EP0079292B1 - Verglasungshalterahmen für Fenster - Google Patents

Verglasungshalterahmen für Fenster Download PDFInfo

- Publication number

- EP0079292B1 EP0079292B1 EP82402069A EP82402069A EP0079292B1 EP 0079292 B1 EP0079292 B1 EP 0079292B1 EP 82402069 A EP82402069 A EP 82402069A EP 82402069 A EP82402069 A EP 82402069A EP 0079292 B1 EP0079292 B1 EP 0079292B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- frame

- flange

- hinge

- glazing

- profile

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000007789 sealing Methods 0.000 claims description 4

- 239000011521 glass Substances 0.000 description 13

- 238000004140 cleaning Methods 0.000 description 5

- 239000000463 material Substances 0.000 description 4

- 230000000284 resting effect Effects 0.000 description 2

- 239000003566 sealing material Substances 0.000 description 2

- 229910000639 Spring steel Inorganic materials 0.000 description 1

- 230000014759 maintenance of location Effects 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B3/00—Window sashes, door leaves, or like elements for closing wall or like openings; Layout of fixed or moving closures, e.g. windows in wall or like openings; Features of rigidly-mounted outer frames relating to the mounting of wing frames

- E06B3/04—Wing frames not characterised by the manner of movement

- E06B3/28—Wing frames not characterised by the manner of movement with additional removable glass panes or the like, framed or unframed

Definitions

- the invention relates to a support frame, in particular single or double glazing, intended to be attached to a window frame, more particularly to an opening.

- frames consisting of four profiles generally comprising a U-shaped groove for housing glass, the profile connected to the upright disposed on the pivoting side of the window being fixed to a retaining angle and able to pivot around. a hinge.

- This hinge allows the opening of the added frame to allow the cleaning of the glass originally existing on the window.

- the other three sections forming the frame do not have a hinge, which causes difficulties in assembling the sections which do not all have the same section.

- German patent 2,614,897 describes an upper section comprising an elastic hinge, the other three sections not comprising a hinge, but holes through which screws can pass, as well as oblong extension holes.

- the elastic hinge of the profile must be deformable transversely because it is necessary to slide the glass upwards to release the three other profiles from the frame. This hinge is therefore fragile, and wears out in practice very quickly.

- these known profiles do not allow cleaning of the glass. original because the additional glass tends to fall back towards the original glass permanently.

- fastening means are also used, for example screws, which must be removed each time one wishes to clean the original glass.

- the means of fixing the retaining angle to the window pillar are hidden by a covering strip.

- the means for fixing the three other profiles forming the frame remain apparent. The aesthetics of the whole therefore leaves something to be desired.

- Another known embodiment consists of a U-shaped profile provided with a hinge fixed on the window pillar, on the side of its pivoting, by screws which are hidden by a snap-on seal.

- the profiles forming the top and bottom crosspieces of the attached support frame and its upright, located on the side opposite to the pivoting side of the frame, comprise V-shaped sealing lips, arranged on a wing of the U-shaped groove for housing window. Clamping screws make it possible to compress these lips more or less to form a seal between the original glass and the added glazing. In this case too, the clamping screws are visible. In addition, during cleaning, it is also necessary to unscrew the means for compressing the sealing lips.

- French patent 2294311 describes a profile surrounding an additional window, which comprises a wing for fixing the window to the frame, and a V-shaped part composed of two wings and a core intended to receive the edge of this window. This profile does not allow easy cleaning of the original glass, because the additional glass must be completely removed.

- the invention aims to remedy. to these disadvantages.

- a glazing support frame intended to be attached to a window frame consisting of uprights, of a high cross member and of a low cross member, the support frame consisting of identical sections, each of the sections comprising a glazing housing groove, a support sole resting on the frame.

- Each of the profiles of a support frame according to the invention further comprises means for pivoting the frame constituted by a hinge located between the sole (21) and the housing groove (20), said hinge being perpendicular to the support plane. of the sole, and possibly of means for gripping the pivoting of the frame.

- the support sole of each profile comprises means for fixing to the chassis, the means for fixing at least one sole being constantly active, while the means for fixing the other soles are temporarily active.

- the constantly active fixing means are the fixing means of the sole on the amount of the chassis located on the side of the pivot axis thereof.

- the fixing means are located in an internal space formed between the hinge and the sole.

- the invention further relates to a profile for a support frame, this profile comprising in transverse cross section a perpendicular sole and hinge, elastically deformable, as well as a U-shaped groove for glazing housing consisting of a core parallel to the hinge. and two wings parallel to the sole, located on the same side as the sole with respect to the hinge, the internal wing being adjacent to the hinge by an extension perpendicular to the hinge.

- the outer wing also has an extension, on the same side as the extension of the inner wing.

- the extensions of the inner wing and the outer wing have wing returns, parallel to the core, directed towards the lower surface of the wings, and forming the means for gripping the frame during its pivoting.

- the sole comprises on either side, at its end portions, elastically deformable lips, situated on the opposite side of the hinge, relative to the sole, and forming with the latter an angle of approximately 55 to 60 °.

- the Shore hardness of the lips is less than the Shore hardness of the support base, for example approximately 25 less.

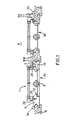

- a window 1 comprising two openings 2a, 2b, which can pivot around the vertical axes 3a, 3b.

- the two openings being substantially symmetrical with respect to a vertical plane, reference will only be made to one of these openings.

- the opening is made up of a first upright 4, of a second upright 5, of a high cross-member 6 and of a low cross-member 7. In addition, it may include small timber 9 and 10.

- a window 11 is fixed by fixing means such as seals 12 to the uprights and crosspieces.

- Such a window structure is well known in the prior art and is not in itself part of the invention.

- the opening rests on a frame made up of a high cross 13, a low cross 14 and uprights 15, 16.

- the amounts of the opening and these cross are made of a material such as wood or any other material.

- the invention provides a frame 17 glazing support 18, intended to be attached to a window frame, more particularly an opening 2.

- the frame 17 consists of identical sections 19, each of the sections 19 comprising a groove 20 of glazing housing 18, a support sole 21 resting on the frame (4, 5, 6, 7) and means for pivoting the frame 17 around an axis substantially parallel to the vertical axis 3 of pivoting of opening it.

- the pivoting means 22 of the frame 17 are active only when it is desired to clean the original glazing 11.

- these pivoting means 22 are constituted by a hinge 23 perpendicular to the bearing plane P of the sole on the chassis, namely the bearing plane of the sole, either on the uprights 4, 5 or on the top crosspieces. and bass 6, 7.

- the frame 17 possibly includes gripping means 24 during the pivoting of the frame 17 about a vertical axis.

- At least one sole comprises means 24 for fixing to the chassis.

- These fixing means 25 to the chassis are constantly active.

- the sole which comprises the continual fixing means is the sole of the profile which is parallel to the pivot axis of the frame 17.

- this axis is horizontal or vertical.

- the pivot axis of the frame 17 is located on the side of the pivot axis of the opening, namely vertical, and located on either side of the window 1.

- the continuous fixing means 25 are fixing means which are closest to the pivot axes 3a, 3b of the openings 2a. 2b.

- the soles of the other profiles forming the frame may include temporary fixing means 26.

- these temporary fixing means are preferably located on the lower crosspieces on the internal upright 16.

- the continuous fixing means 25 are located in the internal space 27 formed between the sole 21 and the hinge 23. These fixing means are therefore not visible from the outside E.

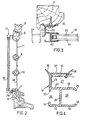

- the invention further relates to a profile 19 for forming a frame 17 according to the invention.

- the section 19 comprises in transverse cross section a sole 21 and a hinge 23 perpendicular, elastically deformable, and a groove 20 in U of glazing housing 18, the groove 20 comprising a core 28 parallel to the hinge 23 and two wings 29, 30 , parallel to the sole 21, situated on the same side as the sole 21 relative to the hinge 23, the internal wing 29 being adjacent to the hinge 23.

- the internal wing 29 is adjacent to the hinge 23 by its extension 31, perpendicular to the hinge 23.

- the external wing 30 has an extension 32 situated on the same side as the extension 31 of the internal wing 29 relative to soul 28.

- the extensions 31, 32 of the wings 29, 30 preferably have wing returns 33, 34 directed towards the underside of the wings 29, 30.

- These wing returns 33, 34 constitute the means 24 for gripping the profile, more particularly of the frame formed by the four sections, during the pivoting of the frame around its axis parallel to the pivot axis 3a of the opening 2.

- the sole 21 has at its ends, on both sides, lips 35, 36, elastically deformable, located on the opposite side of the hinge 23, relative to the sole 21 and forming with this sole 21 an angle a of about 55 to 60 °.

- the lips 35, 36 which extend on the side opposite to the hinge 23 have a Shore hardness less than the Shore hardness of the support base 21.

- the Shore hardness of the lips is less than about 25 at the Shore hardness of the support base.

- the Shore hardness of the lips 35, 36 is substantially equal to the Shore hardness of the hinge 23.

- the lips 35, 36 and the hinge 23 are made of the same material, while the support sole 21 as well as the rest of the profile formed by the core 28, the wings 29, 30, the wing extensions 31, 32 and the wing returns 33, 34 are made of a second material.

- the support sole 21 has grooves 37, allowing a more correct bearing surface on the uprights 4 or 5 or on the upper and lower crosspieces 6, 7.

- the wings 29, 30 of the housing groove 20 each have a curved end 38, 39, with a concavity directed towards the groove 20, to allow better retention of the glazing 18.

- the flanges 21 are fixed by continuous fixing means 25 in the part of the chassis closest to the axis of pivoting of it.

- continual fixing means are, for example, screws which are introduced into the upright 4.

- the lips 35, 36 are thus crushed, which then form a lesser angle with the sole (see FIG. 3).

- temporary fixing means 26 which can be constituted for example by spring steel clips or by magnets . There is thus perfect sealing of the internal space 38 comprised between the initial glass 11 and the glazing 18 added by means of the frame 17.

- the fixing means 25, 26, whether active or inactive, are hidden because they are located between the sole 21, the hinge 23 and the wing 29.

- the glazing 18 may consist of two panes. (40, 41) joined together, which are introduced into the groove 20 by spreading the wings 29, 30 and crushing a sealing material 42.

- a device is obtained consisting of a support frame 17 rigidly associated with a double glazing 18 by mechanical connection means 42 constituted by a compressed sealing material filling the space left between the double glazing 18 and the groove 20.

- the frame 17 is formed by four sections 19, it is possible, thanks to the flexibility of the hinge, to recover the differences in flatness of the uprights and crosspieces of the window frame.

- brackets between the wing returns 33, 34, at the four angles are possible to introduce brackets between the wing returns 33, 34, at the four angles, the intermediate space between 33 and 34 being always free to allow entry.

Landscapes

- Engineering & Computer Science (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Wing Frames And Configurations (AREA)

- Window Of Vehicle (AREA)

- Securing Of Glass Panes Or The Like (AREA)

Claims (11)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT82402069T ATE32118T1 (de) | 1981-11-10 | 1982-11-10 | Verglasungshalterahmen fuer fenster. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8121035A FR2516154A1 (fr) | 1981-11-10 | 1981-11-10 | Cadre-support de vitrage pour fenetre |

| FR8121035 | 1981-11-10 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0079292A2 EP0079292A2 (de) | 1983-05-18 |

| EP0079292A3 EP0079292A3 (en) | 1985-01-02 |

| EP0079292B1 true EP0079292B1 (de) | 1988-01-20 |

Family

ID=9263870

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82402069A Expired EP0079292B1 (de) | 1981-11-10 | 1982-11-10 | Verglasungshalterahmen für Fenster |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0079292B1 (de) |

| AT (1) | ATE32118T1 (de) |

| DE (1) | DE3278020D1 (de) |

| FR (1) | FR2516154A1 (de) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2141165B (en) * | 1983-06-08 | 1986-12-31 | Forster F M O | Hollow plastics frame member |

| FR2676497B1 (fr) * | 1991-05-17 | 1993-09-24 | Mainka Jean | Profile-charniere en matiere plastique en bande, pour la pose de survitres. |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2292843A1 (fr) * | 1974-11-28 | 1976-06-25 | Delooz Jacques | Profile pour chassis ouvrant de double vitrage et chassis constitue a l'aide de tels profiles |

| DE2459017C3 (de) * | 1974-12-13 | 1978-07-13 | Schlegel Gmbh, 2000 Hamburg | Profilstreifen aus Kunststoff zum Einfassen und Befestigen einer Vorsatzscheibe an einem Fensterrahmen |

| FR2313537A1 (fr) * | 1975-06-03 | 1976-12-31 | Del Signore Gerard | Survitrage clipse |

| DE2614897A1 (de) * | 1976-04-07 | 1977-10-27 | Horst Dipl Phys Schramm | Zusatzscheibe fuer fenster |

| GB1535315A (en) * | 1976-05-06 | 1978-12-13 | Bloom A | Double glazing system |

| FR2483505A1 (fr) * | 1980-05-29 | 1981-12-04 | Dubois Claude | Profiles en matiere plastique pour encadrement de survitrage |

-

1981

- 1981-11-10 FR FR8121035A patent/FR2516154A1/fr active Granted

-

1982

- 1982-11-10 AT AT82402069T patent/ATE32118T1/de not_active IP Right Cessation

- 1982-11-10 EP EP82402069A patent/EP0079292B1/de not_active Expired

- 1982-11-10 DE DE8282402069T patent/DE3278020D1/de not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| FR2516154A1 (fr) | 1983-05-13 |

| EP0079292A2 (de) | 1983-05-18 |

| ATE32118T1 (de) | 1988-02-15 |

| EP0079292A3 (en) | 1985-01-02 |

| FR2516154B1 (de) | 1984-06-08 |

| DE3278020D1 (en) | 1988-02-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| FR1438790A (fr) | Dispositif de fixation d'un profilé de recouvrement sur un profilé de support | |

| EP0079292B1 (de) | Verglasungshalterahmen für Fenster | |

| BE1000298A5 (fr) | Vitre et dispositif pour sa fixation a un support. | |

| FR2787498A1 (fr) | Dispositif de securite pour baie vitree a volet mobile | |

| EP0412904B1 (de) | Holzumrahmung mit einer Nut für die Verglasung | |

| EP0435748A1 (de) | Verbindungselement zwischen zwei Profilen | |

| EP0274320B1 (de) | Öffnung mit einer Klappe, insbesondere für Autobusse | |

| CA2085085A1 (fr) | Dispositif de jonction invisible, notamment pour toiles tendues | |

| EP0834639A1 (de) | Vorrichtung für die Montage einer Verglasung in einem Tragrahm für eine Tür, ein Fenster oder ähnliches | |

| EP2189616B1 (de) | Montageverfahren eines Öffnungselements in einer Fassade vom Typ Vorhangfassade | |

| FR2726027A1 (fr) | Bloc-porte preregle pour cloison, cloison modulaire, procede d'assemblage d'un bloc-porte et procede d'installation d'un bloc-porte dans une cloison | |

| FR2517722A1 (fr) | Dispositif de fixation des panneaux de revetement de plafonds | |

| EP0501640A1 (de) | Einrahmungselement für Platten | |

| EP0887484B1 (de) | Fassade, insbesondere eine Glasfassade | |

| EP0323940A1 (de) | Schutzschirm | |

| FR2634043A1 (fr) | Pince en particulier pour cadre support d'affichage | |

| BE1006481A5 (fr) | Dispositif de fixation pour une paroi et construction utilisant un tel dispositif. | |

| FR2856422A1 (fr) | Curseur auto-bloquant | |

| FR2763987A1 (fr) | Dispositif pour la fixation d'une vitre | |

| FR2658858A1 (fr) | Profile pour la realisation de cadres dormants et ouvrants de fermetures metalliques. | |

| FR2883313A1 (fr) | Ossature de cloison demontable ou amovible a double paroi | |

| WO1995028117A1 (fr) | Moyens d'assistance pour paroi pour cabine de douche ou baignoire | |

| FR2701997A1 (fr) | Encadrement pour vitrage à vitres multiples. | |

| FR2514400A1 (fr) | Dispositif de survitrage pour vantail de fenetre ou porte | |

| FR2751016A1 (fr) | Batiment constitue d'une ossature et de cadres vitres destines a etre fixes sur ladite ossature, et profiles destines a constituer ladite ossature et ledit cadre |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE GB IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19850130 |

|

| 17Q | First examination report despatched |

Effective date: 19860130 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE GB IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19880120 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 19880120 Ref country code: AT Effective date: 19880120 |

|

| REF | Corresponds to: |

Ref document number: 32118 Country of ref document: AT Date of ref document: 19880215 Kind code of ref document: T |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19880131 |

|

| REF | Corresponds to: |

Ref document number: 3278020 Country of ref document: DE Date of ref document: 19880225 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19881121 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19881130 Ref country code: LI Effective date: 19881130 Ref country code: CH Effective date: 19881130 Ref country code: BE Effective date: 19881130 |

|

| 26N | No opposition filed | ||

| BERE | Be: lapsed |

Owner name: GENUIST GERARD Effective date: 19881130 Owner name: FLAMBART JEAN-PAUL Effective date: 19881130 Owner name: FOUSSE CLAUDE Effective date: 19881130 Owner name: PAQUET CLAUDE Effective date: 19881130 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19890801 |