EP0100944B2 - Dispositif d'alimentation dans une machine de traitement ou jet abrasif - Google Patents

Dispositif d'alimentation dans une machine de traitement ou jet abrasif Download PDFInfo

- Publication number

- EP0100944B2 EP0100944B2 EP19830107193 EP83107193A EP0100944B2 EP 0100944 B2 EP0100944 B2 EP 0100944B2 EP 19830107193 EP19830107193 EP 19830107193 EP 83107193 A EP83107193 A EP 83107193A EP 0100944 B2 EP0100944 B2 EP 0100944B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- means according

- workpiece

- supports

- conveyor

- workpiece holder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000005270 abrasive blasting Methods 0.000 title 1

- 238000005422 blasting Methods 0.000 claims description 15

- 230000001154 acute effect Effects 0.000 claims description 2

- 210000000078 claw Anatomy 0.000 description 4

- 230000000712 assembly Effects 0.000 description 2

- 238000000429 assembly Methods 0.000 description 2

- 230000006835 compression Effects 0.000 description 2

- 238000007906 compression Methods 0.000 description 2

- 238000006073 displacement reaction Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000000969 carrier Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 238000009420 retrofitting Methods 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24C—ABRASIVE OR RELATED BLASTING WITH PARTICULATE MATERIAL

- B24C3/00—Abrasive blasting machines or devices; Plants

- B24C3/08—Abrasive blasting machines or devices; Plants essentially adapted for abrasive blasting of travelling stock or travelling workpieces

- B24C3/083—Transfer or feeding devices; Accessories therefor

Definitions

- the invention relates to a conveyor device according to the preamble of claim 1.

- Such a conveyor is known from DE-C-2 510 827, in which a pliers-like workpiece holder with a free-ended support rod is provided as a workpiece support, which is arranged immovably in the axis of rotation of the pliers.

- the workpiece is clamped by means of a clamping claw via disc springs, which are prevented from unwanted relaxation by self-locking.

- Workpieces to be picked up cannot be arranged concentrically to the axis of rotation regardless of their shape and size, so that a correspondingly uneven radiation results when the workpiece is rotated.

- the object of the invention is to provide a conveyor of the type mentioned, by means of which workpieces of different shapes and sizes can be transported through a blasting chamber of a centrifugal blasting machine in a continuous or intermittent and preferably automatic mode of operation, while at the same time a uniform blasting effect on all sides by a definable rotation of the workpieces and a good emptying of the cavities arranged in the workpieces is achieved.

- the workpiece receiving device as a workpiece support provided with a clamping device, it is possible to use the same device to transport workpieces of different shapes and sizes rotating through a centrifugal blasting machine and to treat them uniformly on all sides with blasting media.

- FIG. 1 shows a workpiece carrying yoke 1 of a suspended conveyor 2, by means of which workpieces 3 are transported from a loading station through a centrifugal blasting machine for the purpose of all-round blasting treatment to an unloading station.

- the support yoke 1 is slidably suspended by means of rollers 4 on a rail 5 and with a traction means 6 z. B. connected to a chain.

- each support yoke is equipped with its own travel drive.

- the support yoke 1 has two opposite supports or support yoke legs 7, at the lower ends of which in bearings 8 there is rotatably mounted a workpiece holding device 9 provided with a workpiece support 10 and at least one clamping device 11.

- a clamping device 9 is arranged on each of the two bearing parts 12 and can thus be rotated with them about the axis of rotation 13.

- the workpiece support 10 is formed by a grate 14, which is easily exchangeably fastened in the bearing parts, so that an exchange when worn or against another workpiece family adapted support such. B. a single rod for cylinder blocks is possible.

- the clamping device 11 has clamping claws 16 which are arranged on a pivot lever 15 and which are pressed against the workpiece 3 by means of a force accumulator 18.

- the pivot lever 15 is pivotally mounted on the bearing part 12 about an axis 17, wherein a prestressed tension spring 18, which forms the energy accumulator, acts on the pivot lever 15.

- the tension spring 18 is advantageously arranged in an axial bore 19 of the bearing part 12, protected against blasting agents.

- Compression springs such as. B. disc spring assemblies can be used if the position of the axis 17 to the point of application of the spring force on the lever is selected accordingly.

- Piston-cylinder assemblies fed by a pressure accumulator with a pressure medium can also be used as energy stores.

- the swivel lever 15 On an additional lever arm, the swivel lever 15 has an engagement surface 20, on which, according to arrow 21, an actuating device 22 acts on the loading or unloading station for lifting the clamping claw 16 from the workpiece 3.

- the actuating device can be an electromechanical, or hydraulically or pneumatically actuated ram.

- One of the two bearing parts 12 is operatively connected to a rotary drive 23, by means of which the workpiece is set in rotation about the axis of rotation 13 during the blasting treatment and subsequently for emptying the cavities.

- the rotation drive can also be carried out by means of a drag chain as described in DE-C3-22 12 487.

- two smaller workpieces can also be clamped by means of the two clamping devices 11 in addition to the shown clamping of a workpiece 3, whereby an arrangement of the workpieces which is offset obliquely on the grate also enables their all-round blasting treatment.

- FIGS. 2 and 3 show an embodiment variant in which the workpiece support is designed as an exchangeable pallet 24.

- the pallet 24 has driving pins 25 arranged in the axis of rotation 13 which, lying in corresponding recesses 26 in the two bearing parts 12a and 12b, connect the pallet to the support yoke 1 during transport.

- the two support yoke legs 7a and 7b can be displaced from and to one another in the direction of the axis of rotation 13 by means of a displacement device 26 - preferably a hydraulically or pneumatically actuatable cylinder, whereby the pallet 24 is picked up by the support yoke at the loading station and deposited again at the unloading station.

- a displacement device 26 preferably a hydraulically or pneumatically actuatable cylinder

- FIG 3 shows the pallet 24 with the workpiece 3 on a lifting table 27 at the loading or unloading station, the yoke legs 7a and 7b having moved apart and the clamping device 11 being opened by means of the actuating device 22.

- a good blasting effect on the workpiece surfaces is achieved when the workpiece makes a wobble movement. This is achieved when the support plane for the workpiece on the grate 14 or the pallet 24 forms an acute angle to the axis of rotation 13.

- FIG. 4 shows a workpiece holding device 9, the workpiece support 10 of which can be adjusted for workpieces 3 of different heights.

- the workpiece support 10 has rods 31 which are articulated on pivotable levers 30 and which can be brought into different distances 33 from the axis of rotation 13 by pivoting the lever 30 about an axis 32 running transversely to the axis of rotation 13. If only two different distances 33 are required, a lower and an upper position of the rods 31 can be defined by end stops 34 and 35, the desired position in the loading and unloading station being controlled by an actuating device such as, for example, B. a piston-cylinder unit 36 is adjustable between unloading and loading, this z. B. can be done automatically according to a predetermined program.

- FIG. 5 and 6 show an embodiment variant of the adjustable workpiece support 10, the axes 32a of levers 30a being arranged parallel to the axis of rotation 13.

- a continuous adjustment of the distance 35 between the axis of rotation 13 and the rods 31a can in this case, for. B. by means of a built-in worm gear 37, which in the loading and unloading station with a drive, for. B. an electric motor 38 can be coupled.

- Such an actuating device which can adjust the workpiece support 10 within a given area to any distance from the axis of rotation 13, can also be used in the embodiment variant shown in FIG. 4.

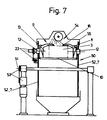

- FIG. 7 shows an embodiment variant of the conveyor device, which is designed as a drum conveyor 50 of a multi-station centrifugal jet machine.

- the drum conveyor 50 rotating about an axis 51 has two side walls 52, which at the same time form the carriers 7 of a plurality of workpiece holding devices 9 arranged circumferentially distributed.

- the workpiece holding devices 9 are conveyed from a loading and unloading station into one or more blasting chambers 54 of a housing 55 of the blasting machine by rotating the drum conveyor 50 by means of a drive 53.

- the workpiece holding devices 9 likewise have a workpiece support 10, clamping devices 11 and bearing parts 12 and can each be rotated about an axis of rotation 13 by means of a rotary drive 23.

- the workpieces 3 are held by means of clamping claws 16, which are supported by energy stores such as, for. B. springs are pressed against the workpiece. In the loading and unloading station, these are lifted off the workpiece by means of an actuating device.

- the workpiece receiving devices described are also in other conveyors such. B. applicable to transportable trolleys on rails or rolling cages.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Specific Conveyance Elements (AREA)

- Jigs For Machine Tools (AREA)

Claims (14)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH490482 | 1982-08-16 | ||

| CH4904/82 | 1982-08-16 |

Publications (4)

| Publication Number | Publication Date |

|---|---|

| EP0100944A2 EP0100944A2 (fr) | 1984-02-22 |

| EP0100944A3 EP0100944A3 (en) | 1985-10-23 |

| EP0100944B1 EP0100944B1 (fr) | 1987-10-14 |

| EP0100944B2 true EP0100944B2 (fr) | 1992-04-15 |

Family

ID=4284566

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19830107193 Expired - Lifetime EP0100944B2 (fr) | 1982-08-16 | 1983-07-22 | Dispositif d'alimentation dans une machine de traitement ou jet abrasif |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0100944B2 (fr) |

| DE (1) | DE3374049D1 (fr) |

| ES (1) | ES524420A0 (fr) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3309619A1 (de) * | 1983-03-17 | 1984-09-27 | BMD Badische Maschinenfabrik Durlach GmbH, 7500 Karlsruhe | Foerdereinrichtung fuer grosse gussstuecke in putzanlagen |

| DE3560697D1 (en) * | 1984-08-10 | 1987-11-05 | Fischer Ag Georg | Abrasive blasting machine with at least one rotary holding device for workpieces |

| GB8705271D0 (en) * | 1987-03-06 | 1987-04-08 | Coated Electrodes Internationa | Coating carbon articles |

| JP2771517B2 (ja) * | 1996-07-16 | 1998-07-02 | 山形日本電気株式会社 | 垂直移載装置および垂直移載方法 |

| KR100716925B1 (ko) | 2005-12-29 | 2007-05-10 | 주식회사 포스코 | 숏 블라스트 장치의 소재 고정 장치 |

| CN103753408B (zh) * | 2014-02-11 | 2016-02-24 | 中航飞机股份有限公司西安飞机分公司 | 一种自动预应力夹具 |

| CN111673624A (zh) * | 2020-06-23 | 2020-09-18 | 苏州安井自动化设备有限公司 | 喷砂上下料的自动化线 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1176560A (en) * | 1966-11-08 | 1970-01-07 | Pangborn Corp | Continuous Cleaning Apparatus |

| GB1242933A (en) * | 1968-06-20 | 1971-08-18 | Badische Maschf Gmbh | Multi-station blasting machines |

| DE2020516A1 (de) * | 1970-04-27 | 1971-11-25 | Walker Helen H | Kugel- oder Sandstrahlvorrichtung |

| CH529614A (de) * | 1971-03-31 | 1972-10-31 | Fischer Ag Georg | Verfahren und Hängebahn-Schleuderstrahlmaschine zur Oberflächenbehandlung von Werkstücken |

-

1983

- 1983-07-22 EP EP19830107193 patent/EP0100944B2/fr not_active Expired - Lifetime

- 1983-07-22 DE DE8383107193T patent/DE3374049D1/de not_active Expired

- 1983-07-26 ES ES524420A patent/ES524420A0/es active Granted

Also Published As

| Publication number | Publication date |

|---|---|

| ES8406056A1 (es) | 1984-07-16 |

| DE3374049D1 (en) | 1987-11-19 |

| EP0100944B1 (fr) | 1987-10-14 |

| EP0100944A2 (fr) | 1984-02-22 |

| ES524420A0 (es) | 1984-07-16 |

| EP0100944A3 (en) | 1985-10-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2825213C2 (de) | Vorrichtung zum Überführen von Gegenständen aus einer Förderbahn in eine Arbeitsstation | |

| DE2902197C2 (fr) | ||

| DE2310990C3 (de) | Einrichtung zum Umsetzen von Werkstücken mit einem Armstern, dessen Arme Greifer tragen | |

| DE2510827C2 (de) | Foerdereinrichtung fuer zylinderbloecke oder aehnliche werkstuecke durch eine schleuderstrahlanlage | |

| DE3883922T2 (de) | Düsen-Wechselvorrichtung für Extruder. | |

| DE3133588C2 (fr) | ||

| EP0967041B1 (fr) | Procédé et dispositif pour le guidage d'une lame de scie à ruban | |

| EP0100944B2 (fr) | Dispositif d'alimentation dans une machine de traitement ou jet abrasif | |

| DE3618093A1 (de) | Selbsttaetige vorrichtung zum induktionshaerten | |

| EP3406362B1 (fr) | Machine à étirer à chenilles et procédé d'étirage | |

| DE2122990C3 (de) | Maschine zum Bearbeiten der Kanten von Glasscheiben o.dgl. | |

| DE2227369A1 (de) | Vorrichtung zum automatischen abloesen von knochen aus fleisch, insbesondere aus schinken | |

| EP2260975B1 (fr) | Rectifieuse plane et procédé de traitement de pièce usinée par rectification plane | |

| DE1201245B (de) | Vorrichtung zum Foerdern eines Werkstueckes | |

| DE1777187B2 (de) | Spitzenlose schleifmaschine zum schleifen von langgestreckten stangen unterschiedlicher durchmesser im durchlaufverfahren | |

| DE1658304C3 (de) | Maschine zum Abschleifen des Schweißgrates von stumpfgeschweißten, nichtverlegten Schienen | |

| DE2727226C3 (de) | Wendevorrichtung für chargenweise durch eine Schleuderstrahlanlage geförderte magnetisierbare Werkstücke | |

| DE1777175C3 (de) | Werkstück-Transportvorrichtung an einer Doppelscheibenschleifmaschine | |

| DE69129077T2 (de) | Verfahren und vorrichtung zum schneiden von rohren, in welchem die rohre mittels einer rotierenden festhaltplatte in schneidposition gebracht werden | |

| DE2162928B1 (de) | Saegevorrichtung zum zuschneiden von baukoerpern | |

| DE1602870B1 (de) | Schaelmaschine | |

| CH665159A5 (de) | Schleifmaschine. | |

| DE2334328C2 (de) | Einrichtung zur Durchführung mehrerer aufeinander folgender Bearbeitungsgänge an einem Werkstück | |

| DE4212903C2 (fr) | ||

| DE3040447C1 (de) | Rollentisch fuer Blechbearbeitungsmaschinen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19830722 |

|

| AK | Designated contracting states |

Designated state(s): BE CH DE FR GB IT LI NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): BE CH DE FR GB IT LI NL SE |

|

| 17Q | First examination report despatched |

Effective date: 19860717 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE CH DE FR GB IT LI NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19871014 Ref country code: BE Effective date: 19871014 |

|

| REF | Corresponds to: |

Ref document number: 3374049 Country of ref document: DE Date of ref document: 19871119 |

|

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] | ||

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: BMD BADISCHE MASCHINENFABRIK DURLACH GMBH Effective date: 19880712 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19881122 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 19920415 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): BE CH DE FR GB IT LI NL SE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AEN |

|

| ET3 | Fr: translation filed ** decision concerning opposition | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19920615 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19920619 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19920623 Year of fee payment: 10 |

|

| ITF | It: translation for a ep patent filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19921016 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19930723 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19930731 Ref country code: CH Effective date: 19930731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19940331 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19940401 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 83107193.1 Effective date: 19940210 |