CN1378990A - 陶瓷多晶体及其制造方法 - Google Patents

陶瓷多晶体及其制造方法 Download PDFInfo

- Publication number

- CN1378990A CN1378990A CN02105000.7A CN02105000A CN1378990A CN 1378990 A CN1378990 A CN 1378990A CN 02105000 A CN02105000 A CN 02105000A CN 1378990 A CN1378990 A CN 1378990A

- Authority

- CN

- China

- Prior art keywords

- ceramic

- crystalline

- crystal

- multicrystal

- transmission rate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000000919 ceramic Substances 0.000 title claims abstract description 40

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 11

- 239000002245 particle Substances 0.000 claims abstract description 23

- 239000013078 crystal Substances 0.000 claims description 33

- 230000005540 biological transmission Effects 0.000 claims description 19

- 239000000126 substance Substances 0.000 claims description 12

- 238000000034 method Methods 0.000 claims description 8

- 241000276425 Xiphophorus maculatus Species 0.000 claims description 7

- 239000004927 clay Substances 0.000 claims description 7

- 238000000465 moulding Methods 0.000 claims description 4

- 238000001125 extrusion Methods 0.000 claims description 3

- 230000015572 biosynthetic process Effects 0.000 claims description 2

- 238000002834 transmittance Methods 0.000 abstract description 5

- RKTYLMNFRDHKIL-UHFFFAOYSA-N copper;5,10,15,20-tetraphenylporphyrin-22,24-diide Chemical compound [Cu+2].C1=CC(C(=C2C=CC([N-]2)=C(C=2C=CC=CC=2)C=2C=CC(N=2)=C(C=2C=CC=CC=2)C2=CC=C3[N-]2)C=2C=CC=CC=2)=NC1=C3C1=CC=CC=C1 RKTYLMNFRDHKIL-UHFFFAOYSA-N 0.000 abstract 1

- 238000002425 crystallisation Methods 0.000 description 9

- 230000008025 crystallization Effects 0.000 description 9

- 239000000463 material Substances 0.000 description 6

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 6

- 208000019901 Anxiety disease Diseases 0.000 description 3

- 229910052782 aluminium Inorganic materials 0.000 description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 3

- 230000036506 anxiety Effects 0.000 description 3

- 239000000843 powder Substances 0.000 description 3

- 238000005245 sintering Methods 0.000 description 3

- 206010070834 Sensitisation Diseases 0.000 description 2

- 239000004411 aluminium Substances 0.000 description 2

- 230000009920 chelation Effects 0.000 description 2

- 238000010304 firing Methods 0.000 description 2

- 238000000227 grinding Methods 0.000 description 2

- 230000008313 sensitization Effects 0.000 description 2

- 229910017083 AlN Inorganic materials 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N Alumina Chemical compound [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- PIGFYZPCRLYGLF-UHFFFAOYSA-N Aluminum nitride Chemical compound [Al]#N PIGFYZPCRLYGLF-UHFFFAOYSA-N 0.000 description 1

- QGZKDVFQNNGYKY-UHFFFAOYSA-O Ammonium Chemical compound [NH4+] QGZKDVFQNNGYKY-UHFFFAOYSA-O 0.000 description 1

- KCXVZYZYPLLWCC-UHFFFAOYSA-N EDTA Chemical compound OC(=O)CN(CC(O)=O)CCN(CC(O)=O)CC(O)=O KCXVZYZYPLLWCC-UHFFFAOYSA-N 0.000 description 1

- AEEAZFQPYUMBPY-UHFFFAOYSA-N [I].[W] Chemical compound [I].[W] AEEAZFQPYUMBPY-UHFFFAOYSA-N 0.000 description 1

- 150000001732 carboxylic acid derivatives Chemical class 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 230000003628 erosive effect Effects 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 229910001507 metal halide Inorganic materials 0.000 description 1

- 150000005309 metal halides Chemical class 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 239000011505 plaster Substances 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

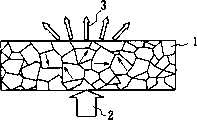

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/01—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics

- C04B35/10—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics based on aluminium oxide

- C04B35/111—Fine ceramics

- C04B35/115—Translucent or transparent products

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/622—Forming processes; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/626—Preparing or treating the powders individually or as batches ; preparing or treating macroscopic reinforcing agents for ceramic products, e.g. fibres; mechanical aspects section B

- C04B35/63—Preparing or treating the powders individually or as batches ; preparing or treating macroscopic reinforcing agents for ceramic products, e.g. fibres; mechanical aspects section B using additives specially adapted for forming the products, e.g.. binder binders

- C04B35/632—Organic additives

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Ceramic Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Materials Engineering (AREA)

- Structural Engineering (AREA)

- Organic Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Compositions Of Oxide Ceramics (AREA)

- Vessels And Coating Films For Discharge Lamps (AREA)

- Crystals, And After-Treatments Of Crystals (AREA)

- Producing Shaped Articles From Materials (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001095673A JP2002293609A (ja) | 2001-03-29 | 2001-03-29 | セラミックス多結晶体及びその製造方法 |

| JP95673/01 | 2001-03-29 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN1378990A true CN1378990A (zh) | 2002-11-13 |

Family

ID=18949689

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN02105000.7A Pending CN1378990A (zh) | 2001-03-29 | 2002-03-29 | 陶瓷多晶体及其制造方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20020155944A1 (enExample) |

| EP (1) | EP1251112A3 (enExample) |

| JP (1) | JP2002293609A (enExample) |

| CN (1) | CN1378990A (enExample) |

| HU (1) | HUP0201031A2 (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN100398476C (zh) * | 2004-10-29 | 2008-07-02 | 株式会社电装 | 多晶陶瓷体的制备方法 |

| CN100419466C (zh) * | 2005-02-08 | 2008-09-17 | 卡西欧计算机株式会社 | 陶瓷复合透镜及其制造方法 |

| CN101951855A (zh) * | 2008-08-13 | 2011-01-19 | 奥姆科公司 | 美观正牙支架及其制造方法 |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060145625A1 (en) * | 2003-09-22 | 2006-07-06 | Nobuyoshi Takeuchi | Metal halide lamp |

| JP2006160595A (ja) * | 2004-06-10 | 2006-06-22 | Ngk Insulators Ltd | 透光性セラミックス、その製造方法および発光容器 |

| US20060211568A1 (en) | 2005-03-16 | 2006-09-21 | Osram Sylvania Inc. | High Total Transmittance Alumina Discharge Vessels Having Submicron Grain Size |

| CN102272070B (zh) * | 2008-12-25 | 2014-12-17 | 株式会社根本研究所 | 透光性多晶材料及其制造方法 |

| JPWO2010079655A1 (ja) * | 2009-01-07 | 2012-06-21 | 日本碍子株式会社 | 単結晶育成用の反応容器および単結晶の育成方法 |

| JP5570027B2 (ja) * | 2011-02-14 | 2014-08-13 | 大学共同利用機関法人自然科学研究機構 | 透光性多結晶材料とその製造方法 |

| WO2016084723A1 (ja) | 2014-11-28 | 2016-06-02 | 日本碍子株式会社 | 板状アルミナ粉末の製法及び板状アルミナ粉末 |

| JP6649959B2 (ja) * | 2015-09-30 | 2020-02-19 | 日本碍子株式会社 | 透明アルミナ焼結体の製法 |

| CN108137411B (zh) * | 2015-09-30 | 2021-03-02 | 日本碍子株式会社 | 外延生长用取向氧化铝基板 |

| CN107074574B (zh) | 2015-09-30 | 2020-09-22 | 日本碍子株式会社 | 板状氧化铝粉末的制法 |

| JP6681406B2 (ja) * | 2015-09-30 | 2020-04-15 | 日本碍子株式会社 | エピタキシャル成長用配向アルミナ基板 |

| JP6928621B2 (ja) * | 2017-01-18 | 2021-09-01 | 日本碍子株式会社 | 光学部品および照明装置 |

| JP6826691B2 (ja) * | 2018-02-19 | 2021-02-03 | 日本碍子株式会社 | 光学部品および照明装置 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0667322B1 (en) * | 1993-09-02 | 2001-01-10 | Toto Ltd. | Light-permeable ceramic material and method of manufacturing the same |

| JPH11226923A (ja) * | 1998-02-18 | 1999-08-24 | Kagawa Prefecture | 透光性アルミナの製造方法 |

| JP2001048638A (ja) * | 1999-08-02 | 2001-02-20 | Agency Of Ind Science & Technol | 石膏型を用いた泥漿鋳込成形における透光性アルミナの作製方法 |

| JP2001064075A (ja) * | 1999-08-30 | 2001-03-13 | Sumitomo Chem Co Ltd | 透光性アルミナ焼結体およびその製造方法 |

| JP3401559B2 (ja) * | 1999-12-24 | 2003-04-28 | 独立行政法人産業技術総合研究所 | アルミナ−ガラス複合多孔質体の作製とその多孔質型による透光性アルミナの作製方法 |

-

2001

- 2001-03-29 JP JP2001095673A patent/JP2002293609A/ja not_active Abandoned

-

2002

- 2002-03-15 US US10/099,450 patent/US20020155944A1/en not_active Abandoned

- 2002-03-20 HU HU0201031A patent/HUP0201031A2/hu unknown

- 2002-03-27 EP EP02252265A patent/EP1251112A3/en not_active Withdrawn

- 2002-03-29 CN CN02105000.7A patent/CN1378990A/zh active Pending

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN100398476C (zh) * | 2004-10-29 | 2008-07-02 | 株式会社电装 | 多晶陶瓷体的制备方法 |

| CN100419466C (zh) * | 2005-02-08 | 2008-09-17 | 卡西欧计算机株式会社 | 陶瓷复合透镜及其制造方法 |

| US7471457B2 (en) | 2005-02-08 | 2008-12-30 | Casio Computer Co., Ltd. | Ceramic hybrid lens and method for manufacturing the same |

| US7790071B2 (en) | 2005-02-08 | 2010-09-07 | Casio Computer Co., Ltd. | Ceramic hybrid lens and method for manufacturing the same |

| CN101951855A (zh) * | 2008-08-13 | 2011-01-19 | 奥姆科公司 | 美观正牙支架及其制造方法 |

| CN101951855B (zh) * | 2008-08-13 | 2014-08-13 | 奥姆科公司 | 美观正牙支架及其制造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1251112A3 (en) | 2003-10-08 |

| US20020155944A1 (en) | 2002-10-24 |

| HUP0201031A2 (en) | 2002-10-28 |

| HU0201031D0 (enExample) | 2002-05-29 |

| JP2002293609A (ja) | 2002-10-09 |

| EP1251112A2 (en) | 2002-10-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1378990A (zh) | 陶瓷多晶体及其制造方法 | |

| EP3003969B1 (fr) | Produit céramique à particules orientées et son procédé de fabrication | |

| CN1028018C (zh) | 高温低热膨胀陶瓷 | |

| US8329090B2 (en) | Compound transparent ceramics and methods of preparation thereof | |

| JP2008511524A (ja) | ジルコニアセラミック | |

| CN101918338A (zh) | 一种具有择优取向的多晶氧化铝透明陶瓷及其制备方法 | |

| CN101224974A (zh) | 钇铝系小晶粒透明陶瓷材料及制备方法 | |

| CN1238303C (zh) | 负热膨胀系数可调的叠层陶瓷基复合材料及其制备方法 | |

| CN101948305B (zh) | 低温烧结(Ba | |

| CN100404462C (zh) | 一种微米级片状钛酸钡晶体及其制备方法 | |

| Mohammadi et al. | Influence of solid loading on the rheological, porosity distribution, optical and the microstructural properties of YAG transparent ceramic | |

| US9240506B2 (en) | Transparent ceramic photo-optical semiconductor high power switches | |

| Stastny et al. | High strength alumina tapes prepared by gel-tape casting method | |

| CN100420651C (zh) | 具有高线性透光率的亚微米晶粒透明氧化铝陶瓷 | |

| KR100494188B1 (ko) | 질화알루미늄질 세라믹스, 반도체 제조용 부재, 내식성 부재 및 도전성 부재 | |

| SUGAWARA et al. | Fabrication of‹ 111› Oriented BaTiO3 Bulk Ceramic by Reactive Templated Grain Growth Method | |

| Hou et al. | (Na0. 8K0. 2) 0.5 Bi0. 5TiO3 Nanowires: Low‐Temperature Sol–Gel–Hydrothermal Synthesis and Densification | |

| DE102017104166A1 (de) | Verfahren zum fertigen von hochdichten und defektarmen gesinterten bauteilen, transparentes keramikbauteil und verwendung eines solchen | |

| JP4502493B2 (ja) | 酸化亜鉛質焼結体およびその製造方法 | |

| CN1169747C (zh) | 纳米氧化钇稳定的四方相氧化锆多晶材料的低温烧结方法 | |

| KR102246258B1 (ko) | pH가 조절된 수계 분산 슬러리를 이용한 나노 이트리아 소결체의 제조방법 | |

| JP4582835B2 (ja) | アクチュエータ用圧電部材の製造方法 | |

| JP2003128465A (ja) | 透光性酸化スカンジウム焼結体及びその製造方法 | |

| CN1880253A (zh) | 一种厚膜材料及其使用的铁电(Ba,Sr)T iO3微晶玻璃陶瓷 | |

| Vovk et al. | Production of the Y3Al5O12 transparent nanostructured ceramics |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication |