EP0099827B1 - Plateaux intercalaires pour charges palettisées - Google Patents

Plateaux intercalaires pour charges palettisées Download PDFInfo

- Publication number

- EP0099827B1 EP0099827B1 EP19830401466 EP83401466A EP0099827B1 EP 0099827 B1 EP0099827 B1 EP 0099827B1 EP 19830401466 EP19830401466 EP 19830401466 EP 83401466 A EP83401466 A EP 83401466A EP 0099827 B1 EP0099827 B1 EP 0099827B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- plate according

- rim

- bottles

- plate

- receptacles

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D71/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material

- B65D71/70—Trays provided with projections or recesses in order to assemble multiple articles, e.g. intermediate elements for stacking

Definitions

- the bottom of glass containers has a certain concavity, so as to create a heel which gives them a regular peripheral reach capable of giving them good stability, sufficient even for it to be possible to stack these containers, jars for example, in several beds separated from each other by relatively flexible spacers, usually made of corrugated cardboard sheets.

- Such a method makes it possible to store them when they are full and closed but already, before use, while they are still empty and open.

- the object of the invention is therefore to provide spacers capable of allowing the handling of fragile articles and in particular glass articles or containers such as high quality bottles, by heavy loads such as pallets containing up to 4000 bottles in bunk beds in which these articles are spaced from each other, loads capable of undergoing storage in piles and transport over long distances without risk of deterioration or collapse when the cover is opened. Its use will make it possible to operate with great simplicity, both to constitute the charges and during the recovery of the articles, therefore to work quickly, and if necessary in a fully automatic manner, that is to say with a great economy of workforce.

- Such a plate will simply consist of a sheet of material of substantially constant thickness, of the order of a millimeter, formed so as to bring reliefs to the desired spacing; to make it reusable, it will advantageously be a thermoformed thermoplastic material, polyethylene for example.

- a similar plate described by patent FR-A-2 450 753, consists of a flat support sheet with a regular pitch of imprints each comprising two concentric circular ribs but of opposite directions, which form in its center and on a first face a cell capable of receiving the neck of the neck of the containers of a lower bed, at its periphery and on the second face a seat capable of receiving the base of the containers of an upper bed.

- the free space remaining between the plate and the base in the center of each footprint gives the assembly the desired elasticity to provide each of the successive beds with horizontal support despite the manufacturing tolerances of the bottles.

- the profile of each imprint of a tray of the same type will on the contrary, towards the center, be close enough to that of the base to bring the imprint in contact with this by stacking. last, with tightening of the plate between the neck of the neck of the receptacles of the lower bed and the base of those of the upper bed, this only opposite the outer rim of the upper lip of the ring of the neck of the former, the heel of the base of the latter always resting on the periphery of the imprint but imposing only a minimal elastic deformation on it.

- each imprint while being as close as possible to the profile of the base of the upper container, will provide the ring of the lower container with a housing provided with an enlarged inlet, forming on the upper face of the tray a nipple connected to a annular seat and the top of which will carry a circular step of internal diameter adapted to that of said ring, with a central clearance which will leave only a peripheral crown of width less than that of the rim and a rounded nose of radius of curvature at least equal to that of the outer rim of this drink; the crown will be located, relative to the seat above which, centered on the nipple, is then placed the lower reach of the heel, at a height in principle just lower, taking into account the tolerances, than that of the corresponding return part of the base.

- the imprint thus draws down a bowl with a central alveolus which offers scope to the bank only on its external rim, in front of which the base will come to rest, the heel of which will however find secondary contact on the annular

- the inclined portion of the nipple or the conical part of the cavity will have a slope greater than the coefficient of friction of the glass on the material of this intermediate plate, that is to say in practice at least equal to 20%, and a sufficient diameter; the base of the nipple is connected to the bottom either directly or at least via a slight cylindrical trimming, or on the contrary by an asymmetrical groove compensating for any excess height of the nipple.

- the imprints will advantageously be separated by a quincunx of moles forming on the upper face of the housings able to immobilize the caps of the containers.

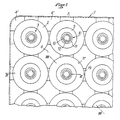

- FIG. 1 shows a plate 1, made of polypropylene, with a thickness of 0.8 to 1.6 mm approximately depending on the case, the bottom 2 of which bears circular imprints 3, in relief according to a square mesh which can range from 80 at around 120 mm for 75 cl bottles, at the rate of 9 to 11 rows of 11 to 14 cavities for example. These are further separated from each other by moles 4 of quadrangular shape arranged in staggered rows. A rim 5 connecting projecting elements 4 ′ whose shape partially reproduces that of the moles 4 stiffens the whole of the plate.

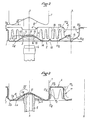

- each tray intended here to serve as an interlayer between two beds of 75 cl bottles with pricked bottom, will rest on the necks 6 of the bottles of the lower bed and will in turn receive the lower peripheral surface or heel 7a of the caps 7 of the bottles of the upper bed, the imprints 3 coming to be housed in the space left free by the stitching 8.

- These imprints are formed of nipples of generally frustoconical shape whose axes X are spaced d '' a distance slightly greater than the maximum diameter of the bottles, thus preventing them from touching each other.

- the top of the conical wall 9 of the nipples carries in step a crown 10 which has a rounded nose 11, their upper face forming a button 12 protruding slightly thanks to a narrow conical wall 13, while at their base is a clipping cylindrical 14 of low height around which the bottom 2 constitutes a horizontal annular seat 2a.

- the rounding of the nose 11 is preferably connected to a rounded edge 15, to form a narrow vertical belt whose internal diameter adjusts without friction to that of the ring and it has internally a radius of curvature r, greater than that of the outer rim of the rim by an amount at least equal to the tolerance of the diametral play and preferably of the order of twice; in practice, this radius may reach 1.5 mm.

- the imprint thus forms downwards a cell capable of being housed on the ring by enclosing it in the corner to secure the various bottles of the lower bed.

- the button 12 has a diameter greater than that of the internal edge of the rim and thus leaves only a narrow portion 16 located from the bottom, placed, above the seat 2a, at a height h lower by a few tenths of a millimeter to the height p that the bite has at the level of the nose 11, and of a width which is quite clearly less than the thickness of the lip.

- the base radius of the nipple exceeds at least about 1 cm that of the bottle ring while the slope of its wall 9, in any case greater than 20%, preferably corresponds to an angle of 30 to 45 °, its total height therefore reaching about 0.5 to 1 cm.

- the main purpose of the clipping 14 is to ⁇ facilitate the manufacture of the mold but also increases the flat surface belonging to the bottom 2, therefore its flexibility.

- a tray in accordance with the invention could exclusively comprise the imprints 3, projecting from a flat bottom or bearing, if necessary, a rib avoiding the seats 2a: the imprints can, by example, forming light basins on the bottom, which increases rigidity; if these basins are close enough to join, there remains between them only moles 4 mentioned above.

- FIGS 2 and 3 they have a significant height, greater than that of the nipple. They have four sidewalls 17, vertical (apart from the manufacturing spindles, which also allow them to be stacked empty under a small volume, possible stops, not shown here, avoiding jamming) or of a profile corresponding substantially to that of the caps. bottles ; these sides preferably follow the circular form of the base in this case and are therefore of revolution, four to four, around the axes X. They advantageously connect to the bottom 2 by rounded portions 17a and can have rounded inlets 17b. At the four angles of each mole, they are limited by cut sides 18 which, to avoid brutal shapes, also have connections 18a and if necessary 18b, which, in this case, creates on the bottom, a mole to another, a rib 19.

- the moles 4, with the ribs 19 which connect them two by two increase the overall rigidity of the plates by preventing the surface of the latter from presenting any straight portion; they also help to center the bottles during their installation and then to keep them in place.

- the mesh of the trays could just as well be rectangular, or the shape of the nipples deviate from the circular shape, for loading ovalized, square or flat bottles etc., with a more complex nesting if necessary.

- a first tray is placed on a pallet, then a first series of bottles is deposited, at the appropriate spacing, which are housed between the moles 4, centering, even approximately, on the imprints 3 and the bed thus formed is covered with a second plate identical to the first: thanks to the conical inlets formed by the walls 9 of the nipples, the necks of the bottles come from themselves fitting onto the cells defined by their crowns 10 , which secures these bottles.

- the outer rim 6a of the rim comes to bear at 3a in the rounding of the nose 11, the seam of the ring mold, which is usually located on its internal edge 6b, on the contrary not coming into contact with the plate but being placed at the inside the free space created by the button 12, as shown in FIG. 4.

- the bottles of the second bed are in turn deposited, the heel of which then comes into contact with the seat 2a along a line 2b: the weight of each of them is enough to cause the support zone to bend, due of its planar shape, and this until the puncture, catching up with the small difference in height which existed initially in this area, comes in turn to bear obliquely in 3b on the nose 11, without, on the other hand, its top presses the button 12.

- a plate identical to the previous ones is capable of supporting the bending that the retraction of the cover imposes on its edges but, if one wants to be able to stack a second load on the first, it is necessary that the flat bottom of the pallet corresponds essentially to the top of the imprints 3: it would indeed punch or, at the very least, deform the plate if the force were to be exerted on the upper face of the moles 4, that is to say in false while, suitably drawn, the buttons 12 on the contrary are capable of supporting their successive loads and the efforts due to transport.

- the height of the moles is greater than that of the nipples, it is therefore necessary, to allow the vertical stacking of several pallets, to use for the cover a tray of a different model, provided only with alveoli or imprints similar to the imprints 3, or more simply a network of corrugations not only capable of stiffening it but constituting on its lower face rectilinear grooves capable of coming to fit on the necks of the bottles of the various rows of the upper bed, to maintain them at least in one direction.

- Such a tray is shown diagrammatically under the reference 21, FIG. 5, before it is placed on the last bed of bottles of a charge being built up.

- the dimensions of the plate 21 are slightly smaller than those of the intermediate plate 1 because it is advantageous for it to only cover the necks of the bottles.

- the tray 21 only has two grooves 22, of rectangular layout, concentric and whose profile, not detailed, of course corresponds to that of the rings of these bottles: once the tray is placed on the upper bed, the latter are housed there, which is enough to immobilize the entire upper bed.

- FIG. 6 shows, as a variant, bottles 30 placed on a plate 31, the bottom 32 of which carries circular imprints 33 and holding moles 34, 34 ′ arranged in a triangular mesh, which, as we know, has for the disadvantage of somewhat complicating the handling of the bottles, but in return makes it possible to obtain more compact charges.

- this tray will not be described again in all its details because it is similar to the previous one. But, intended to receive bottles with a "flat bottom (in fact and of course this bottom is very slightly tucked in and has a concavity of the order of a few millimeters), its imprints 33, which are separated from the moles 34, cannot be identical to those of a tray intended to receive bottles with a "pique" bottom. As shown in FIG.

- each essentially comprises a nipple 35 crowned with a step 36, in the top of which a cutout 37 simply opens; here again the imprint thus forms downwards a cell whose wall comes to bear along a line 33a on the only outer rim of the rim of the bottles of the lower bed, while connecting to a conical wall 38, inclined at 30 °, which is used to guide the necks when installing the intermediate plate.

- the total height H of the nipple is necessarily greater than the depth p of the retracted part 39 of the base of the bottles of the upper bed: for this reason, the annular seats 32a formed by the bottom 32 are connected to the conical wall 38 not directly or by the sole intermediary of a cylindrical wall trimming like the previous case but on the contrary by a groove 40, so that the total height h of the imprint above the bottom is reduced to a value very slightly lower at the depth p of the concavity of the base.

- the groove 40 is advantageously provided with a relatively vertical wall 41 and a flat bottom 42 giving it a substantially trapezoidal profile.

- the load When the load is constituted, first placing a first plate on a transport pallet 43, the latter rests there by means of the groove bottoms 42; the bottles of the first bed then come to bear on the seats 32a of the bottom 32: the walls 41 will therefore distribute the entire weight of the stack but their rigidity is sufficient to prevent them from being crushed, which would compromise balance.

- the pallets could moreover be fitted with appropriate housings.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Stackable Containers (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8212442A FR2530226A1 (fr) | 1982-07-16 | 1982-07-16 | Plateaux intercalaires pour charges palettisees |

| FR8212442 | 1982-07-16 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0099827A1 EP0099827A1 (fr) | 1984-02-01 |

| EP0099827B1 true EP0099827B1 (fr) | 1986-10-01 |

Family

ID=9276023

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19830401466 Expired EP0099827B1 (fr) | 1982-07-16 | 1983-07-18 | Plateaux intercalaires pour charges palettisées |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0099827B1 (OSRAM) |

| DE (1) | DE3366596D1 (OSRAM) |

| ES (1) | ES282055Y (OSRAM) |

| FR (1) | FR2530226A1 (OSRAM) |

| PT (1) | PT77038B (OSRAM) |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD319129S (en) | 1988-04-26 | 1991-08-13 | Rehrig-Pacific Company, Inc. | Stackable castle crate |

| USD465417S1 (en) | 2001-04-16 | 2002-11-12 | Rehrig Pacific Company | Stackable low depth tray |

| USD466018S1 (en) | 2001-06-25 | 2002-11-26 | Rehrig Pacific Company | Stackable low depth tray |

| US7017746B2 (en) | 2001-04-16 | 2006-03-28 | Rehrig Pacific Company | Stackable low depth tray |

| US7086531B2 (en) | 1992-07-29 | 2006-08-08 | Rehrig Pacific Company | Stackable low depth bottle case |

| US7207458B1 (en) | 1999-07-02 | 2007-04-24 | Rehrig Pacific Company | Low-depth nestable tray for fluid containers |

| US7281641B2 (en) | 2001-06-25 | 2007-10-16 | Rehrig Pacific Company | Stackable low depth tray |

| US8109408B2 (en) | 2009-11-16 | 2012-02-07 | Rehrig Pacific Company | Low depth crate |

| US8353402B2 (en) | 2008-10-06 | 2013-01-15 | Rehrig Pacific Company | Stackable low depth tray |

| US8636142B2 (en) | 2009-09-10 | 2014-01-28 | Rehrig Pacific Company | Stackable low depth tray |

| US8893891B2 (en) | 2008-03-31 | 2014-11-25 | Rehrig Pacific Company | Stackable low depth tray |

| US9475602B2 (en) | 2008-10-06 | 2016-10-25 | Rehrig Pacific Company | Stackable low depth tray |

Families Citing this family (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ZA841225B (OSRAM) * | 1984-02-20 | 1984-08-16 | ||

| US4700836A (en) * | 1985-08-01 | 1987-10-20 | International Container Systems, Inc. | Universal case for transporting bottles |

| DE3535325A1 (de) * | 1985-10-03 | 1987-04-09 | H & K Verpackungstechnik Gmbh | Trennlage zum stapeln von verpackungsbehaeltern |

| FR2589139B1 (fr) * | 1985-10-24 | 1988-04-15 | Saint Gobain Emballage | Conditionnement automatique dans des recipients |

| US4700837A (en) * | 1985-11-15 | 1987-10-20 | International Container Systems, Inc. | Universal bottle case |

| FR2596025B1 (fr) * | 1986-03-18 | 1988-09-30 | Bsn Emballage | Plateau intercalaire thermoforme a mamelon pour le conditionnement de bouteilles en lits superposes |

| US4899874A (en) * | 1988-04-26 | 1990-02-13 | Rehrig-Pacific Company, Inc. | Stackable low depth bottle case |

| US4978002A (en) * | 1988-04-26 | 1990-12-18 | Rehrig-Pacific Company, Inc. | Cross-stacking bottle case |

| FR2637264B1 (fr) * | 1988-09-30 | 1991-04-05 | Bsn Emballage | Plateau intercalaire pour la constitution de charges palettisables a partir de lits superposes de recipients |

| US5316172A (en) * | 1988-11-15 | 1994-05-31 | Rehrig-Pacific Company, Inc. | Can tray assembly |

| JPH0345866U (OSRAM) * | 1989-09-11 | 1991-04-26 | ||

| GB9001825D0 (en) * | 1990-01-26 | 1990-03-28 | Formold Ltd | Article-retaining trays |

| FR2679878B1 (fr) * | 1991-07-31 | 1993-10-29 | Saint Gobain Emballage | Plateaux de palettisation. |

| DE4212466A1 (de) * | 1992-04-14 | 1993-10-28 | Al Ko Enzler Gmbh | Vorrichtung zum Stapeln von Wickelkörpern |

| US5660279A (en) * | 1992-07-29 | 1997-08-26 | Rehrig Pacific Company, Inc. | Stackable low depth bottle case |

| US5651461A (en) * | 1992-07-29 | 1997-07-29 | Rehrig-Pacific Company, Inc. | Stackable low depth bottle case |

| DE9422024U1 (de) * | 1993-11-03 | 1997-10-09 | Schoeller-Plast S.A., Romont | Flaschenträger |

| US5330050A (en) * | 1993-11-12 | 1994-07-19 | Cornos Corporation | Pallet merchandising system for containers |

| NO180039B (no) * | 1994-08-03 | 1996-10-28 | Bjarne Lerum | Transportsystem for flasker |

| FI2550U1 (fi) * | 1995-03-13 | 1996-08-27 | Perstorp Ab | Kuljetusalusta pulloja varten |

| SE9600391L (sv) * | 1996-02-02 | 1997-05-20 | Lars Erik Trygg | Bärplatta för hantering och exponering av flaskor och tillsammans med denna användbar flaska |

| SE512679C2 (sv) * | 1996-08-21 | 2000-05-02 | Perstorp Ab | Anordning vid brätte för flaskor |

| FR3004703B1 (fr) * | 2013-04-19 | 2015-05-22 | Ctci Production | Un plateau de conditionnement et sa methode de fabrication |

| MX2015016756A (es) | 2014-12-04 | 2016-06-03 | Rehrig Pacific Co | Caja para bebidas. |

| USD831962S1 (en) | 2017-12-22 | 2018-10-30 | Rehrig Pacific Company | Beverage crate |

| US11390415B2 (en) | 2018-10-25 | 2022-07-19 | Rehrig Pacific Company | Nestable bottle crate |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1233175A (fr) * | 1959-06-08 | 1960-10-12 | Pulp Packaging Ltd | Perfectionnements concernant l'emballage des bouteilles, récipients ou objets semblables en verre ou autres matériaux fragiles |

| US3219233A (en) * | 1963-06-11 | 1965-11-23 | Poly Pak Corp Of America | Carrier for bottles and the like |

| DE1560079A1 (de) * | 1966-12-24 | 1971-03-04 | Kalle Ag | Einrichtung zur Transportsicherung von bewickelten konischen Textilspulen und Faerbehulsen |

| US4162738A (en) * | 1977-06-15 | 1979-07-31 | Metrolina Design Group | Stacking plastic bottle case |

| FR2450753A1 (fr) * | 1979-03-08 | 1980-10-03 | Delteil Claude | Plateau de calage thermoforme pour le regroupement de bouteilles ou tout autre objet fragile |

-

1982

- 1982-07-16 FR FR8212442A patent/FR2530226A1/fr active Granted

-

1983

- 1983-07-15 ES ES1983282055U patent/ES282055Y/es not_active Expired

- 1983-07-15 PT PT7703883A patent/PT77038B/pt unknown

- 1983-07-18 DE DE8383401466T patent/DE3366596D1/de not_active Expired

- 1983-07-18 EP EP19830401466 patent/EP0099827B1/fr not_active Expired

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD319129S (en) | 1988-04-26 | 1991-08-13 | Rehrig-Pacific Company, Inc. | Stackable castle crate |

| US7086531B2 (en) | 1992-07-29 | 2006-08-08 | Rehrig Pacific Company | Stackable low depth bottle case |

| US7207458B1 (en) | 1999-07-02 | 2007-04-24 | Rehrig Pacific Company | Low-depth nestable tray for fluid containers |

| USD465417S1 (en) | 2001-04-16 | 2002-11-12 | Rehrig Pacific Company | Stackable low depth tray |

| US7549539B2 (en) | 2001-04-16 | 2009-06-23 | Rehrig Pacific Company | Stackable low depth tray |

| USD485756S1 (en) | 2001-04-16 | 2004-01-27 | Rehrig Pacific Company | Handle portion for stackable low depth crate |

| US7017746B2 (en) | 2001-04-16 | 2006-03-28 | Rehrig Pacific Company | Stackable low depth tray |

| US7281641B2 (en) | 2001-06-25 | 2007-10-16 | Rehrig Pacific Company | Stackable low depth tray |

| USD494867S1 (en) | 2001-06-25 | 2004-08-24 | Rehrig Pacific Company | Stackable low depth tray |

| USD466018S1 (en) | 2001-06-25 | 2002-11-26 | Rehrig Pacific Company | Stackable low depth tray |

| US8893891B2 (en) | 2008-03-31 | 2014-11-25 | Rehrig Pacific Company | Stackable low depth tray |

| US8353402B2 (en) | 2008-10-06 | 2013-01-15 | Rehrig Pacific Company | Stackable low depth tray |

| US9475602B2 (en) | 2008-10-06 | 2016-10-25 | Rehrig Pacific Company | Stackable low depth tray |

| US8636142B2 (en) | 2009-09-10 | 2014-01-28 | Rehrig Pacific Company | Stackable low depth tray |

| US8109408B2 (en) | 2009-11-16 | 2012-02-07 | Rehrig Pacific Company | Low depth crate |

| US8448806B2 (en) | 2009-11-16 | 2013-05-28 | Rehrig Pacific Company | Low depth crate |

Also Published As

| Publication number | Publication date |

|---|---|

| PT77038B (fr) | 1986-02-03 |

| ES282055U (es) | 1985-04-16 |

| DE3366596D1 (en) | 1986-11-06 |

| PT77038A (fr) | 1983-08-01 |

| ES282055Y (es) | 1985-11-16 |

| EP0099827A1 (fr) | 1984-02-01 |

| FR2530226B1 (OSRAM) | 1985-03-01 |

| FR2530226A1 (fr) | 1984-01-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0099827B1 (fr) | Plateaux intercalaires pour charges palettisées | |

| EP0013855B1 (fr) | Caisse à claire-voie pour le transport de bouteilles ou analogues | |

| FR3005457A1 (fr) | Contenant en plastique pour emballer des produits alimentaires, moules pour fabriquer celui-ci, et procede pour fabriquer celui-ci | |

| CH657339A5 (fr) | Procede pour fabriquer un recipient tel que fut en matiere thermoplastique et recipient ainsi fabrique. | |

| FR2656591A1 (fr) | Boite modulaire et empilable. | |

| EP1623934B1 (fr) | Plateau intercalaire de manutention pour empiler des conditionnements en couches | |

| FR2679878A1 (fr) | Plateaux de palettisation. | |

| EP0604315B1 (fr) | Palettisation de bouteilles | |

| FR2792290A1 (fr) | Ensemble de decoupes, caisse, procede et machine pour la fabrication de caisse a partir d'un tel ensemble | |

| EP0409731A2 (fr) | Boîte d'emballage | |

| FR2653410A1 (fr) | Caisse de transport et de presentation pour un ensemble d'objets. | |

| EP1136374B1 (fr) | Palette à usage multiple | |

| FR3011228A1 (fr) | Plateau en matiere en feuille de carton, flan, dispositif et procede pour la realisation d'un tel plateau. | |

| FR2810968A1 (fr) | Plateau, flan, emballage, procede et appareil de constitution d'emballage pour produits cylindriques ou boites a couvercle | |

| EP0567412A1 (fr) | Boîte en carton ou analogue, notamment destinée à contenir des pots pour produits laitiers, et flan pour la réalisation d'une telle boîte | |

| EP0847366B1 (fr) | Plaque intercalaire pour des ensembles de piles de plateaux alveoles recevant des oeufs | |

| FR2618312A1 (fr) | Casier mecanise pour la separation de six ou douze bouteilles | |

| FR2872488A1 (fr) | Plateau emboitable a fond biseaute avec poignee rembordee, flan correspondant et machine de formation d'un tel plateau | |

| BE1009636A3 (fr) | Caisse de manutention. | |

| FR2862615A1 (fr) | Plateau emboitable avec poignee rembordee, flan et emballage corresponadant | |

| EP2716576B1 (fr) | Renfort de bac pour la collecte des déchets | |

| FR2821335A1 (fr) | Plateau, flan et emballage pour boites ou produits cylindriques | |

| FR2741595A1 (fr) | Plateau d'emballage et procede de fabrication de ce plateau | |

| WO1995001916A2 (fr) | Dispositif pour le conditionnement d'une pluralite de produits et procede de fabrication d'un tel dispositif | |

| FR2745789A1 (fr) | Dispositif d'emballage de recipients en verre |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE DE FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19840519 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE DE FR GB IT |

|

| REF | Corresponds to: |

Ref document number: 3366596 Country of ref document: DE Date of ref document: 19861106 |

|

| ITF | It: translation for a ep patent filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20020703 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20020717 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20020724 Year of fee payment: 20 Ref country code: BE Payment date: 20020724 Year of fee payment: 20 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20030717 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 |