EP0068546B1 - Wetting device for printing elements in printing machines - Google Patents

Wetting device for printing elements in printing machines Download PDFInfo

- Publication number

- EP0068546B1 EP0068546B1 EP19820200706 EP82200706A EP0068546B1 EP 0068546 B1 EP0068546 B1 EP 0068546B1 EP 19820200706 EP19820200706 EP 19820200706 EP 82200706 A EP82200706 A EP 82200706A EP 0068546 B1 EP0068546 B1 EP 0068546B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- printing

- roller

- moistening

- dampening

- pressure

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F7/00—Rotary lithographic machines

- B41F7/20—Details

- B41F7/24—Damping devices

- B41F7/38—Absorbent pads

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F7/00—Rotary lithographic machines

- B41F7/20—Details

- B41F7/24—Damping devices

Definitions

- the invention relates to a device for moistening printing elements in printing presses, in particular for metering the dampening solution onto printing plates in offset printing presses, in which a pressure vessel receiving the dampening solution is arranged over the length and diameter of a dampening duct assigned to the printing plate cylinder, the dampening application roller and the dampening roller part of the jacket facing the damp duct has a capillary-porous structure.

- Mifder AT-A No. 181602 has become known a dampening unit for offset printing presses, which is provided with at least one roller intended for the release of moisture to a plate cylinder.

- the dampening solution is applied to the distributor roller through a single water metering tube which is connected to a stationary water reservoir via a movable hose and which faces the opening of a distributor roller assigned to two application rollers and which is movably arranged by rollers on the rails which are assigned to the roller in parallel.

- the water metering tube which forms a slide together with rollers, is moved back and forth uniformly on the rails when the offset printing machine is started up.

- the water flows from the water reservoir onto the distributor roller, which is intended to achieve a uniform release of water onto the circumference of the roller.

- the amount of water to be applied is regulated by metering the water pressure by adjusting the height of the water reservoir.

- DE-A No. 1954316 further describes a method and a device for loading rollers in printing units of printing presses with a liquid medium, e.g. Color, and described for dosing the medium.

- a liquid medium e.g. Color

- a pressure vessel Arranged over the length and diameter of a dampening duct assigned to the printing plate cylinder is a pressure vessel which holds the dampening solution and whose part of the jacket facing the dampening duct has a capillary-porous structure.

- the aim of the invention is to develop a device for moistening printing plate cylinders in offset printing presses, with which the balance of dampening solution and ink required for quality printing can be ensured over the entire length of the printing cylinder.

- the object is achieved in that electrical resistors are embedded next to one another in this structure, which can be connected to voltage individually or in groups by means of an electronic control circuit, so that the size of the capillaries and thus their dampening solution passage changes due to the heat generated. It is advantageous to adapt the surface of the capillary-porous jacket part to the curvature of the damp duct and to arrange the pressure vessel in a height-adjustable manner.

- a pressure regulator should be connected upstream of the pressure vessel.

- this moistening device it is possible due to an adjustable and controllable constant pressure of the dampening solution in the pressure container and due to the structure according to the invention of the jacket part of the pressure container covering the dampening duct, to continuously form a homogeneous dampening solution film over the entire dampening roller and thus also over the pressure plate cylinder.

- the resistances applied individually or in groups to voltages of different sizes it is also achieved that the equilibrium ratio of moisture and color can also be maintained zonally, that is to say in very narrow areas, in accordance with the amount of ink supplied to the printing plate cylinder, since the different temperatures adhere to one another

- the resistances change the size of the capillary and a different dampening solution passage is achieved at constant pressure conditions.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Inking, Control Or Cleaning Of Printing Machines (AREA)

- Rotary Presses (AREA)

Description

Die Erfindung betrifft eine Vorrichtung zum Befeuchten von Druckelementen in Druckmaschinen, insbesondere zur Dosierung des Feuchtmittels auf Druckplatten in Offsetdruckmaschinen, in der über die Länge und den Durchmesser eines dem Druckplattenzylinder, der Feuchtauftragswalze und der Feuchtreiberwalze zugeordneten Feuchtduktors ein das Feuchtmittel aufnehmender Druckbehälter angeordnet ist, dessen dem Feuchtduktor zugewandter Teil des Mantels eine kapillar-poröse Struktur aufweist.The invention relates to a device for moistening printing elements in printing presses, in particular for metering the dampening solution onto printing plates in offset printing presses, in which a pressure vessel receiving the dampening solution is arranged over the length and diameter of a dampening duct assigned to the printing plate cylinder, the dampening application roller and the dampening roller part of the jacket facing the damp duct has a capillary-porous structure.

Mifder AT-A Nr. 181602 ist ein Feuchtwerk für Offsetdruckmaschinen bekanntgeworden, das mit mindestens einer zur Feuchtigkeitsabgabe an einen Plattenzylinder bestimmten Walze versehen ist. Durch ein einzelnes, über einen beweglichen Schlauch mit einem stationären Wasserreservoir verbundenes Wasserdosierrohr, das einer zwei Auftragswalzen zugeordneten Verreiberwalze mit seiner Öffnung zugewandt und das durch Laufrollen auf den der Walze parallel zugeordneten Schienen bewegbar angeordnet ist, wird das Feuchtmittel auf die Verreiberwalze aufgetragen. Das Wasserdosierrohr, das zusammen mit Laufrollen einen Schlitten bildet, wird bei Inbetriebnahme der Offsetdruckmaschine auf den Schienen gleichförmig hin- und herbewegt. Dabei fliesst das Wasser aus dem Wasserreservoir auf die Verreiberwalze, wodurch eine gleichmässige Abgabe von Wasser auf den Walzenumfang erreicht werden soll. Die Regulierung der aufzutragenden Wassermenge wird durch die Dosierung des Wasserdruckes vorgenommen, indem das Wasserreservoir in seiner Höhe verstellt wird.Mifder AT-A No. 181602 has become known a dampening unit for offset printing presses, which is provided with at least one roller intended for the release of moisture to a plate cylinder. The dampening solution is applied to the distributor roller through a single water metering tube which is connected to a stationary water reservoir via a movable hose and which faces the opening of a distributor roller assigned to two application rollers and which is movably arranged by rollers on the rails which are assigned to the roller in parallel. The water metering tube, which forms a slide together with rollers, is moved back and forth uniformly on the rails when the offset printing machine is started up. The water flows from the water reservoir onto the distributor roller, which is intended to achieve a uniform release of water onto the circumference of the roller. The amount of water to be applied is regulated by metering the water pressure by adjusting the height of the water reservoir.

Da das Befeuchten der Verreiberwalze durch das Wasserdosierrohr nur während der gleichförmigen axialen Bewegung erfolgt, ist es mit dieser Vorrichtung nicht möglich, das Feuchtmittel zu jeder Zeit des Befeuchtungsvorganges über die ganze Länge des Walzenmantels kontinuierlich oder zonal derart aufzutragen, dass an jeder Stelle der Druckplatte das Feuchtmittel und die Farbe in einem Gleichgewichtsverhältnis stehen.Since the wetting roller is moistened by the water metering tube only during the uniform axial movement, it is not possible with this device to apply the dampening solution continuously or zonally at any time during the moistening process over the entire length of the roller shell in such a way that at every point on the pressure plate The fountain solution and the ink are in an equilibrium ratio.

In der DE-A Nr. 1954316 ist weiter ein Verfahren und eine Vorrichtung zum Beschicken von Walzen in Druckwerken von Druckmaschinen mit einem flüssigen Medium, z.B. Farbe, und zum Dosieren des Mediums beschrieben. Über die Länge und den Durchmesser eines dem Druckplattenzylinder zugeordneten Feuchtduktors ist ein das Feuchtmittel aufnehmender Druckbehälter angeordnet, dessen dem Feuchtduktor zugewandter Teil des Mantels eine kapillar-poröse Struktur aufweist.DE-A No. 1954316 further describes a method and a device for loading rollers in printing units of printing presses with a liquid medium, e.g. Color, and described for dosing the medium. Arranged over the length and diameter of a dampening duct assigned to the printing plate cylinder is a pressure vessel which holds the dampening solution and whose part of the jacket facing the dampening duct has a capillary-porous structure.

Diese Lehre hat die gleichen Nachteile, die oben bei der Würdigung der Lehre der AT-A Nr. 181602 erwähnt sind.This teaching has the same disadvantages mentioned above in the assessment of the teaching of AT-A No. 181602.

Ziel der Erfindung ist es, eine Vorrichtung zum Befeuchten von Druckplattenzylindern in Offsetdruckmaschinen zu entwickeln, mit der das für Qualitätsdruck erforderliche Gleichgewichtsverhältnis von Feuchtmittel und Farbe über die ganze Länge des Druckzylinders gesichert werden kann.The aim of the invention is to develop a device for moistening printing plate cylinders in offset printing presses, with which the balance of dampening solution and ink required for quality printing can be ensured over the entire length of the printing cylinder.

Der Erfindung liegt die Aufgabe zugrunde, eine Befeuchtungsvorrichtung für derartige Druckplattenzylinder zu schaffen, mit der entsprechend der zonal erfolgten Farbdosierung das Feuchtmittel entweder über die Länge des Druckzylinders kontinuierlich oder zonal differenziert aufgetragen wird.The invention has for its object to provide a moistening device for printing plate cylinders of this type, with which the dampening solution is applied continuously or differentially zonally according to the zonal ink metering, either over the length of the printing cylinder.

Erfindungsgemäss wird die Aufgabe dadurch gelöst, dass in dieser Struktur nebeneinander elektrische Widerstände eingelagert sind, die mittels einer elektronischen Steuerschaltung einzeln oder gruppenweise an Spannung legbar sind, so dass durch die erzeugte Wärme die Grösse der Kapillaren und damit deren Feuchtmitteldurchlass sich ändert. Dabei ist es vorteilhaft, die Oberfläche des kapillar-porösen Mantelteiles der Krümmung des Feuchtduktors anzupassen und den Druckbehälter höhenverstellbar anzuordnen. Dem Druckbehältersollteein Druckreglervorgeschaltetsein. Mit dieser Befeuchtungsvorrichtung ist es auf Grund eines einstell- und regelbaren konstanten Druckes des Feuchtmittels im Druckbehälter sowie auf Grund der erfindungsgemässen Struktur des den Feuchtduktor überdeckenden Mantelteiles des Druckbehälters möglich, über die ganze Feuchtreiberwalze und damit auch über den Druckplattenzylinder kontinuierlich einen homogenen Feuchtmittelfilmzu bilden. Mittels der einzeln oder gruppenweise an Spannung unterschiedlicher Grösse gelegten Widerstände wird darüber hinaus erreicht, dass das Gleichgewichtsverhältnis von Feuchtigkeit und Farbe entsprechend der dem Druckplattenzylinder zonal zugeführten Farbmenge auch zonal, also in sehr engen Bereichen, aufrechterhalten werden kann, da sich durch die unterschiedlichen Temperaturen an den Widerständen die Kapillare in ihrer Grösse verändern und ein unterschiedlicher Feuchtmitteldurchlass bei konstanten Druckverhältnissen erzielt wird.According to the invention, the object is achieved in that electrical resistors are embedded next to one another in this structure, which can be connected to voltage individually or in groups by means of an electronic control circuit, so that the size of the capillaries and thus their dampening solution passage changes due to the heat generated. It is advantageous to adapt the surface of the capillary-porous jacket part to the curvature of the damp duct and to arrange the pressure vessel in a height-adjustable manner. A pressure regulator should be connected upstream of the pressure vessel. With this moistening device, it is possible due to an adjustable and controllable constant pressure of the dampening solution in the pressure container and due to the structure according to the invention of the jacket part of the pressure container covering the dampening duct, to continuously form a homogeneous dampening solution film over the entire dampening roller and thus also over the pressure plate cylinder. By means of the resistances applied individually or in groups to voltages of different sizes, it is also achieved that the equilibrium ratio of moisture and color can also be maintained zonally, that is to say in very narrow areas, in accordance with the amount of ink supplied to the printing plate cylinder, since the different temperatures adhere to one another The resistances change the size of the capillary and a different dampening solution passage is achieved at constant pressure conditions.

Mit der erfindungsgemässen Vorrichtung ist es ausserdem möglich, die zonale Feuchtmitteldosierung mittels Voreinstellung und Fernverstellung in bezug zur zonalen Farbwerkeinstellung wirksam werden zu lassen.With the device according to the invention it is also possible to let the zonal dampening solution metering take effect by means of presetting and remote adjustment in relation to the zonal inking unit setting.

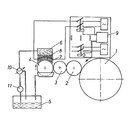

Die Erfindung soll nachstehend an einem Ausführungsbeispiel näher erläutert werden, das in der einzigen Figur schematisch dargestellt ist.The invention will be explained in more detail below using an exemplary embodiment which is shown schematically in the single figure.

Überdie Länge und Breiteeinesdem Druckplattenzylinder 1, der Feuchtauftragswalze 2 und der Feuchtreiberwalze 3 funktionell zugeordneten Feuchtduktors 4 ist der das Feuchtmittel 5 aufnehmende Druckbehälter 6 höhenverstellbar angeordnet, dessen dem Feuchtduktor 4 zugewandter Teil des Mantels 7 eine kapillar-poröse Struktur aufweist. In diesem Teil des Mantels 7, dessen Oberfläche zum Zwecke eines direkten Kontaktes der Krümmung des Feuchtduktors angepasst ist, sind nebeneinander elektrische Widerstände 8 eingelagert, die durch die elektronische Steuerschaltung 9 einzeln oder gruppenweise an Spannung legbar sind. Dem Druckbehälter 6 ist zum Zwecke des Einstellens und des Aufrechterhaltens des Druckes, mit dem das Feuchtmittel 5 die kapillar-poröse Schicht des Mantels 7 durchdringen soll, ein Druckregler 10 vorgeschaltet.The

Bei Inbetriebnahme der Druckmaschine wird von der Pumpe 11 das Feuchtmittel 5 in den Druckbehälter 6 befördert, wo sich der am Druckregler 10 eingestellte Feuchtmitteldruck aufbaut. Mithin wird das Feuchtmittel 5 durch den kapillar-porösen Teil des Druckbehältermantels gedrückt und über den Feuchtduktor 4, die Feuchtreiberwalze 3 und die Feuchtauftragswalze 2 auf den Druckplattenzylinder 1 als homogener Feuchtigkeitsfilm übertragen. Dabei wird der Feuchtmitteldruck vom Druckregler 10 in der eingestellten Grösse gehalten.When the press is started up from the

Wird die Farbe zonal in unterschiedlichen Mengen auf den Druckplattenzylinder 1 aufgetragen, so ist es möglich, die unterschiedlichen Gleichgewichtsverhältnisse von Feuchtmittel und Farbe gleichfalls zonal dadurch herzustellen, indem die Widerstände 8 einzeln oder gruppenweise an Spannung unterschiedlicher Grösse gelegt werden. Durch die Wärme ändert sich die Grösse der Kapillare und damit deren Feuchtmitteldurchlass. Demnach stellen der Feuchtmitteldruck und die Durchlassfähigkeit des kapillar-porösen Teiles des Druckbehältermantels zwei für das Erzielen eines über die Feuchtreiberwalzenlänge kontinuierlichen oder zonal differenzierten homogenen Feuchtmittelauftrages auf den Druckplattenzylinder 1 wichtige und beherrschbare veränderliche Grössen dar.If the ink is applied zonally in different amounts to the printing plate cylinder 1, it is possible to also zonally create the different equilibrium ratios of dampening solution and ink by applying the

Claims (4)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DD23133881A DD200512A1 (en) | 1981-07-01 | 1981-07-01 | DEVICE FOR MOISTURIZING PRESSURE ELEMENTS ON PRINTING MACHINES |

| DD231338 | 1981-07-01 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0068546A1 EP0068546A1 (en) | 1983-01-05 |

| EP0068546B1 true EP0068546B1 (en) | 1984-12-05 |

Family

ID=5532018

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP19820200706 Expired EP0068546B1 (en) | 1981-07-01 | 1982-06-09 | Wetting device for printing elements in printing machines |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0068546B1 (en) |

| DD (1) | DD200512A1 (en) |

| DE (1) | DE3261450D1 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ATE35944T1 (en) * | 1983-07-07 | 1988-08-15 | Roland Man Druckmasch | INKING OR DAMPENING UNIT FOR ROTARY PRINTING MACHINES. |

| IE60046B1 (en) * | 1987-10-19 | 1994-05-18 | Anthony Clarke | Lacquering mechanism for use with a rotary printing press |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1423823A (en) * | 1972-03-03 | 1976-02-04 | Drg Packaging Ltd | Coating techniques |

| DE1954316A1 (en) * | 1969-10-29 | 1971-05-19 | Schluckebier Wilhelm | Method and device for charging rollers in printing units of printing machines with a liquid medium, e.g. Color, and for dosing the medium |

-

1981

- 1981-07-01 DD DD23133881A patent/DD200512A1/en not_active IP Right Cessation

-

1982

- 1982-06-09 EP EP19820200706 patent/EP0068546B1/en not_active Expired

- 1982-06-09 DE DE8282200706T patent/DE3261450D1/en not_active Expired

Also Published As

| Publication number | Publication date |

|---|---|

| DD200512A1 (en) | 1983-05-11 |

| DE3261450D1 (en) | 1985-01-17 |

| EP0068546A1 (en) | 1983-01-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DD140226A5 (en) | METHOD FOR TRANSFERRING FLOW-CONDUCTIVE APPLICATION MEDIA AND DEVICE FOR CARRYING OUT THE METHOD | |

| DD278551A1 (en) | METHOD AND DEVICE FOR PROCESSING SPECIAL COLORS IN BORENO PRESSURE MACHINES | |

| DE4324631C2 (en) | Device for applying liquid media to a substrate in offset printing machines | |

| DE19937467A1 (en) | Device for tempering coating media | |

| EP0518892B1 (en) | Short inking apparatus for a rotary press | |

| DE4334803C1 (en) | Device for metering liquid media in offset printing machines, preferably for varnishing units | |

| EP0068546B1 (en) | Wetting device for printing elements in printing machines | |

| DE4344084C1 (en) | Apparatus for metering fluid media of different viscosities in offset printing machines, preferably in varnishing units | |

| DE19732497A1 (en) | Smoothing roller in a printing unit of a rotary printing press | |

| DD144155B1 (en) | WETTING WORK FOR ROTATION OFFSET PRINTING MACHINES | |

| WO1999042291A1 (en) | Sheet-fed letterpress rotary with printing units for multicolour printing and at least one coating unit | |

| DE3324382C2 (en) | Inking unit for direct or indirect flat printing | |

| DE68904381T2 (en) | PRINTING MACHINE WITHOUT COLOR KNIFE. | |

| DE3906647C2 (en) | Short inking unit | |

| EP0761432B2 (en) | Damping unit for an offset printing machine | |

| DE3025546A1 (en) | DEVICE FOR APPLYING A LIQUID OR SEMI-FLUID MEDIUM ON THE PRINT PLATE OF A PRINTING MACHINE, IN PARTICULAR OFFSET PRINTING MACHINE | |

| DE19529204C2 (en) | Dampening unit for an offset printing machine | |

| DE3837979C2 (en) | Device for direct imaging of a printing form cylinder | |

| DE4410161C2 (en) | Method and device for removing slugs on the printing plate of a printing press | |

| DD238575A1 (en) | painting equipment | |

| DE4303282C2 (en) | Device for dampening solution supply in an offset printing machine | |

| DE2343935A1 (en) | Rotary offset printer dampening unit - one roller does not contact plate cylinder while distributor surface picks up ink | |

| CH649037A5 (en) | INK DOSING DEVICE FOR PRINTING MACHINES. | |

| DE3301699C2 (en) | Rotogravure printing machine with at least one printing unit | |

| DE2457509A1 (en) | Rotary offset printing machine web treatment - web wetted differentially in accordance with quantity of ink to be applied |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): CH DE GB LI SE |

|

| 17P | Request for examination filed |

Effective date: 19830113 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): CH DE GB LI SE |

|

| REF | Corresponds to: |

Ref document number: 3261450 Country of ref document: DE Date of ref document: 19850117 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19880609 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19880610 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19880630 Ref country code: CH Effective date: 19880630 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19900629 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19920401 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 82200706.8 Effective date: 19890220 |