46.

- the insert 32 is designed as a cup-shaped or cup-shaped threaded part with an external thread 47, which has an internal thread 48 in the area of its cup or pot edge, into which a second thread part 49, likewise cup-shaped or cup-shaped, is screwed can be.

- the two threaded parts thus form the entire insert 32 and delimit the receiving space 29 for the propellant charge.

- a bore 50 is provided which continues in a bore 51 in the bottom of a threaded bore 52.

- a delay set 53 is screwed into this threaded bore 52, which is described in more detail with reference to FIG. 10. This delay set 53 has, according to FIG.

- a delay piece 54 which is provided with an external thread on the head side (without reference number) so that it can be screwed into the threaded bore 52, and a bore 56, which prevents undesired spontaneous burning and expulsion of the burning material opens in the assembled state in the two bores 50 and 51, and on the foot side a delay device 57 with a smaller bore 58.

- the delay set 53 is shown differently in FIG. the position of the delay set 53 is only to be shown schematically there.

- the bridge igniter 26 (FIG. 2) is surrounded by a steel cap 59 which, together with the bridge igniter 26, is screwed into a threaded bore 60.

- the threaded bore 60 continues in the bores 27 and 28 and a transverse bore 28 'in the insert 32 in the receiving space 29.

- the electrical connecting lines 24 and 25 are inserted through the steel cap 59, specifically through a space 61 between the casing 21 and the contact head 11, which is filled with synthetic resin after the connecting lines 25 and 25 'have been inserted.

- the shock protection 36 is designed as an O-ring seal and at the same time serves to produce a vacuum seal. The vacuum tightness is achieved together with the synthetic resin in room 61.

- FIG. 6 shows the insert 32 in a top view of the bottom section.

- Three nozzles 34 can be seen here, which are evenly distributed over the circumference. 6, these nozzles 34 are shown axially parallel.

- the nozzles 34 are shown running obliquely inwards.

- the nozzles 34 To generate a swirl, it is sufficient to drill the nozzles 34 at an angle a; the nozzle axes should preferably not intersect the projectile axis.

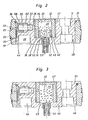

- FIGS. 1 to 3 shows a further embodiment of the invention.

- the contact head 65 shown here has no extension 38; the hollow cylindrical projection 40 delimits a pot space 66 into which an insert 67 protrudes.

- a cover 68 can be screwed onto this insert 67, which then limits the receiving space 29 for the propellant charge 30 downwards.

- the delay set 53 is then screwed into the cover 68, a bore 69 corresponding to the bores 50 and 51 being made in the cover 68 between the delay set 53 and the receiving space 29.

- both the insert 67 and the cover 68 supplementing the insert 67 are made of steel.

- the insert 32 or 67 is shown in FIGS. 1 to 3 as being screwed into the contact head 11 or 65. It is of course also possible to press it in or to fix it in the contact head 11 or 65 using a conical design and a counter-cone.

- FIG. 4 Another embodiment of the invention is shown in FIG. 4.

- the contact head 70 has an opening 71 in its central region with an internal thread, into which an insert 72 is screwed.

- This insert 72 is again pot-shaped and has a pot bottom 73 at its upper end, in which two bores 74 and 75 and a slot 76 are made on the outer surface (see also FIG. 7).

- the bores 74 and 75 correspond to the nozzles 34 and are dimensioned practically the same as these.

- a propellant charge 77 is introduced into the interior of the insert 72 and, as can be seen from FIGS. 13 and 14, is designed as a star burner.

- This propellant charge 77 is arranged at a distance from the pot bottom 73 and surrounds a star-shaped space 78 in which a bridge igniter 79 in the form of a squib is housed. It can be seen from FIG. 13 that the bridge igniter 79 is arranged in the region of the upper end of the propellant charge 77. In contrast to this, in the embodiment according to FIG. 4, the bridge igniter 79 is arranged approximately in the central region of the star-shaped space 78.

- the propellant charge 77 designed as a star burner, has a weight of approx. 2 g.

- the bridge igniter 79 designed as a squib has an insulation body 80, to the front end of which explosive 81 and to the rear end of which connection conductors 82 and 83 are connected. These two connection conductors 82 and 83 are led out of the interior of the insert 72 through the bores 74 and 75 and lie in a guide channel 84 which extends in the axial direction between the contact head 70 and the insert 72.

- the connecting lines 82 and 83 enter a pot space 86 corresponding to the pot space 66 and are led out via two channel bores 85 into a channel 87 corresponding to the space 61.

- the insert 72 is screwed into the aluminum contact head 70 via the slot 76 and is deepened relative to the surface of the contact head 70, so that a silicone rubber seal 88s can be inserted into the depression formed.

- the insert 72 like the other inserts 32, 67, is also made of high-strength material, in this case steel.

- a steel threaded piece 90 is screwed into the end of the insert 72 opposite the pot bottom 73 and has an inner bore 91 which is divided into two spaces 93 and 94 by an intermediate wall 92 approximately in the central area.

- the intermediate wall 92 there is a small through opening 95 and above the intermediate wall 92, that is to say towards the combustion chamber or the propellant charge 77 (star burner), there is a delay set 96 and on the opposite, lower side an ignition charge 97. If after ignition the Ignition cap burns the propellant charge 77, the ignition charge 97 is ignited via the delay set 96, as a result of which the fog charge is ignited.

- FIG. 8 and 9 show sections A of FIG. 1 in an enlarged representation in two variants.

- the seal 43 is inserted, which due to a chamfer 100 on the insulating sleeve 21 and one conical projection 101 on the can 12 an obliquely ko niche upwardly bent portion 102. Accordingly, the seal 43 is turned over at its edge with a section 102 designed as a cone. This section 102 lies in the extension of the nozzle openings 103 of the nozzle ring 45.

- the angled section 102 is not formed.

- the seal 43 is flat in a ring shape and only seals the nozzle openings 103 of the nozzle ring 45.

- the combustion of the sealing material takes place much faster, which means that, in addition to the faster burn-up of the deceleration set, the fog can also be accelerated if desired.

- FIG. 11 and 12 show the plate 41 sealing the can 12 with the nozzle ring 45 and the nozzle openings 103.

- a collar 104 is provided on the plate 41, which is provided with an external thread 105 and is screwed into the upper edge of the can 12 can be.

- the plate 41 there are a threaded bore 106 for receiving the deceleration set 53 (see FIG. 1) and three threaded bores 107 into which screw connections 42 can be screwed.

- the longitudinal direction or longitudinal axis of the nozzle openings 103 can run through the center of the plate 41. There is also the possibility, as indicated in FIG.

- the connecting lines 82, 83 are guided through the bores 74, 75 (FIG. 4) serving as nozzles has the advantage that no sealing problems have to be taken into account, as is necessary when the connecting lines are led through to the side.

- the spacing of the bores 74, 75 is preferably 5 mm and their diameter is 0.8 to 1.5 mm, whereas the thickness of the connecting lines is preferably also 0.8 to 1.5 mm.

- rocket fuel is preferably used, which consists of nitrocellulose powder or nitroglycerin powder as base components and a binder. This star burner can be pressed or extruded. The material is chosen so that all rocket propellants for such smoke launchers are designed with degressive combustion so that they do not burn as spontaneously as loose powder.

- Hexachloroethane is used for the main fog sets (13, 14). This evaporates and can close the primer by means of precipitation and react with it with a delayed effect.

- the bore 91 in the intermediate wall 92 is 0.5 to 1 mm thick and at the bottom, that is to say towards the fog sets, the ignition set is closed with a foil 98 based on a lead-tin alloy , wherein it can also cover (not shown) the entire threaded piece 90.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- General Engineering & Computer Science (AREA)

- Combustion & Propulsion (AREA)

- Life Sciences & Earth Sciences (AREA)

- Botany (AREA)

- Pest Control & Pesticides (AREA)

- Plant Pathology (AREA)

- Organic Chemistry (AREA)

- Compounds Of Unknown Constitution (AREA)

- Aiming, Guidance, Guns With A Light Source, Armor, Camouflage, And Targets (AREA)

- Infusion, Injection, And Reservoir Apparatuses (AREA)

Claims (26)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT85104036T ATE37746T1 (de) | 1984-04-03 | 1985-04-03 | Nebelwurfkoerper. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3412436 | 1984-04-03 | ||

| DE3412436 | 1984-04-03 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0157421A2 EP0157421A2 (fr) | 1985-10-09 |

| EP0157421A3 EP0157421A3 (en) | 1986-09-10 |

| EP0157421B1 true EP0157421B1 (fr) | 1988-10-05 |

Family

ID=6232508

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP85104036A Expired EP0157421B1 (fr) | 1984-04-03 | 1985-04-03 | Projectile fumigène |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0157421B1 (fr) |

| AT (1) | ATE37746T1 (fr) |

| DE (1) | DE3565426D1 (fr) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3510367A1 (de) * | 1985-03-22 | 1986-09-25 | Nico-Pyrotechnik Hanns-Jürgen Diederichs GmbH & Co KG, 2077 Trittau | Nebelwurfkoerper |

| DE3800599A1 (de) * | 1988-01-12 | 1989-07-27 | Feistel Pyrotech Fab | Kontaktkopf fuer schnellnebelwurfkoerper |

| FR2676805A1 (fr) * | 1991-05-21 | 1992-11-27 | Alsetex | Munition propulsee explosive pour arme individuelle. |

| CN112696990B (zh) * | 2020-12-30 | 2022-08-30 | 浙江警察学院 | 一种防回抛催泪弹 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2307369A (en) * | 1941-04-22 | 1943-01-05 | Clyde B Ferrel | Projectile |

| DE2932922C2 (de) * | 1979-08-14 | 1983-12-01 | Buck Chemisch-Technische Werke Gmbh & Co, 8230 Bad Reichenhall | Nebelwurfkörper |

| DE3238455C2 (de) * | 1982-10-16 | 1987-03-05 | Pyrotechnische Fabrik F. Feistel GmbH + Co KG, 6719 Göllheim | Nebelwurfkörper |

-

1985

- 1985-04-03 AT AT85104036T patent/ATE37746T1/de not_active IP Right Cessation

- 1985-04-03 DE DE8585104036T patent/DE3565426D1/de not_active Expired

- 1985-04-03 EP EP85104036A patent/EP0157421B1/fr not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| DE3565426D1 (en) | 1988-11-10 |

| EP0157421A2 (fr) | 1985-10-09 |

| ATE37746T1 (de) | 1988-10-15 |

| EP0157421A3 (en) | 1986-09-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0806623B1 (fr) | Projectile porteur stabilisé en rotation | |

| DE3515166A1 (de) | Wurfkoerper zur darstellung eines infrarot-flaechenstrahlers | |

| EP0411243B1 (fr) | Allumeur pour sous-munition du type "bomblet" | |

| DE2105295C1 (de) | Pulverkörper für hülsenlose Munition | |

| DE2804270C2 (de) | Vorrichtung zur Bodensogreduzierung an einem Artilleriegeschoß | |

| EP0780658B1 (fr) | Grenade à main fumigène rapide | |

| DE2826497A1 (de) | Treibspiegelgeschoss mit pyrotechnischem satz | |

| DE3316440C2 (fr) | ||

| DE3918005C2 (fr) | ||

| EP0157421B1 (fr) | Projectile fumigène | |

| DE2547528C2 (de) | Artilleriegeschoß mit erhöhter Reichweite | |

| EP1794537B1 (fr) | Corps actif | |

| DE4400545B4 (de) | Rauchladungs-Behälter, vorzugsweise zur Anordnung in einer Rauchladungs-Artilleriegranate | |

| DE3501468C2 (de) | Nebelwurfkörper | |

| EP0270781B1 (fr) | Cartouche d'exercice pour arme à feu sans recul | |

| EP0237711B1 (fr) | Allumeur pour charge propulsive d'une cartouche | |

| DE3701145A1 (de) | Treibladungsanzuender | |

| DE3048595A1 (de) | "gefechtskopf fuer tarn- und/oder taeuschzwecke" | |

| EP0187932A1 (fr) | Sécurité de bouche pour munition d'exercice | |

| AT407573B (de) | Zündnadel für geschosszünder | |

| DE10105867A1 (de) | Geschoss | |

| DE3153378C2 (fr) | ||

| DE3919314A1 (de) | Zerlegergeschoss | |

| DE8410341U1 (de) | Nebelwurfkörper | |

| DE3936065C2 (de) | Mine, insbesondere Landmine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19861015 |

|

| 17Q | First examination report despatched |

Effective date: 19880205 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 37746 Country of ref document: AT Date of ref document: 19881015 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3565426 Country of ref document: DE Date of ref document: 19881110 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Free format text: PIEPENBROCK PYROTECHNIK GMBH |

|

| ITPR | It: changes in ownership of a european patent |

Owner name: CESSIONE;PIEPENBROCK PYROTECHNIK GMBH |

|

| ITTA | It: last paid annual fee | ||

| NLT1 | Nl: modifications of names registered in virtue of documents presented to the patent office pursuant to art. 16 a, paragraph 1 |

Owner name: FEISTEL PYROTECHNIK GMBH + CO. KG TE GOELLHEIM, BO |

|

| NLS | Nl: assignments of ep-patents |

Owner name: PIEPENBROCK PYROTECHNIK GMBH TE GOELLHEIM, BONDSRE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19920317 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19920415 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19920422 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19920423 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19920428 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19920430 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19920506 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19920518 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19920617 Year of fee payment: 8 |

|

| EPTA | Lu: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19930403 Ref country code: GB Effective date: 19930403 Ref country code: AT Effective date: 19930403 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19930404 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19930430 Ref country code: CH Effective date: 19930430 Ref country code: BE Effective date: 19930430 |

|

| BERE | Be: lapsed |

Owner name: PIEPENBROCK PYROTECHNISCHE G.M.B.H. Effective date: 19930430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19931101 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19930403 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19931229 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19940101 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 85104036.0 Effective date: 19931110 |