EP0064617B1 - Procédé et dispositif pour l'exploitation d'une installation de fours à coke - Google Patents

Procédé et dispositif pour l'exploitation d'une installation de fours à coke Download PDFInfo

- Publication number

- EP0064617B1 EP0064617B1 EP82103250A EP82103250A EP0064617B1 EP 0064617 B1 EP0064617 B1 EP 0064617B1 EP 82103250 A EP82103250 A EP 82103250A EP 82103250 A EP82103250 A EP 82103250A EP 0064617 B1 EP0064617 B1 EP 0064617B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cascade

- gas

- coal

- fluidised bed

- bed dryer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 239000000571 coke Substances 0.000 title claims description 47

- 238000000034 method Methods 0.000 title claims description 24

- 239000007789 gas Substances 0.000 claims description 86

- 239000003245 coal Substances 0.000 claims description 46

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 31

- 238000010438 heat treatment Methods 0.000 claims description 27

- 238000001816 cooling Methods 0.000 claims description 14

- 239000000428 dust Substances 0.000 claims description 8

- 238000002485 combustion reaction Methods 0.000 claims description 5

- 238000004939 coking Methods 0.000 claims description 4

- 238000009833 condensation Methods 0.000 claims description 4

- 230000005494 condensation Effects 0.000 claims description 4

- 239000007788 liquid Substances 0.000 claims description 4

- 238000012546 transfer Methods 0.000 claims description 4

- 239000002826 coolant Substances 0.000 claims description 3

- 239000003546 flue gas Substances 0.000 claims description 3

- 238000004140 cleaning Methods 0.000 claims description 2

- 230000001105 regulatory effect Effects 0.000 claims description 2

- 239000007787 solid Substances 0.000 claims description 2

- 239000000446 fuel Substances 0.000 claims 1

- 238000010586 diagram Methods 0.000 description 5

- 238000001035 drying Methods 0.000 description 5

- 239000002918 waste heat Substances 0.000 description 4

- 238000010276 construction Methods 0.000 description 3

- 230000002349 favourable effect Effects 0.000 description 3

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 2

- 230000001413 cellular effect Effects 0.000 description 2

- 239000002817 coal dust Substances 0.000 description 2

- 239000010959 steel Substances 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 239000000498 cooling water Substances 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000002360 explosive Substances 0.000 description 1

- 238000005243 fluidization Methods 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 238000013021 overheating Methods 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 239000004449 solid propellant Substances 0.000 description 1

- 239000002351 wastewater Substances 0.000 description 1

- 238000004065 wastewater treatment Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10B—DESTRUCTIVE DISTILLATION OF CARBONACEOUS MATERIALS FOR PRODUCTION OF GAS, COKE, TAR, OR SIMILAR MATERIALS

- C10B39/00—Cooling or quenching coke

- C10B39/02—Dry cooling outside the oven

-

- C—CHEMISTRY; METALLURGY

- C10—PETROLEUM, GAS OR COKE INDUSTRIES; TECHNICAL GASES CONTAINING CARBON MONOXIDE; FUELS; LUBRICANTS; PEAT

- C10B—DESTRUCTIVE DISTILLATION OF CARBONACEOUS MATERIALS FOR PRODUCTION OF GAS, COKE, TAR, OR SIMILAR MATERIALS

- C10B57/00—Other carbonising or coking processes; Features of destructive distillation processes in general

- C10B57/08—Non-mechanical pretreatment of the charge, e.g. desulfurization

- C10B57/10—Drying

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S165/00—Heat exchange

- Y10S165/92—Particulate heat exchange

Definitions

- the invention relates to a method for operating a coke oven plant, in which the coke ovens are periodically charged with preheated or predried coal and the coke produced is subjected to dry cooling by means of a gaseous cooling medium, the plant for coke drying cooling and coal preheating being connected to one another by a common gas circuit through which heat extracted from the hot coke during cooling is transferred to the coal to be preheated. Furthermore, the invention relates to a special cascade fluidized bed dryer which can advantageously be used for preheating coal when the method according to the invention is used.

- the invention is therefore based on the object of improving the method of the type described in such a way that, on the one hand, the disadvantages described above are avoided and, on the other hand, the operating conditions in both coal preheating and coke oven cooling are of course generally improved.

- FIG. 1 which serves to further explain the method according to the invention using an example, only the system parts that are absolutely necessary for the process explanation are of course shown, while other auxiliary devices and the system parts of the actual coking plant are not shown.

- the coal to be coked is fed in an amount of approx. 100 t / h from the feed bunker 1, which is provided with a cellular wheel sluice 2 at its outlet, to the cascade fluidized bed dryer 3 from above.

- This consists in This case consists of three cascades arranged one above the other, which are separated from one another by the gas-permeable inflow trays 4.

- the number of cascades depends on the moisture content and the desired degree of drying or preheating of the coal used.

- the coal used has a water content of 9 0/0 .

- the coal In the first (top) cascade, the coal is heated up to approx. 80 ° C and dried to a water content of approx. 1.5%.

- the partially dried coal is then transferred via line 5, which is provided with a rotary valve 6, into the second cascade below.

- the coal reaches a temperature of about 150 ° C and a water content of about 0.5 0 / 0th

- the coal then passes through line 7, which in turn is provided with a rotary valve 8, into the third (lowest) cascade, in which it practically dries to a residual water content of - 0% and to a temperature of approx. 200 ° C is heated.

- the dried coal is drawn off from the cascade fluidized bed dryer 3 and transported via a screw conveyor 9 and a chain conveyor 10 to the coal tower of the coking plant, not shown in the flow diagram. Both the screw conveyor 9 and the chain conveyor 10 can be electrically heated in order to prevent heat losses.

- the entire conveyor system is rendered inert in order to prevent the ingress of water vapor from the cascade fluidized bed dryer 3.

- This water vapor is responsible for maintaining the coal-water vapor fluidized bed in the cascade fluidized bed dryer 3 and is at a pressure of approx. 2 bar and a temperature of approx. 200 ° C via line 11 and the inflow floor 4 from below into the third (bottom ) Cascade initiated.

- the water vapor then flows through the individual cascades from bottom to top and emerges from the first (top) cascade at a temperature of approx. 140 ° C. Then it passes through line 12 to the dust collector (cyclone) 13, in which the entrained coal dust is separated.

- This separated coal dust is fed via line 14, which is provided with cellular wheel locks 15 and 16, to the screw conveyor 9 and mixed there with the dried and preheated coal.

- the dedusted water vapor is withdrawn from the dust separator 13 via the line 17. Since the steam flow has additionally absorbed water vapor separated from the moist coal when it passes the individual cascades of the cascade fluidized bed dryer 3, this excess water vapor must be removed from the circuit by partial condensation. For this purpose, a partial flow of the water vapor is branched off from the line 17 via the line 18, which is provided with the control flap 19, and is condensed in the circuit washer 20. The majority of the water vapor, however, gets into the blower 21, in which the required recompression takes place to about 2 bar, the water vapor also being heated to about 200 ° C. at the same time, so that it is reintroduced into the cascade fluidized bed dryer 3 via line 11 nothing stands in the way. The water vapor cycle is now closed. If necessary, inert gas can be fed into the water vapor circuit via line 32.

- the partial stream of water vapor drawn off through line 18 is introduced into the circuit washer 20, in which, in addition to condensation, impurities are also washed out.

- the liquid running out of the circuit washer 20 is fed via the line 22 and the pump 23 to the cooling tower 24, in which it cools down to 40.degree.

- the cooled liquid is then introduced into the cooling water distributor 26 via the line 25.

- the required circulation water is fed back to the circuit washer 20 at different heights via lines 27, 28 and 29. Excess water, however, is withdrawn via line 30 and introduced into the sewer 31.

- a wastewater treatment device not shown in the flow diagram, can also be provided in the line 22 leading from the circuit washer 20 to the cooling tower 24.

- the solids separated from the wastewater which have a high proportion of fine coal, can either be deposited in a landfill or burned.

- the hot gas stream emerging from the upper part of the coke dry cooler 33 at a temperature of approximately 800 ° C. is withdrawn via line 34, from which branches off the gas inlet line 35, through which the partial stream of the gas is withdrawn, which is used for indirect heat transfer in the cascade fluidized bed dryer 3 becomes.

- This partial stream which contains 45 to 55% by volume of the total gas quantity, reaches the heating tubes 36 of the first (top) cascade of the cascade fluidized bed dryer 3 at a temperature of approximately 600 ° C. After passing through the heating tubes 36, the gas stream still has one Temperature of approx. 400 ° C.

- the gas stream is now further divided, one partial stream entering the heating tubes 37 of the second (middle) cascade and the other partial stream entering the heating tubes 38 of the third (lowest) cascade.

- the gas stream emerging from this cascade at a temperature of approximately 288 ° C. is withdrawn through the gas outlet line 39.

- the line 40 opens into this, through which the gas stream emerging from the heating tubes 37 at a temperature of approximately 266 ° C. is mixed with the gas stream in the gas outlet line 39.

- the line 42 branches off from the gas outlet line 39, through which, with the appropriate position of the regulating steps 44 and 45, a partial flow of the gas can be discharged into the atmosphere via the chimney 43.

- bypass line 46 is provided behind the blower 41, through which the gas outlet line 39 is connected to the gas inlet line 35.

- This bypass line 46 allows cold gas from the gas outlet line 39 to be mixed into the hot gas in the gas inlet line 35 for the purpose of temperature control.

- the temperature measuring point 47 is provided in the gas inlet line 35, the value determined there being transmitted via the interrupted pulse line 48 to the control device 49, which in turn actuates the motor-driven control flap 50 in the gas outlet line 39 as a function of a predetermined setpoint. If the gas temperature determined at the temperature measuring point 47 falls below the predetermined target value, the control flap 50 is correspondingly opened further, so that the gas supply to the line 34 and thus to the coke dry cooler 33 is increased.

- the line 34 is used to recycle the gaseous cooling medium which is used in the coke dry cooler 33 to cool the hot coke coming from the coke oven battery, not shown.

- the hot coke is fed in via line 69 in the upper part of the dry coke cooler 33, while the cooled coke is withdrawn from the lower part thereof via line 70.

- the waste heat boilers 52 and 54 are provided, in which the hot gas emerging from the coke dryer cooler 33 is cooled again to a temperature of approximately 150 ° C.

- the two waste heat boilers 52 and 54 are connected to one another by the line (pipe system) 53, which is used for the feed water supply and steam discharge.

- the gas stream is reintroduced from the gas outlet line 39 into the line 39 between the two waste heat boilers 52 and 54, so that the reunited partial streams of the gas together pass through the waste heat boiler 54.

- the gas cooled to approximately 150 ° C. is then compressed again in the blower 55 to the operating pressure of the coke dryer cooler 33.

- the line 71 branches off from the line 34, through which a partial flow of the gas is introduced into the central part of the coke dryer cooler 33, in which the coke to be cooled still has a temperature of approximately 400-600 ° C.

- the remaining part of the gas is simultaneously introduced into the lower part of the coke dryer cooler 33 in a manner known per se.

- the control flap 72 is provided in line 34 and the control flap 73 in line 71. This procedure on the one hand reduces the pressure loss of the gas in the coke dry cooler 33. On the other hand, this has a favorable influence on the temperature differences between the gas and the coke to be cooled and, in addition, is associated with improved controllability both with regard to the gas supply and with regard to the heat removal from the coke to be cooled.

- a combustion chamber 56 which contains a gaseous, liquid or solid fuel via line 57 and the required oxygen (air) via line 58. is fed. Since the hot flue gases produced during the combustion are too high at approx. 1400 ° C., water vapor, which was branched off from line 18, is supplied via line 59. By adding water vapor, the flue gas temperature can be reduced to the desired value of, for example, 600 ° C., and at this temperature the gas is then fed via line 60 into the gas supply line 35.

- the control flap 61 is provided in the line 60, so that the amount of gas released can also be throttled accordingly, if necessary, and the combustion chamber 56 can also be used as an additional heater if necessary.

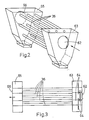

- FIG. 2 shows the representation of a cascade with horizontally installed heating pipes.

- the gas supplied via the gas inlet line, not shown, passes through the opening 62 into the distribution box 63, in which the baffle plates 64 can be arranged.

- the arrangement of these baffle plates 64 can be seen in FIG. 3, which shows a top view of the cascade shown in FIG. 2.

- the baffle plates 64 have the task of equalizing the gas upon entering the cascade to distribute moderately and to partially separate the dust in the gas. This separated dust collects in the tapered lower part of the distribution box 63 and can be removed there from time to time. From the distribution box 63, the gas enters the horizontal heating pipes, which in the present case bear the reference number 36, which indicates that the cascade shown should be the first (top) cascade.

- the cascades underneath also have the same construction.

- the diameter of the heating pipes it has proven to be expedient if the diameter of the heating pipes in the first (top) cascade is larger than in the heating pipes of the cascades below.

- the outer diameter of the heating pipes can be 60.3 mm in the first cascade and 48.3 mm in the second and third cascade.

- the pipe diameter should be selected so that an average gas velocity of approx. 20 m / s can be maintained in the heating pipes. It has been shown that if this gas velocity is maintained, no significant dust deposits on the tube walls are to be expected.

- the outside of the heating tubes can of course also be provided with a certain profile, for. B. the heating pipes as so-called. Fin tubes are designed. The coal to be heated flows, as can be seen from the statements made above, on the outside of the heating pipes from top to bottom.

- the gases After passing through the heating pipes, the gases enter the rear distribution box 65 and from there via the opening 66 into the line (not shown), which either leads to the cascade below or to the gas outlet line 39.

- the system can be quickly made operational again by closing the tube end in the distribution box 63. If an entire cascade fails, operation is not disrupted by the use of the other cascades.

- the cascades are made of wear-resistant steel and can be stiffened on the outside with profiled iron. They are each in a housing, not shown in Fig. 2, which normally consists of a steel frame construction with wall panels that are insulated from the outside.

- the individual cascades are connected to each other by compensators that absorb the thermal expansion and prevent the transmission of vibrations.

- the housing can also taper in the area of the inflow bases 4. This means that the inflow bases 4 then have a smaller diameter than the part of the housing above and below.

- the coal to be preheated or dried is fed onto the cascade fluidized bed dryer 3 from above, so that the coal flows through it and thus onto the individual cascades from top to bottom.

- the casings in which the cascades are accommodated are separated from one another by the gas-permeable inflow trays 4. These have the task of ensuring that the water vapor is distributed as evenly as possible at the entry into the coal-water vapor fluidized bed of the respective cascade. In order to ensure a uniform fluidization of the coal, it is necessary that the pressure drop in the inflow floor is only about 10-15% of the pressure drop in the coal-water vapor fluidized bed.

- a grating 68 as the inflow base, which has been charged with coarse coal 67, the grain size of which is approximately> 40 mm.

- Fig. 4 shows a schematic representation of such an inflow floor.

- sandwich floor This consists of two grids arranged one above the other and offset against each other, between which there is a gas-permeable packing layer.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Organic Chemistry (AREA)

- Coke Industry (AREA)

- Solid Fuels And Fuel-Associated Substances (AREA)

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT82103250T ATE15062T1 (de) | 1981-05-13 | 1982-04-17 | Verfahren und vorrichtung zum betrieb einer kokereianlage. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3118931 | 1981-05-13 | ||

| DE19813118931 DE3118931A1 (de) | 1981-05-13 | 1981-05-13 | Verfahren und vorrichtung zum betrieb einer kokereianlage |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0064617A2 EP0064617A2 (fr) | 1982-11-17 |

| EP0064617A3 EP0064617A3 (en) | 1984-03-28 |

| EP0064617B1 true EP0064617B1 (fr) | 1985-08-21 |

Family

ID=6132152

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82103250A Expired EP0064617B1 (fr) | 1981-05-13 | 1982-04-17 | Procédé et dispositif pour l'exploitation d'une installation de fours à coke |

Country Status (12)

| Country | Link |

|---|---|

| US (2) | US4430161A (fr) |

| EP (1) | EP0064617B1 (fr) |

| JP (1) | JPS57198784A (fr) |

| AR (1) | AR228393A1 (fr) |

| AT (1) | ATE15062T1 (fr) |

| AU (1) | AU547340B2 (fr) |

| BR (1) | BR8202750A (fr) |

| CA (1) | CA1195946A (fr) |

| DE (2) | DE3118931A1 (fr) |

| ES (1) | ES8302070A1 (fr) |

| IN (1) | IN158295B (fr) |

| ZA (1) | ZA822644B (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014000861A1 (fr) | 2012-06-25 | 2014-01-03 | Thyssenkrupp Uhde Gmbh | Procédé et dispositif pour un préchauffage amélioré de charbon par échange de chaleur avec le gaz de refroidissement d'une installation de refroidissement à sec de coke |

Families Citing this family (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3121358A1 (de) * | 1981-05-29 | 1982-12-23 | Krupp-Koppers Gmbh, 4300 Essen | Verfahren zur gleichzeitigen thermischen behandlung mehrerer kohlestroeme |

| AT386071B (de) * | 1985-05-22 | 1988-06-27 | Waagner Biro Ag | Trocknungsanlage fuer koernige feststoffe |

| DE3615624A1 (de) * | 1986-05-09 | 1987-11-12 | Metallgesellschaft Ag | Vorrichtung zur vorwaermung und gegebenenfalls trocknung feinkoerniger feststoffe |

| DE3615622A1 (de) * | 1986-05-09 | 1987-11-12 | Metallgesellschaft Ag | Verfahren zur durchfuehrung endothermer prozesse |

| CS273337B2 (en) * | 1986-12-31 | 1991-03-12 | Rheinische Braunkohlenw Ag | Method of damp loose materials drying in a drier with a whirling bed and equipment for carrying out this method |

| AT390018B (de) * | 1988-05-05 | 1990-03-12 | Waagner Biro Ag | Verfahren und regenerationseinrichtung zur thermischen behandlung wie z.b. trocknung, verschwelung, vergasung pastoeser oder schlammartiger substanzen |

| US5361513A (en) * | 1992-11-25 | 1994-11-08 | Amax Coal Industries, Inc. | Method and apparatus for drying and briquetting coal |

| US6655043B1 (en) * | 2001-09-21 | 2003-12-02 | Apac Inc. | Dryer moisture indicator |

| US8197561B2 (en) * | 2001-10-10 | 2012-06-12 | River Basin Energy, Inc. | Process for drying coal |

| US7695535B2 (en) * | 2001-10-10 | 2010-04-13 | River Basin Energy, Inc. | Process for in-situ passivation of partially-dried coal |

| KR100434737B1 (ko) * | 2002-06-11 | 2004-06-07 | 주식회사 포스코 | 석탄건조기의 증기발생 방지장치 |

| US8579999B2 (en) * | 2004-10-12 | 2013-11-12 | Great River Energy | Method of enhancing the quality of high-moisture materials using system heat sources |

| US8062410B2 (en) | 2004-10-12 | 2011-11-22 | Great River Energy | Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein |

| US7275644B2 (en) * | 2004-10-12 | 2007-10-02 | Great River Energy | Apparatus and method of separating and concentrating organic and/or non-organic material |

| US8523963B2 (en) * | 2004-10-12 | 2013-09-03 | Great River Energy | Apparatus for heat treatment of particulate materials |

| US7540384B2 (en) * | 2004-10-12 | 2009-06-02 | Great River Energy | Apparatus and method of separating and concentrating organic and/or non-organic material |

| US7987613B2 (en) * | 2004-10-12 | 2011-08-02 | Great River Energy | Control system for particulate material drying apparatus and process |

| JP2007039608A (ja) * | 2005-08-05 | 2007-02-15 | Sumitomo Metal Ind Ltd | コークス乾式消火設備の循環冷却ガス利用方法および利用設備 |

| DE102007061136A1 (de) * | 2007-12-19 | 2009-06-25 | Glatt Ingenieurtechnik Gmbh | Verfahren und Vorrichtung zur mehrstufigen Behandlung von dispersen Feststoffen |

| JP5473732B2 (ja) * | 2010-04-02 | 2014-04-16 | 三菱重工業株式会社 | 低品位炭乾燥システム |

| US8956426B2 (en) | 2010-04-20 | 2015-02-17 | River Basin Energy, Inc. | Method of drying biomass |

| US9057037B2 (en) | 2010-04-20 | 2015-06-16 | River Basin Energy, Inc. | Post torrefaction biomass pelletization |

| KR101124629B1 (ko) * | 2010-09-02 | 2012-03-20 | 주식회사 포스코 | 코크스 오븐의 석탄 장입 방법 |

| CA2842930C (fr) * | 2011-07-27 | 2019-08-27 | Research Foundation Of The City University Of New York | Conception optimale de processus systemes de stockage thermique de type a lit tasse et autres applications |

| CN102967134B (zh) * | 2012-11-30 | 2014-11-05 | 山东科院天力节能工程有限公司 | 一种回收废热蒸汽热量的干燥系统及工艺 |

| JP5588077B1 (ja) * | 2014-01-27 | 2014-09-10 | 長松院 泰久 | 小型蒸気発電機を添えたバイオマス回転乾燥装置 |

| CN108559535B (zh) * | 2017-12-29 | 2021-12-14 | 浙江百能科技有限公司 | 一种用于煤热解制高热值煤气和高热值块焦的多级换热装置 |

| CN113091481A (zh) * | 2021-04-15 | 2021-07-09 | 唐山市宝凯科技有限公司 | 一种桥管荒煤气余热回收装置及方法 |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3043752A (en) * | 1957-10-30 | 1962-07-10 | Charbonnages De France | Process of low and high temperature fluidized carbonization of coal |

| US3031773A (en) * | 1958-03-20 | 1962-05-01 | Goodnews Bay Mining Co | Coal drying apparatus |

| US3090131A (en) * | 1959-10-28 | 1963-05-21 | Gladys Elizabeth Dunkle | Apparatus for drying combustible solid |

| US3253650A (en) * | 1960-07-11 | 1966-05-31 | Frank J Mcentee Jr | Heat-exchange apparatus |

| GB1263254A (en) * | 1968-08-08 | 1972-02-09 | Foster Wheeler Brown Boilers | Improvements in tube and shell heat exchangers |

| BE795029A (fr) * | 1972-02-07 | 1973-05-29 | Waagner Biro Ag | Installation de cokerie et procede pour son exploitation |

| US3843458A (en) * | 1972-02-07 | 1974-10-22 | Waagner Biro American | Coal treating method and apparatus for coke plants |

| US3800427A (en) * | 1973-01-18 | 1974-04-02 | Waagner Biro American | Method for drying coal |

| US3814176A (en) * | 1973-01-22 | 1974-06-04 | R Seth | Fixed-fluidized bed dry cooling tower |

| FR2265840B3 (fr) * | 1974-04-01 | 1977-12-02 | Buettner Schilde Haas Ag | |

| AT361892B (de) * | 1975-06-13 | 1981-04-10 | Waagner Biro Ag | Verfahren und einrichtung zur kuehlung von heissen schuettguetern, insbesondere zum trockenen loeschen von heissem koks |

| DE2549784C2 (de) * | 1975-11-06 | 1984-12-20 | Bergwerksverband Gmbh, 4300 Essen | Wirbelschicht-Gasgenerator mit Wärmezufuhr, insbesondere Kernreaktorwärme, von außen |

| DE2738442B2 (de) * | 1977-08-26 | 1979-10-18 | Didier Engineering Gmbh, 4300 Essen | Verfahren bzw. Anlage zur Nutzung der fühlbaren Kokswärme in einer Verkokungsanlage |

| DE2813227C2 (de) * | 1978-03-28 | 1984-05-17 | Bergwerksverband Gmbh, 4300 Essen | Reaktor zur kontinuierlichen thermischen Behandlung von verunreinigten kohlenstoffhaltigen Adsorptionsmitteln |

| DE2816476C3 (de) * | 1978-04-15 | 1980-10-09 | Didier Engineering Gmbh, 4300 Essen | Verfahren zur Rückgewinnung von Koksofenabwärme |

| FR2462467A1 (fr) * | 1979-07-30 | 1981-02-13 | Charbonnages De France | Procede et installation de sechage et/ou prechauffage de charbon a cokefier |

| US4292743A (en) * | 1979-11-27 | 1981-10-06 | Razus Virgiliu T | Cereal dryer |

| DE3013325C2 (de) * | 1980-04-05 | 1985-07-18 | Carl Still Gmbh & Co Kg, 4350 Recklinghausen | Verfahren zur Trocknung und Vorerhitzung von Kohle unter Ausnutzung der fühlbaren Kokswärme bei der trockenen Kokskühlung bzw. -löschung |

-

1981

- 1981-05-13 DE DE19813118931 patent/DE3118931A1/de not_active Withdrawn

-

1982

- 1982-03-03 ES ES510104A patent/ES8302070A1/es not_active Expired

- 1982-04-05 AR AR289006A patent/AR228393A1/es active

- 1982-04-17 AT AT82103250T patent/ATE15062T1/de not_active IP Right Cessation

- 1982-04-17 EP EP82103250A patent/EP0064617B1/fr not_active Expired

- 1982-04-17 DE DE8282103250T patent/DE3265554D1/de not_active Expired

- 1982-04-19 ZA ZA822644A patent/ZA822644B/xx unknown

- 1982-04-20 IN IN438/CAL/82A patent/IN158295B/en unknown

- 1982-05-06 CA CA000402417A patent/CA1195946A/fr not_active Expired

- 1982-05-07 JP JP57075524A patent/JPS57198784A/ja active Pending

- 1982-05-10 US US06/376,843 patent/US4430161A/en not_active Expired - Fee Related

- 1982-05-12 BR BR8202750A patent/BR8202750A/pt unknown

- 1982-05-12 AU AU83613/82A patent/AU547340B2/en not_active Ceased

-

1983

- 1983-02-22 US US06/468,301 patent/US4470878A/en not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014000861A1 (fr) | 2012-06-25 | 2014-01-03 | Thyssenkrupp Uhde Gmbh | Procédé et dispositif pour un préchauffage amélioré de charbon par échange de chaleur avec le gaz de refroidissement d'une installation de refroidissement à sec de coke |

| DE102012012417A1 (de) * | 2012-06-25 | 2014-04-24 | Thyssenkrupp Uhde Gmbh | Verfahren und Vorrichtung zur verbesserten Vorerhitzung von Kohle durch Wärmetausch mit dem Kühlglas einer Kokstrockenkühlanlage |

Also Published As

| Publication number | Publication date |

|---|---|

| JPS57198784A (en) | 1982-12-06 |

| US4430161A (en) | 1984-02-07 |

| ES510104A0 (es) | 1983-02-01 |

| DE3118931A1 (de) | 1982-12-02 |

| IN158295B (fr) | 1986-10-11 |

| ZA822644B (en) | 1983-03-30 |

| US4470878A (en) | 1984-09-11 |

| EP0064617A3 (en) | 1984-03-28 |

| AU547340B2 (en) | 1985-10-17 |

| AR228393A1 (es) | 1983-02-28 |

| EP0064617A2 (fr) | 1982-11-17 |

| ATE15062T1 (de) | 1985-09-15 |

| ES8302070A1 (es) | 1983-02-01 |

| CA1195946A (fr) | 1985-10-29 |

| BR8202750A (pt) | 1983-04-19 |

| DE3265554D1 (en) | 1985-09-26 |

| AU8361382A (en) | 1982-11-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0064617B1 (fr) | Procédé et dispositif pour l'exploitation d'une installation de fours à coke | |

| EP0067299B1 (fr) | Procédé et dispositif pour l'exploitation d'une batterie de fours à coke | |

| AT401418B (de) | Verfahren und vorrichtung zur steuerung der funktion eines wirbelschichtreaktors mit zirkulierender wirbelschicht | |

| DE3787535T2 (de) | Kessel mit fluidisiertem Bett und Verfahren zu dessen Regelung. | |

| DE3013325C2 (de) | Verfahren zur Trocknung und Vorerhitzung von Kohle unter Ausnutzung der fühlbaren Kokswärme bei der trockenen Kokskühlung bzw. -löschung | |

| DE3045253A1 (de) | Verfahren und vorrichtung zum brennen von pellets | |

| EP0550923B1 (fr) | Procédé et appareil pour le refroidissement de matières solides chaudes d'un réacteur à lit fluidisé | |

| CH628972A5 (en) | Tunnel furnace with direct firing | |

| DE2626653C3 (de) | Verfahren und Vorrichtung zum Trocknen und Vorerhitzen von Kokskohle | |

| EP0030376B1 (fr) | Procédé et dispositif de séchage et de réchauffage de charbon humide | |

| DE3050901C2 (de) | Verbrennungseinrichtung mit einer ein Fließbett enthaltenden Brennkammer | |

| DE511792C (de) | Verfahren und Einrichtung zur Waermebehandlung von zerkleinerter Kohle | |

| AT380331B (de) | Fliessbetttrockner fuer schuettgueter, insbesondere kohle | |

| DE2812005C3 (de) | Verfahren zur Herstellung von abtriebfesten Koksformlingen | |

| DD262559A3 (de) | Verfahren und einrichtung zur trocknung und verbrennung von brenn- und abfallstoffen, insbesondere feuchter rohbraunkohle | |

| DE3509275C2 (de) | Verfahren zur thermischen Behandlung von Waschbergen | |

| DE2535683A1 (de) | Verfahren und vorrichtung zur verbrennung von schlaemmen mit hilfe rekuperativer schlammtrocknung | |

| DE3305994A1 (de) | Verfahren zur trockenen destillation von bitumioesen oder oelhaltigen feststoffen | |

| EP0484955B1 (fr) | Procédé et dispositif pour le traîtement des mélanges humides de gaz et de poussières | |

| DE19838686C2 (de) | Vorrichtung und Verfahren zur gleichmäßigen Dampferzeugung auf hohem Niveau in Kokstrockenkühlanlagen | |

| DE458639C (de) | Verfahren und Trockenanlage zum Trocknen von Gut im Schwebezustande | |

| DE767286C (de) | Senkrechter Kammerofen | |

| DE4409056C2 (de) | Verfahren und Anordnung zum Vortrocknen von gebrochener Rohbraunkohle für eine druckaufgeladene Wirbelschichtfeuerung | |

| DE3729884C2 (fr) | ||

| DE2656163A1 (de) | Herstellung von zement im trockenverfahren |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE DE FR GB IT LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE DE FR GB IT LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19840210 |

|

| ITF | It: translation for a ep patent filed | ||

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: KRUPP-KOPPERS GMBH |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT BE DE FR GB IT LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 15062 Country of ref document: AT Date of ref document: 19850915 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3265554 Country of ref document: DE Date of ref document: 19850926 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19920521 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19930309 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19930318 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19930329 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19930330 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19930407 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19930428 Year of fee payment: 12 |

|

| EPTA | Lu: last paid annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19940101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19940417 Ref country code: GB Effective date: 19940417 Ref country code: AT Effective date: 19940417 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19940418 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19940430 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19940430 Year of fee payment: 13 |

|

| BERE | Be: lapsed |

Owner name: KRUPP KOPPERS G.M.B.H. Effective date: 19940430 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19940417 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19941229 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 82103250.5 Effective date: 19941110 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19951101 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19951101 |